Anti-oxidation silver paste for passenger car front windshield and preparation method thereof

A front glass, silver oxide technology, applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, electrical components, etc. The quality of glass screen products and the poor oxidation resistance of silver paste can increase the oxidation resistance, improve the oxidation resistance and meet the conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

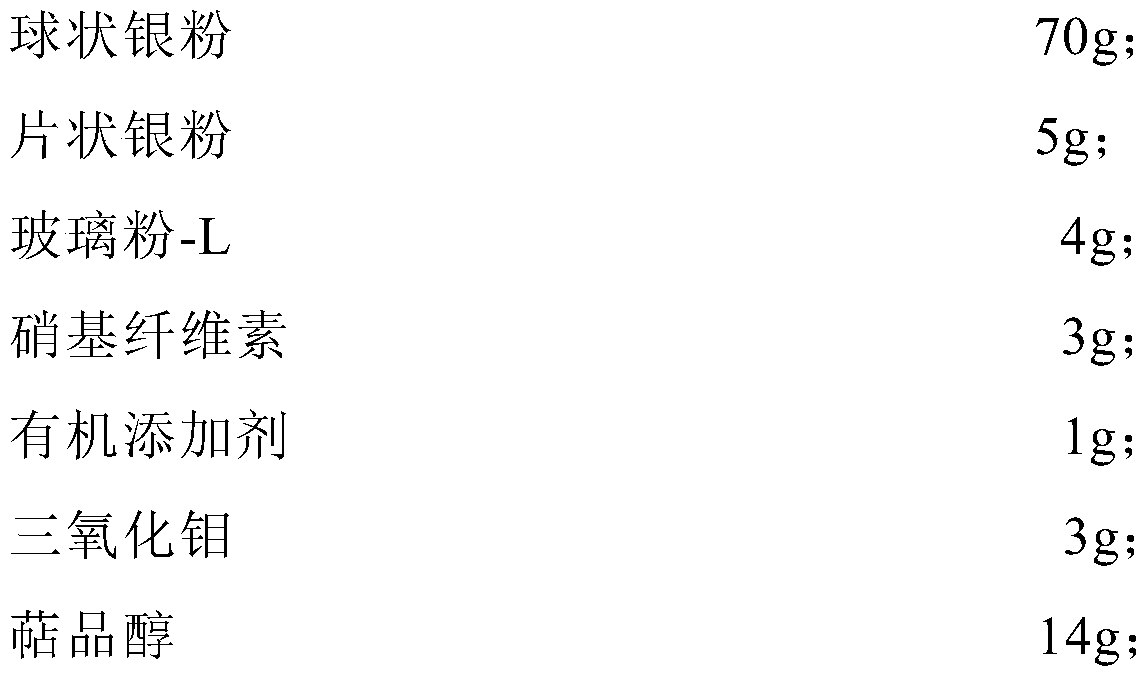

[0034] (1) Prepare 100g of raw materials, prepare raw materials according to the following components and quality:

[0035]

[0036]

[0037] The particle size of the spherical silver powder used is 2.3 μm, and the tap density is 3.2 g / ml; the particle size of the flake silver powder is 6 μm, and the tap density is 2.4 g / ml;

[0038] The composition and percentage of glass powder-L used are: Bi 2 o 3 65.B 2 o 3 18. ZnO 9. SiO 2 4. Al 2 o 3 2. Na 2 O 1, Fe 2 o 3 0.5, ZrO 20.5;

[0039] The organic additives used are 0.25g dibutyl phthalate and 0.25g silane coupling agent KH550.

[0040] The titanium dioxide used was of analytical grade. The organic solvent is mixed with terpineol and diethylene glycol butyl ether at a volume ratio of 1:4.

[0041] (2) Preparation of carrier: Weigh ethyl cellulose and organic solvent, then heat it up to 80°C and keep the temperature constant. After the ethyl cellulose is completely dissolved, filter and remove impurities ...

Embodiment 2

[0045] (1) Prepare 100g of raw materials, prepare raw materials according to the following components and quality:

[0046]

[0047] The particle size of the spherical silver powder used is 2.8 μm, and the tap density is 3.8 g / ml; the particle size of the flake silver powder is 6 μm, and the tap density is 2.4 g / ml;

[0048] The composition and percentage of glass powder-L used are: Bi 2 o 3 70.B 2 o 3 16. ZnO 8. SiO 2 3.5, Al 2 o 3 1.5, Na 2 O 1.0, Fe 2 o 3 0. ZrO 2 0;

[0049] The organic additives used were 0.5 g dioctyl phthalate and 0.5 g silicone resin.

[0050] The molybdenum trioxide used was of analytical grade.

[0051] (2) Preparation of carrier: Weigh nitrocellulose and terpineol, then heat it up to 80°C and keep the temperature constant. After the nitrocellulose is completely dissolved, filter and remove impurities on a mesh cloth of 300-400 mesh. That is, the carrier is obtained;

[0052] (3) Preparation of silver paste: Weigh spherical silv...

Embodiment 3

[0055] (1) Prepare 100g of raw materials, prepare raw materials according to the following components and quality:

[0056]

[0057] The particle size of the spherical silver powder used is 1.8 μm, and the tap density is 2.6 g / ml; the particle size of the flake silver powder is 7.5 μm, and the tap density is 1.9 g / ml;

[0058] The composition and percentage of glass powder-L used are: Bi 2 o 3 70.B 2 o 3 16. ZnO 8. SiO 2 3.5, Al 2 o 3 1.5, Na 2 O 1.0, Fe 2 o 3 0. ZrO 2 0;

[0059] The organic additives used are 0.6g tributyl citrate, 0.2g hydrogenated castor oil and 0.20g silane coupling agent KH570.

[0060] The tricobalt tetroxide and vanadium pentoxide used are of analytical grade.

[0061] (2) Preparation of the carrier: weigh ethyl hydroxyethyl cellulose, terpineol and butyl carbitol acetate, then heat them up to 80°C and keep the temperature constant until the ethyl hydroxyethyl cellulose is completely dissolved , filter and remove impurities on a me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com