Vehicle body end wall synthesis tool and process

A technology of end wall and tooling, which is applied in the field of car body end wall synthesis tooling and technology, can solve the problems of reduced welding quality, increased welding difficulty of end wall components and end wall auxiliary plates, etc., to reduce the depth of indentation and avoid welding The effect of excessive post-deformation and reduced deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

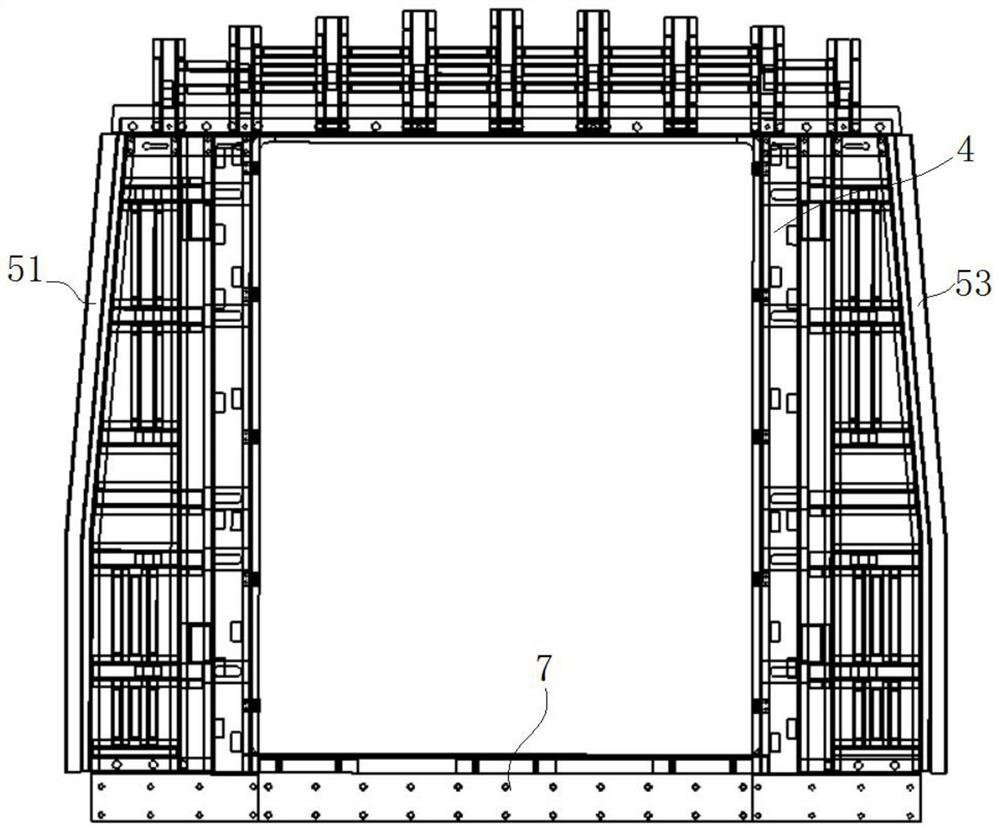

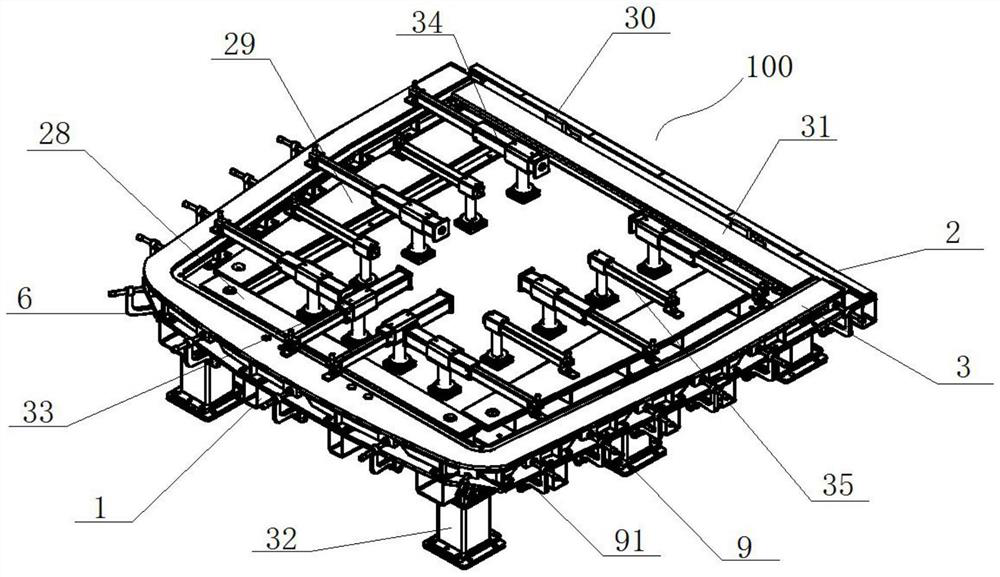

[0085] like Figure 1-6 As shown, the present embodiment provides a car body end wall synthesis tooling 100, which mainly includes a tooling platform 1, a supporting copper platform 3 and a pressing assembly. Wherein, the auxiliary electrode 2 is arranged on the tooling platform 1; the supporting copper platform 3 is arranged on the tooling platform 1; the supporting copper platform 3 is used for loading the end wall auxiliary board 4 and the end wall assembly 5, and can be used for the end wall auxiliary board 4 and the end wall assembly 5. The to-be-welded part between the end wall components 5 forms a continuous surface support; the supporting copper platform 3 and the auxiliary electrode 2 are connected by copper strips; 5 is compressed on the tooling platform 1.

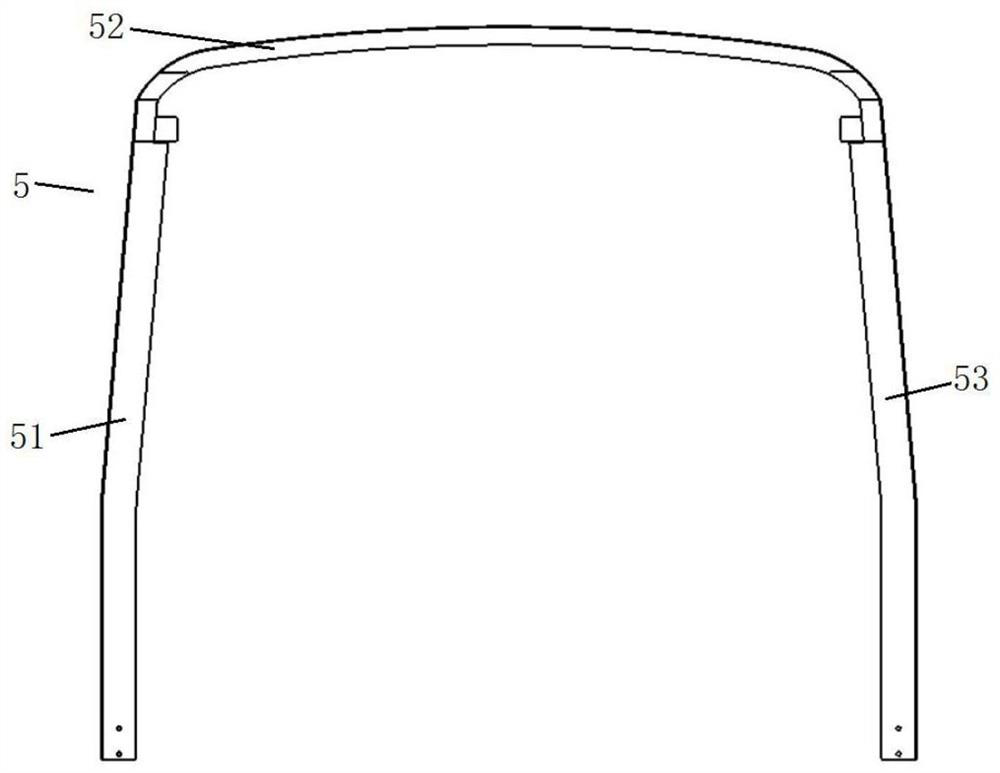

[0086] In this example, if figure 1 As shown, the end wall assembly 5 includes a first end wall corner post 51 ( figure 1 end corner post on the left as shown), end top curved beam 52 and second end corner po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com