Electric socket

A technology for electrical sockets and conductive sheets, applied in circuits, electrical components, contact parts, etc., can solve the problems of reduced pressure, increased contact resistance, and many socket solder joints or riveting points, and achieves soft, fatigue-resistant characteristics. Improves high temperature resistance, elasticity and tactile results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The detailed structure of the present invention will be described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited to the following embodiments.

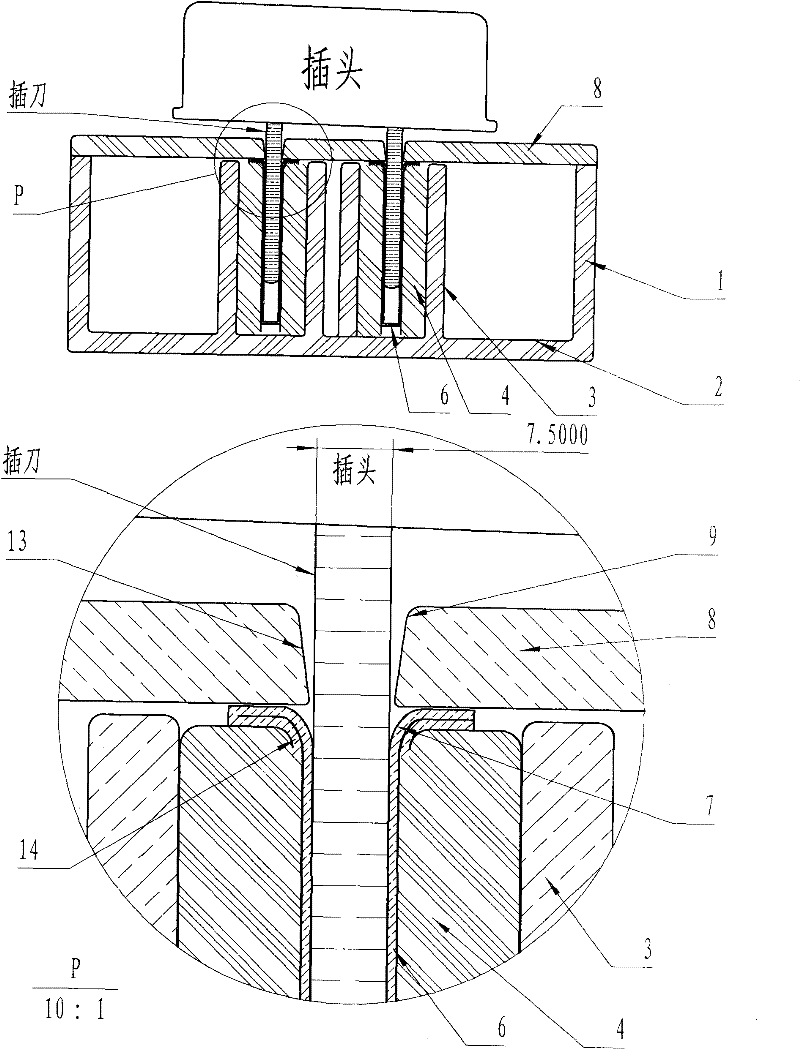

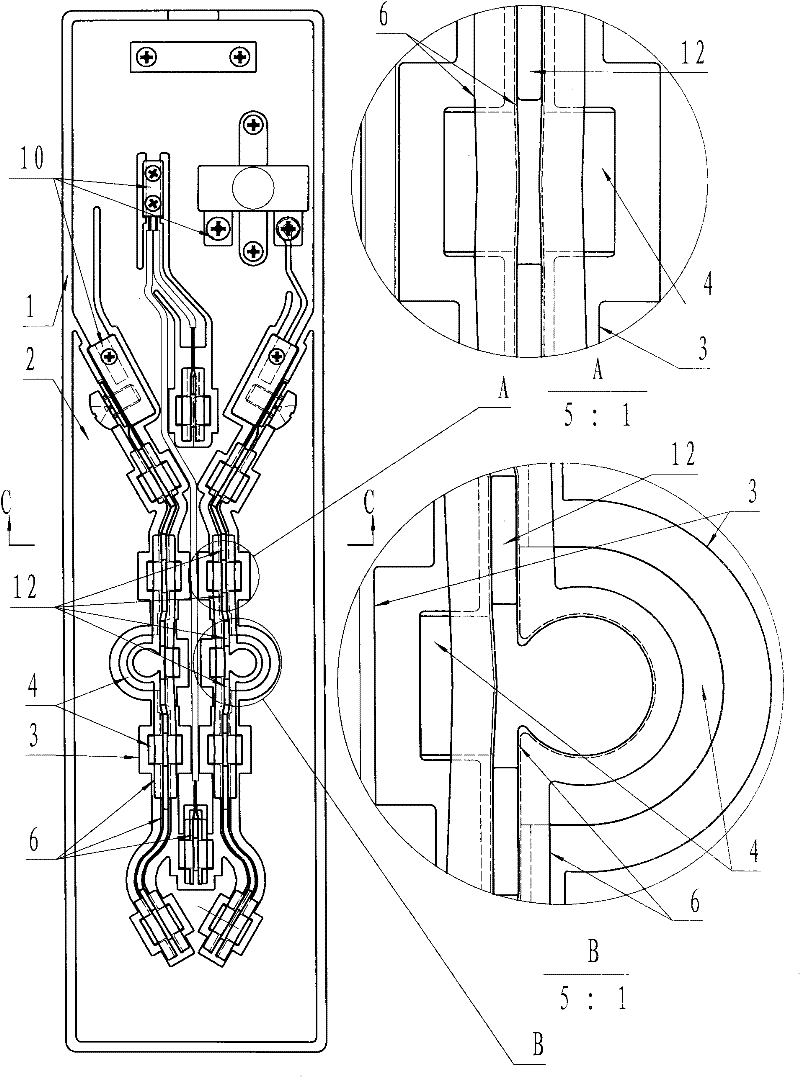

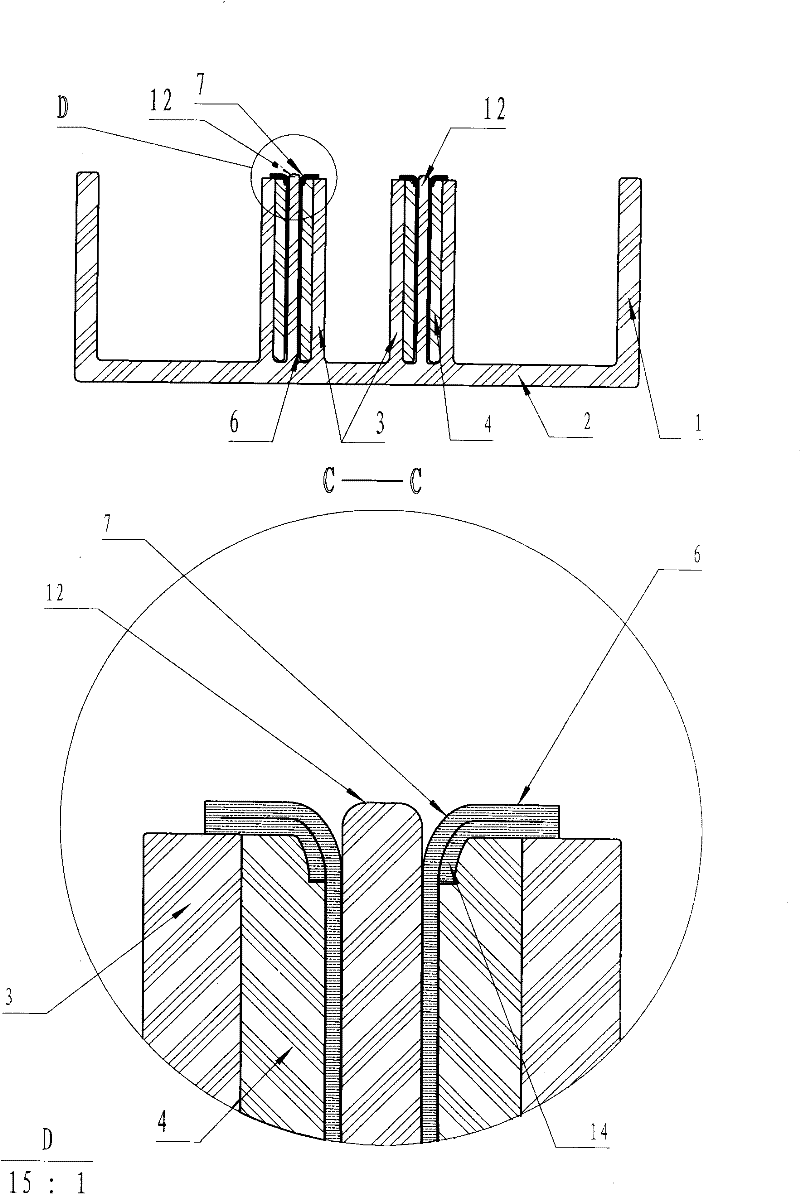

[0042] Embodiment 1 of the present invention sees figure 1 , figure 2 and image 3 , which includes: a base 1, a base plate 2, a limiting groove 3, an elastic body 4, a conductive sheet 6, an upper cover 8, a limiting member 12, and a wiring device 10, and the feature is that the base plate 2 is formed on the base 1, The limiting groove 3 and the limiting member 12 are arranged on the bottom plate 2; The end portion forms a bending section 14 and a transition surface 7 to improve its strength, regularity and help inserting the insertion sleeve; the upper cover 8 has a slit 9, the upper opening of the slit 9 is larger than the lower opening, and the gap between the two openings A transition surface 13 is placed; the wiring device 10 is placed at the end of the li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com