Copper alloy and method for producing copper alloy

A manufacturing method and technology of copper alloys, applied in the direction of metal/alloy conductors, conductive materials, conductive materials, etc., can solve the problems of high strength, high conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

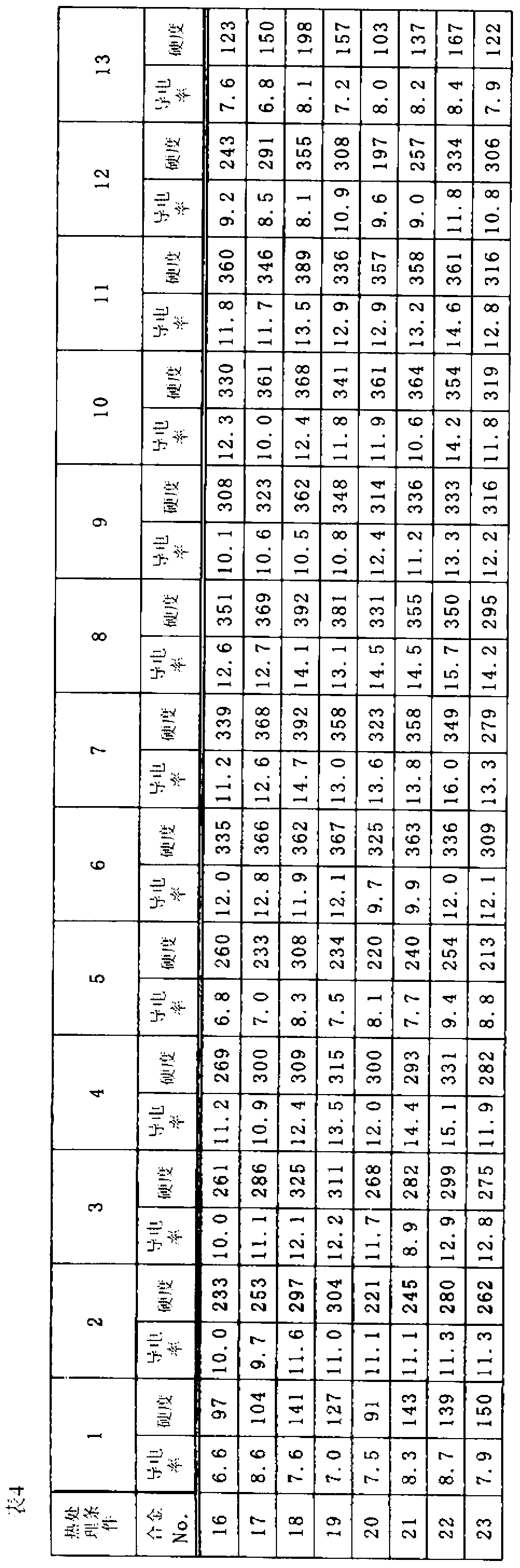

[0116] Within the scope of the copper alloy of the present invention, the copper alloy samples having the compositions of Examples 1 to 57 were integrally charged into a high-frequency induction melting furnace, melted, and melt-mixed. It is made into cast ingot (as-cast).

[0117] (Composition of Examples 1-57)

[0118] Table 1-1

[0119] Alloy No.

Ni (mass%)

Al (mass%)

Si (mass%)

1

3

1.8

0.5

2

5

2.5

0.1

3

5

1.3

0.7

4

5

0.3

0.7

5

7.5

2.8

0.75

6

7.5

1.8

0.5

7

7.5

0.8

0.5

8

9.5

3.7

0.1

9

10

2.5

1

10

10

2.8

0.7

11

10

2.3

0.5

12

10

1.9

0.3

13

10

1.4

0.2

14

10

0.9

0.2

15

14

1.4

0.3

16

13

2.8

0.2

17

13

2.5

0.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com