Organic self-supporting single crystal film and preparation method and application thereof

A self-supporting, single crystal technology, used in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc., can solve the problems of small size, film structure and performance damage, and achieve short production cycle, low cost and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

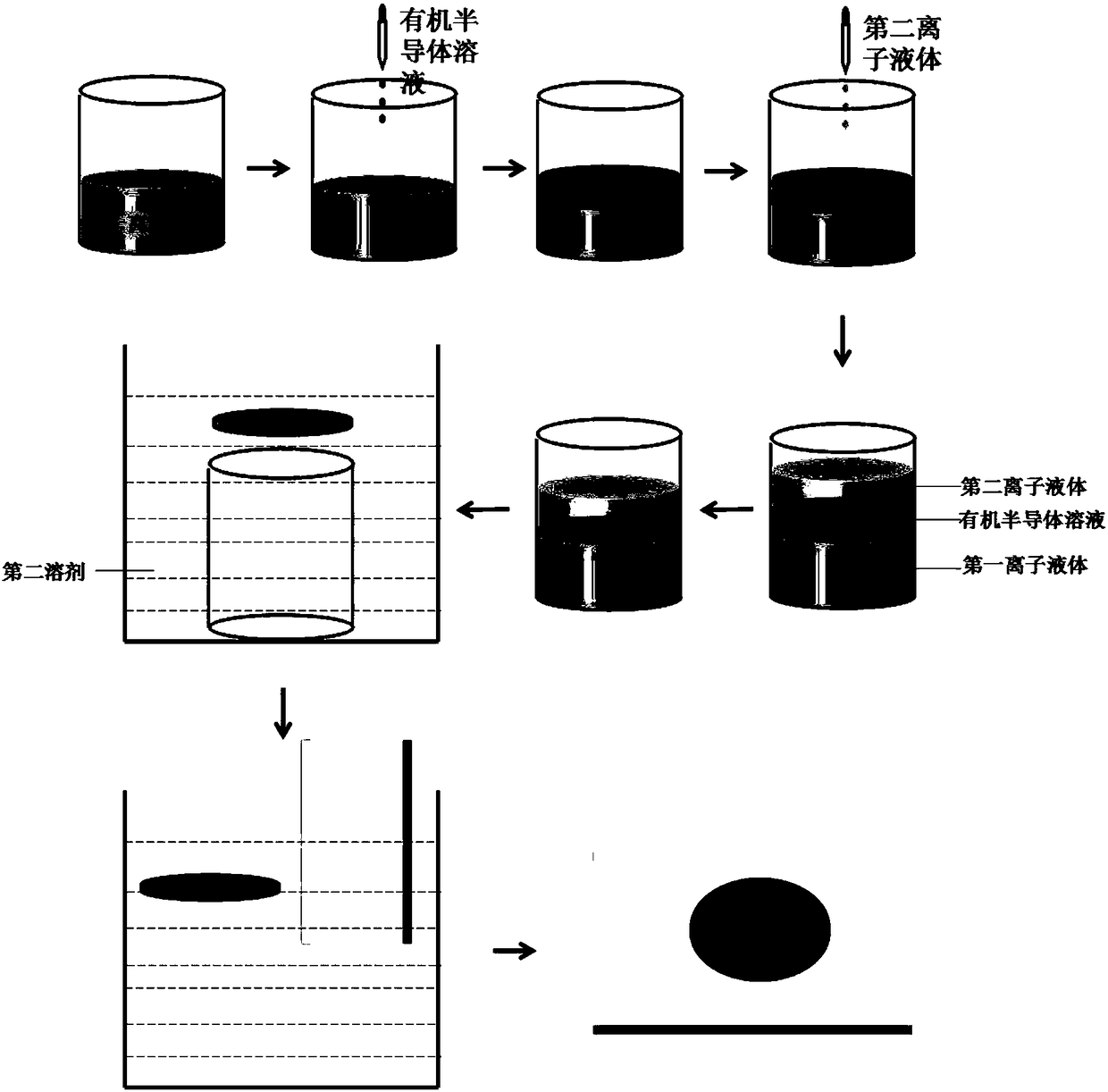

[0048] An aspect of the embodiments of the present invention provides a method for preparing an organic self-supporting single crystal film, which includes:

[0049]Provide a "sandwich" structure consisting of an organic semiconductor solution and two ionic liquids, the first ionic liquid is immiscible with the organic semiconductor solution, the second ionic liquid is slightly soluble in the organic semiconductor solution, and the density of the first ionic liquid is greater than The density of the organic semiconductor solution and the density of the second ionic liquid are less than the density of the organic semiconductor solution;

[0050] The solvent in the organic semiconductor solution and the second ionic liquid are slowly dissolved, and the solvent in the organic semiconductor solution penetrates the second ionic liquid to volatilize, so that the organic semiconductor material slowly self-assembles between the two ionic liquids to form an organic self-supporting sing...

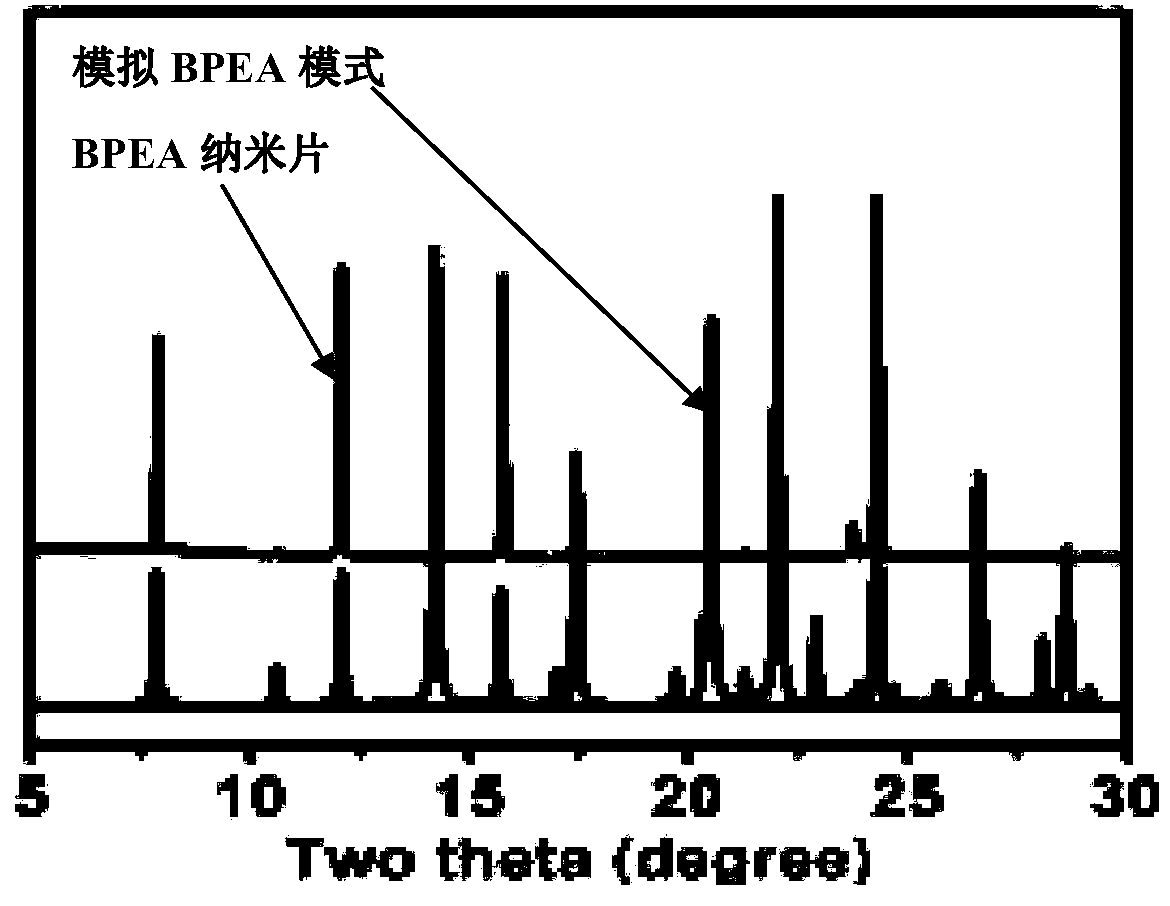

Embodiment 1

[0101] The raw materials for the preparation of the organic self-supporting single crystal film in this embodiment are: 9,10-benzylethynyl anthracene (BPEA) is used as the organic semiconductor material, the first solvent is dichloromethane, and the second solvent is a mixture of distilled water and methanol , the ratio of distilled water to methanol is 1:1; the first ionic liquid is 1-ethyl-3-methylimidazolium tetrafluoroborate, and the second ionic liquid is 1-ethyl-3-methylimidazolium trifluoroborate Fluoroborate.

[0102] The preparation method of the organic self-supporting single crystal film of this embodiment comprises the following steps:

[0103] Step 1: Adding a certain amount of 1-ethyl-3-methylimidazolium tetrafluoroborate into a beaker as a liquid substrate for organic single crystal self-assembly.

[0104] Step 2: Dissolving 9,10-diphenylethynylanthracene powder in dichloromethane to form a mixture with a 9,10-diphenylethynylanthracene concentration of 2 mg / mL....

Embodiment 2

[0112] The raw materials for the preparation of the organic self-supporting single crystal film in this embodiment are: zinc octaethylporphyrin is used as the organic semiconductor material, the first solvent is chlorobenzene, the second solvent is a mixture of distilled water and methanol, and the ratio of distilled water to methanol is 1:1; the first ionic liquid is 1-ethyl-3-methylimidazolium tetrafluoroborate, and the second ionic liquid is 1-butyl-3-methylimidazolium acetate.

[0113] The preparation method of the organic self-supporting single crystal film of this embodiment comprises the following steps:

[0114] Step 1: Adding a certain amount of 1-ethyl-3-methylimidazolium tetrafluoroborate into a beaker as a liquid substrate for the self-assembly of an organic self-supporting single crystal film.

[0115] Step 2: dissolving the zinc octaethylporphyrin powder in chlorobenzene to form a mixture with a zinc octaethylporphyrin concentration of 1 mg / mL.

[0116] Step 3: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com