Patents

Literature

47 results about "Selective sweep" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In genetics, a selective sweep is the reduction or elimination of variation among the nucleotides near a mutation in DNA. It results from a beneficial allele having recently reached fixation due to strong positive natural selection.

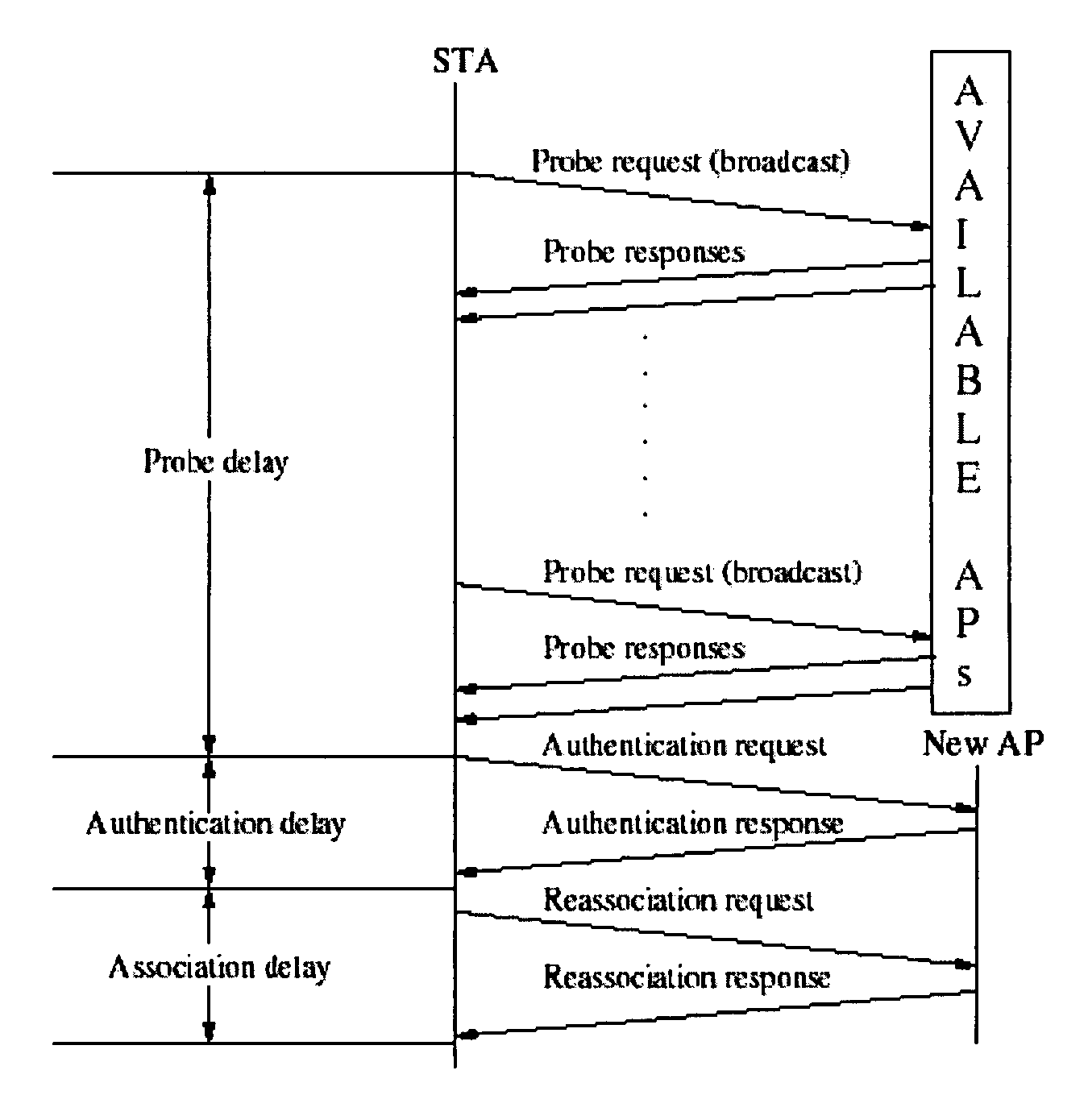

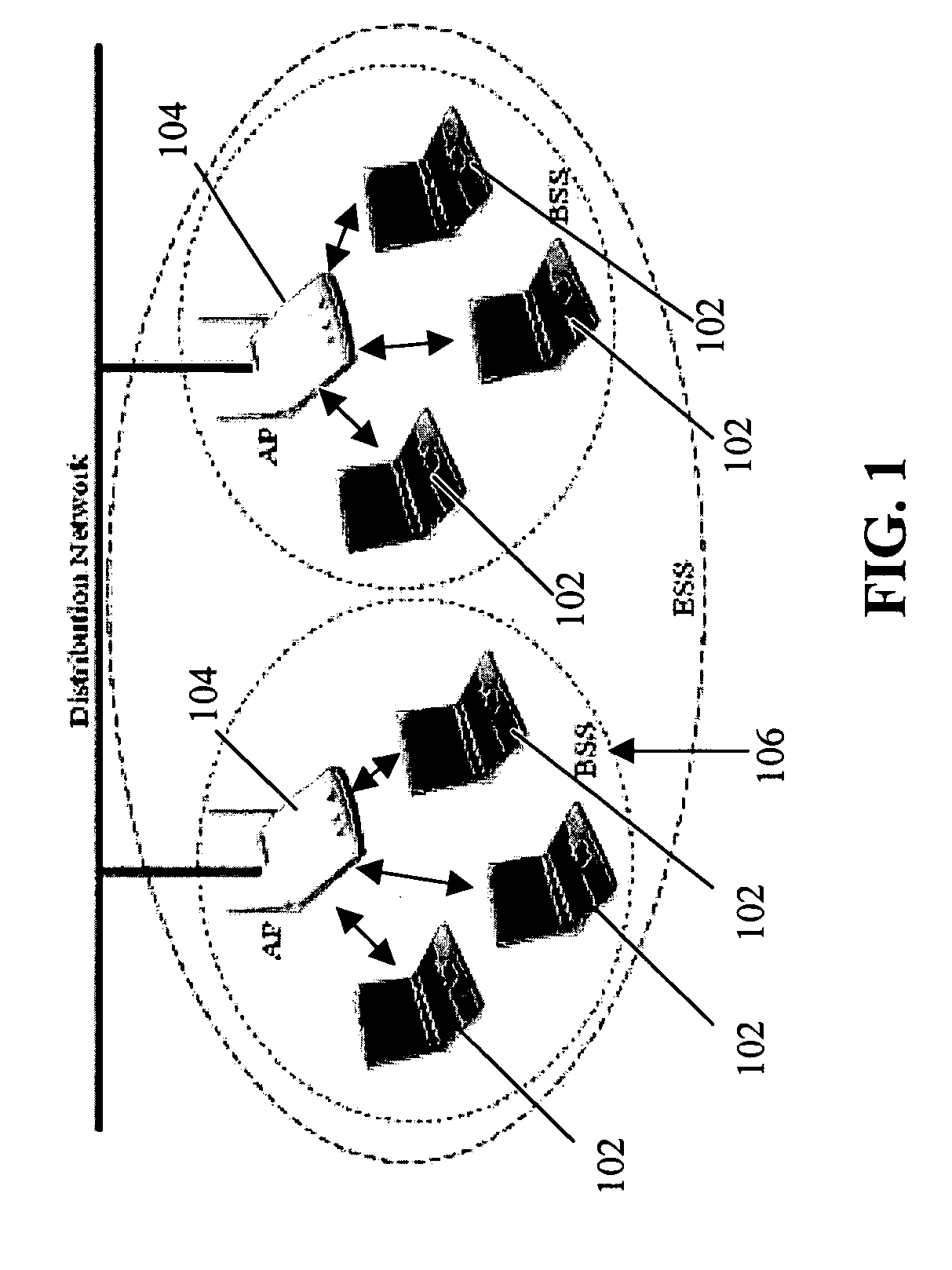

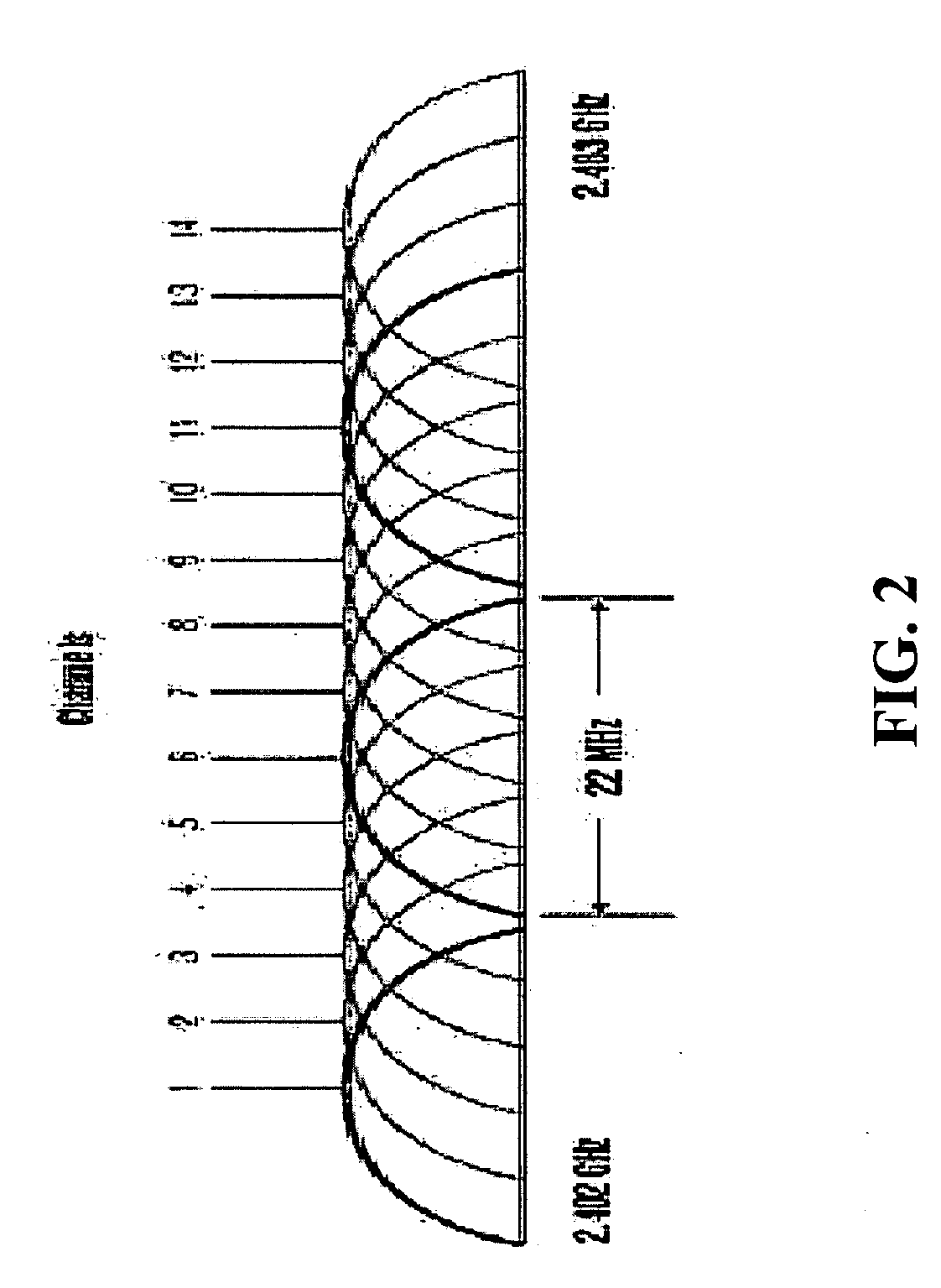

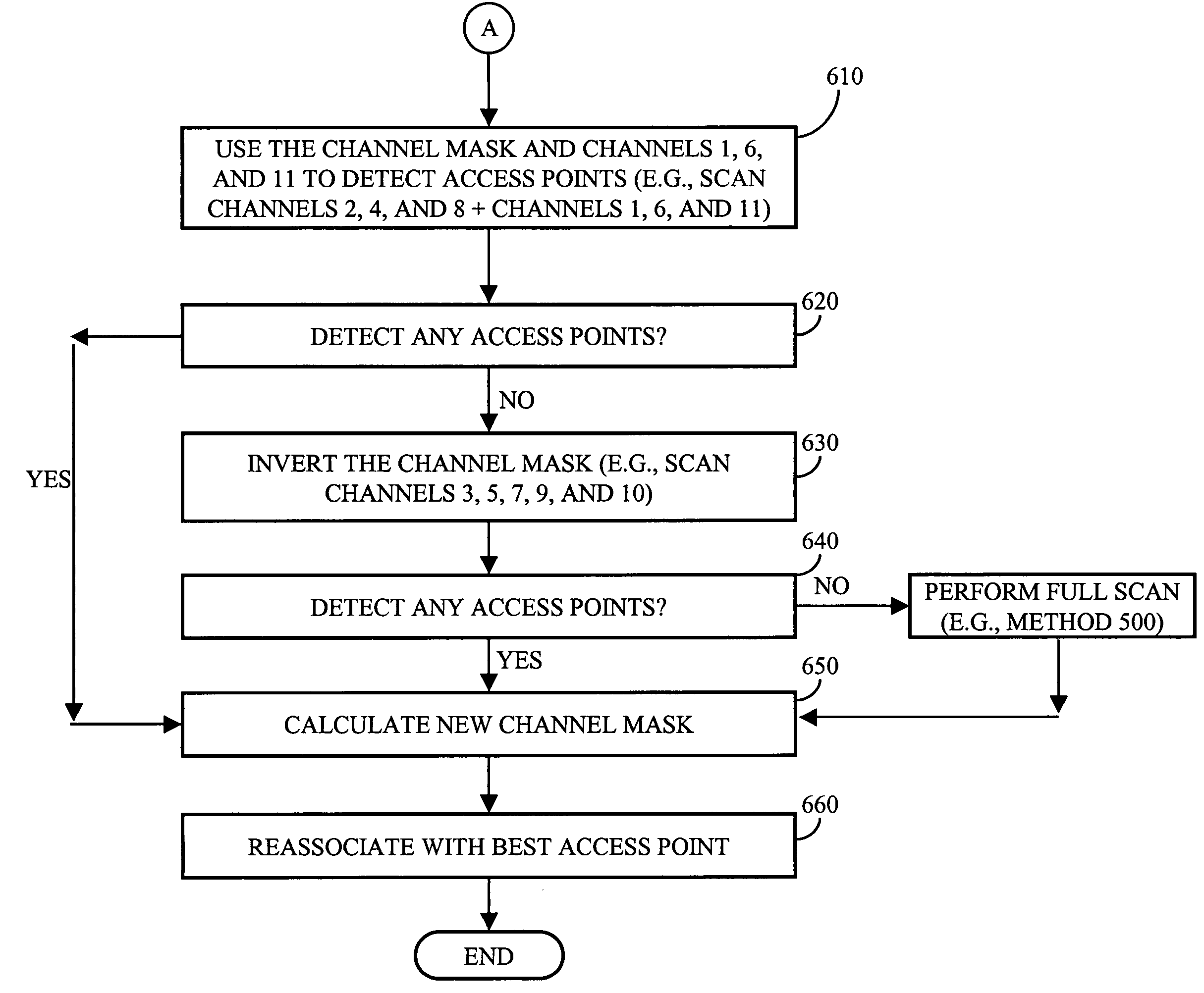

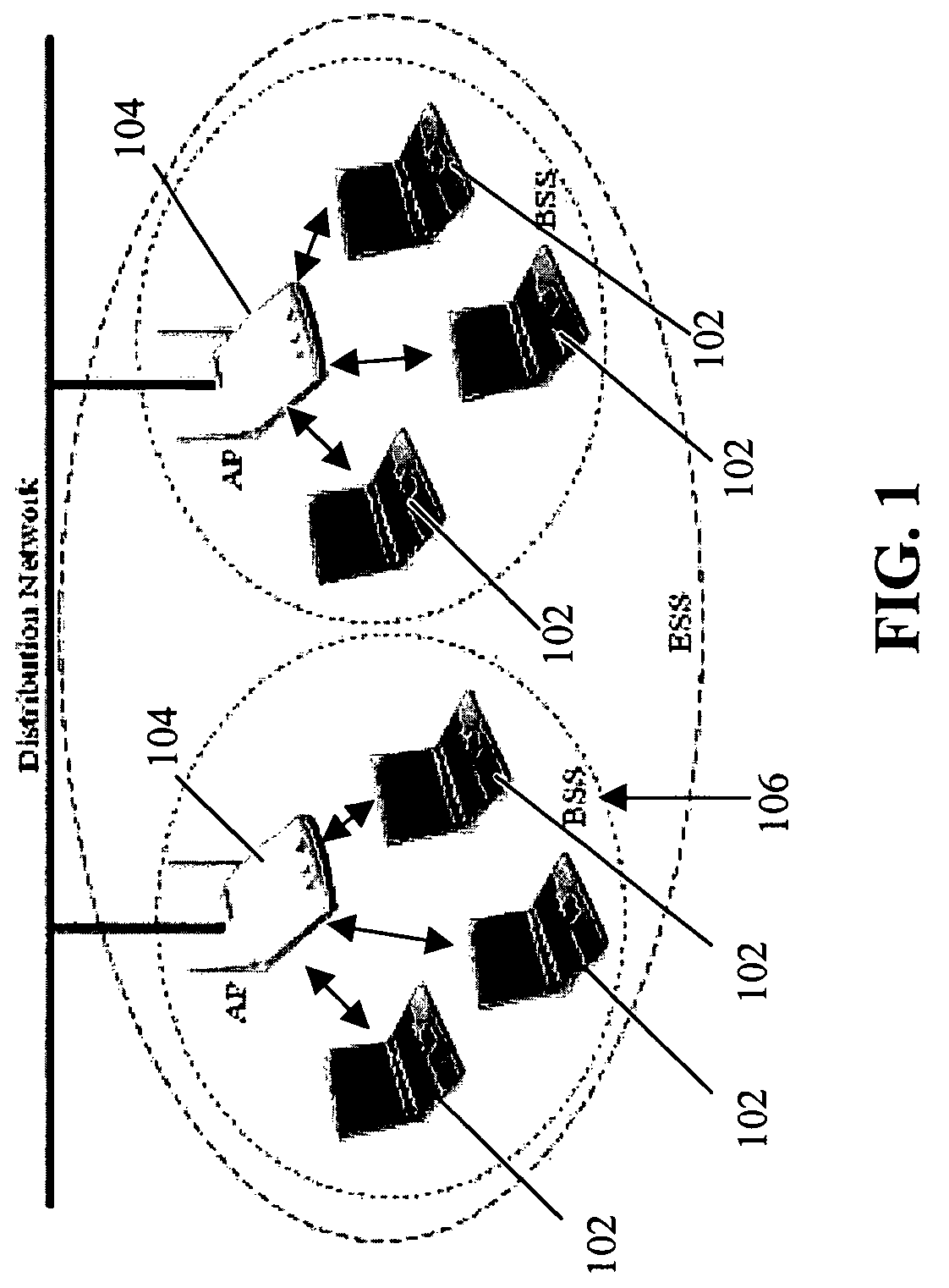

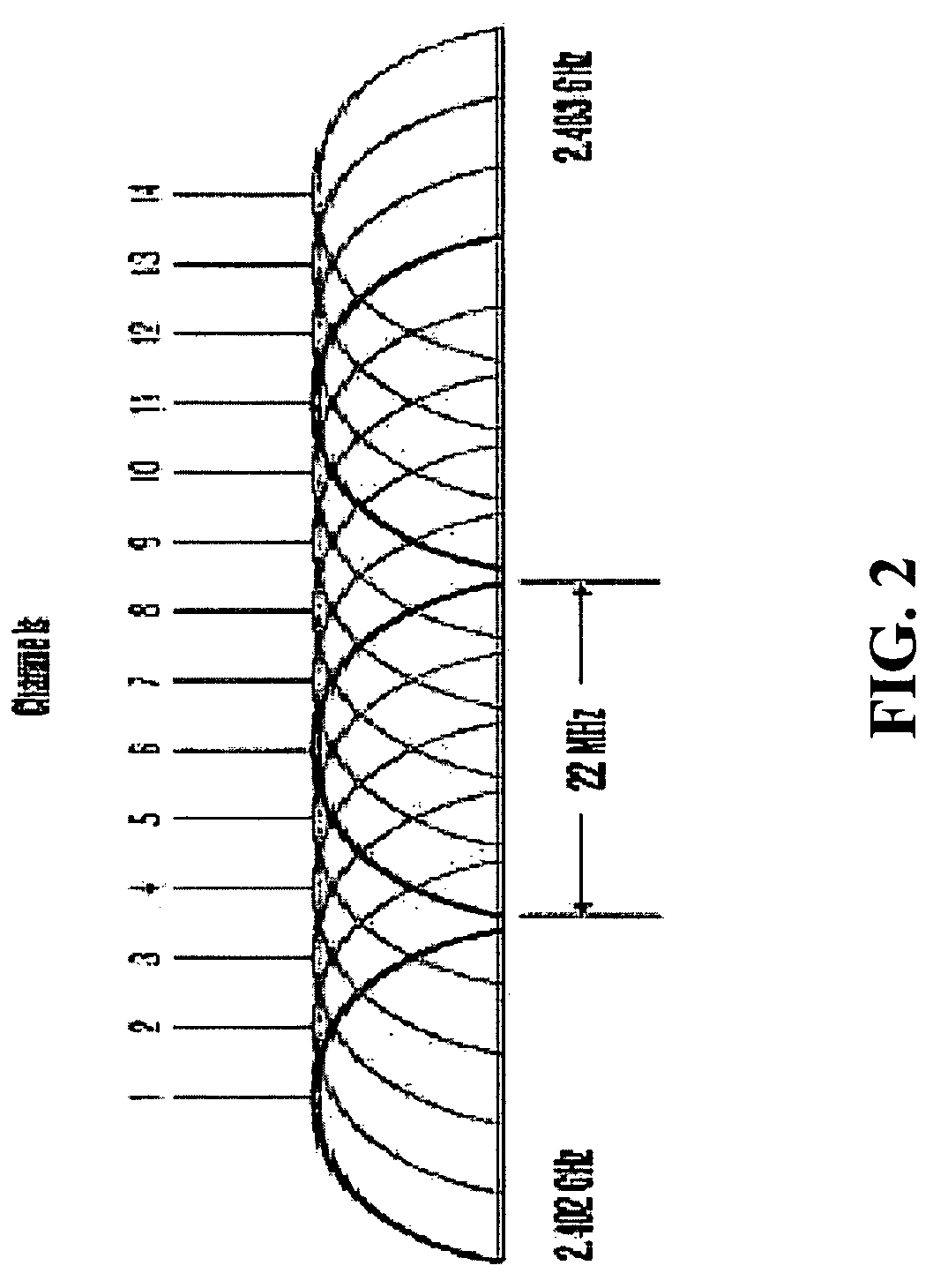

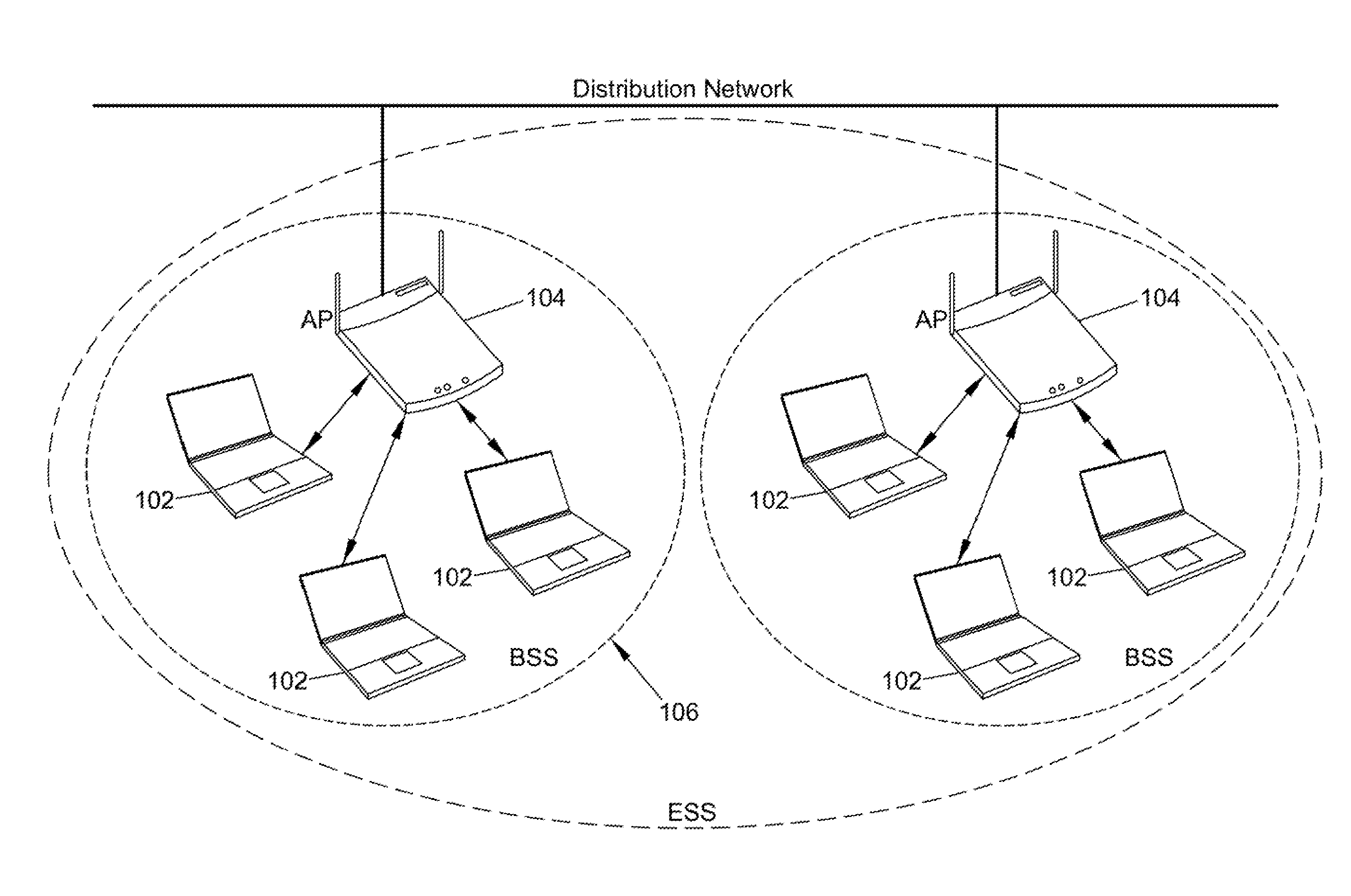

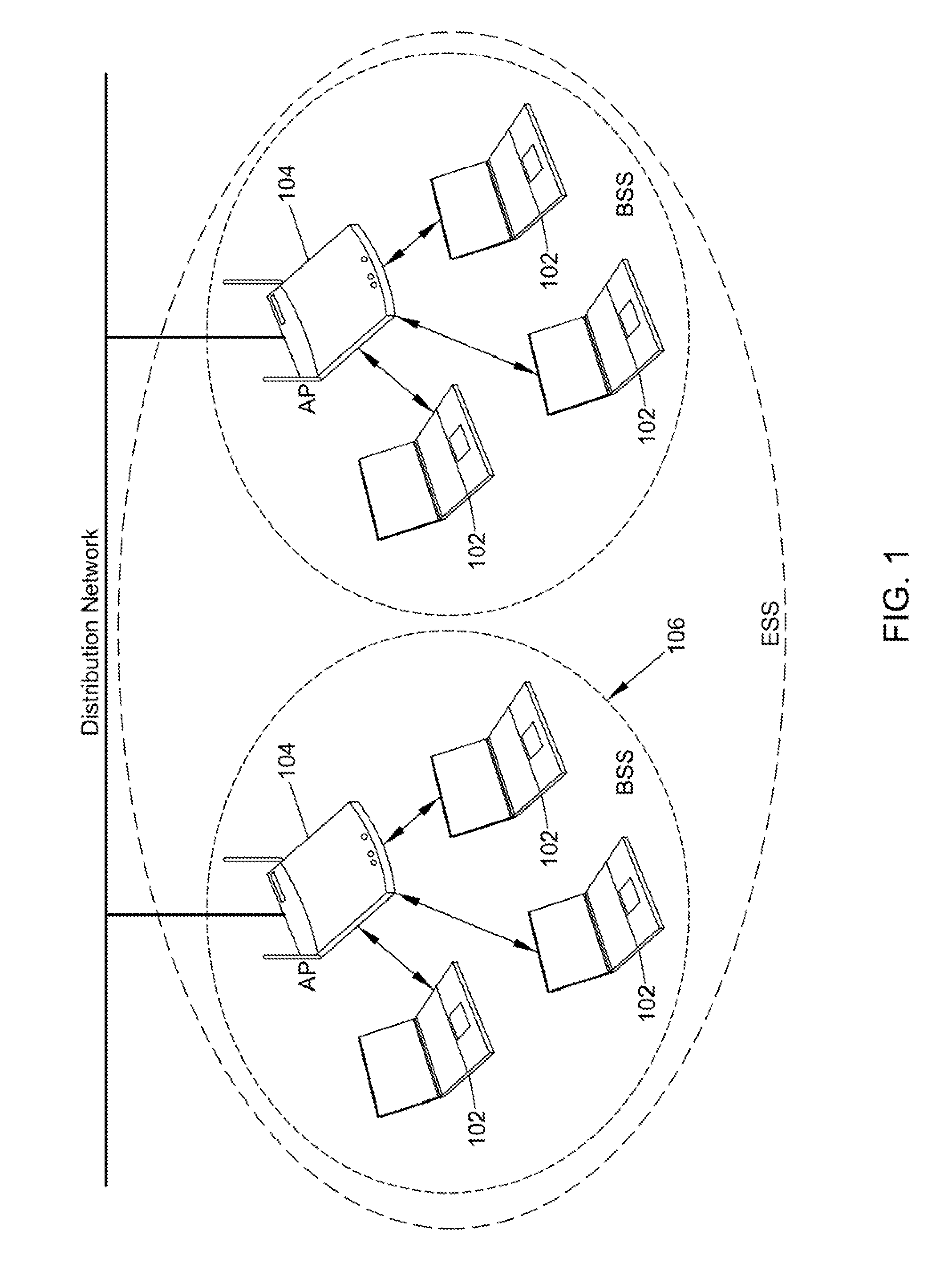

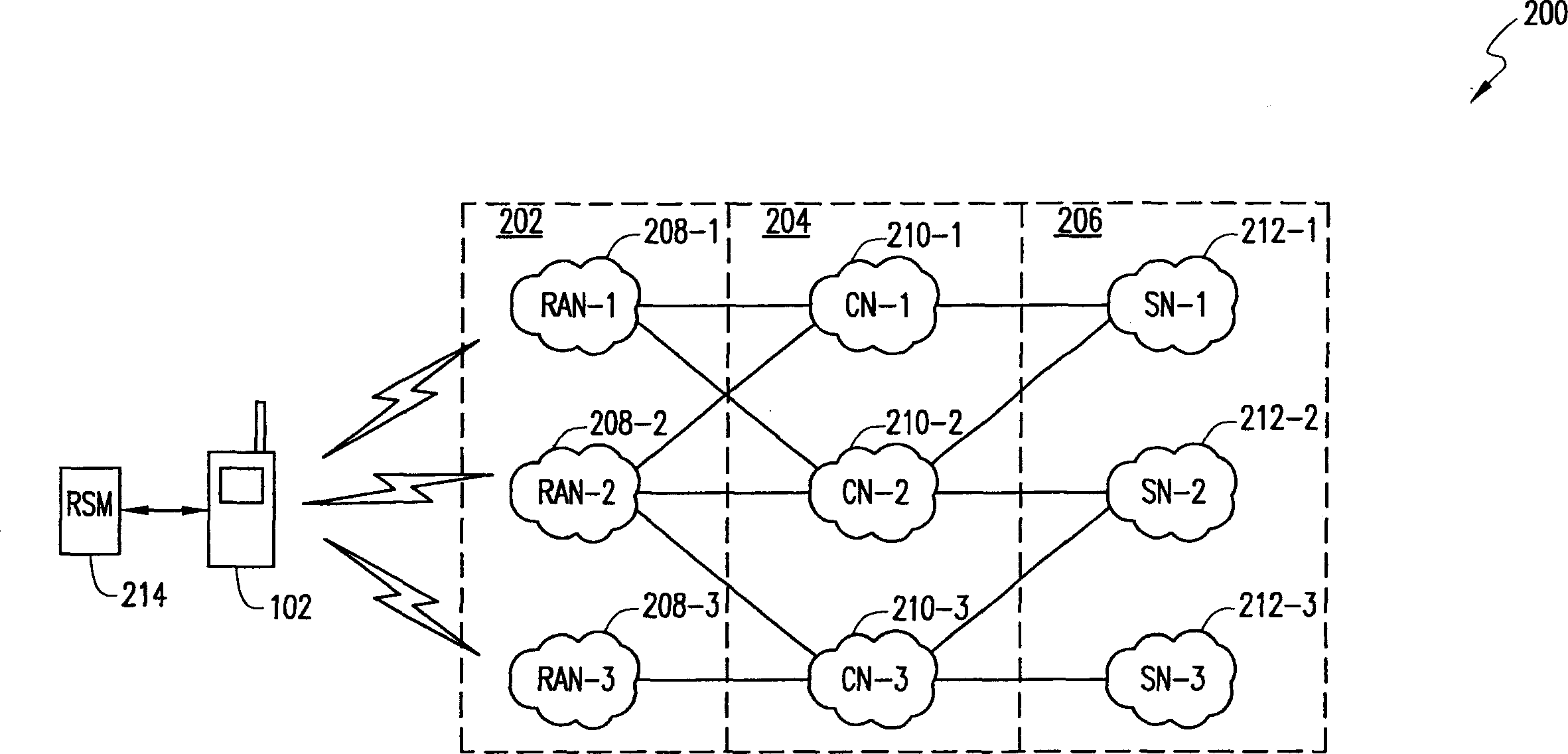

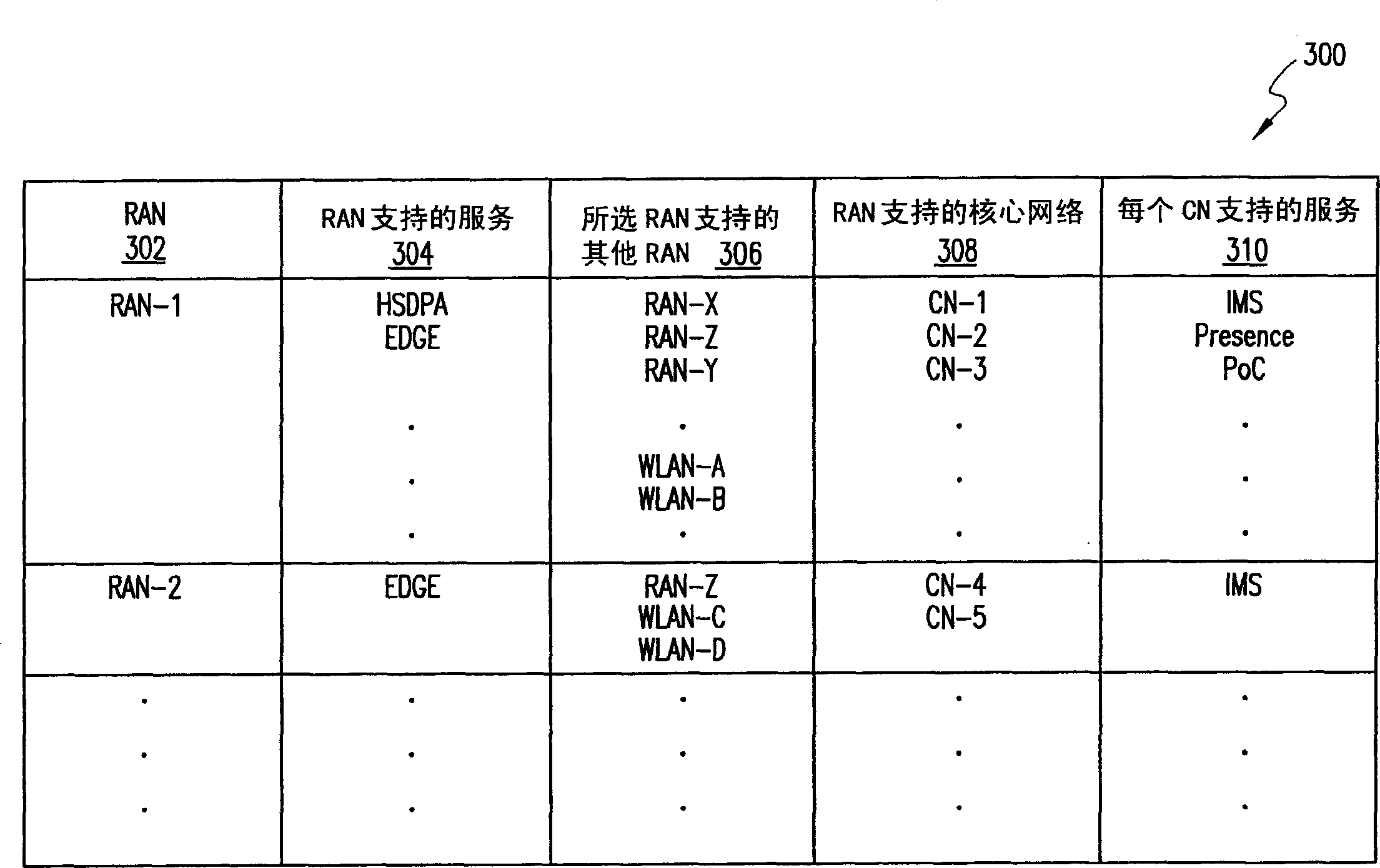

Methods and systems for reducing MAC layer handoff latency in wireless networks

ActiveUS20060062183A1Reduce switching delayReduce delaysRadio/inductive link selection arrangementsWireless commuication servicesCache algorithmsHandover latency

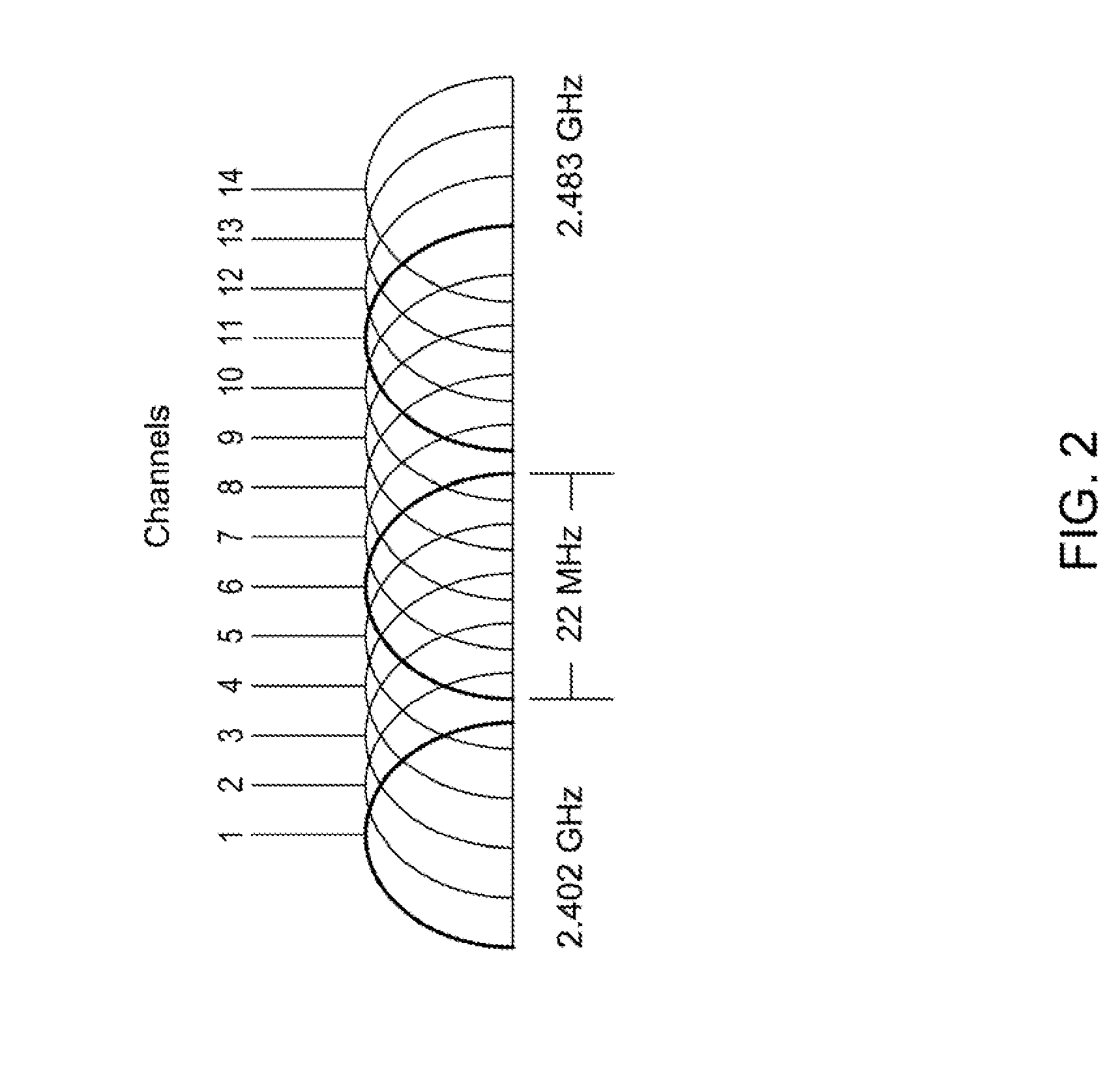

In accordance with the present invention, computer implemented methods and systems are provided for reducing handoff latency in a wireless network. In response to detecting that a handoff is necessary, the present invention uses a selective scanning algorithm that includes the use of a channel mask and / or a caching algorithm for detecting one or more new access points.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

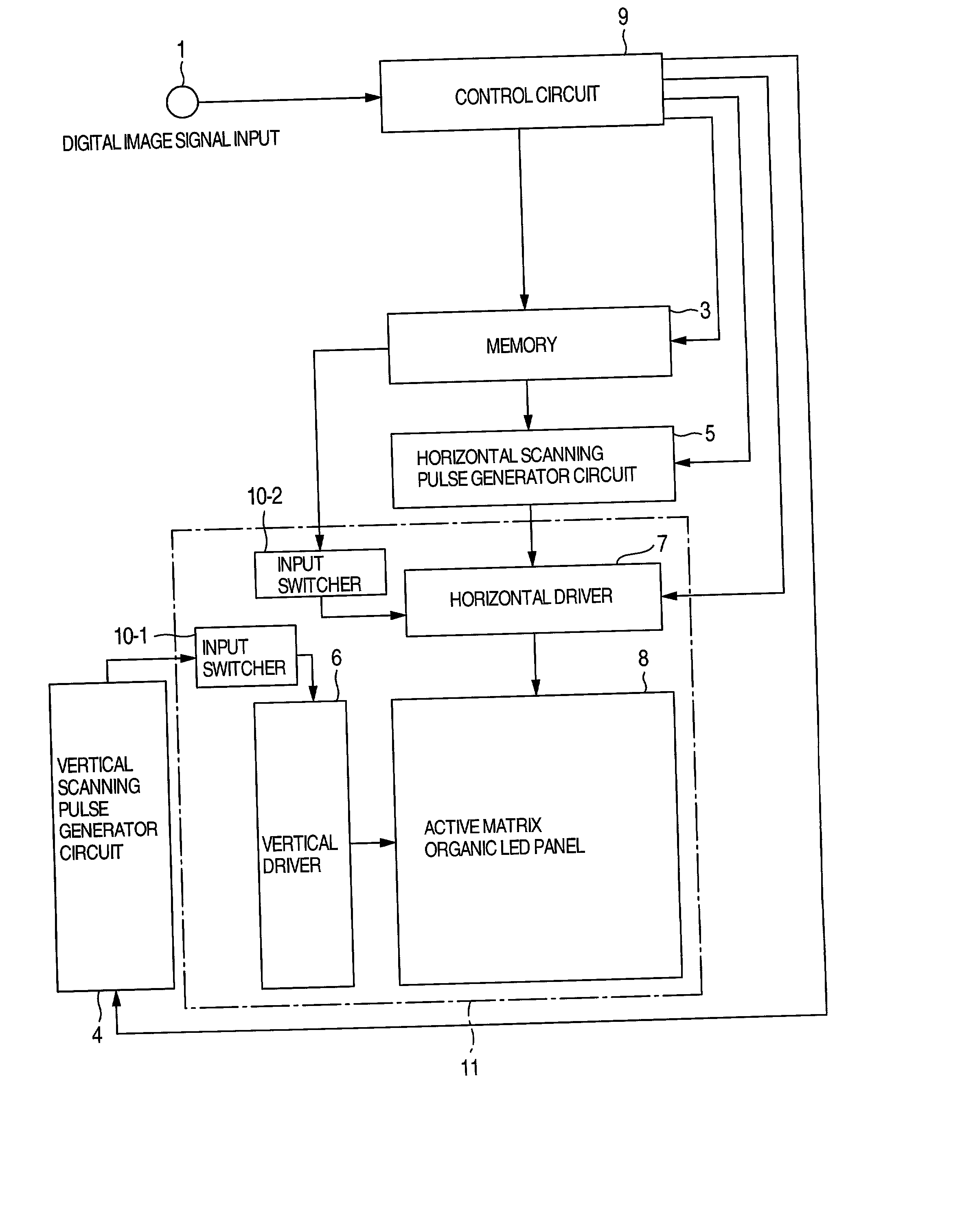

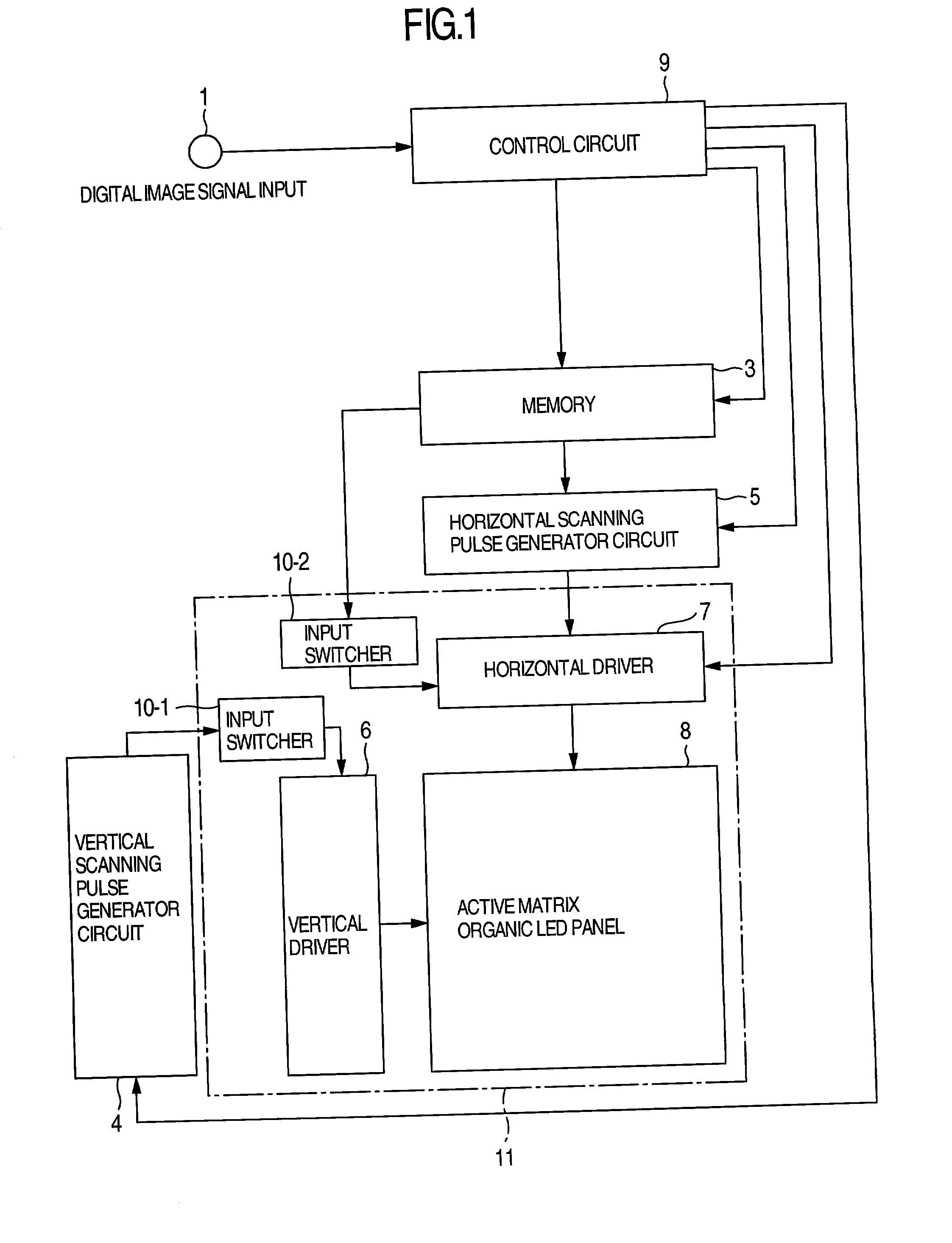

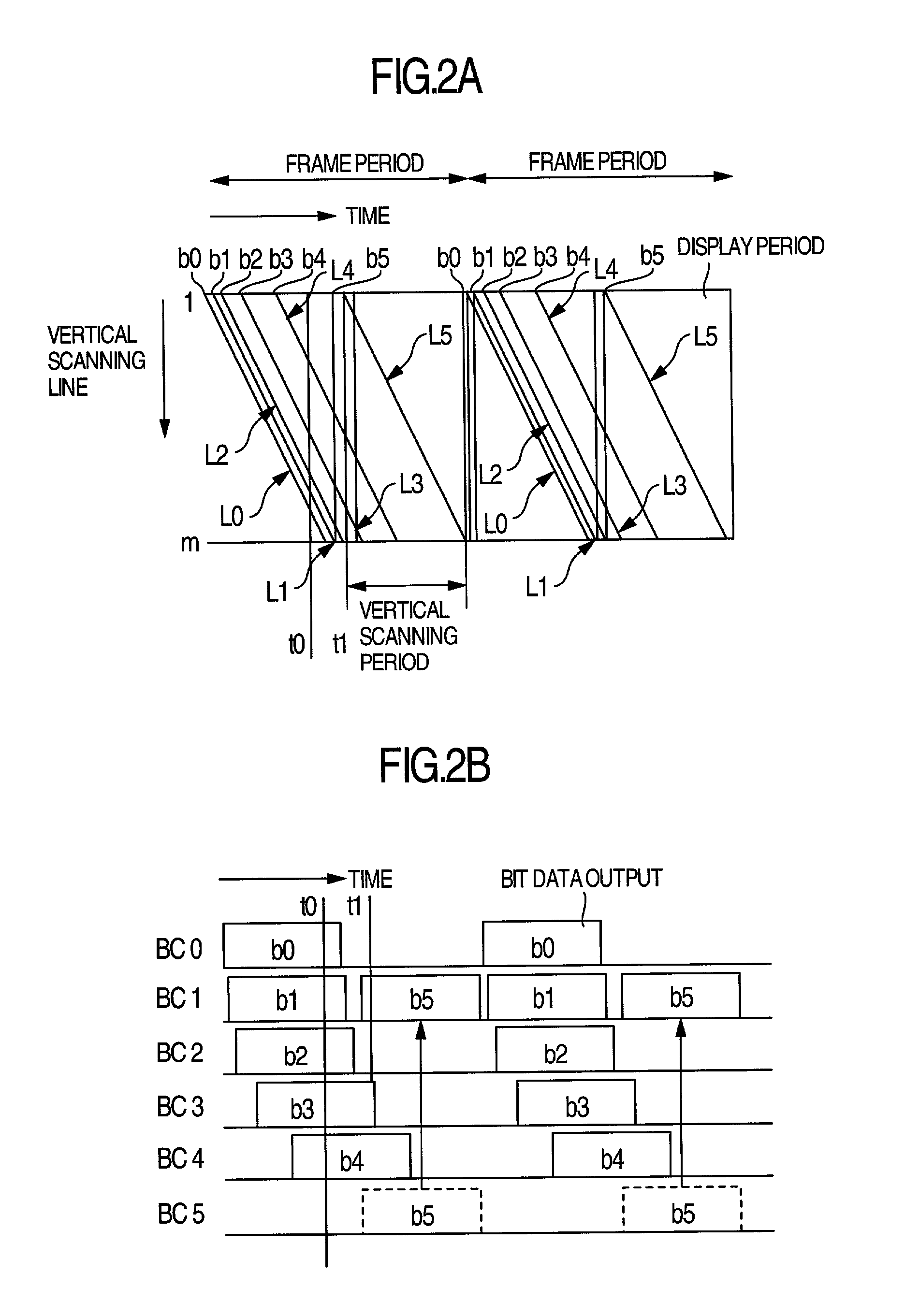

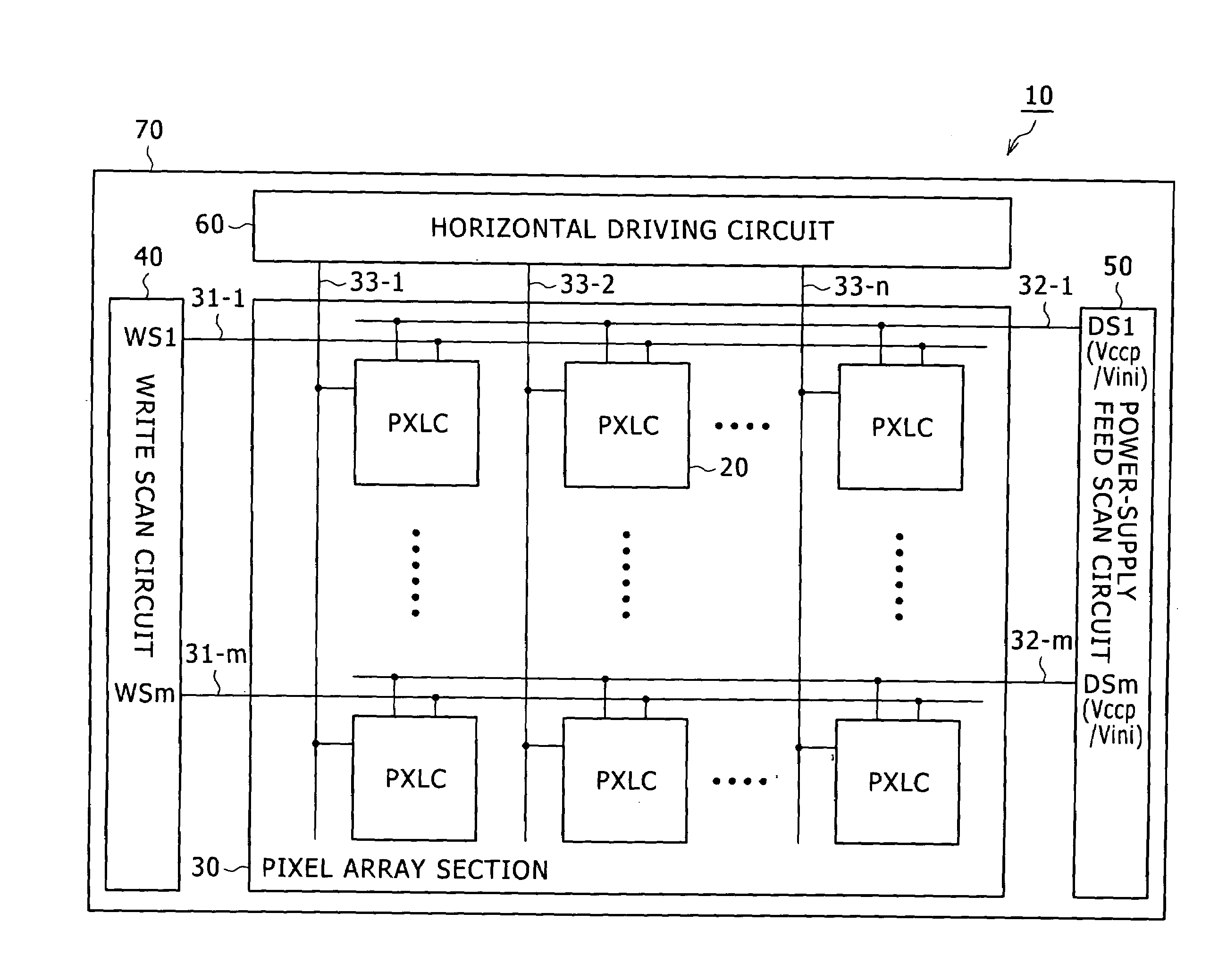

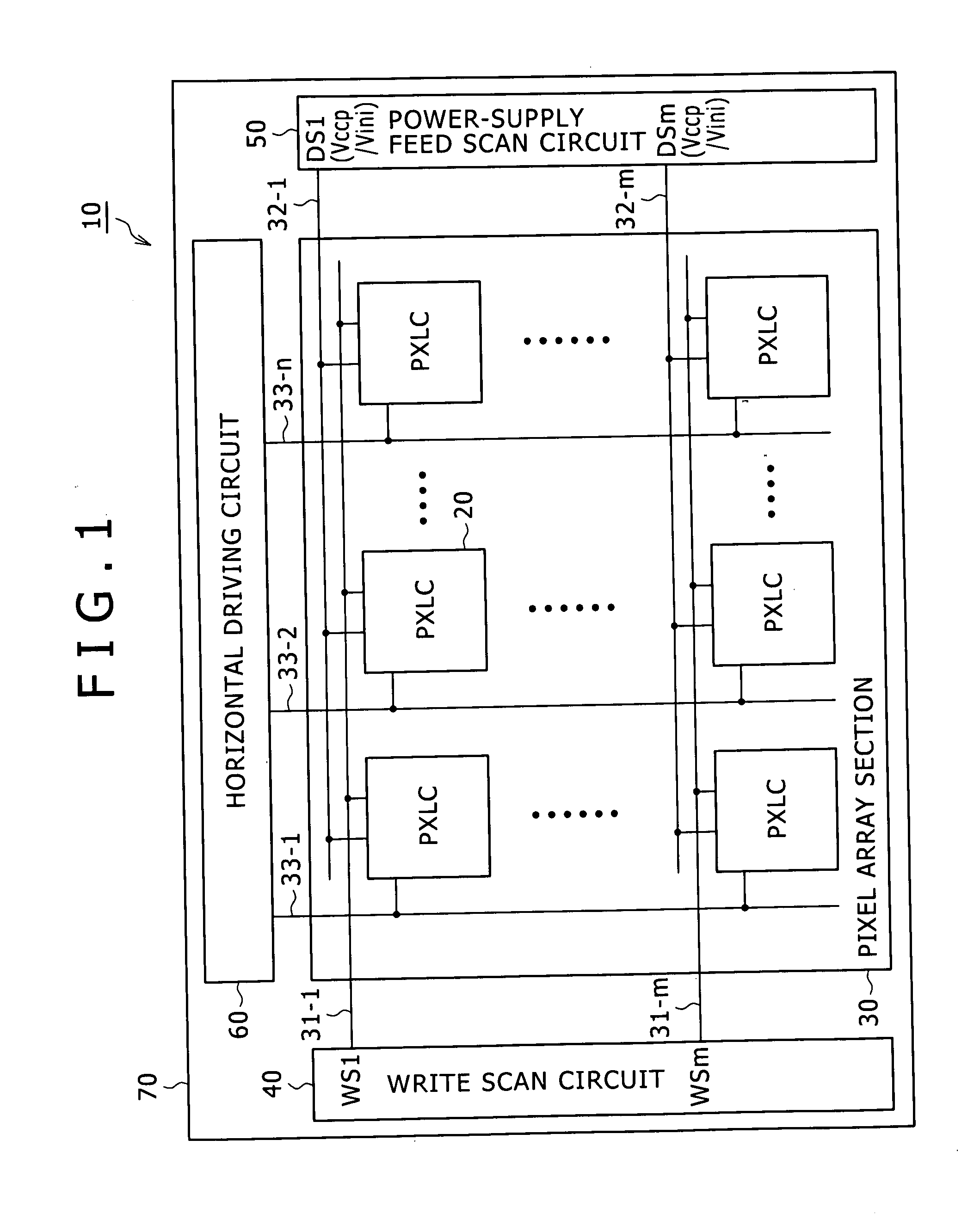

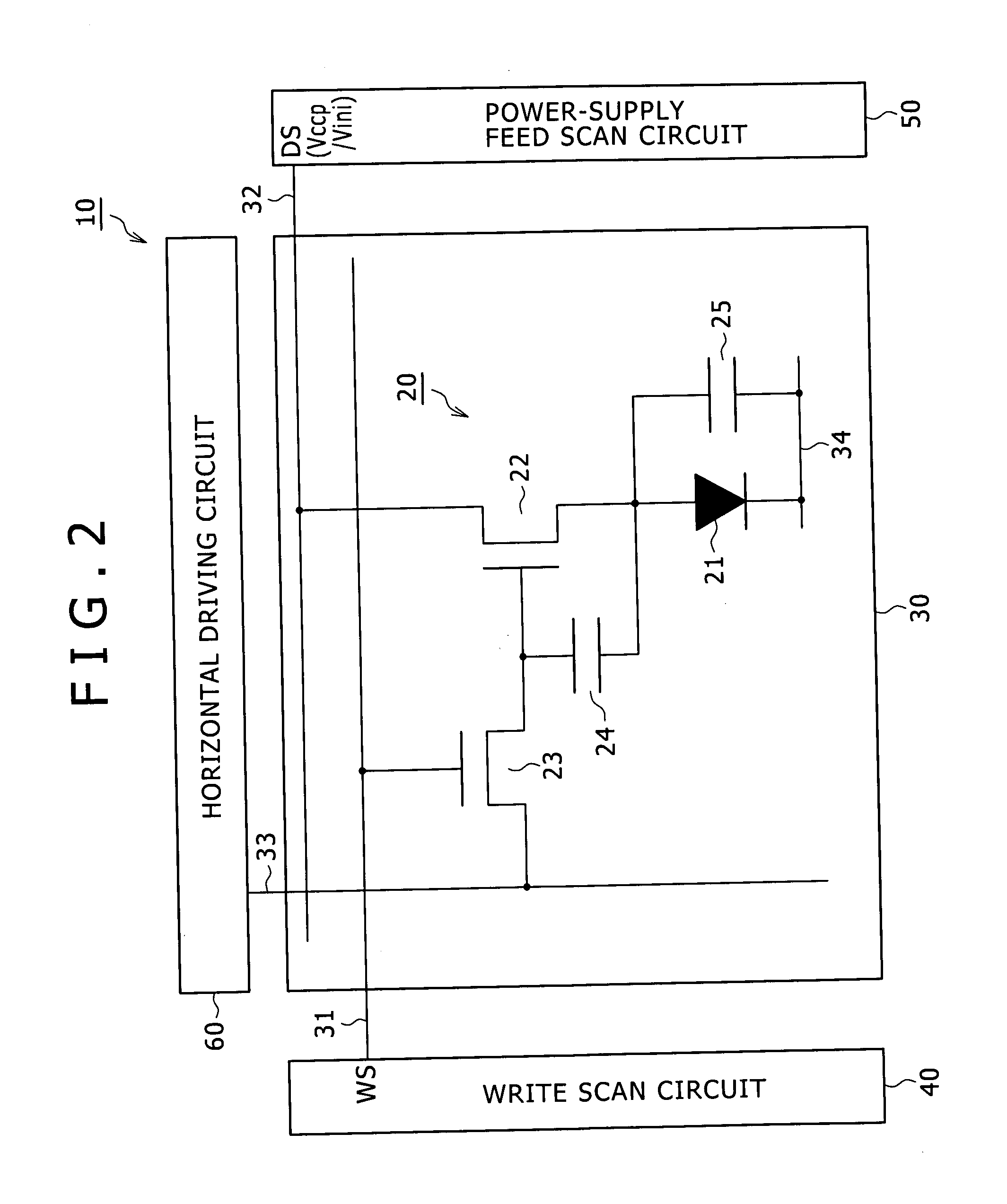

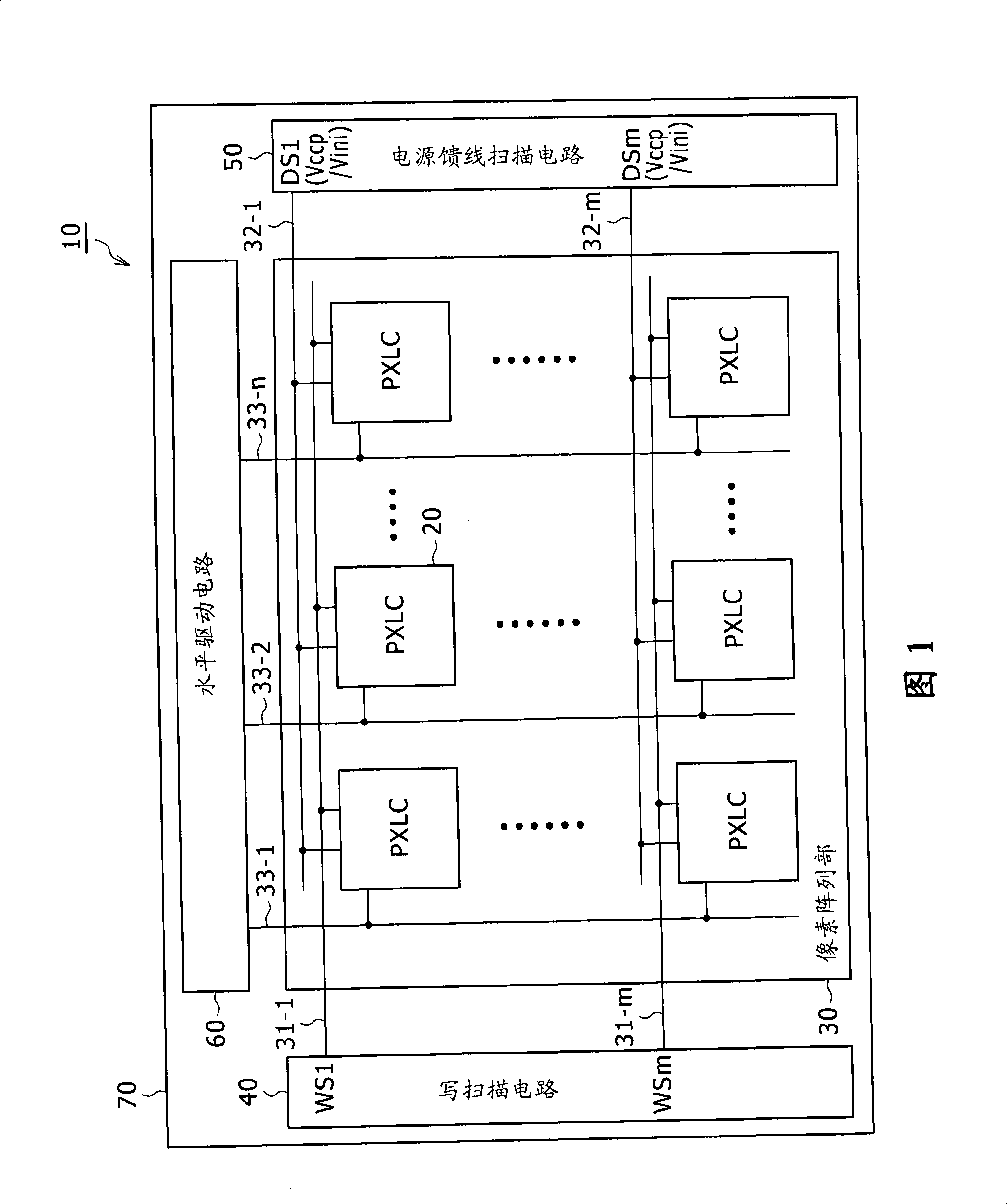

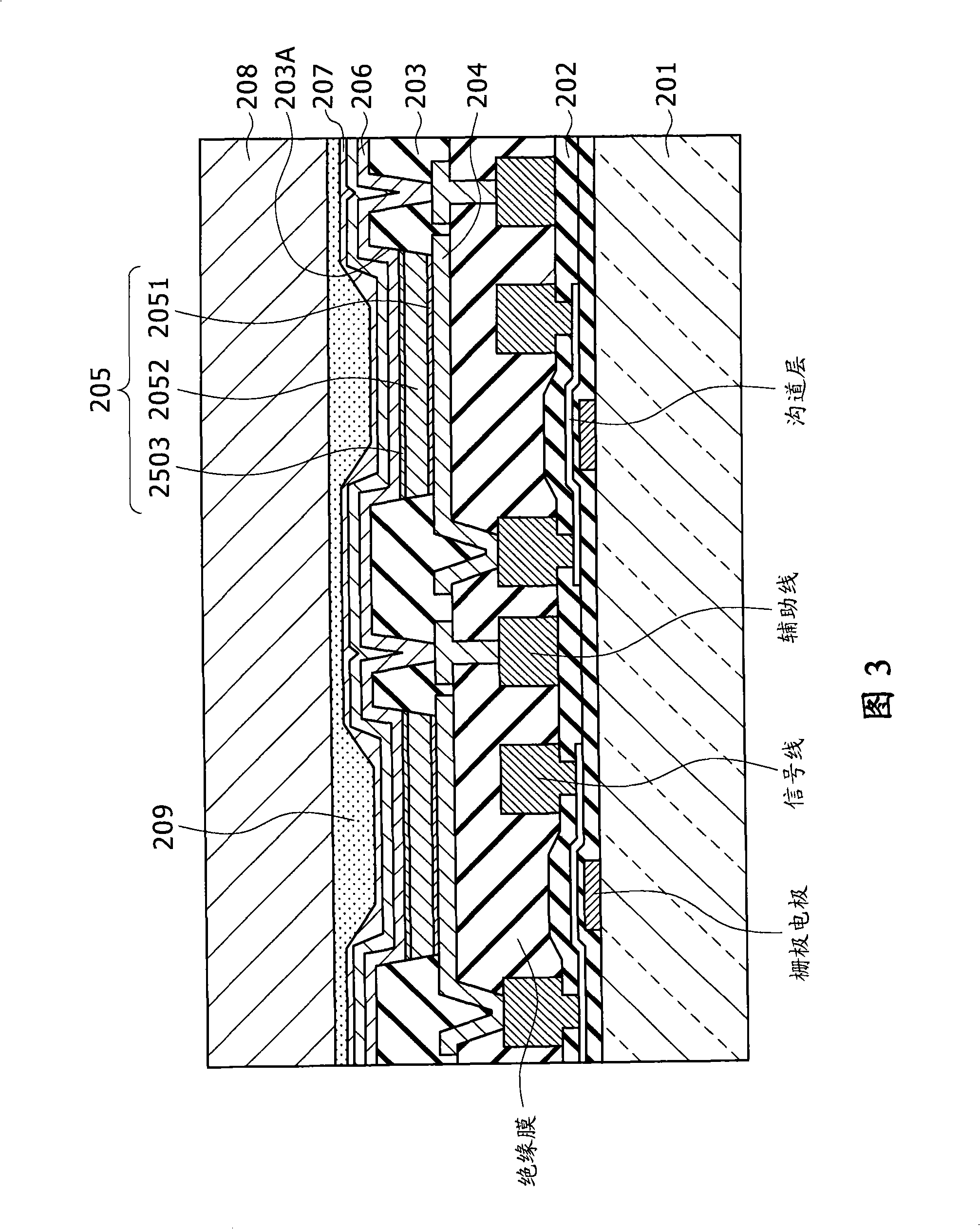

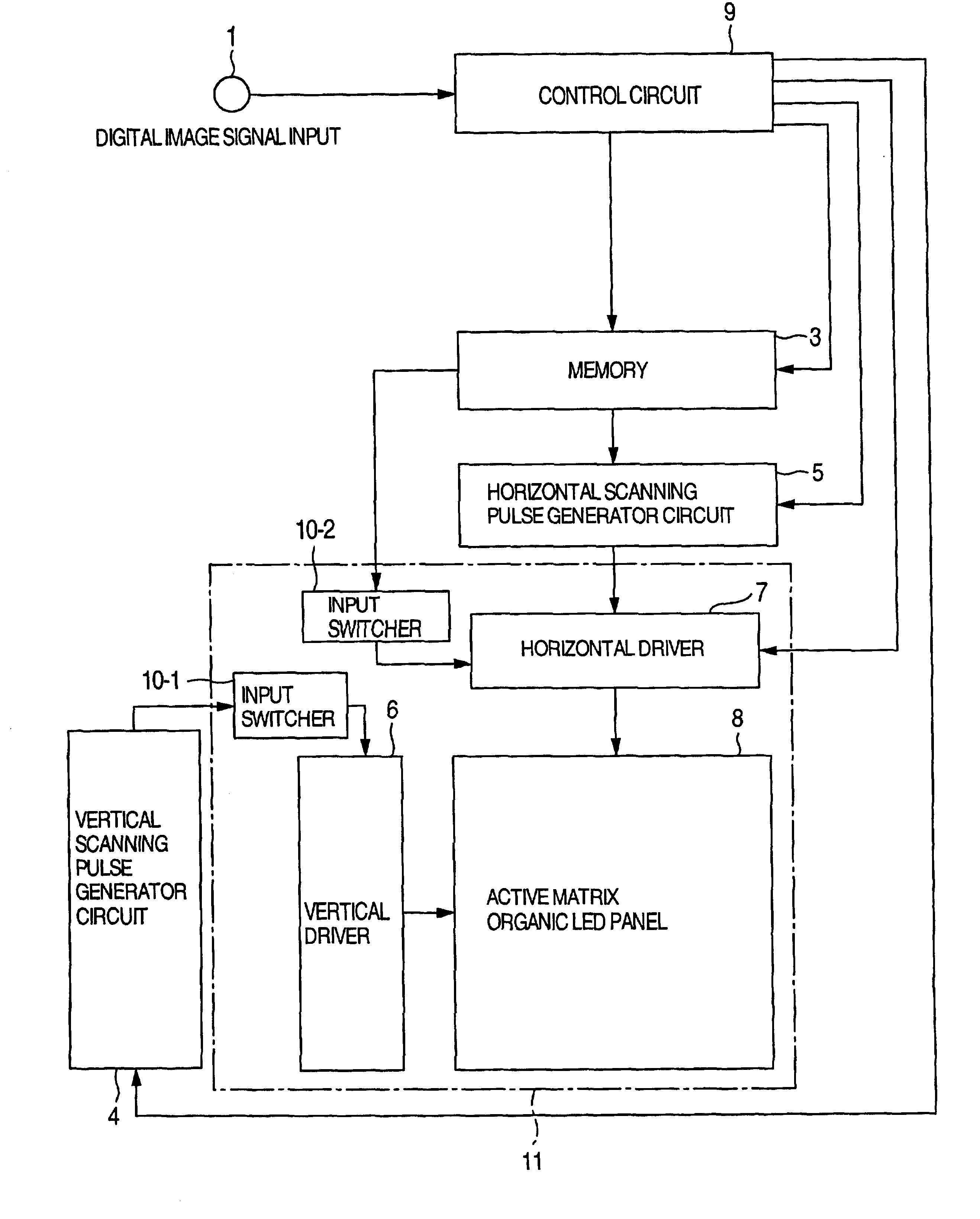

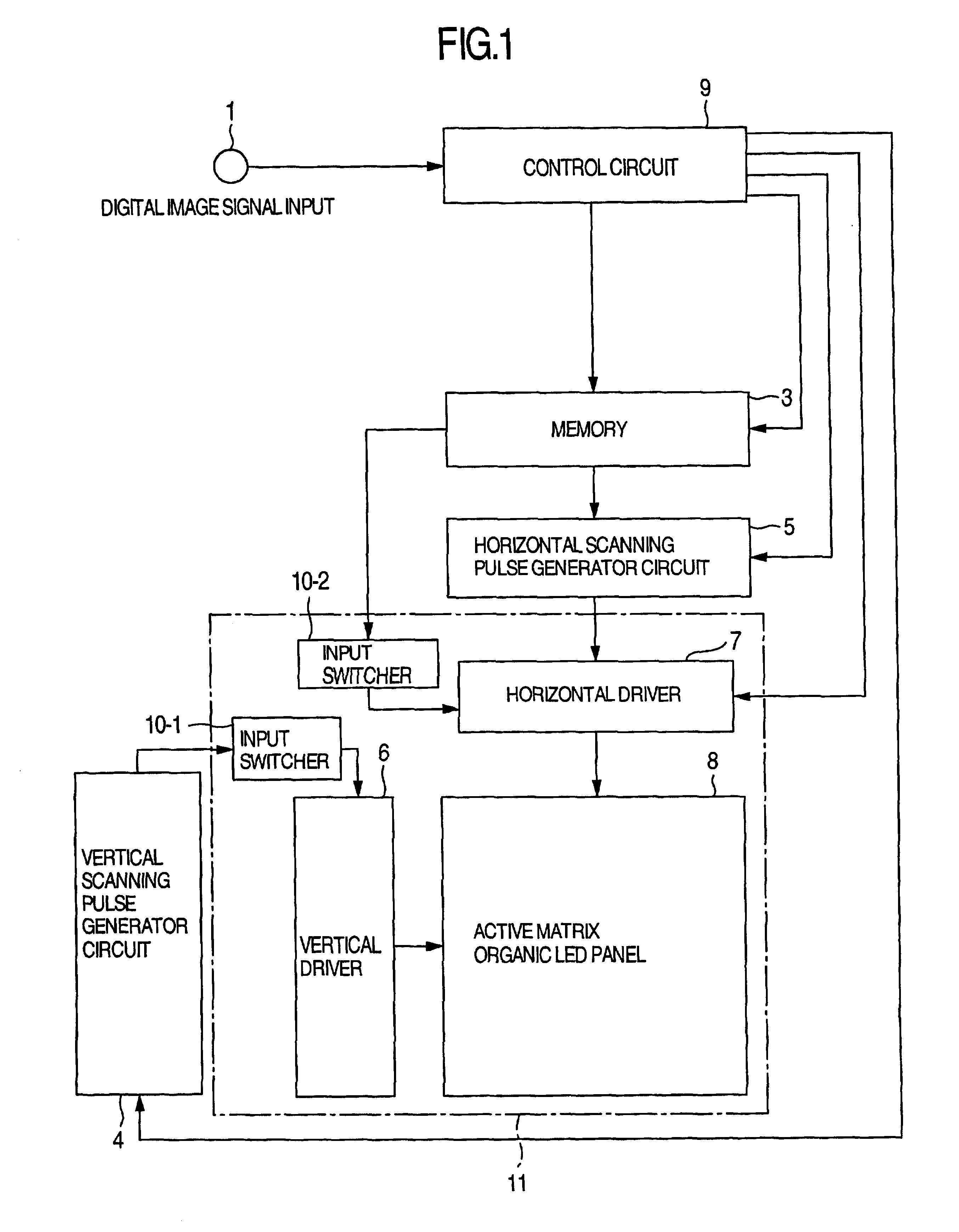

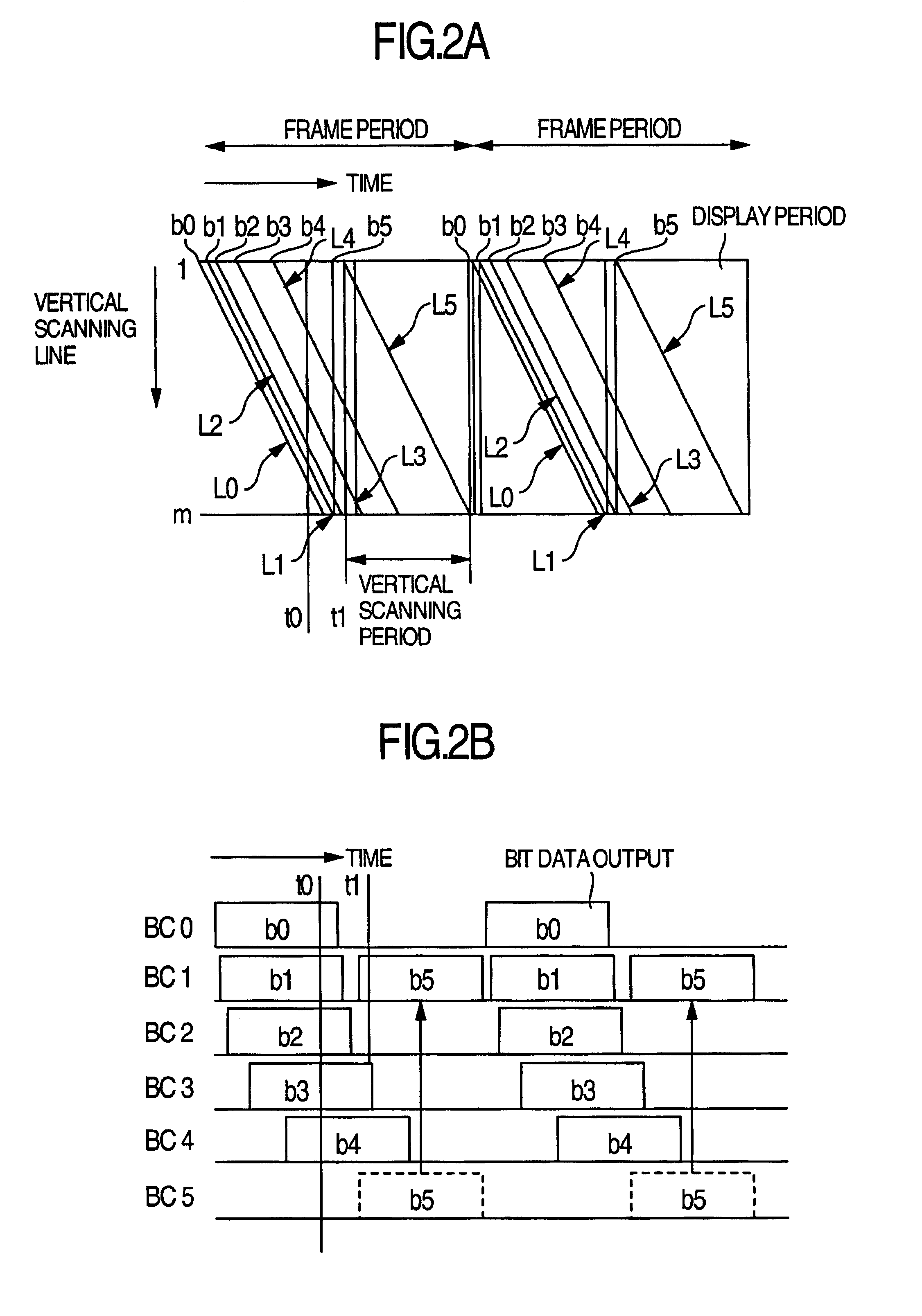

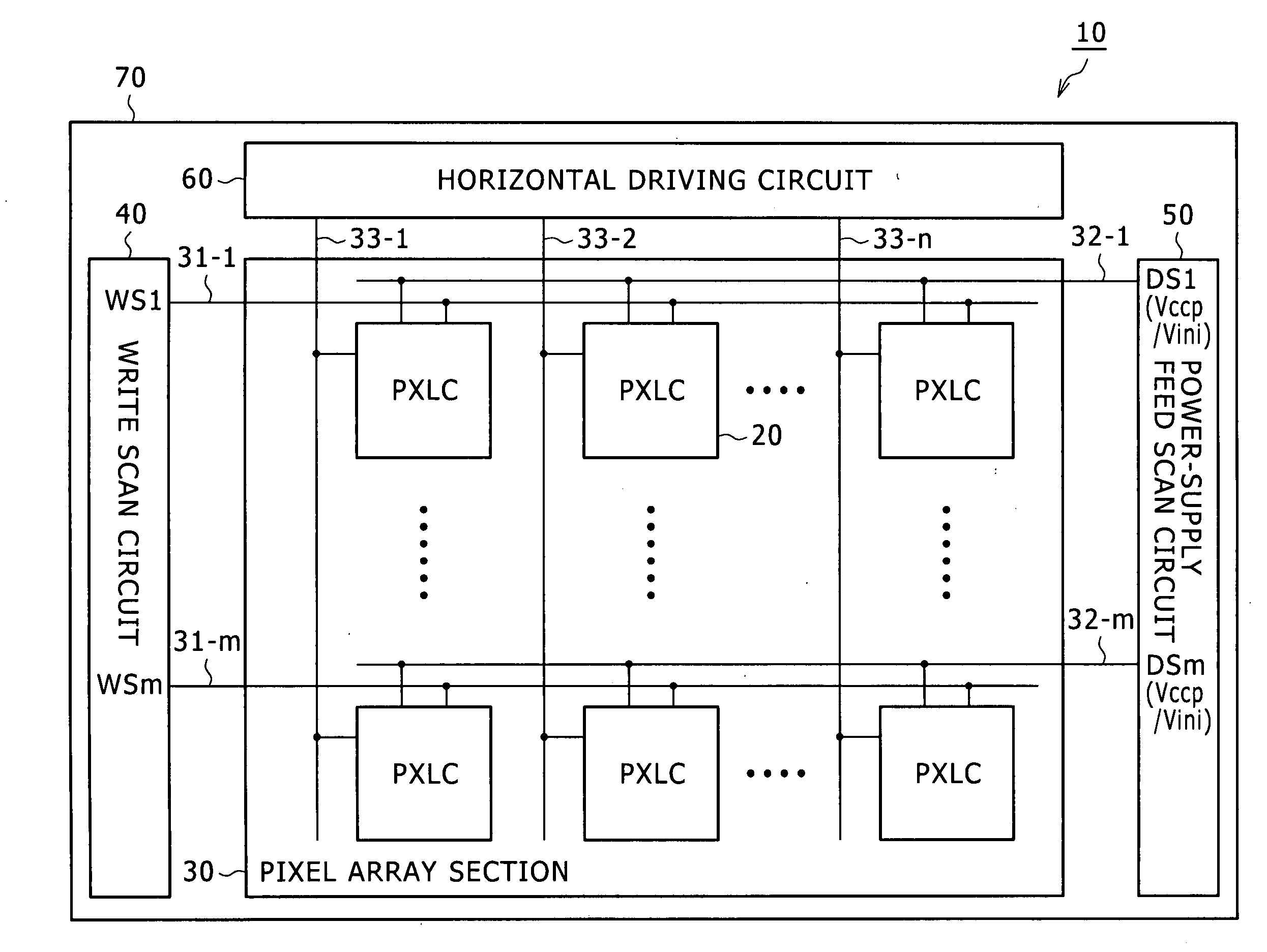

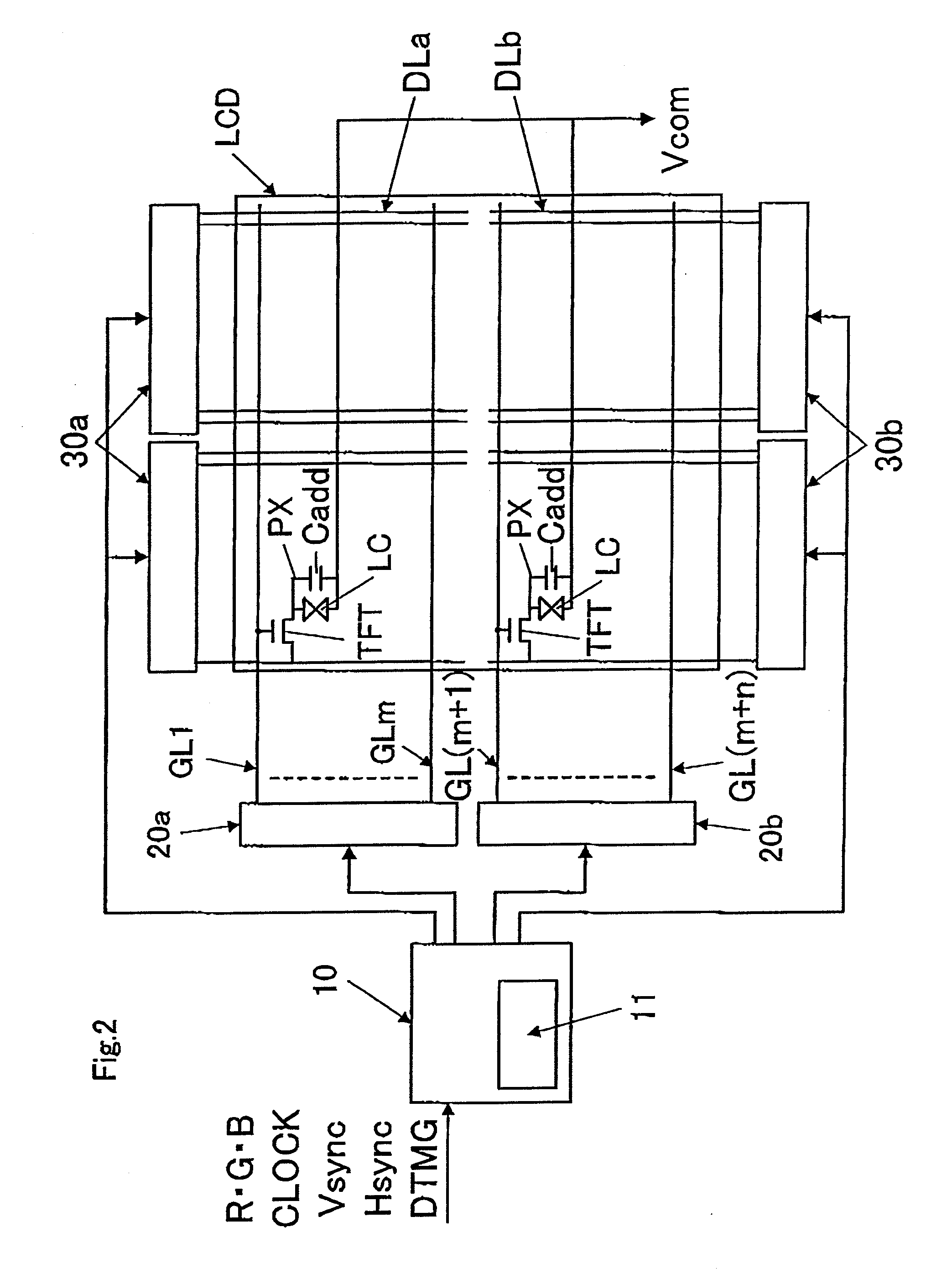

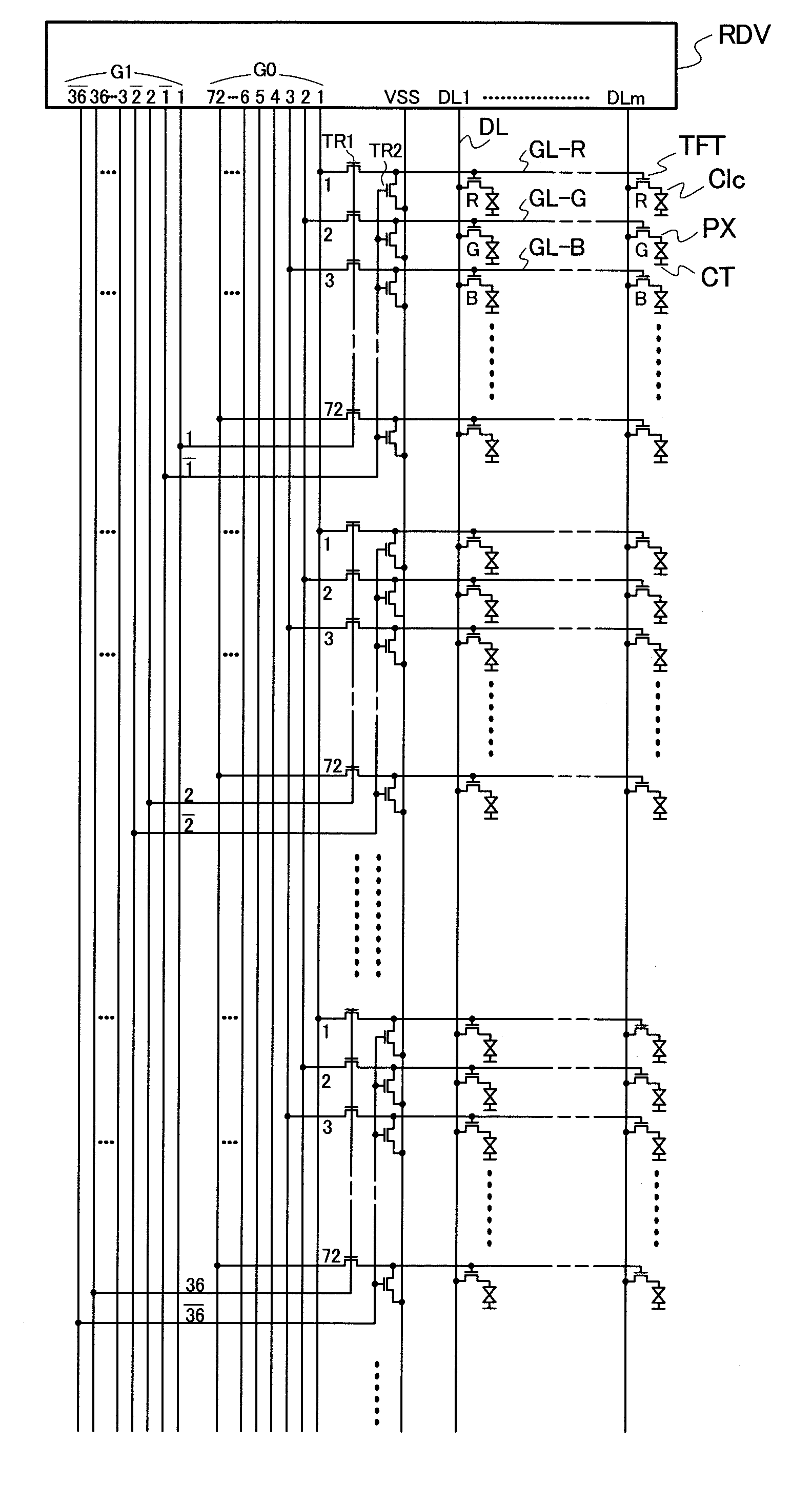

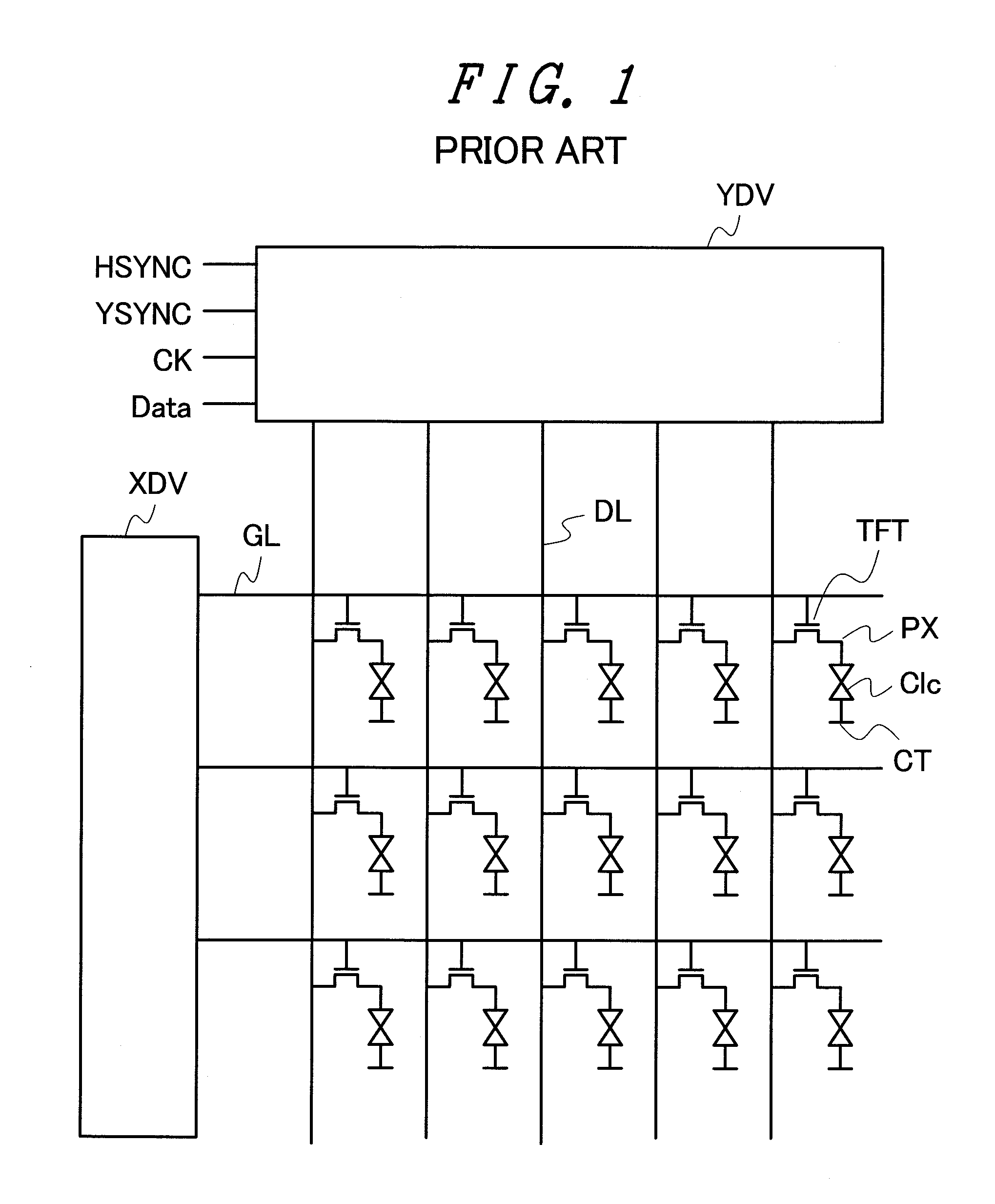

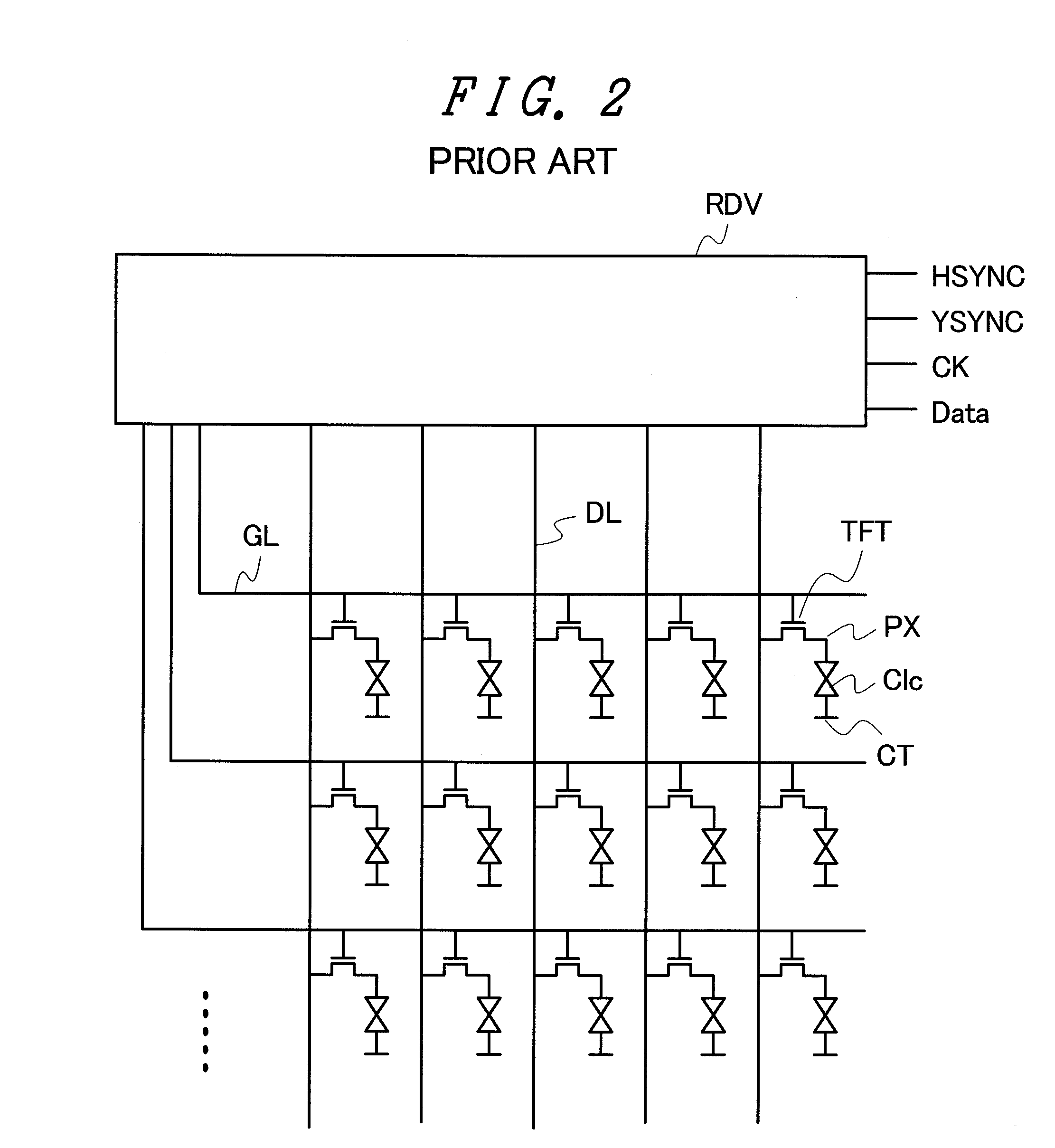

Image display apparatus

InactiveUS20020140712A1Suppress power consumptionElectroluminescent light sourcesSolid-state devicesDigital dataDisplay device

An image display apparatus includes a display having data holding function, a vertical drive circuit sequentially and selectively scanning matrix form display elements, and a horizontal drive circuit writing a voltage among binary voltage preliminarily assigned depending upon the digital data of the image signal. The horizontal drive circuit and the vertical drive circuit are operated for performing selective scan of respective display element for at least m times in one frame period. The vertical drive circuit is constituted of n number of sequence circuits and logic operation circuits for outputs of the sequence circuits, where n is smaller than m, a period from inputting to the sequence circuit to outputting from the final stage being less than or equal to half of one frame period, and at least one of the sequence circuits being used with selectively inputting a plurality of inputs.

Owner:SAMSUNG DISPLAY CO LTD +1

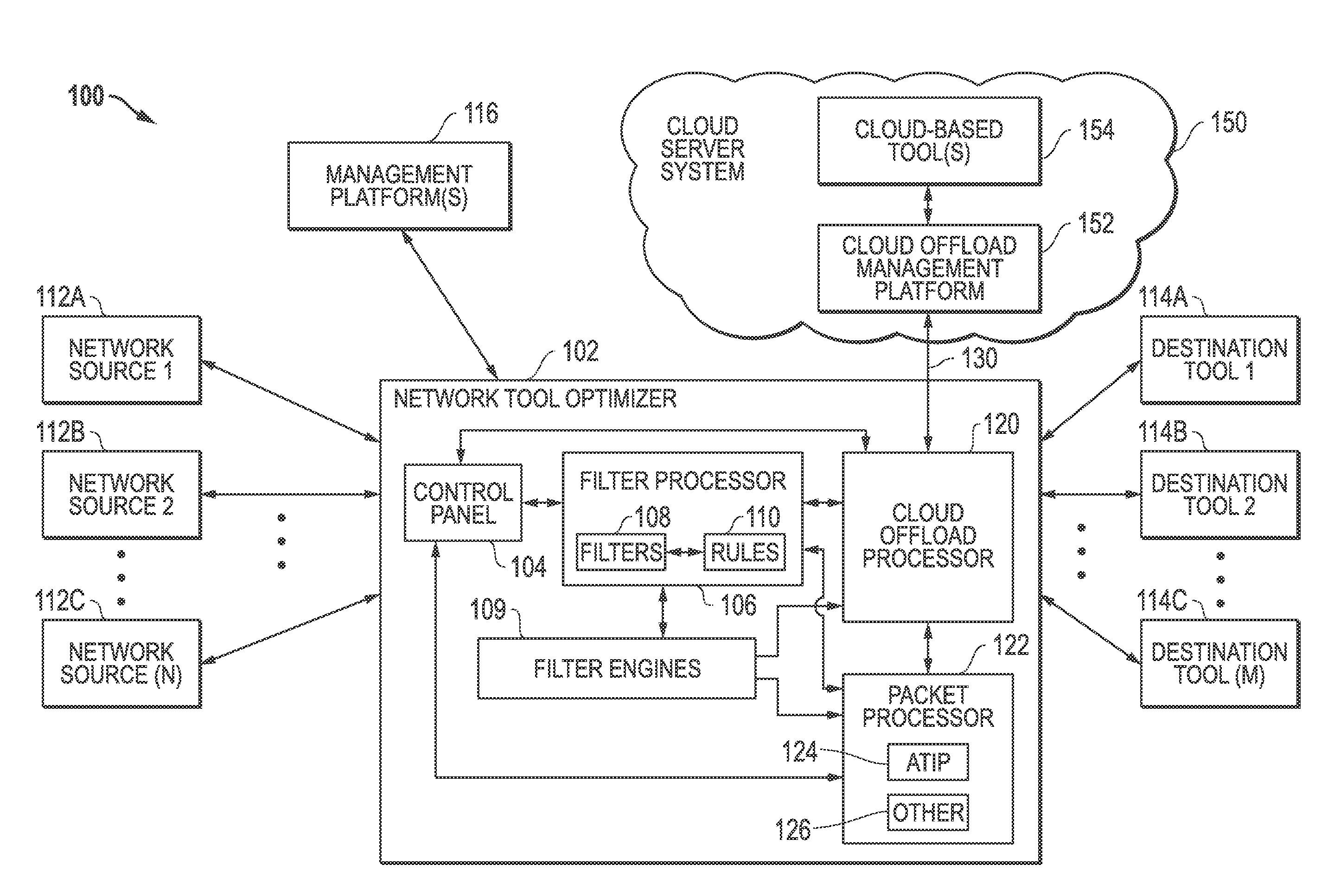

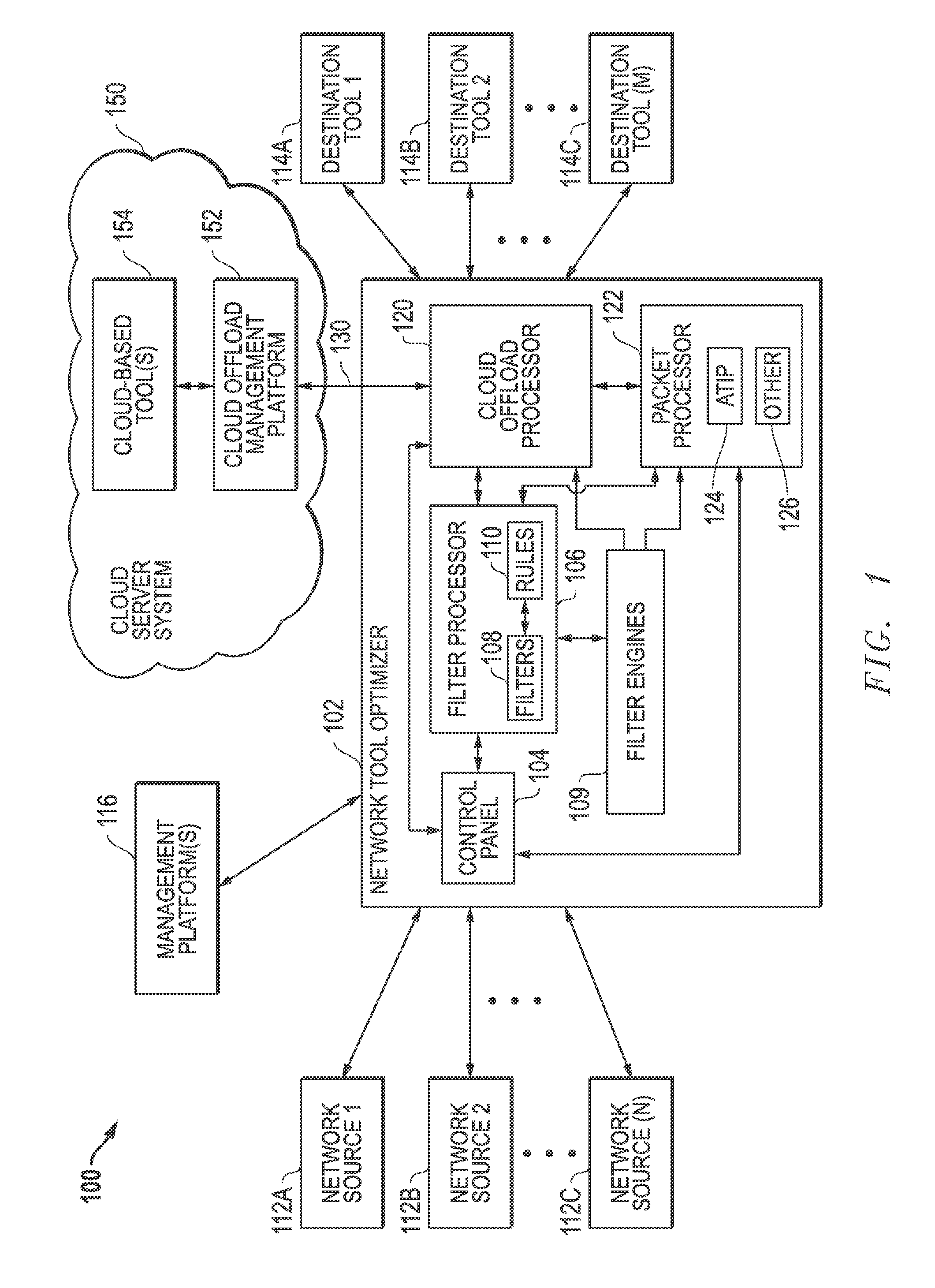

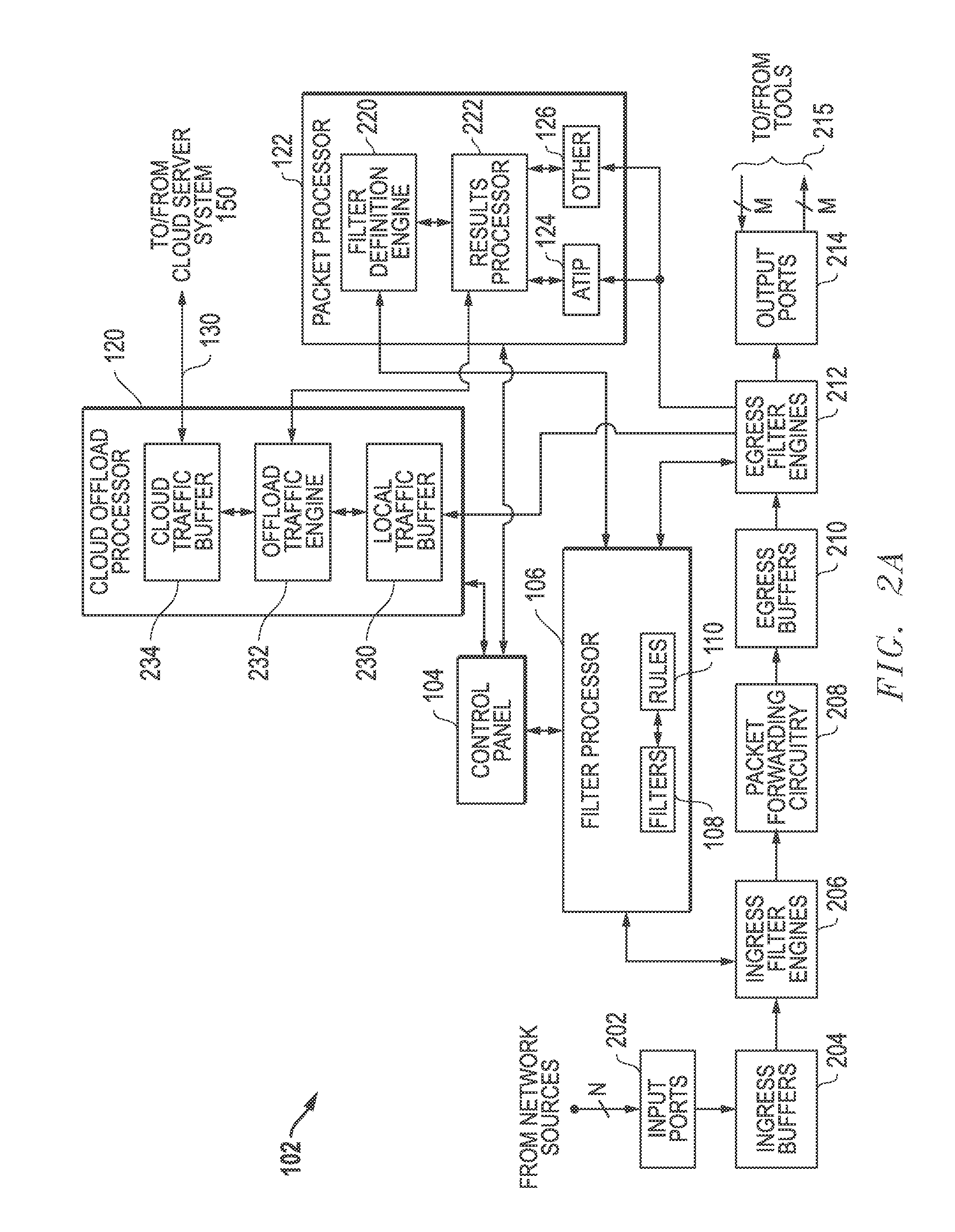

Selective Scanning of Network Packet Traffic Using Cloud-Based Virtual Machine Tool Platforms

Owner:KEYSIGHT TECH SINGAPORE (SALES) PTE LTD

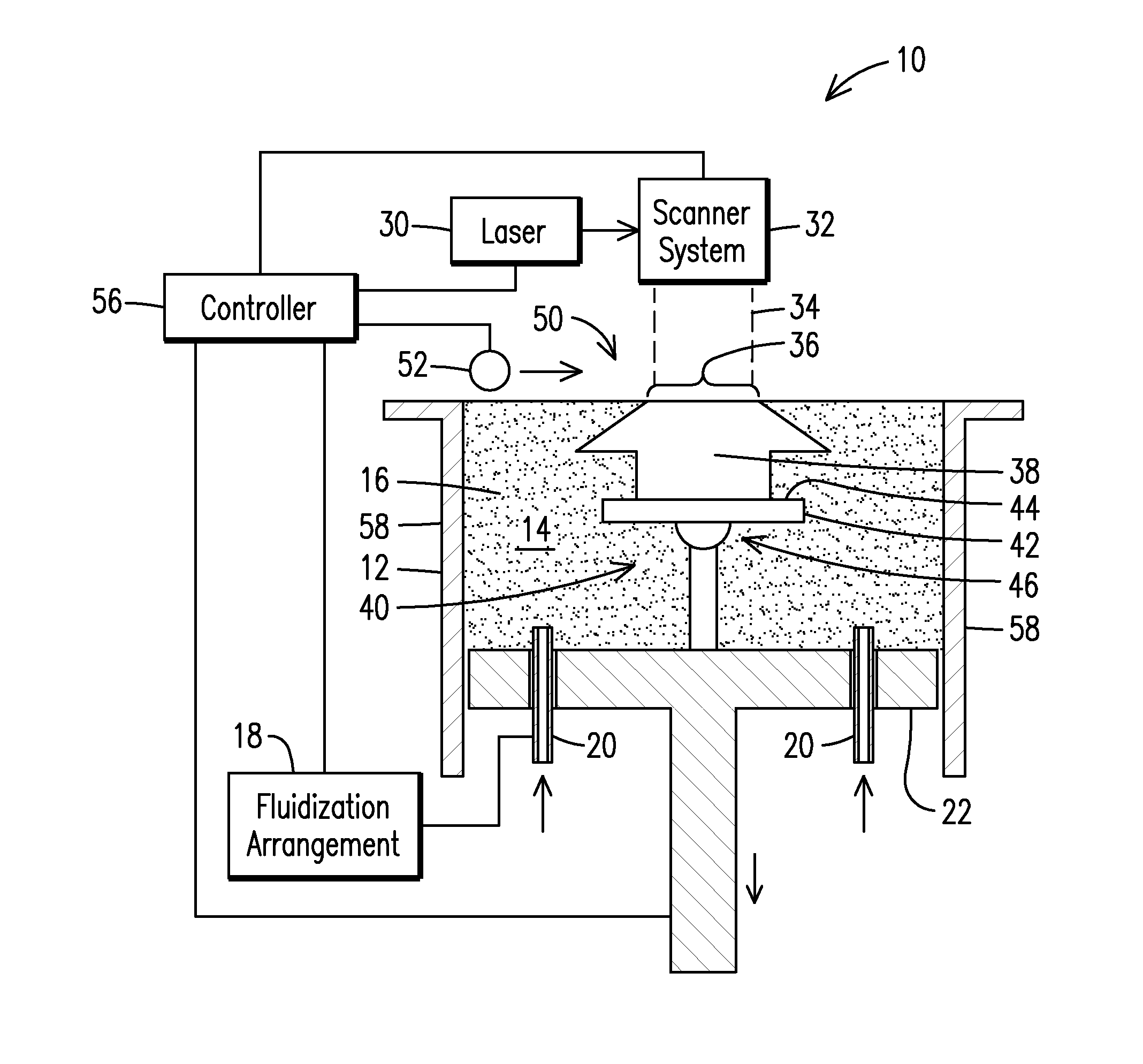

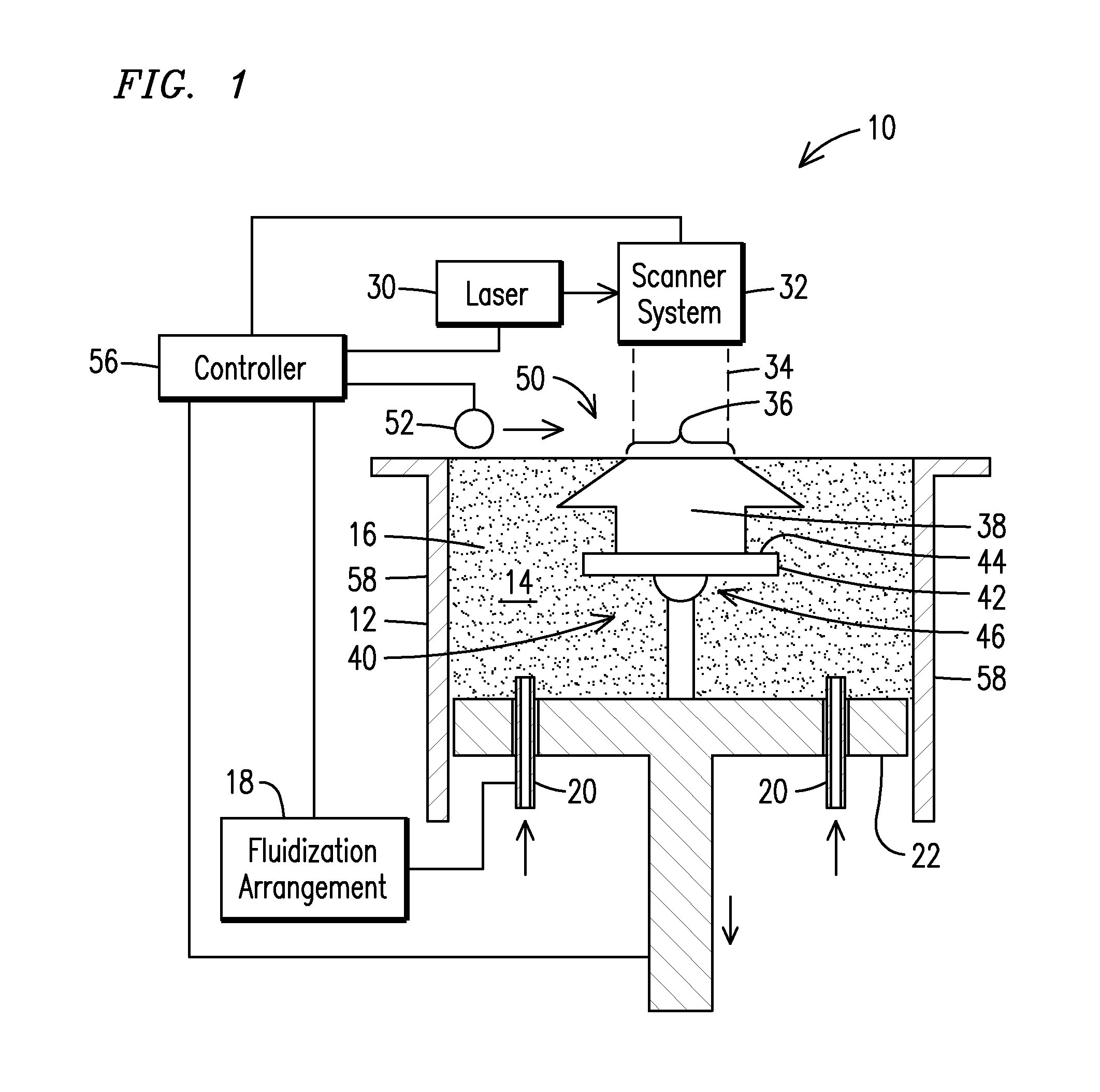

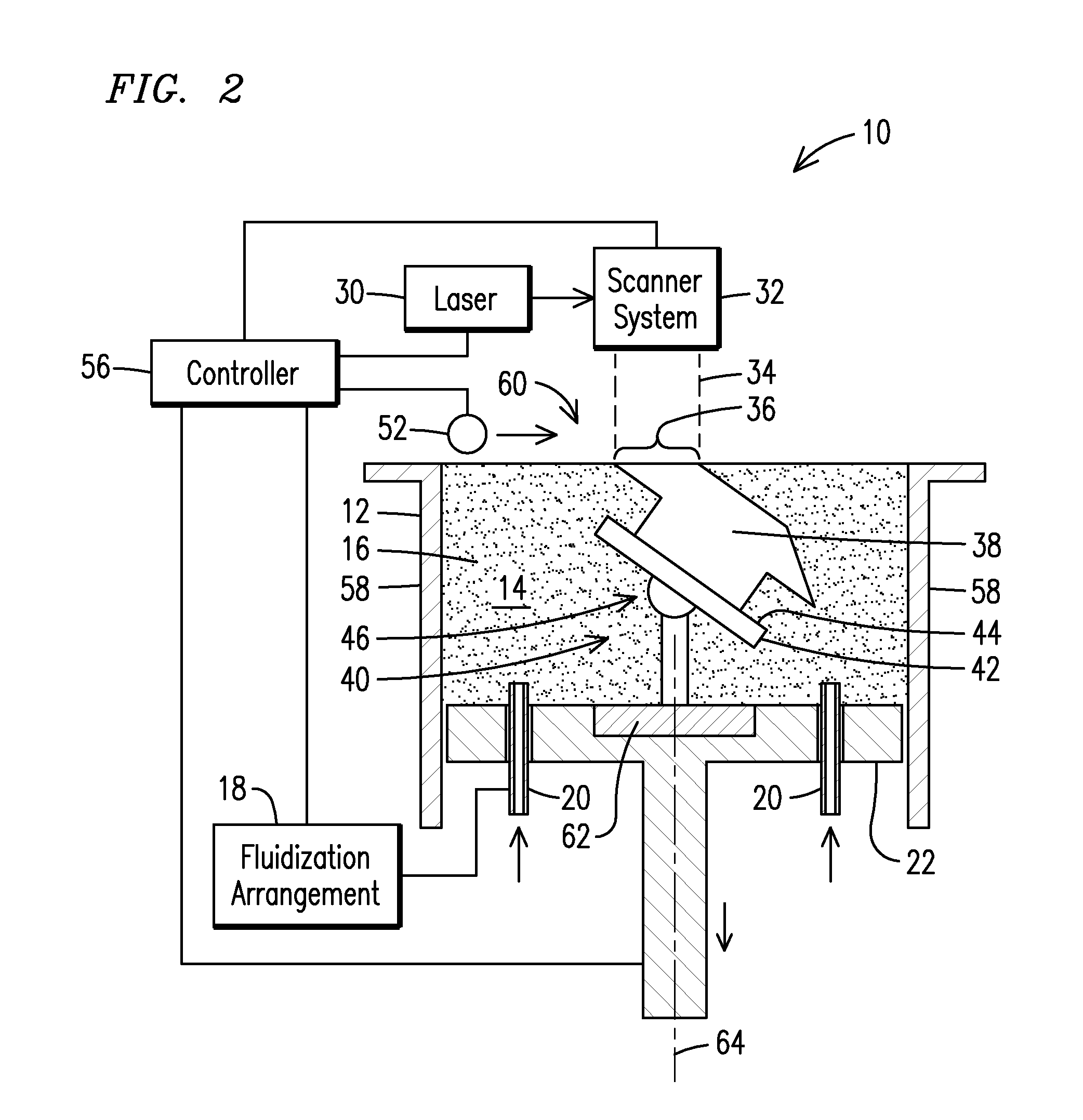

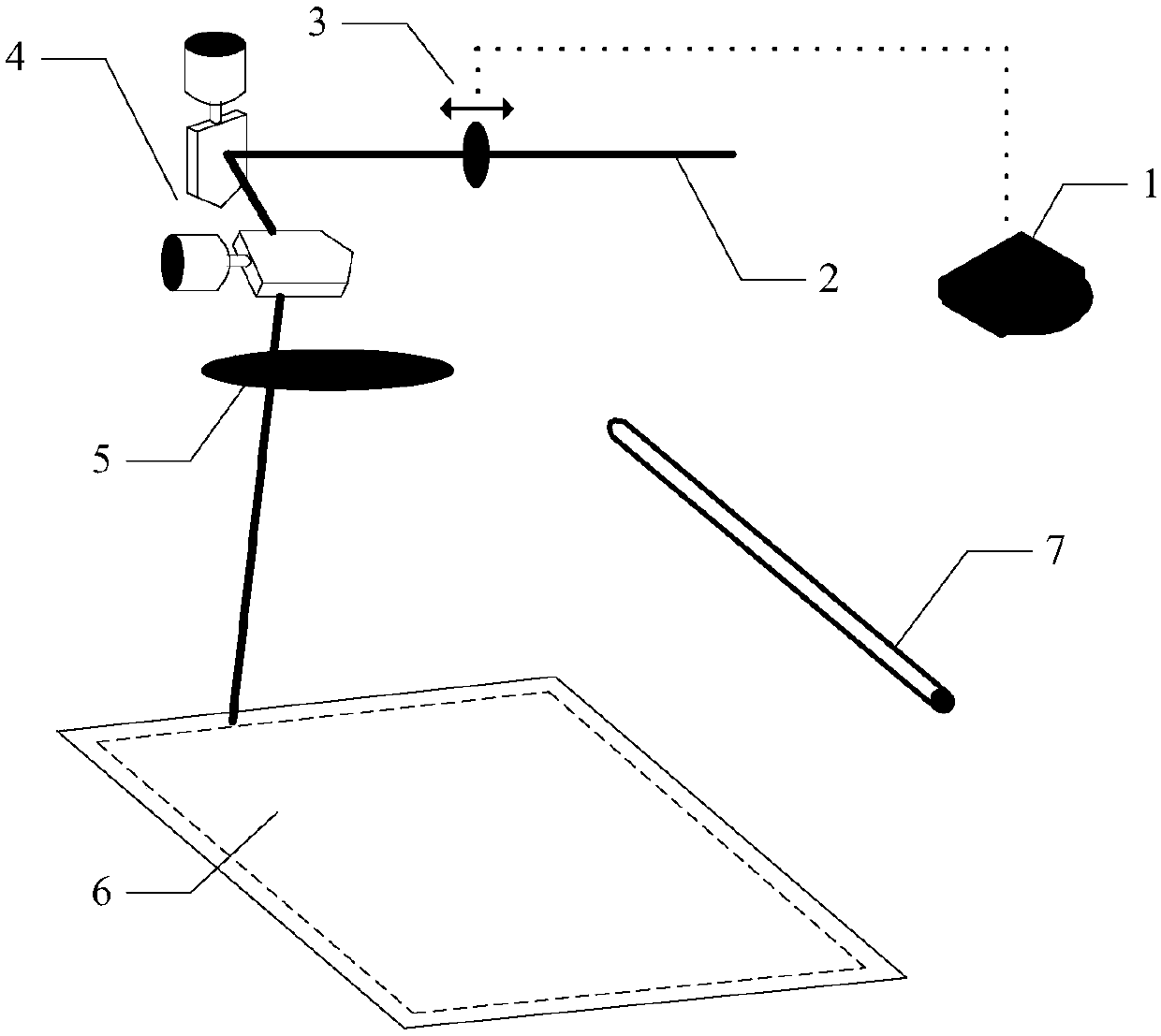

Articulating build platform for laser additive manufacturing

ActiveUS20160067923A1Additive manufacturing apparatusAuxillary shaping apparatusMarine engineeringMetallic materials

An additive manufacturing apparatus (10) including: a container (12) configured to bound a bed of powdered metal material; a fluidization arrangement (18) configured to fluidize the bed of powered material; an articulation mechanism (40) disposed within the container and configured to support and to rotate a component (38) about at least one horizontal axis; and an energy beam (34) configured to selectively scan portions (36) of a surface of the bed of powdered metal material to melt or sinter the selectively scanned portions onto the component.

Owner:SIEMENS ENERGY INC

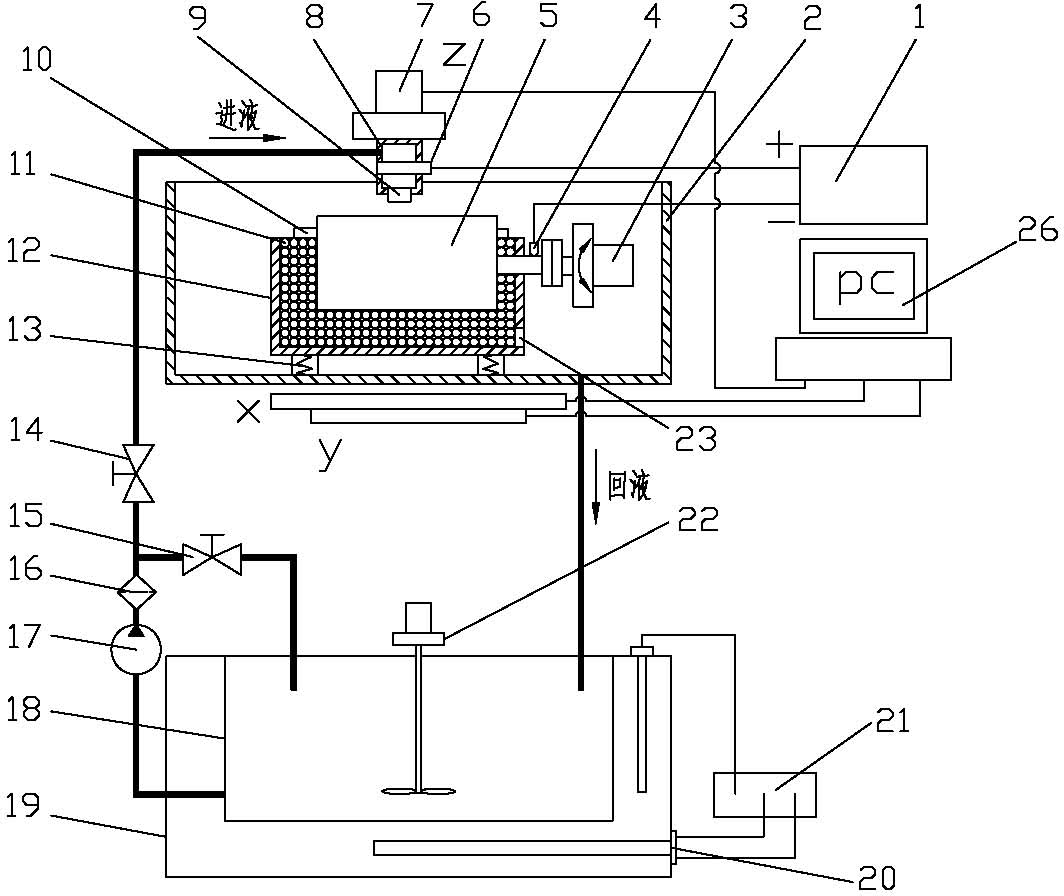

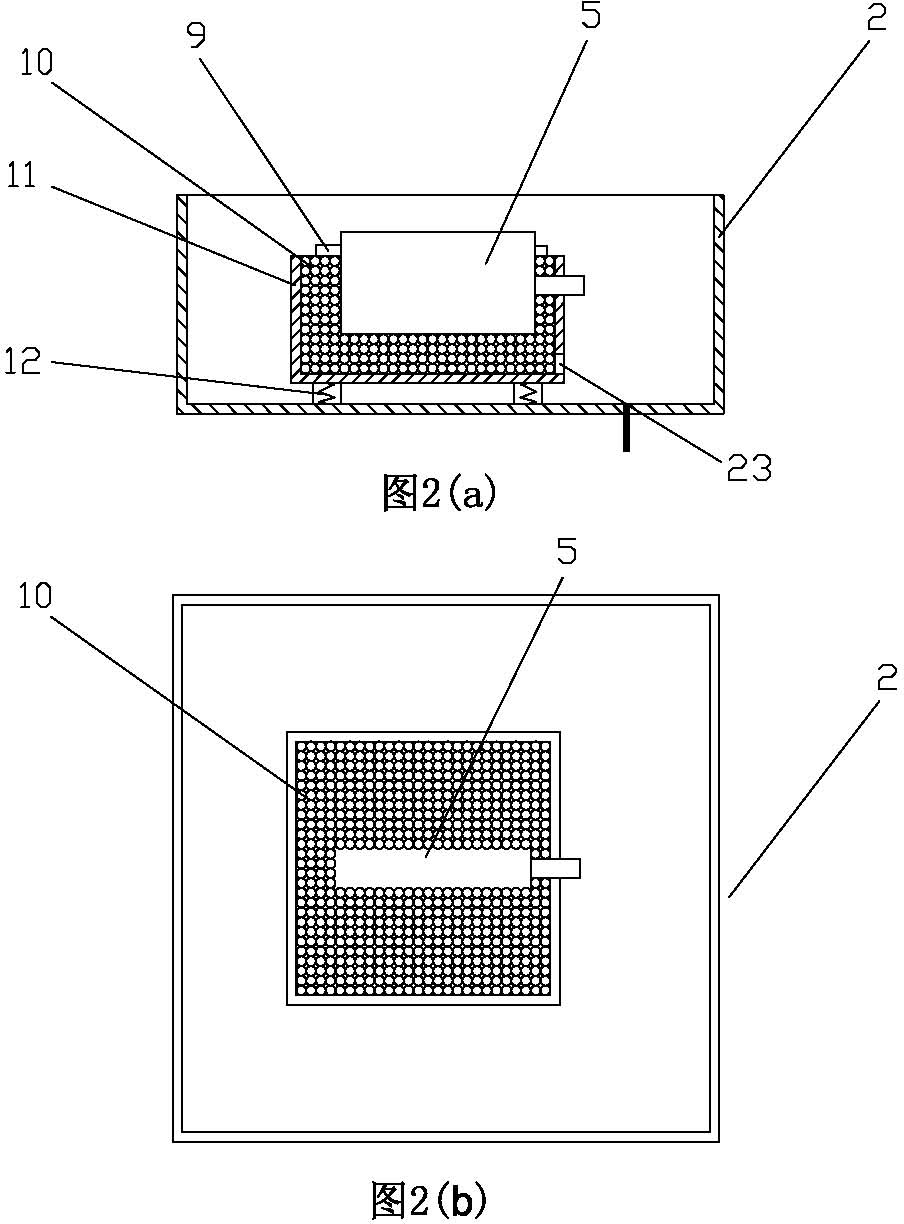

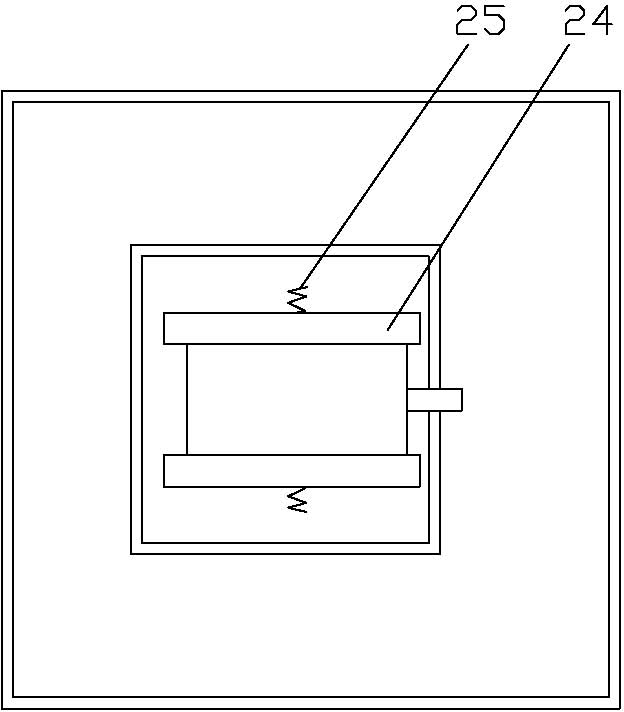

Method and device for processing revolving parts by high-speed jet injection electroforming

InactiveCN101994137AReduce thicknessOvercome timeElectroforming processesTemperature controlControl system

The invention provides a method and device for processing revolving parts by high-speed jet injection electroforming. The method is characterized in that an electroforming core mould is partially buried in an electroforming groove which is filled with hard particles or is in direct contact with a plated negative pole surface through a friction piece, so that the defects of accumulated tumors, burrs and the like on a deposition surface can be effectively removed by the friction of the hard particles or the friction piece on an electroforming layer; and a computer is used for controlling a jet nozzle to scan along with a certain track and cooperates with the rotary motion of the electroforming core mould at the same time, so that the exposed electroforming core mould surface is subjected to selective scanning electroforming so as to pile up the required parts layer by layer. The device of the invention mainly comprises a table movement mechanism, a negative pole rotation drive device, a control system, a temperature control device, an electroforming liquid circulating filter system and the like. The method and device for processing the revolving parts by high-speed jet injection electroforming of the invention are adopted, thus not only effectively removing the defects of hard spots, air holes, accumulated tumors and the like on the electroforming layer surface and manufacturing the electroforming layer with compact and even texture at higher deposition speed, but also abandoning the complicated negative pole female die of the traditional electroforming and rapidly and efficiently forming the revolving parts with different shapes and wall thicknesses by one step.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

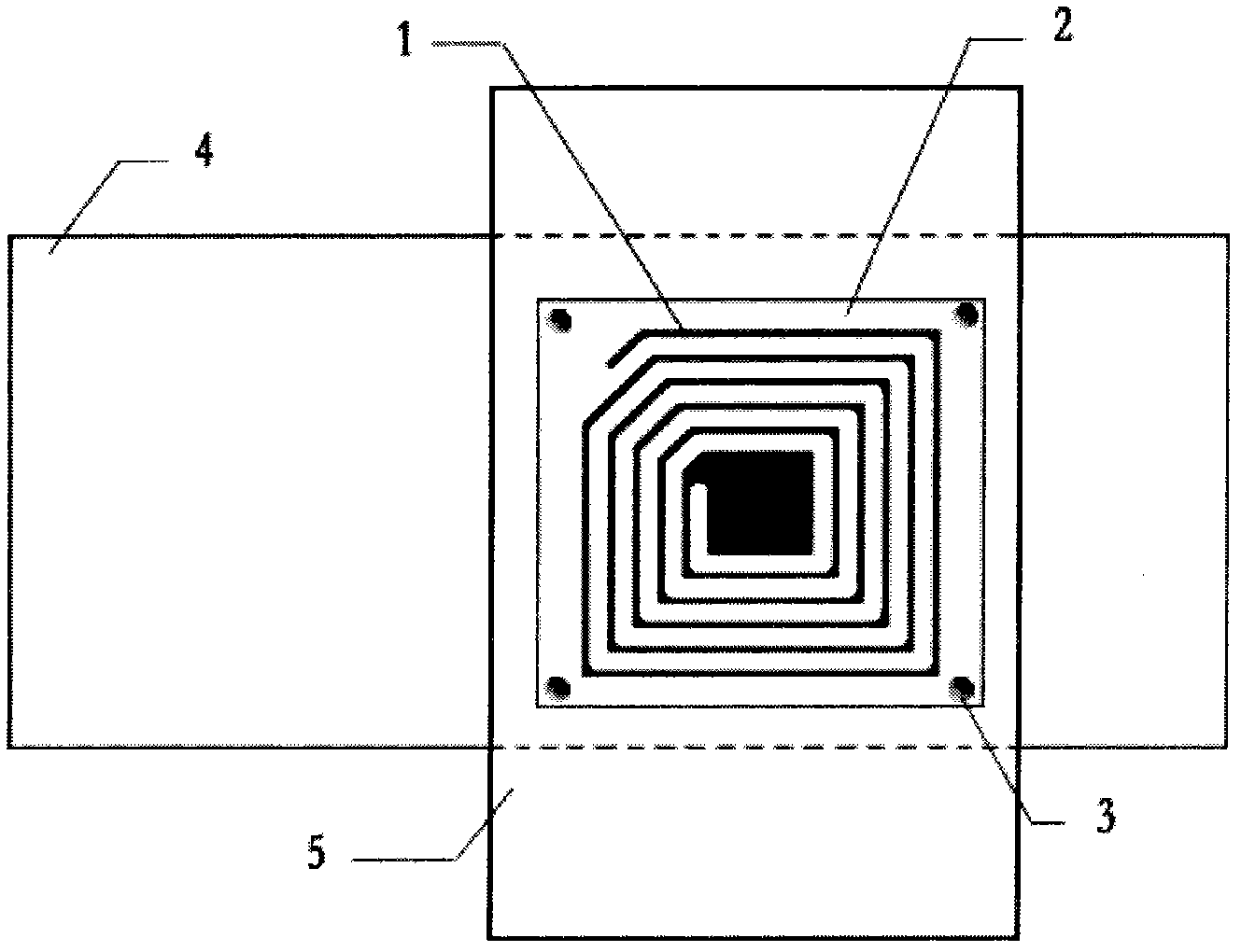

Structure and manufacturing method for selectively forming metal on plastic substrate

InactiveCN103088321AElectroless plating process shortenedGood value for moneySynthetic resin layered productsLiquid/solution decomposition chemical coatingChemical platingManufacturing technology

The present invention relates to a structure and a method for selectively forming a compact and precise metal pattern on a plastic substrate surface. The structure comprises three layers of materials such as a plastic substrate, nickel or zinc or an indium tin oxide material, and a metal subsequently deposited on the material, wherein the nickel or the zinc or the indium tin oxide material is formed through adopting laser to irradiate the plastic substrate, decomposing an additive previously added to the plastic, and adopting reductive chemical plating to treat. The manufacturing method comprises: adopting laser to selectively scan the plastic substrate. According to the present invention, the additive does not adopt a copper-containing oxide, a copper chelate, a copper complex and a metal oxide having a spinel structure, and adopts the environmentally friendly non-toxic inorganic salt containing nickel and zinc, and the indium tin oxide material, the coupling agent is adopted to carry out coating modification to prepare the additive having a core-shell structure, and the additive is added to the plastic to prepare the laser composite plastic; the laser is adopted to decompose the shell part of the additive so as to release active ingredients in the core; the present invention belongs to a new material based advanced assembly and manufacturing technology in the field of electronic and electric apparatuses; and the structure and the method are used for manufacturing mobile phone antennas, transparent lamp parts, automobile parts, three-dimensional circuits and other products.

Owner:深圳市微航磁电技术有限公司

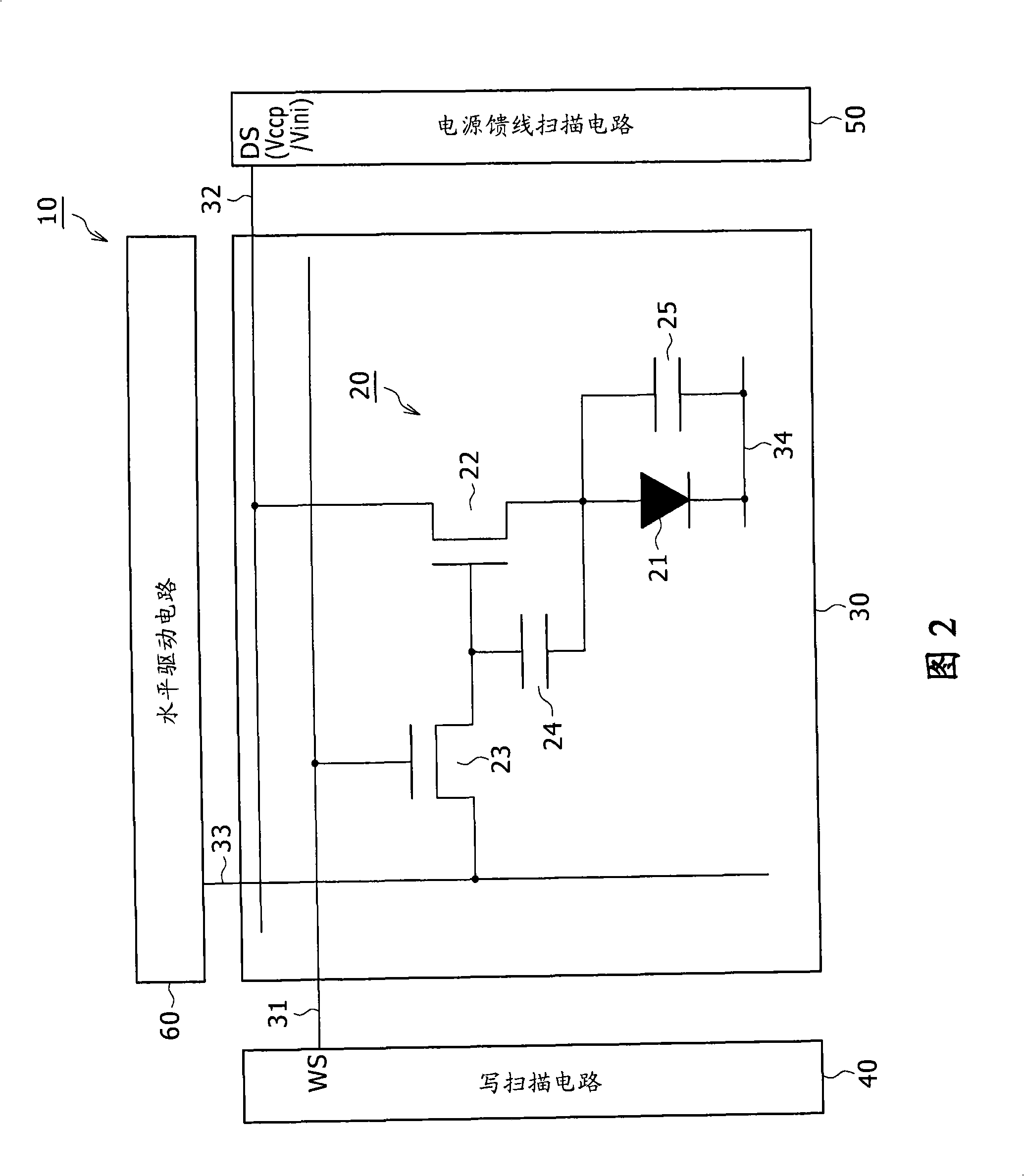

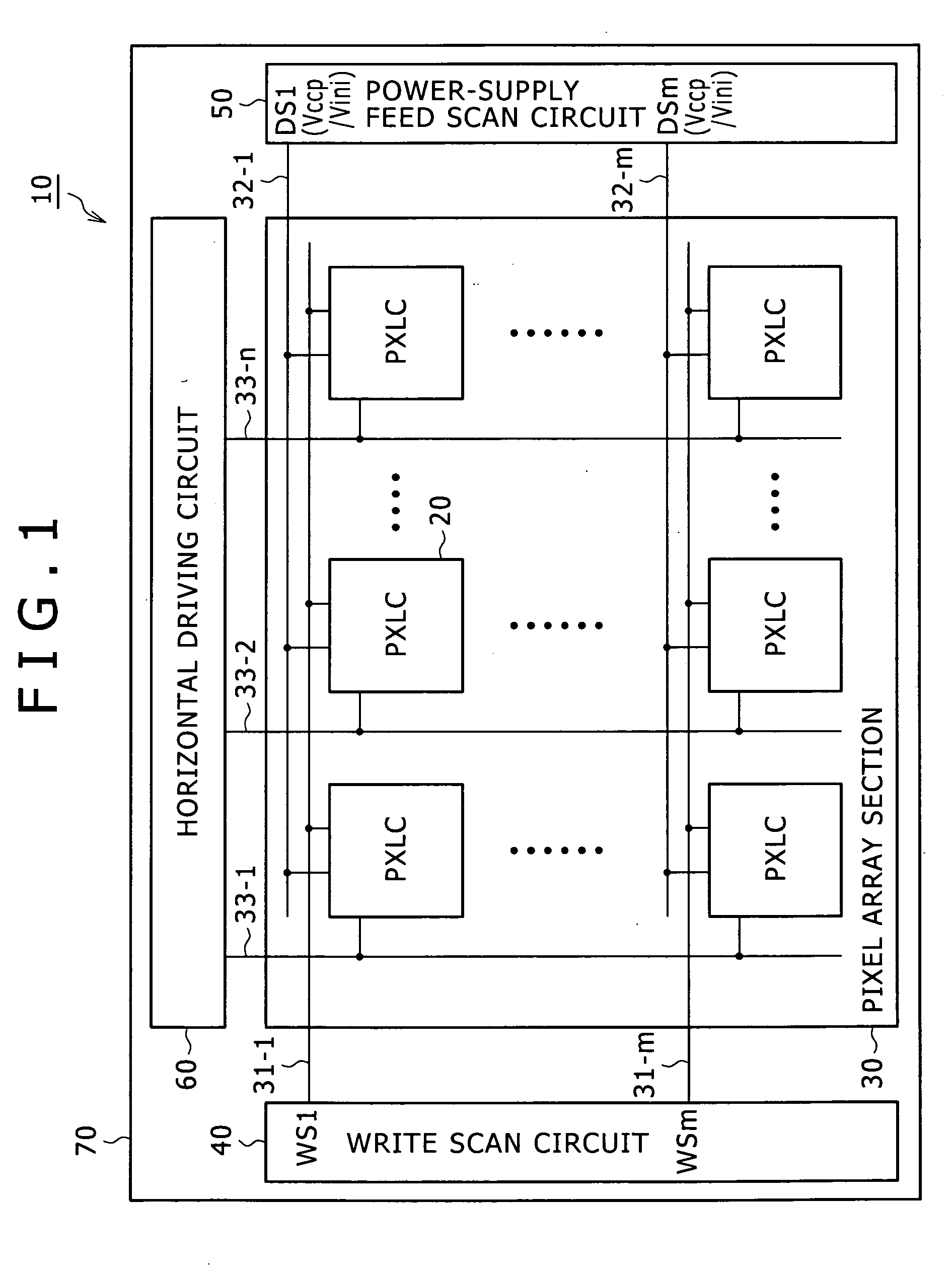

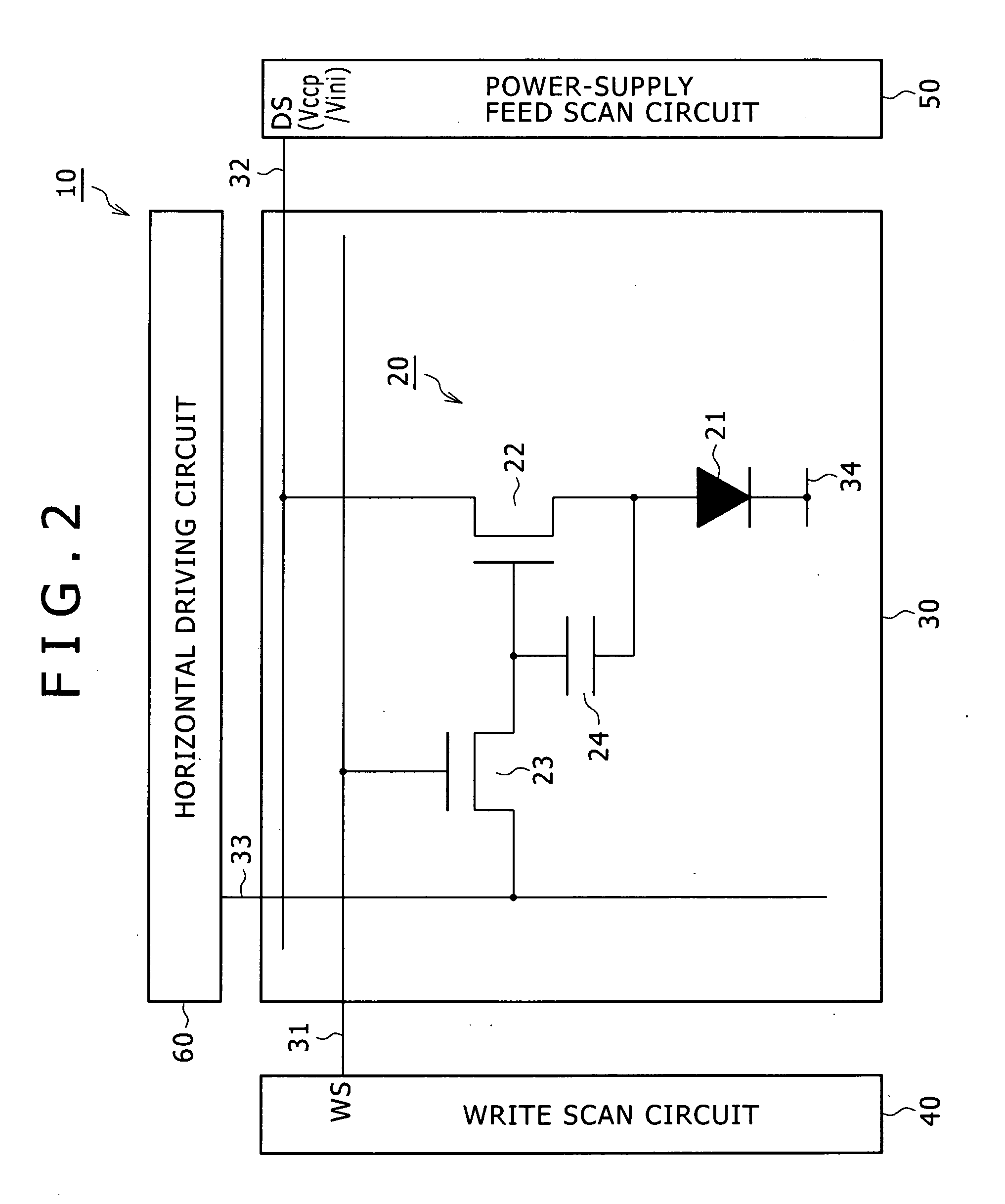

Display apparatus, display-apparatus driving method and electronic equipment

InactiveUS20080224964A1Improve reliabilityHigh can be obtainedElectrical apparatusStatic indicating devicesEngineeringCapacitor

In the present invention, there is provided a display apparatus including: a pixel array section including pixel circuits each having an electro-optical device, a write transistor configured to carry out a voltage storing process, a holding capacitor configured to hold the sampled video signal, and a driving transistor configured to drive the electro-optical device; first scan means for carrying out a selective scan operation in row units and driving each of the write transistors; second scan means for selectively supplying either a first or second electric potential synchronously with the selective scan operation for feeding a current to each of the driving transistors; and control means for sustaining a power-supply feed line in a floating state during a period ending at a time not earlier than the start of the voltage storing process after a voltage corresponding to the threshold voltage of the driving transistor has been held in the holding capacitor.

Owner:JOLED INC

Display apparatus, display apparatus driving method and electronic equipment

InactiveCN101266754APrevent flowQuality improvementStatic indicating devicesElectroluminescent light sourcesEngineeringOpto electronic

In the present invention, there is provided a display apparatus including: a pixel array section including pixel circuits each having an electro-optical device, a write transistor configured to carry out a voltage storing process, a holding capacitor configured to hold the sampled video signal, and a driving transistor configured to drive the electro-optical device; first scan means for carrying out a selective scan operation in row units and driving each of the write transistors; second scan means for selectively supplying either a first or second electric potential synchronously with the selective scan operation for feeding a current to each of the driving transistors; and control means for sustaining a power-supply feed line in a floating state during a period ending at a time not earlier than the start of the voltage storing process after a voltage corresponding to the threshold voltage of the driving transistor has been held in the holding capacitor.

Owner:JOLED INC

Image display apparatus

InactiveUS6885385B2Reduce circuit sizeIncrease the number ofElectroluminescent light sourcesSolid-state devicesDigital dataDisplay device

Owner:SAMSUNG DISPLAY CO LTD +1

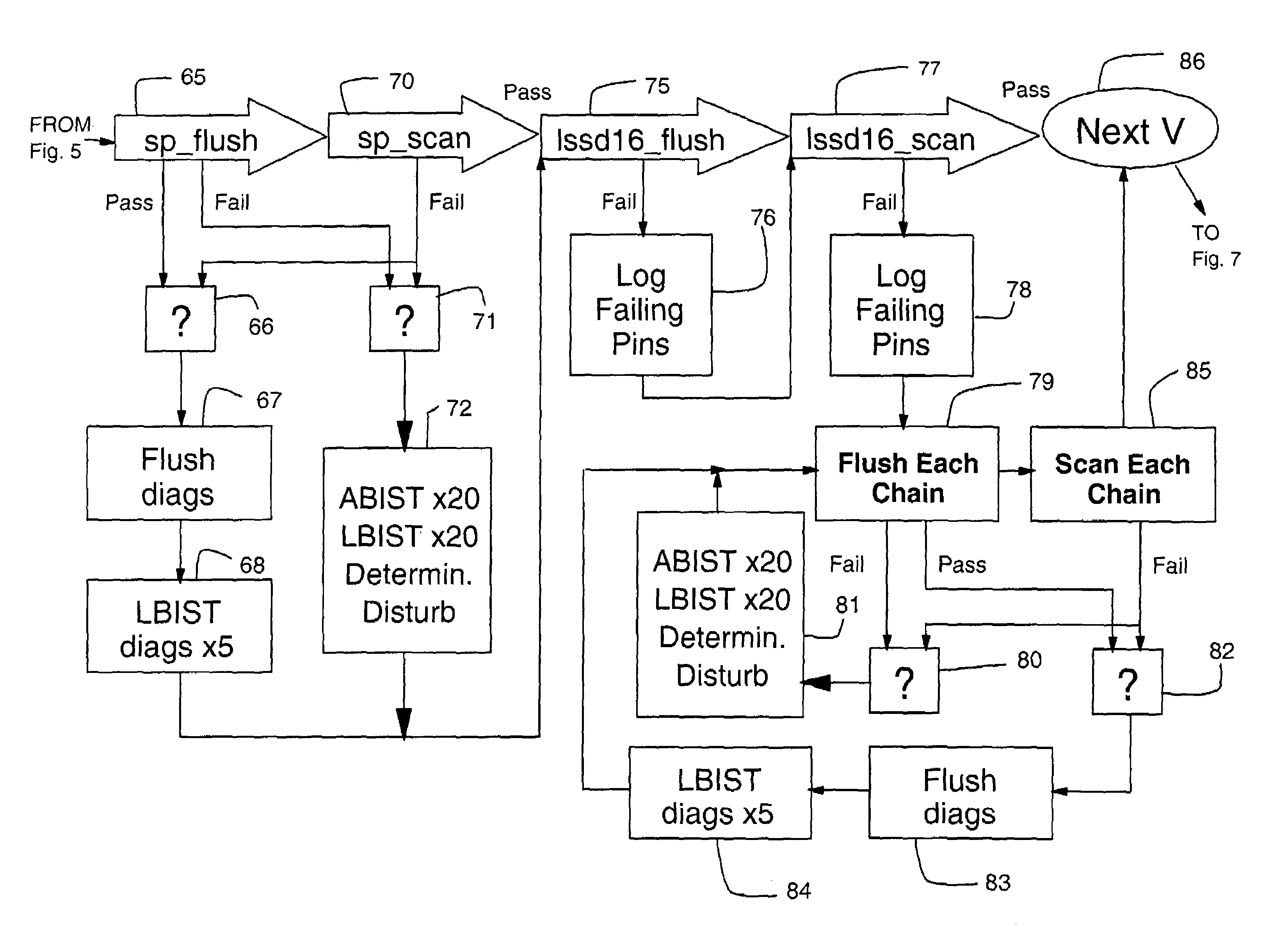

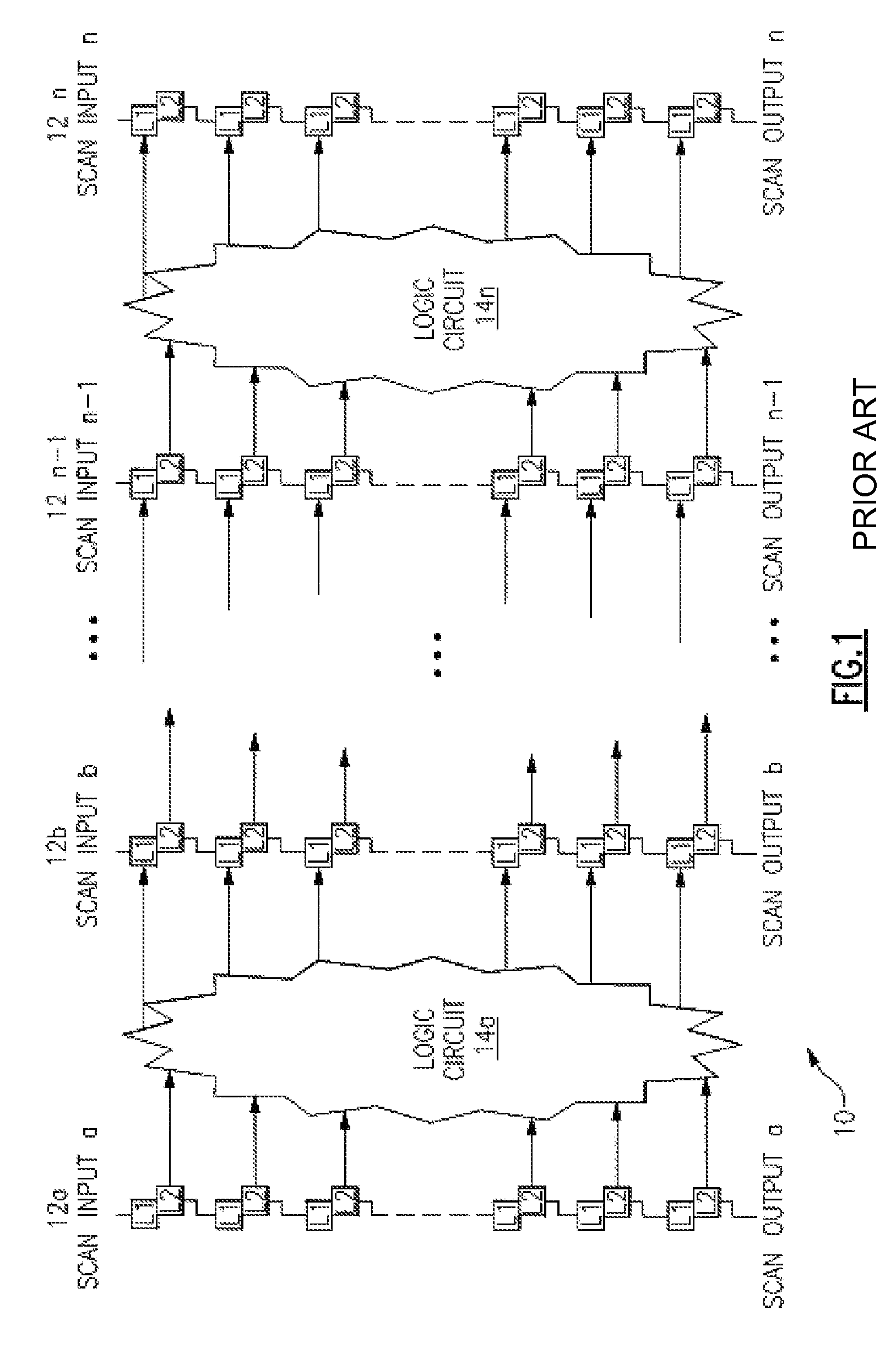

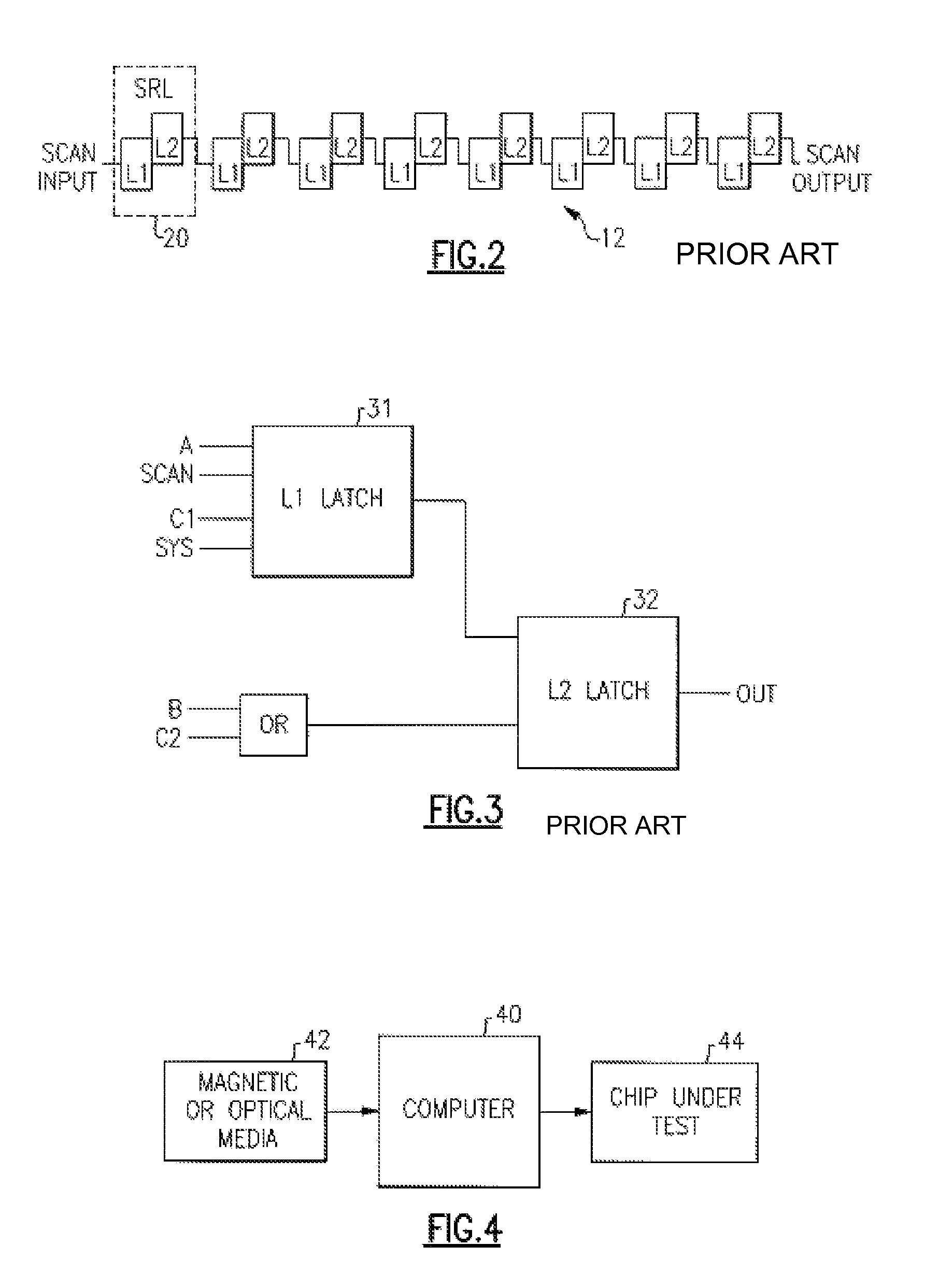

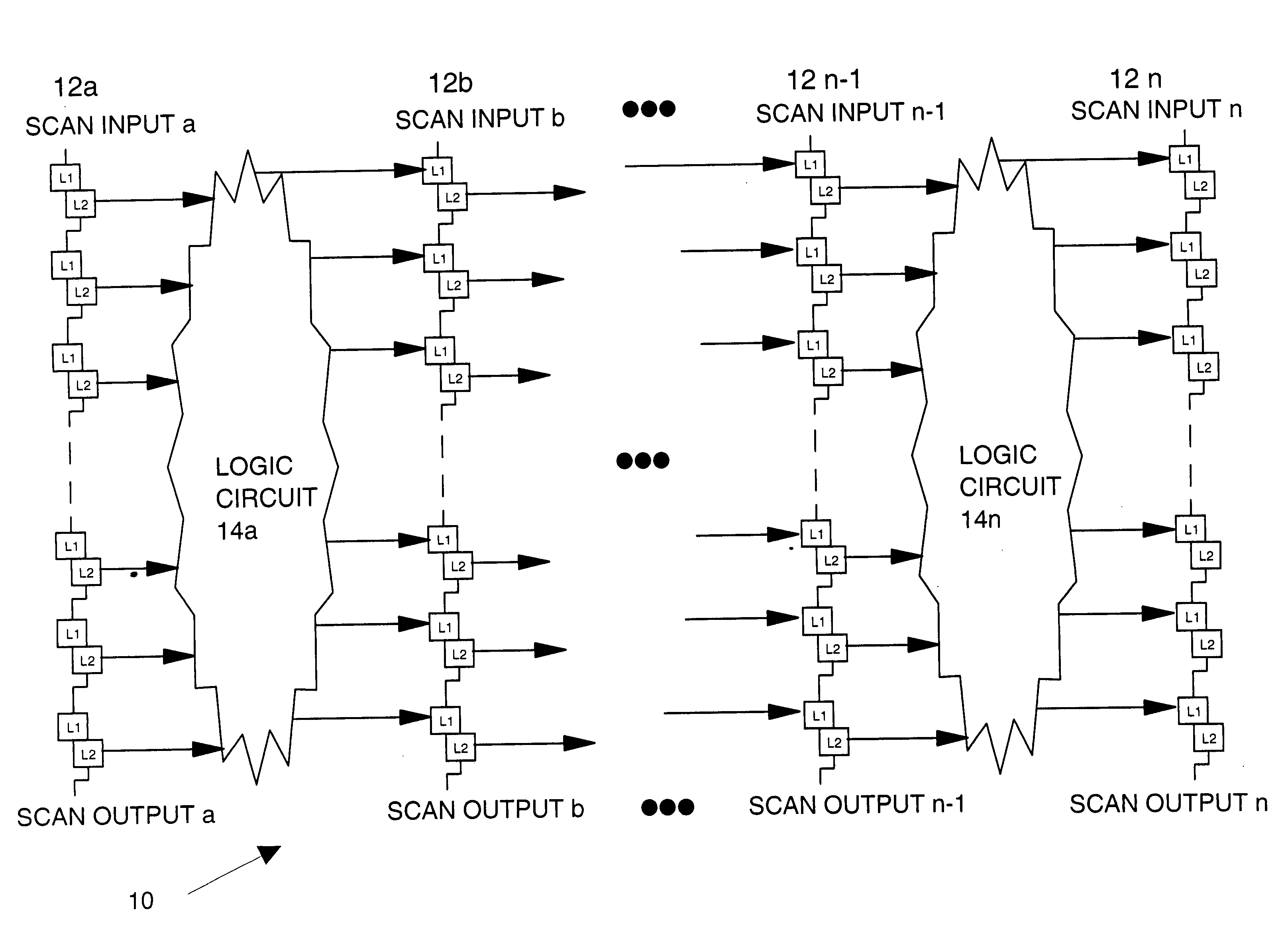

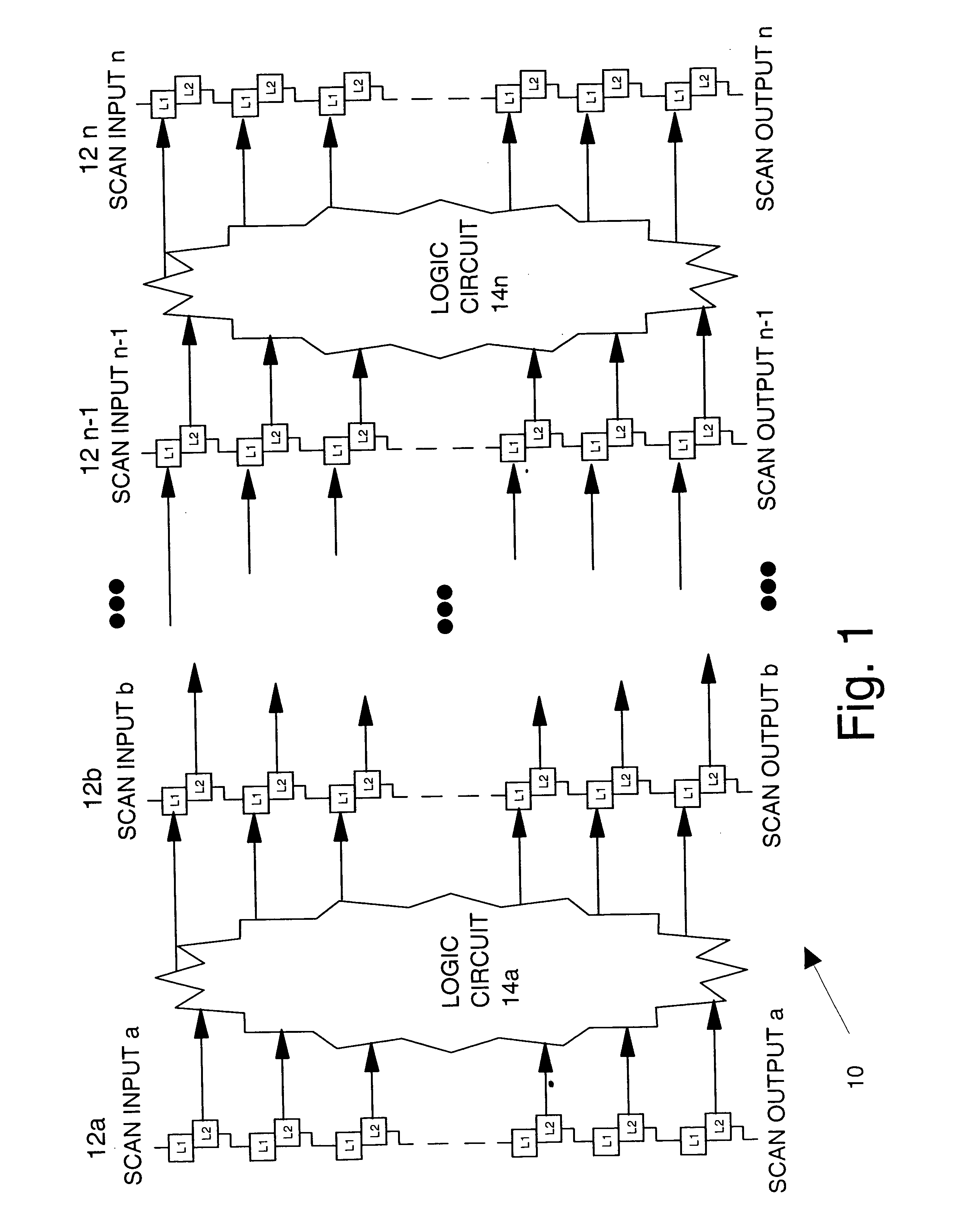

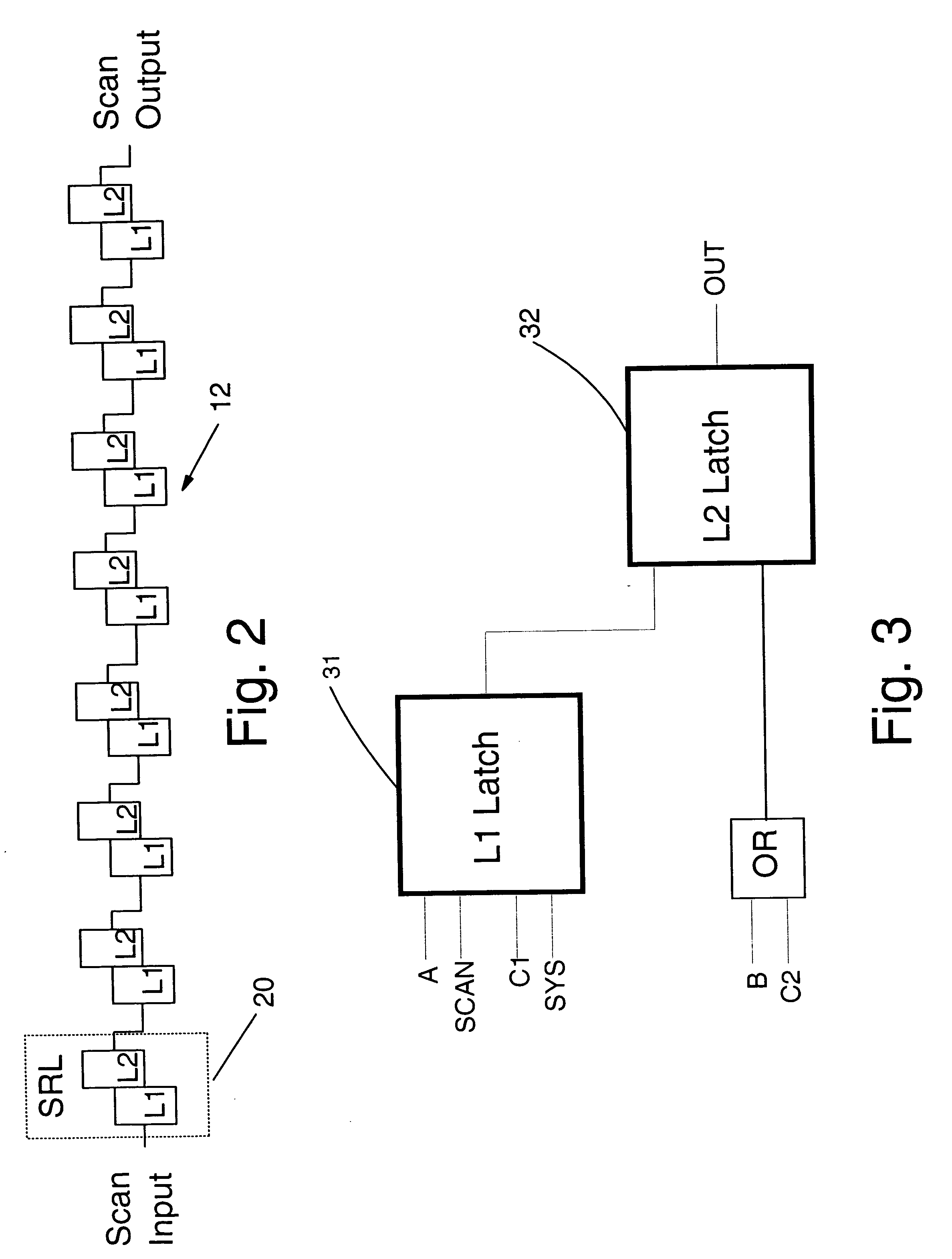

Method and apparatus for selective scan chain diagnostics

InactiveUS7234090B2Shorten the timeReduce probabilityElectronic circuit testingSpecial data processing applicationsShift registerElectronic chip

A method, apparatus and program product for testing at least one scan chain in an electronic chip in which the scan chain is formed by shift register latches arranged in the chain having a scan path with input pins and output pins. A flush test is executed for the scan chain under test and the flush test diagnostics for the flush test are recorded. A scan test is then executed for the scan chain under test and further test diagnostics are recorded in the event either or both the flush test or the scan test fails. The recorded flush test diagnostics and further test diagnostics are then analyzed to identify a call to one or more probable failed or failing shift register latches in the tested scan chain. The further scan chain diagnostics may include Disturb, Deterministic, ABIST, LBIST and Look-Ahead diagnostics. The tests may also be conducted for different voltage levels to determine the sensitivity of the scan chain being tested to differing voltage levels.

Owner:GOOGLE LLC

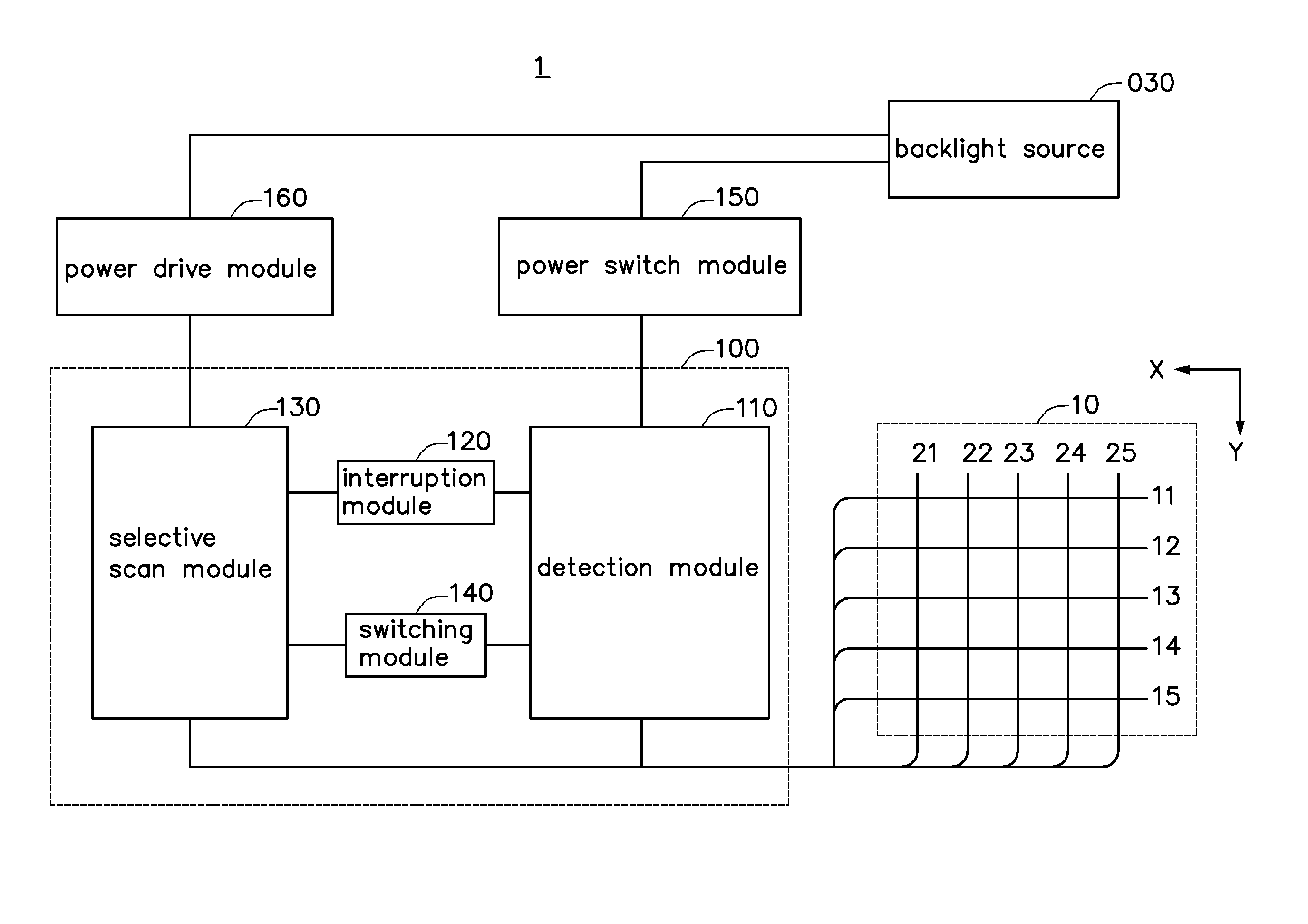

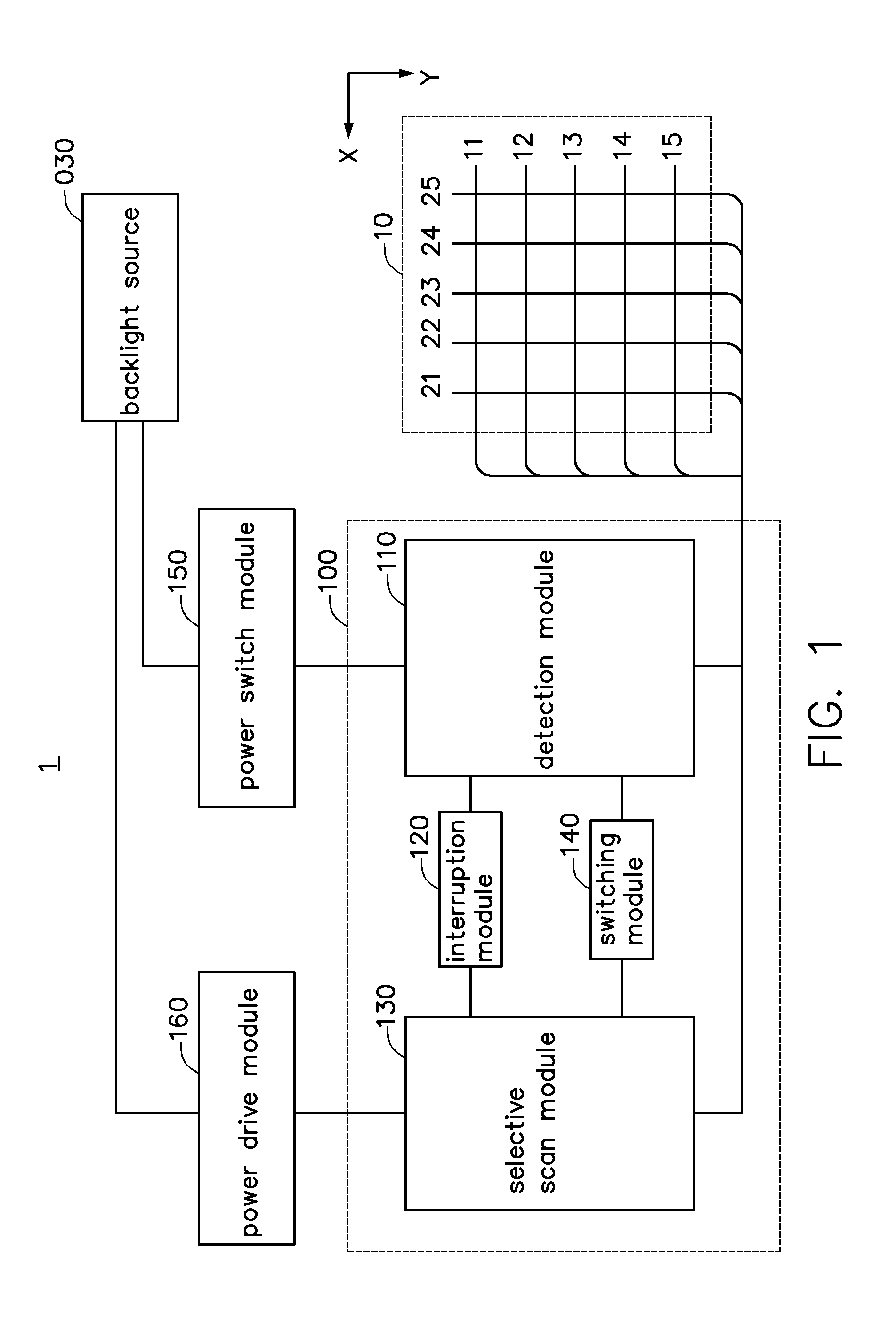

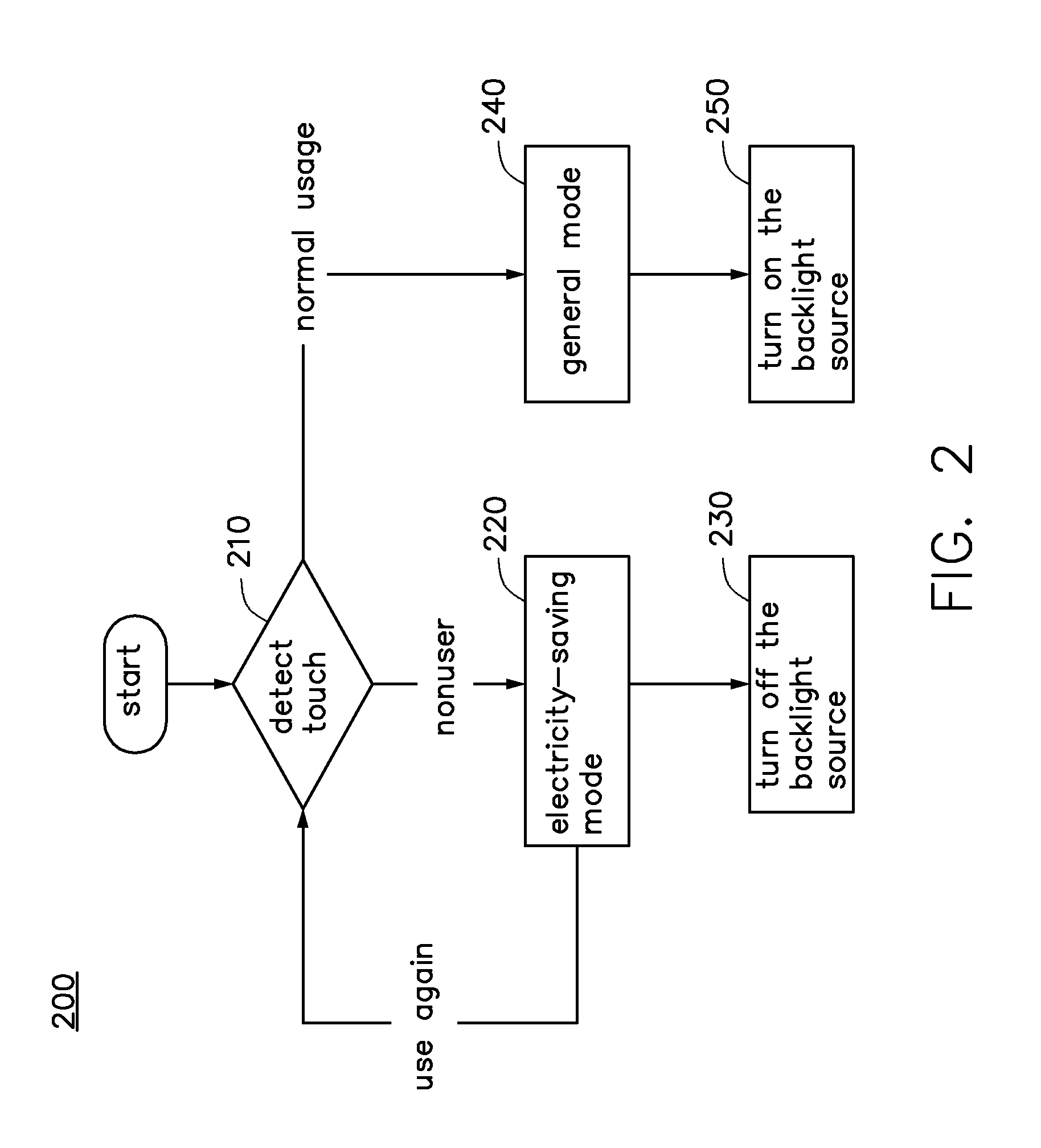

Driving circuit and method for driving touch display

ActiveUS20100265199A1Reduce in quantityReduce the numberEnergy efficient ICTDigital data processing detailsScan lineTouchpad

A driving circuit and method for a touch panel having a plurality of scan lines includes a detection module, an interruption module and a selective scan module. The detection module can periodically scan the scan lines, so as to detect whether the touch panel is controlled by touch. The interruption module can turn off the detection module when the touch panel is not controlled by touch. The selective scan module can select at least one set of scan lines from the plurality of scan lines to periodically and synchronously scan the set of selected scan lines when the detection module is turned off, where scanning of the selected scan lines detects whether the touch panel is touched.

Owner:INNOLUX CORP

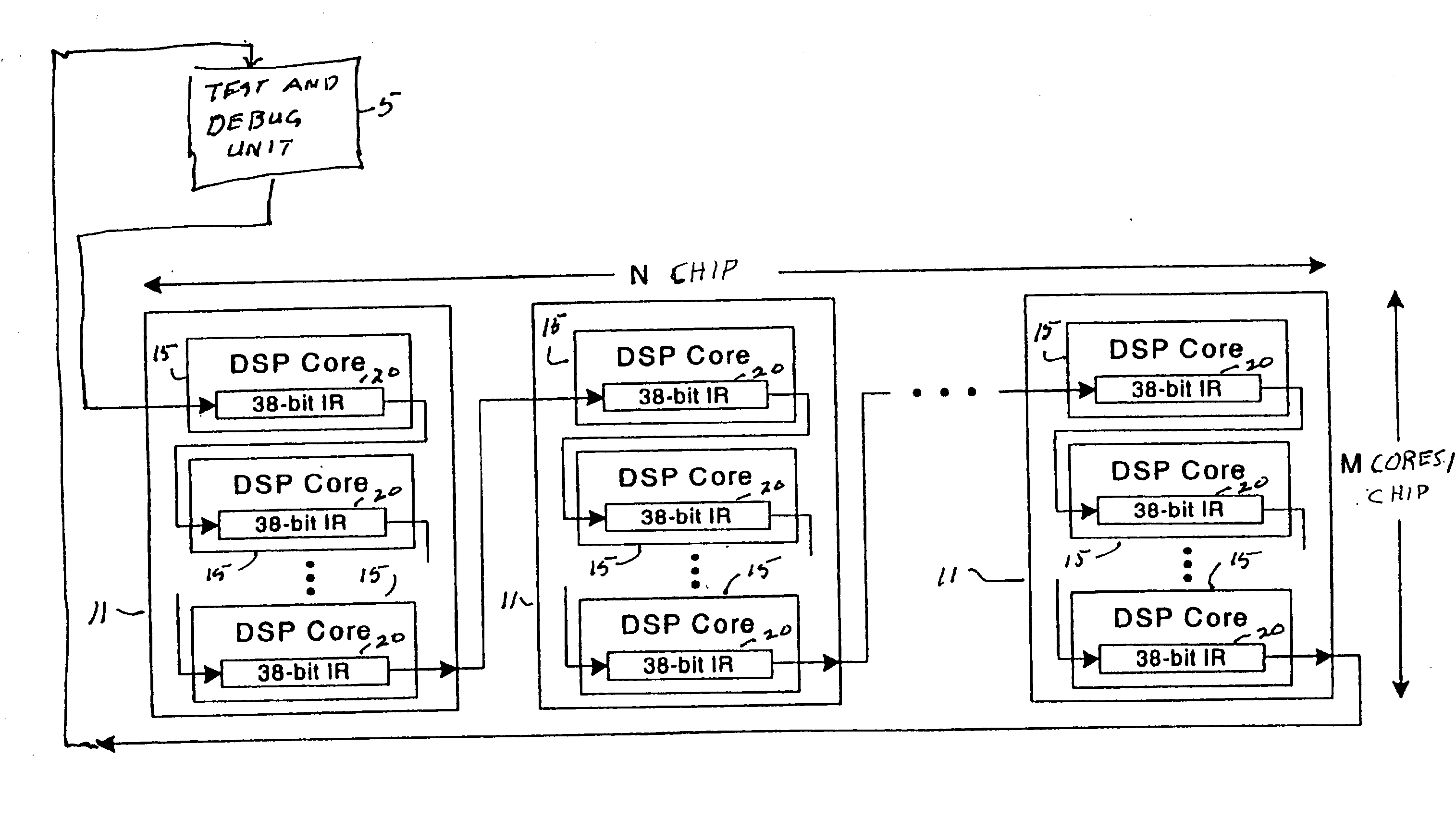

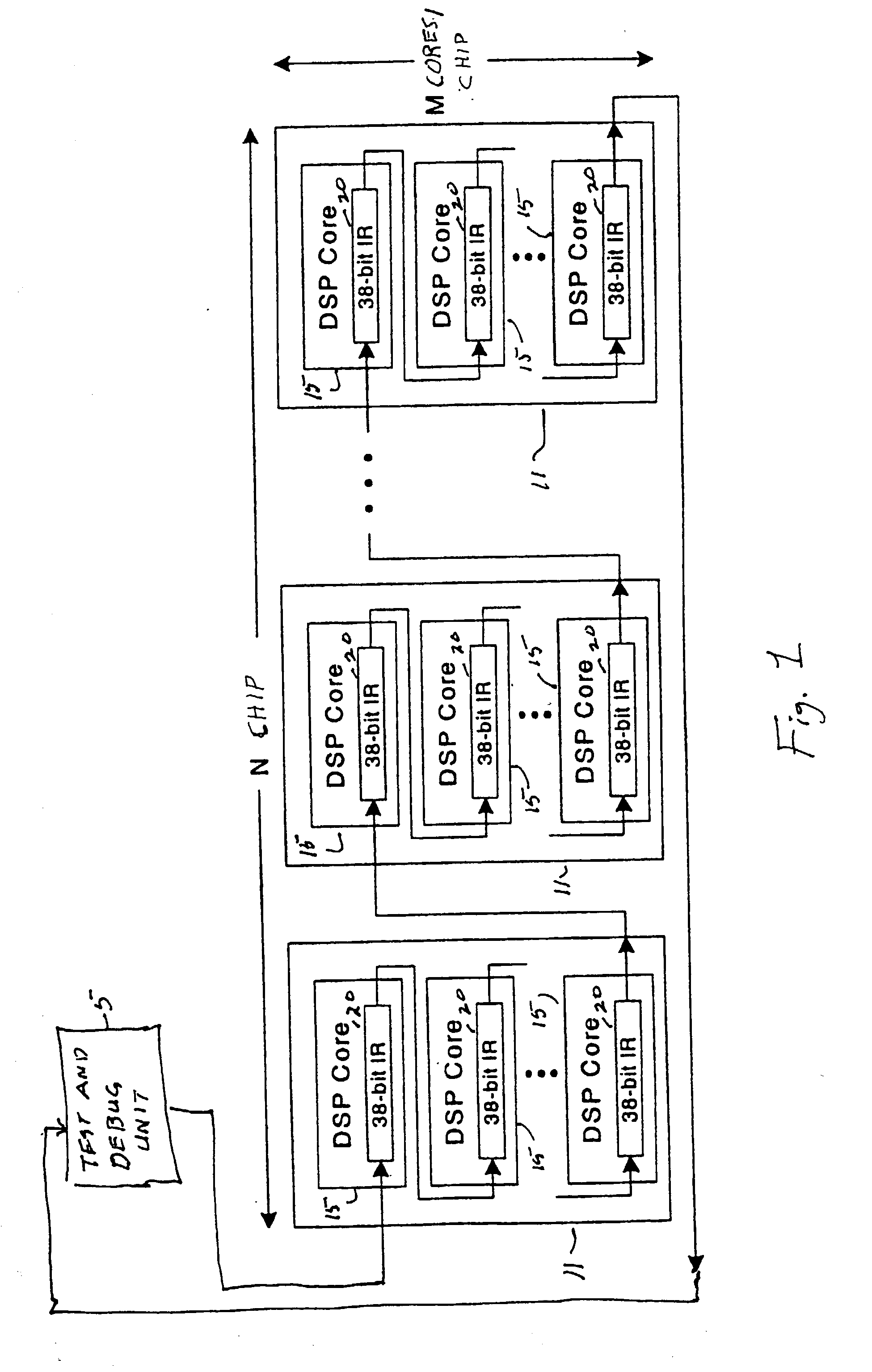

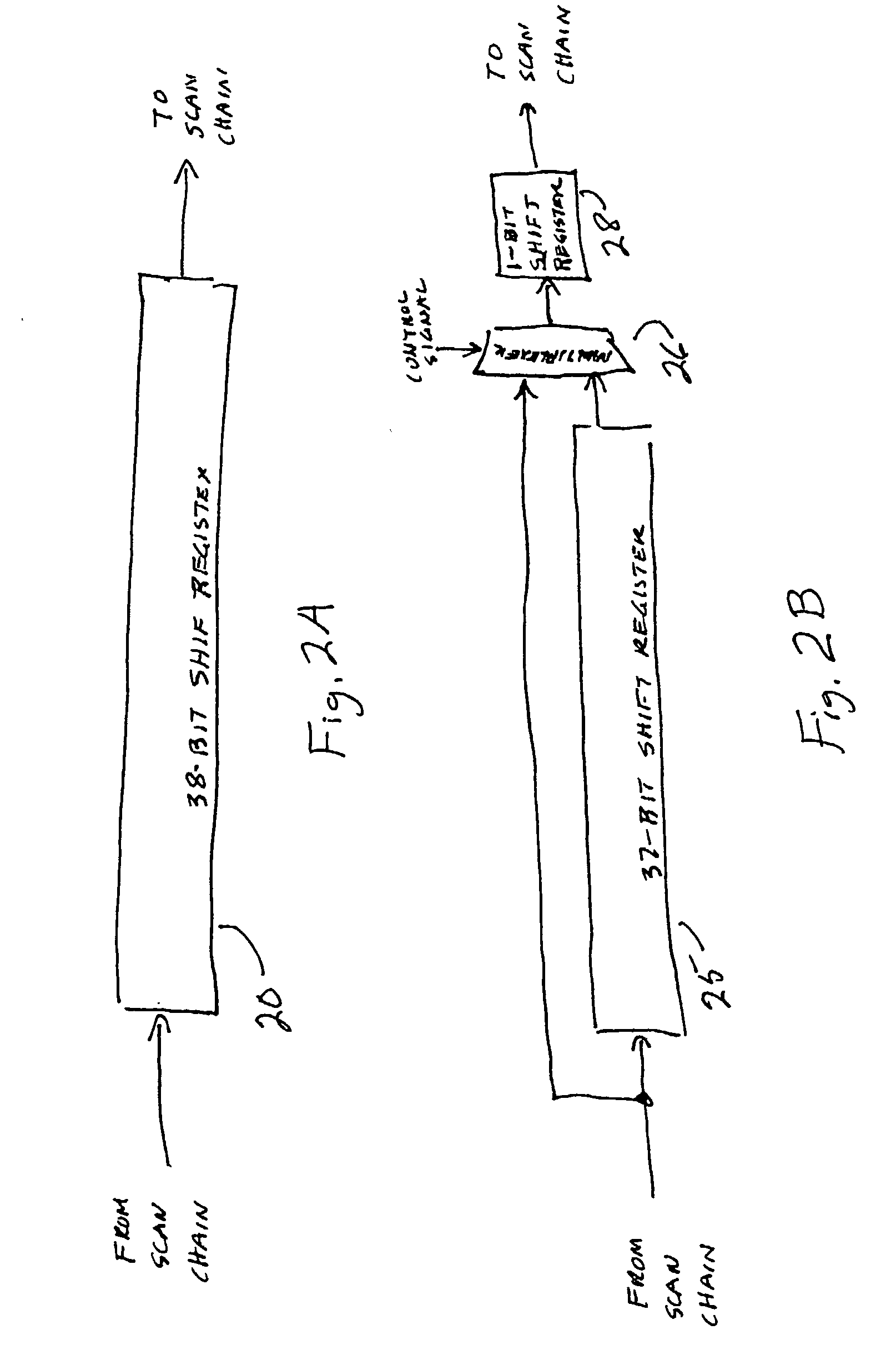

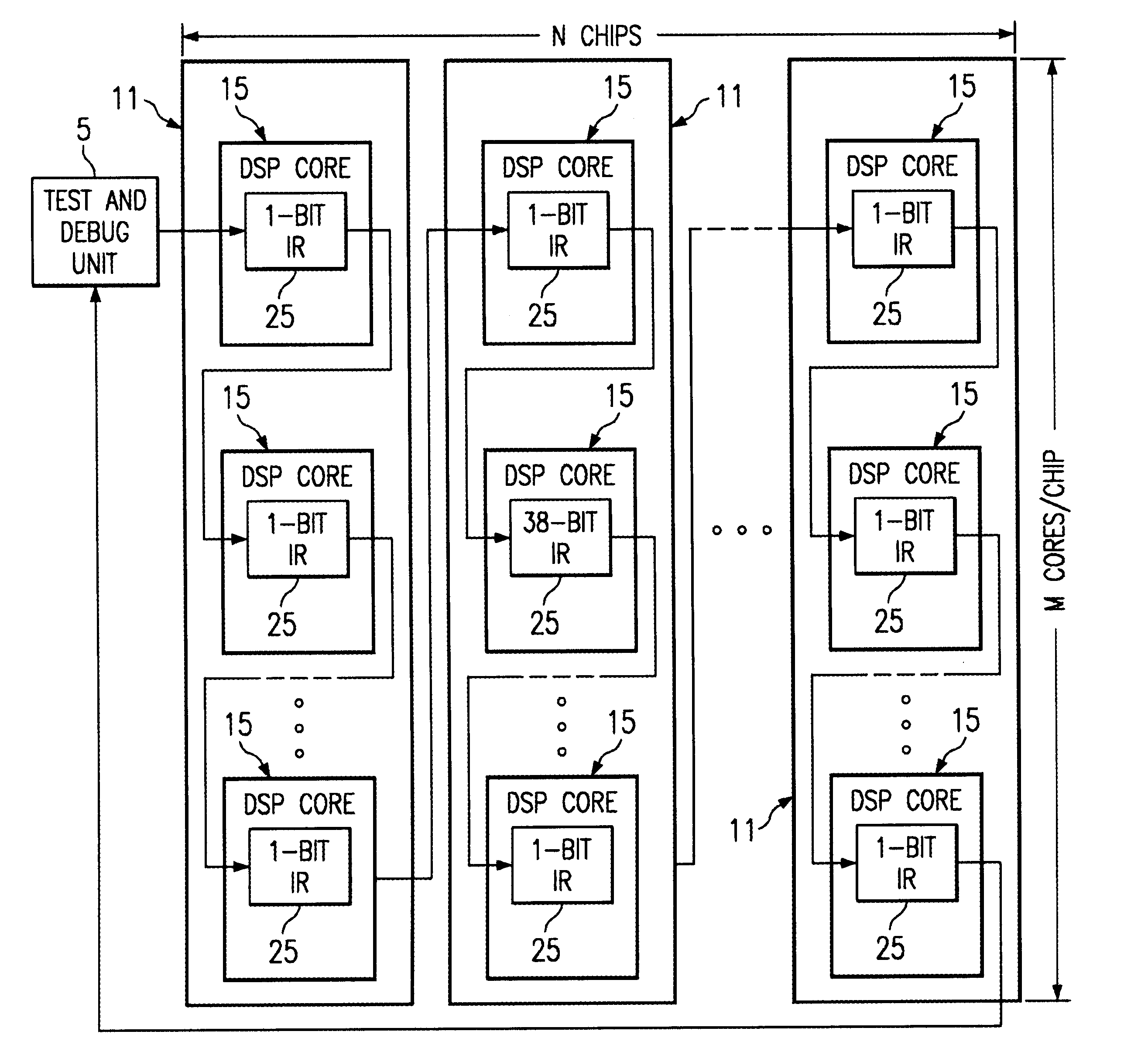

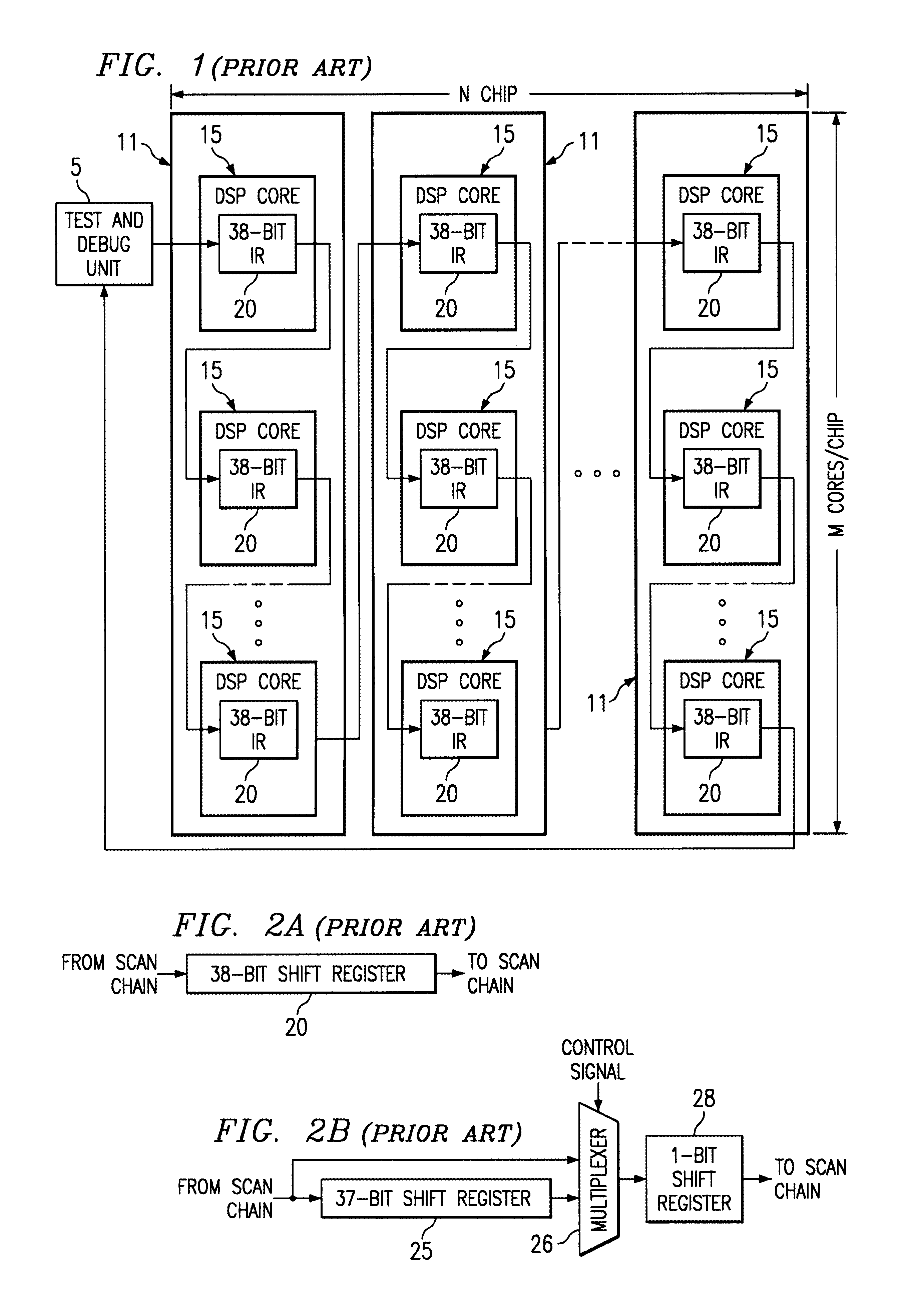

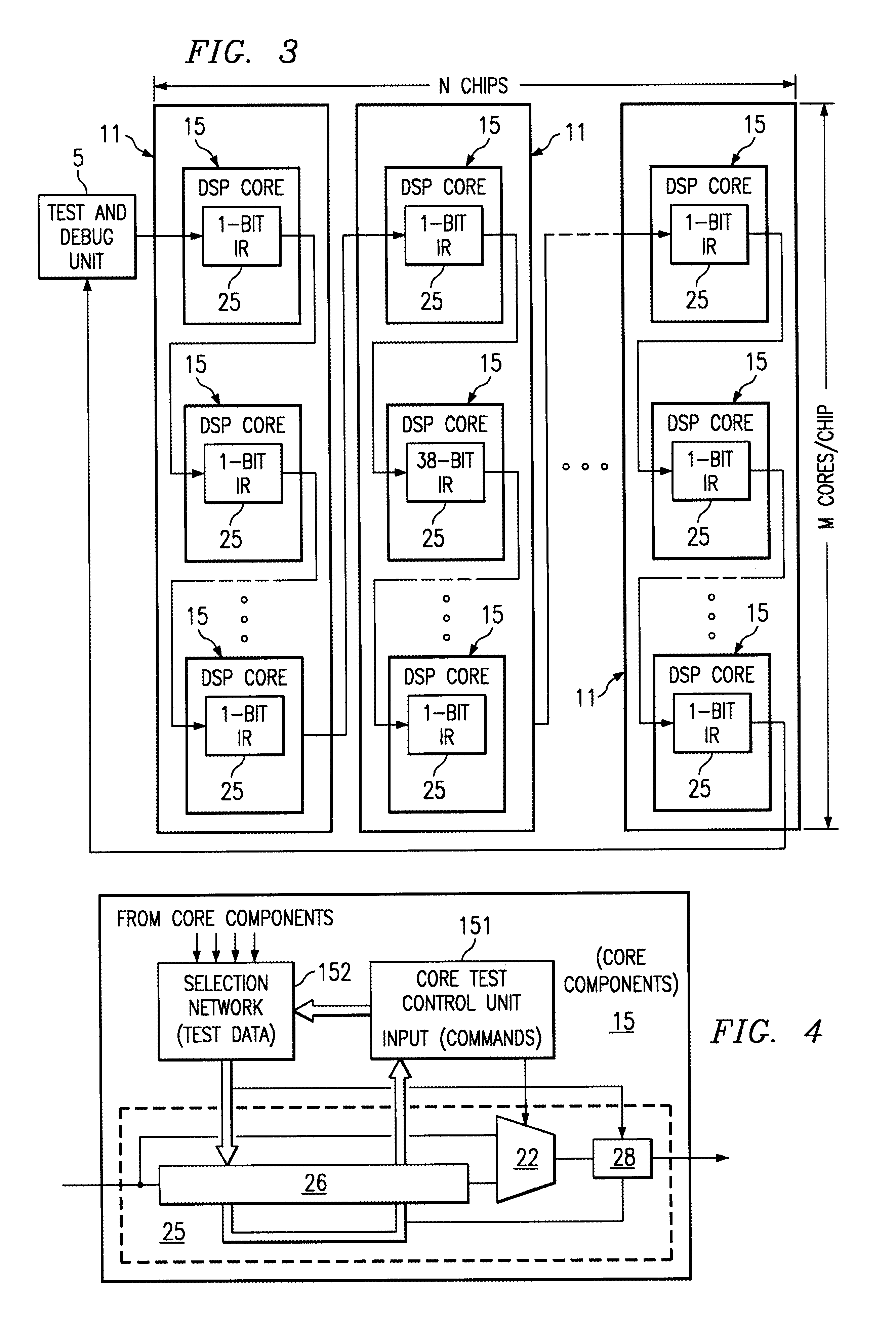

Apparatus and method for device selective scans in data streaming test environment for a processing unit having multiple cores

In a multi processor environment wherein the processors are capable of implementing a streaming data mode of operation, a technique is provided that reduces the number of bits shifted through the scan chain necessary to select a processor for operating in the streaming data mode. All test control device associated with the processor have an instruction entered therein. After execution of the instruction, all of the processors are entered in a bypass mode of operation. Then, a logic "0" in the bypass register will cause the associated target processor to enter the streaming data mode, while a logic "1" in the bypass register will cause the processor to enter the bypass mode. To select a new target processor, logic "1"s in the bypass register will reset the test control unit and thereafter the entry of a logic "1" will cause the non-target processors to enter the bypass mode, while a logic "0" in a bypass register will select the new target processor (i.e., for operating in the streaming data mode).

Owner:TEXAS INSTR INC

Methods and systems for reducing MAC layer handoff latency in wireless networks

ActiveUS7636336B2Reduce switching delayReduce delaysWireless commuication servicesCache algorithmsComputer science

In accordance with the present invention, computer implemented methods and systems are provided for reducing handoff latency in a wireless network. In response to detecting that a handoff is necessary, the present invention uses a selective scanning algorithm that includes the use of a channel mask and / or a caching algorithm for detecting one or more new access points.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

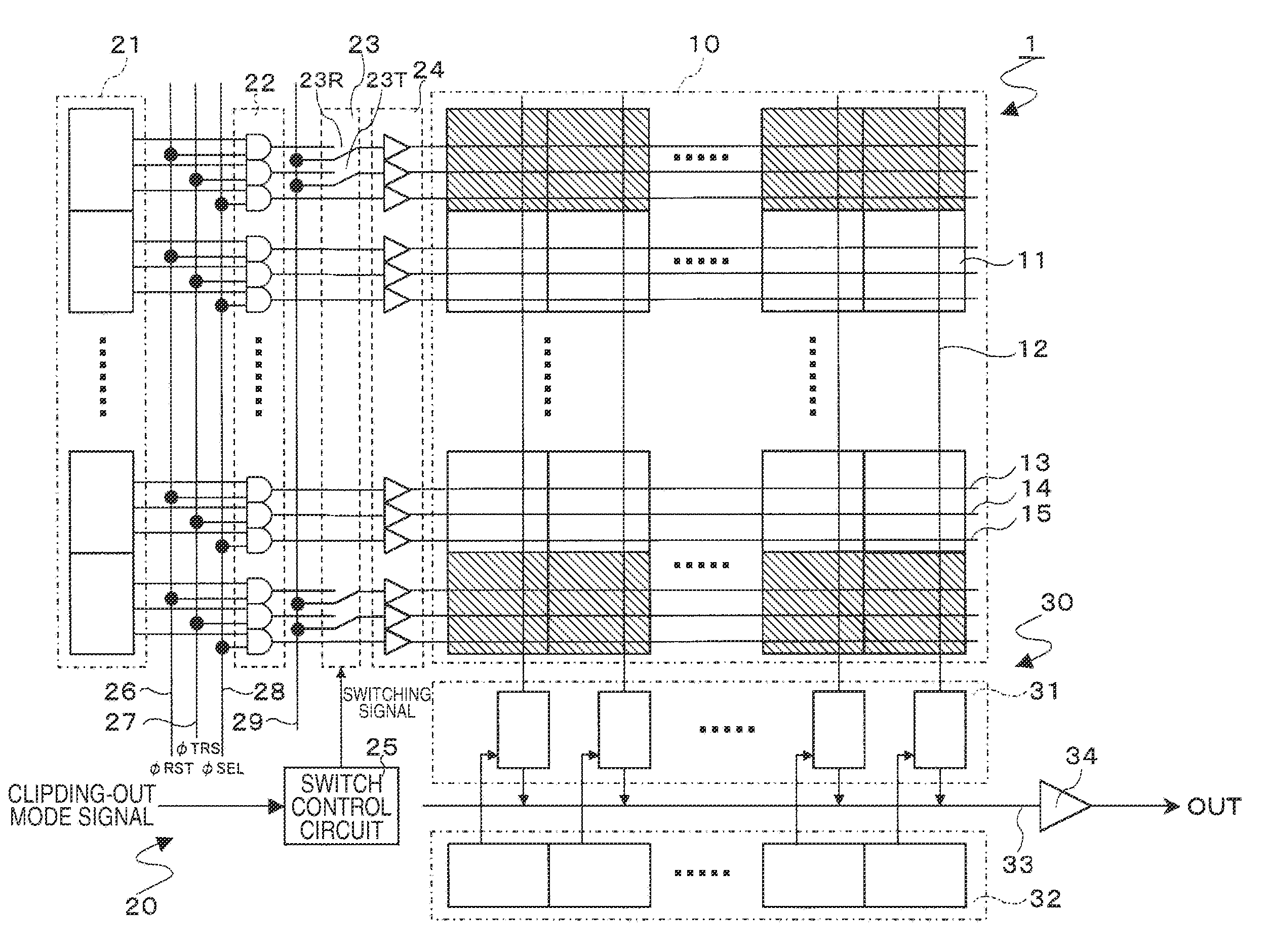

Display apparatus, display-apparatus driving method and electronic equipment

ActiveUS20080238901A1Improve reliabilityEnough timeElectrical apparatusElectroluminescent light sourcesEngineeringCapacitor

In the present invention, there is provided a display apparatus including: a pixel array section including pixel circuits each having an electro-optical device, a write transistor configured to carry out a voltage storing process to sample a video signal and store the sampled video signal, a holding capacitor configured to hold the sampled video signal, and a driving transistor configured to drive the electro-optical device; and a driving circuit configured to carry out a selective scan operation on the pixel circuits in row units, and a threshold-voltage correction operation to correct variations of the threshold voltage of every driving transistor wherein, before the driving circuit carries out a threshold-voltage correction operation in a horizontal scan period, the driving circuit performs a preparatory operation prior to the horizontal scan period in order to fix each of electric potentials appearing on the gate and the source of the driving transistor at a predetermined level.

Owner:JOLED INC

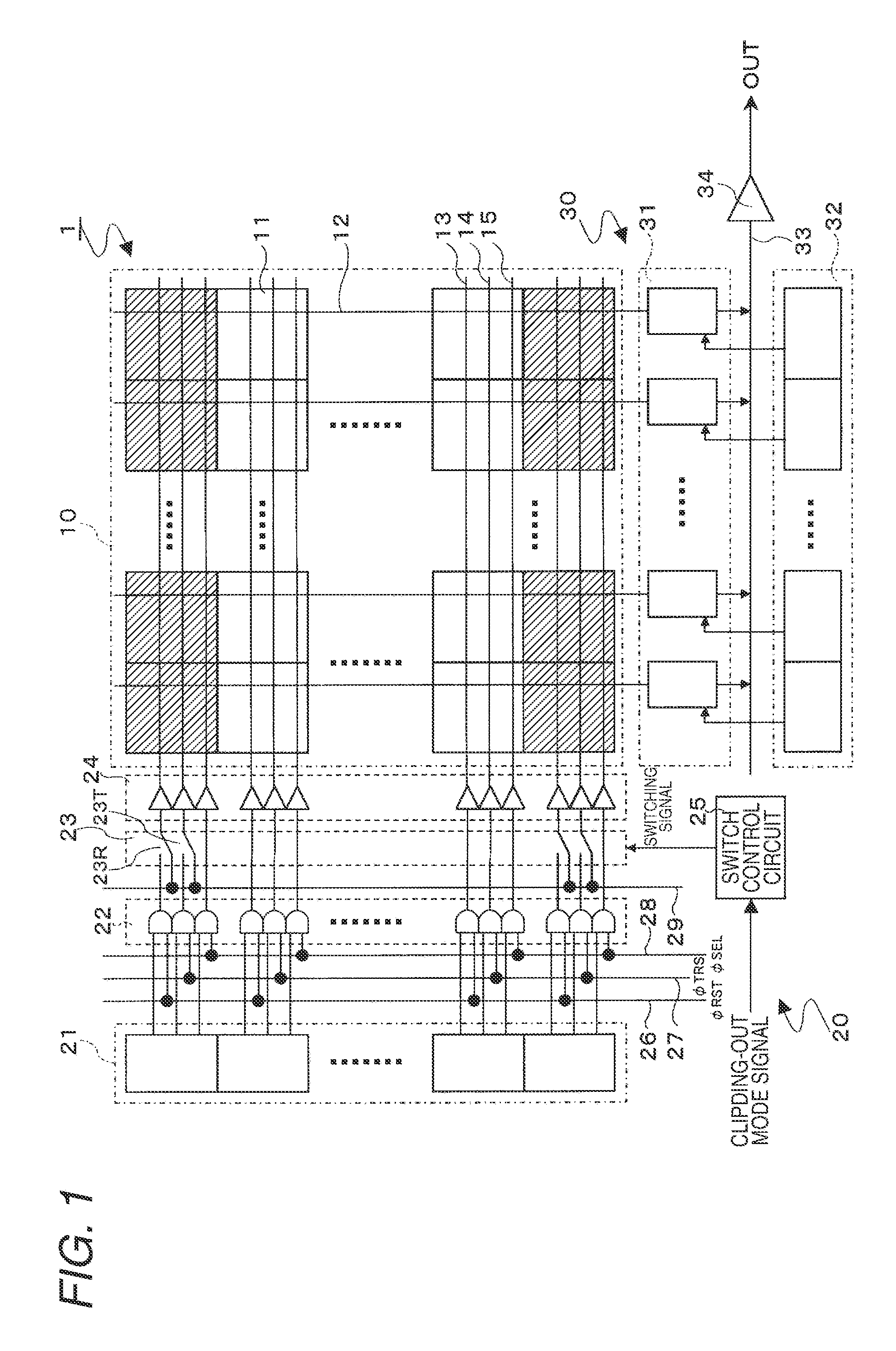

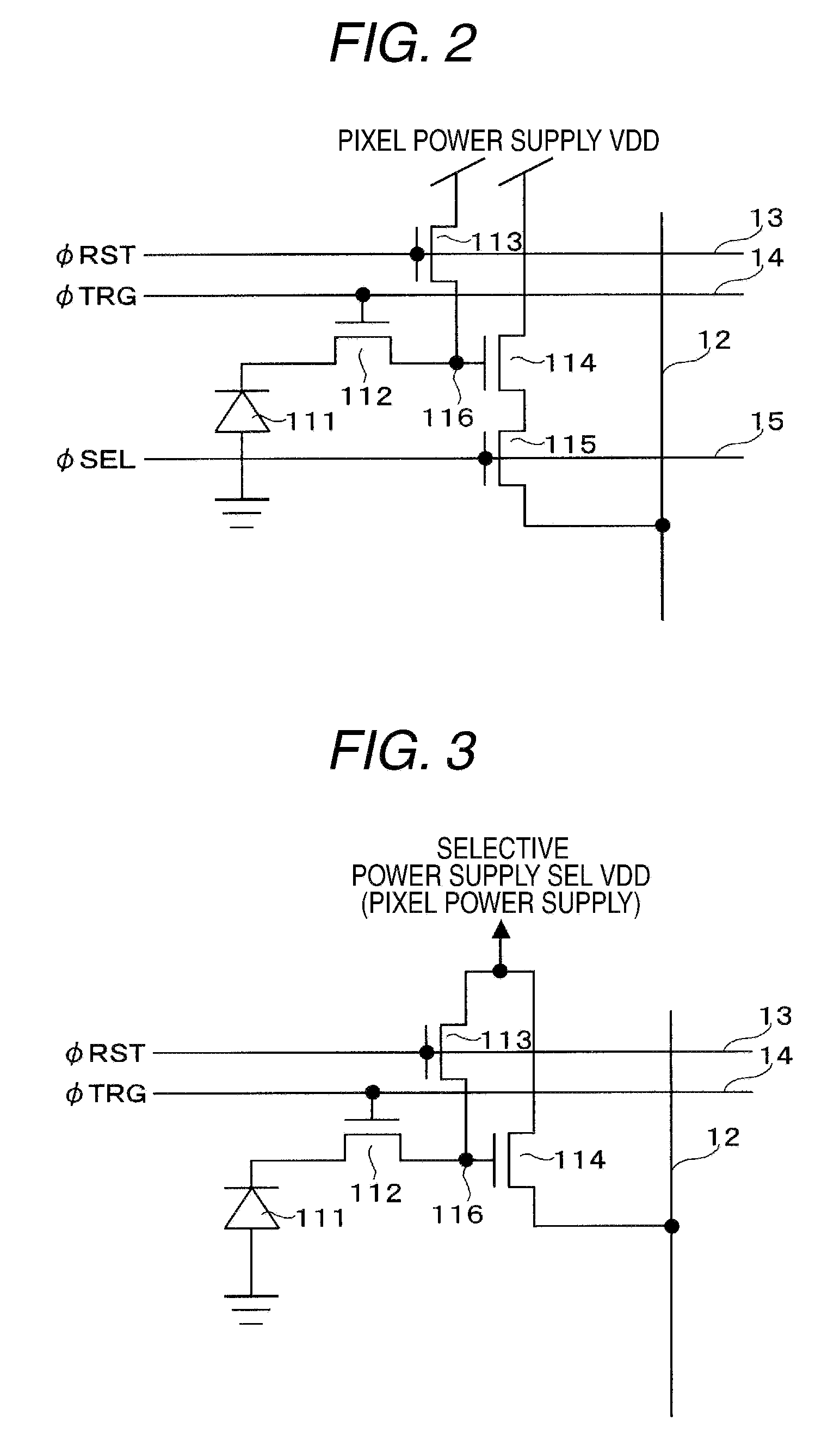

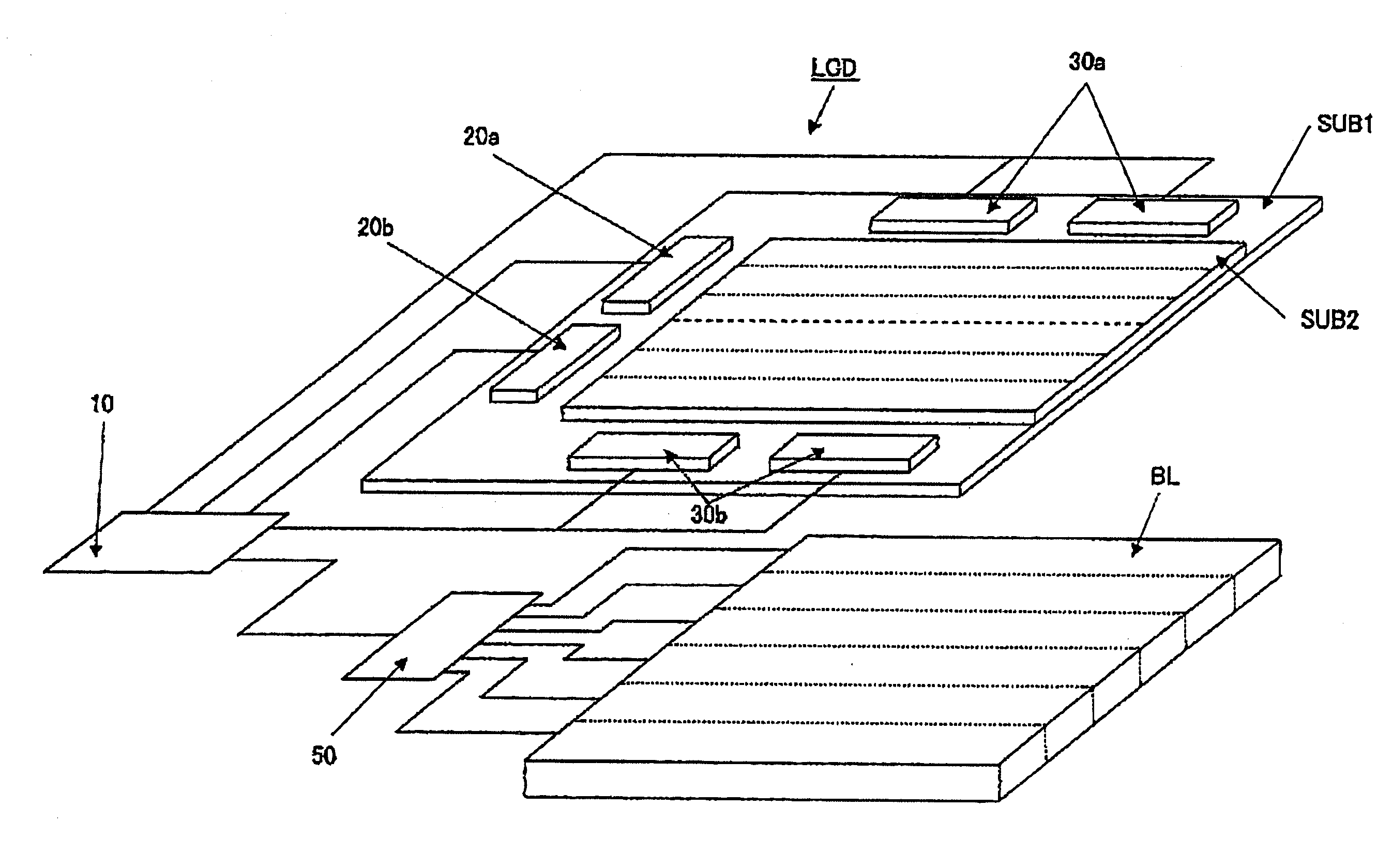

Solid state imaging device, method of driving solid state imaging device, and image pickup apparatus

InactiveUS20060186313A1Avoid chargingTelevision system detailsTelevision system scanning detailsEngineeringPhotoelectric conversion

A solid state imaging device includes: a pixel array section in which pixels including photoelectric conversion elements are two dimensionally arranged; a vertical selector that sequentially applies selective scanning to respective rows of the pixel array section; and a controller that discharges, when a mode for reading out only pixel signals of respective rows in a given row range in the pixel array section is set by the vertical selector, charges generated in the photoelectric conversion elements in respective pixels of rows outside the row range to a pixel power supply.

Owner:SONY CORP

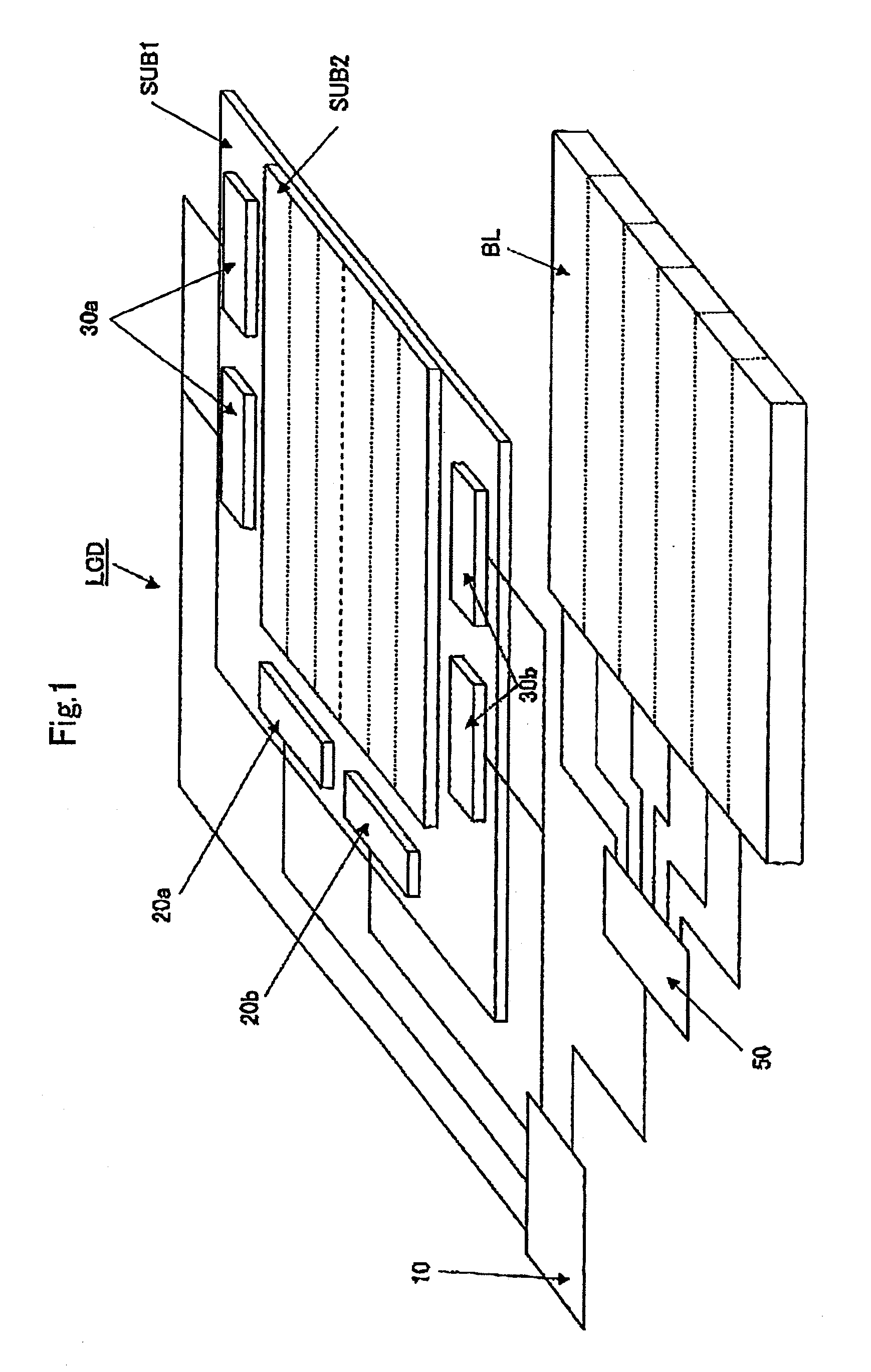

Liquid crystal display device

InactiveUS20090066687A1Cathode-ray tube indicatorsNon-linear opticsLiquid-crystal displayEngineering

(Object) To provide a liquid crystal display device which simultaneously uses a method for simultaneously driving two screens and a method for driving scan-back light.(Means for Achieving Object) A number of first scanning lines are divided into M groups when M is an integer of 2 or more (M≧2), a number of second scanning lines are divided into N groups when N is an integer of 2 or more (N≧2), and the jth region of the backlight (1≦j≦M) is turned off when the first scanning line driving circuit is supplying a selective scanning voltage to the first scanning lines within the jth group of the number of first scanning lines, the jth region of the backlight is turned on when no selective scanning voltage is supplied to the first scanning lines within the jth group, the kth region of the backlight (1≦k≦N) is turned off when at least one of the second scanning line driving circuits supplies a selective scanning voltage to the second scanning lines within the kth group of the number of second scanning lines, and the kth region of the backlight is turned on when no selective scanning voltage is supplied to the second scanning lines within the kth group.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Display device

ActiveUS20110032284A1Inhibit deteriorationReducing stress appliedCathode-ray tube indicatorsInput/output processes for data processingDisplay deviceTransistor

A display device includes first transistors provided for every scanning line and second transistors having a first electrode connected to each scanning line and a second electrode to which a reference potential is inputted. A first electrode of the first transistor is connected to any one of gate lines belonging to a first group. A control electrode of the first transistor is connected to any one of gate lines belonging to a second group. A control electrode of the second transistor is connected to any one of reverse gate lines belonging to a second group. A scanning line drive circuit intermittently outputs, when the scanning line drive circuit outputs a non-selective scanning voltage to any one of the gate lines belonging to the second group, a selective reversal scanning voltage to a reverse gate line corresponding to the gate line in the reverse gate lines belonging to the second group.

Owner:JAPAN DISPLAY INC +1

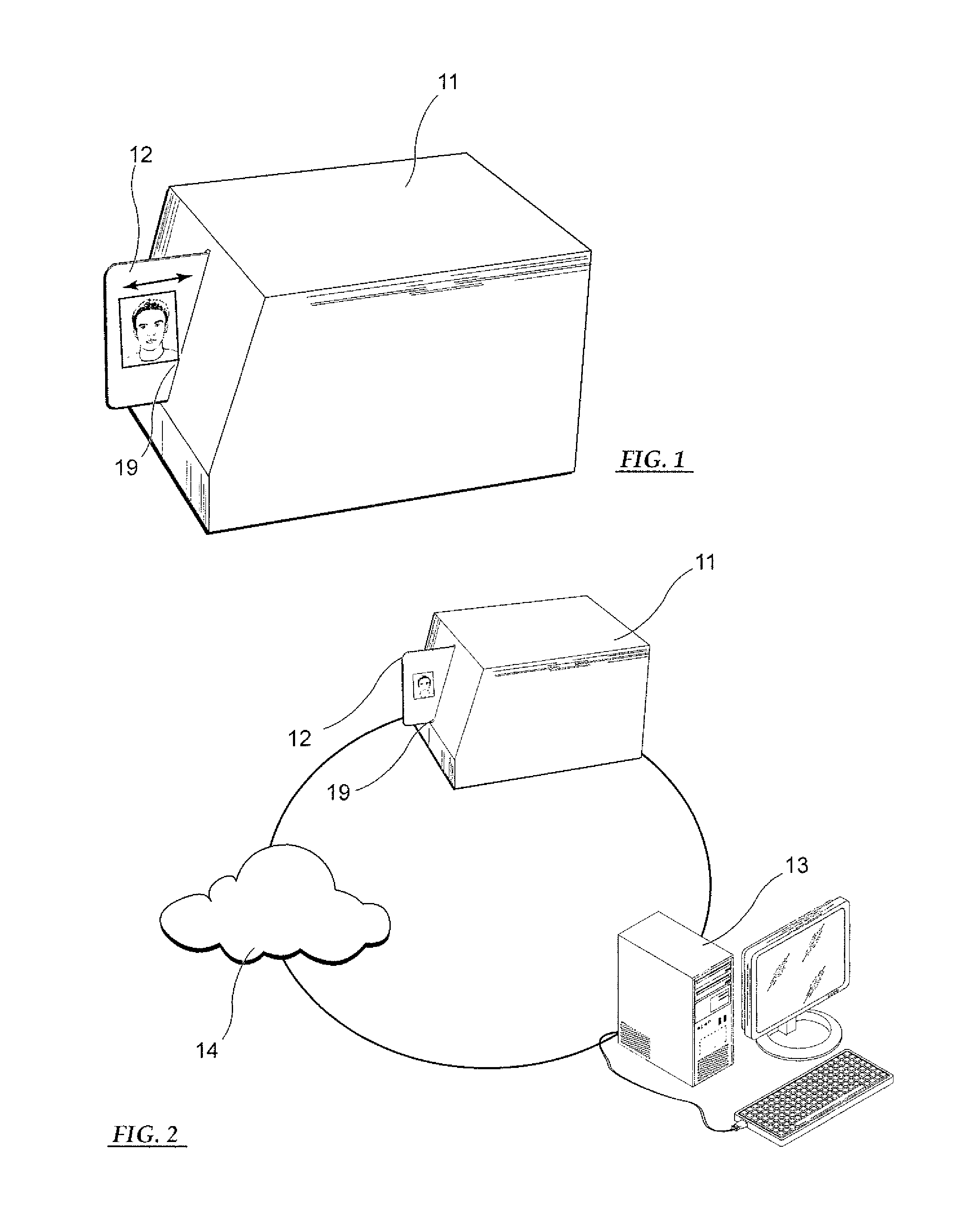

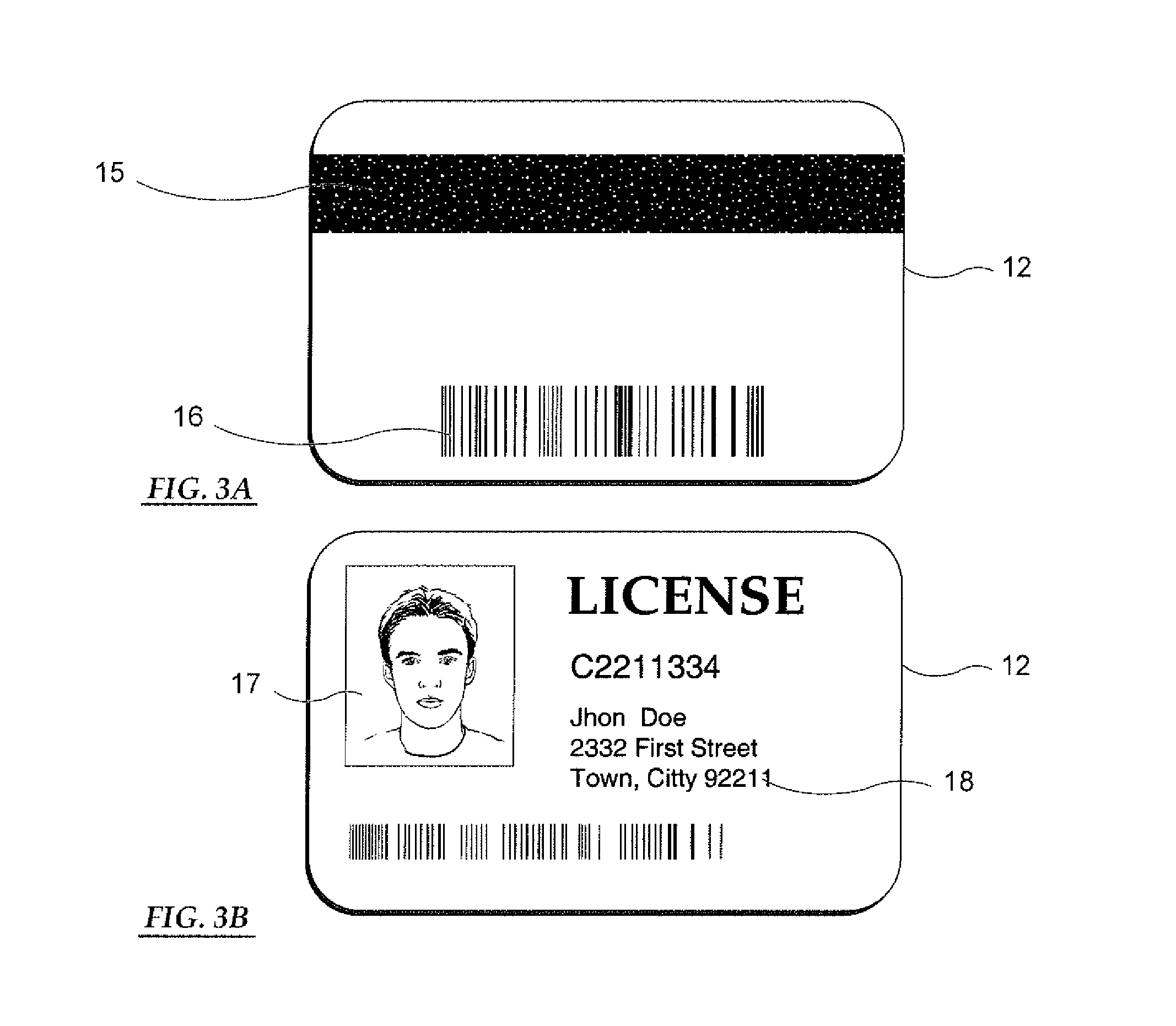

Method for Scanning and Processing Documents

InactiveUS20150002915A1Resourceful, swift, and effectiveAdequate identificationSpecial data processing applicationsPictoral communicationComputer hardwareImage resolution

An adaptive and selective scanning method, particularly for identifying and authenticating identification cards, is disclosed herein. The present invention evolved from a trend of more intricate security features configured to modern ID cards motivating more sophisticated counterfeits. These intricate features would typically require higher resolution (therefore large electronic files) and increased scanning times that would be unworkable in many environments where scan time is very important, such as airport security. Essentially, the method comprises multiple timely passes where specific target data is obtained. Initial ID card passes are concentrated to magnetic strip, as well as one and two dimensional barcode information. Subsequent card passes are focused to high resolution images of a specific portion of the card thereby reducing scan time.

Owner:LEBASCHI ALI

Methods and systems for reducing mac layer handoff latency in wireless networks

InactiveUS20100135252A1Reduce switching delayReduce delaysWireless commuication servicesCache algorithmsHandover latency

In accordance with the present invention, computer implemented methods and systems are provided for reducing handoff latency in a wireless network. In response to detecting that a handoff is necessary, the present invention uses a selective scanning algorithm that includes the use of a channel mask and / or a caching algorithm for detecting one or more new access points.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

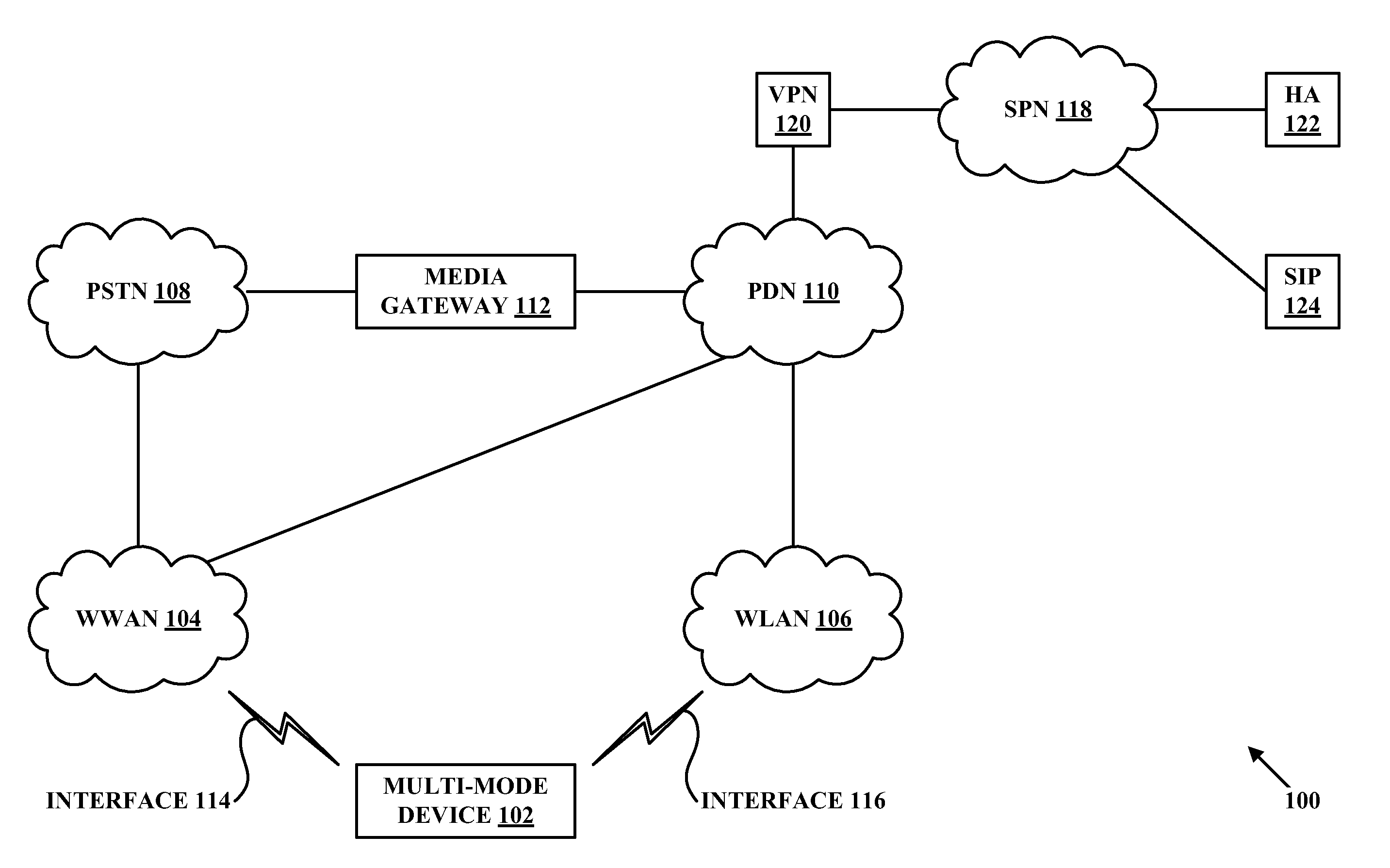

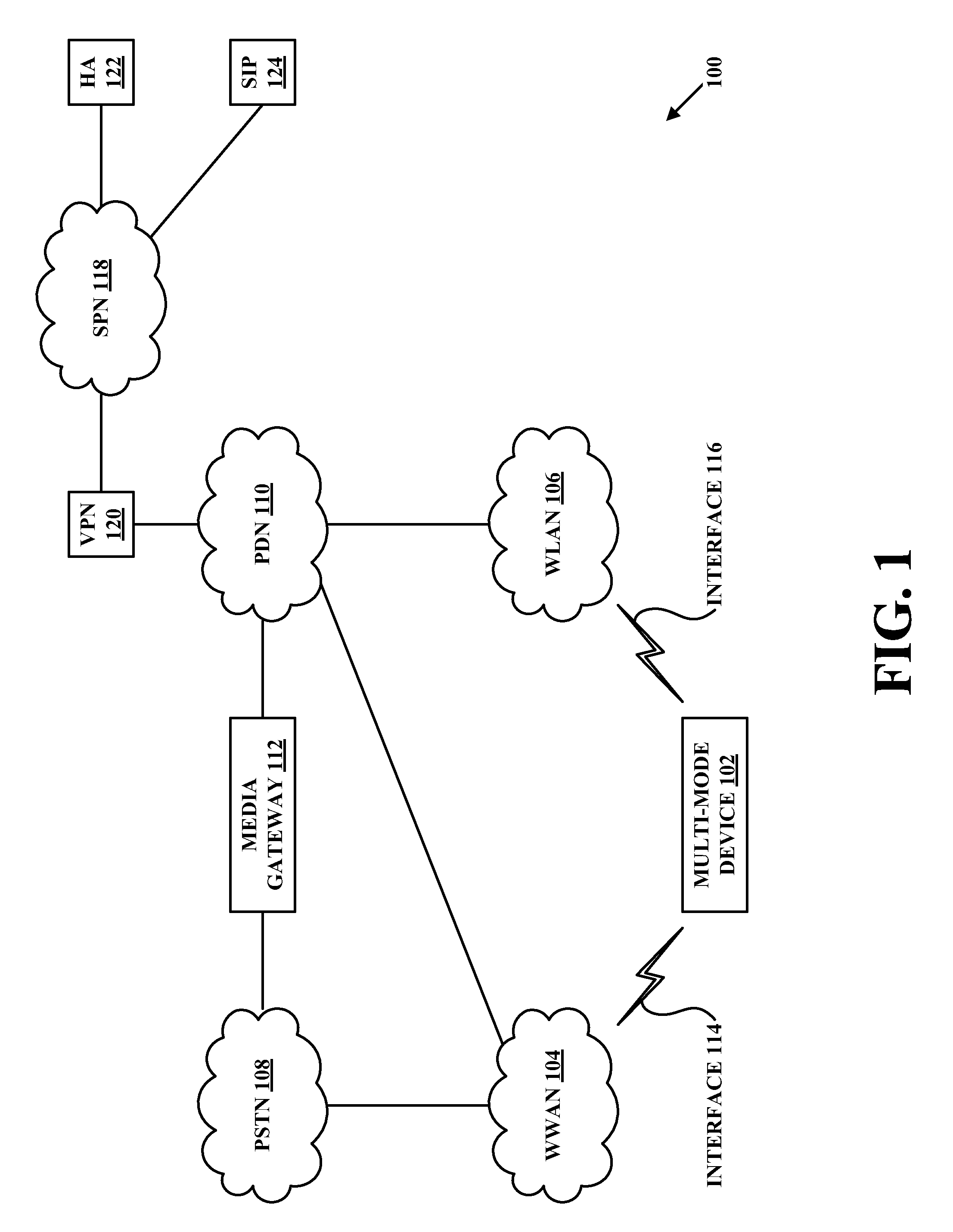

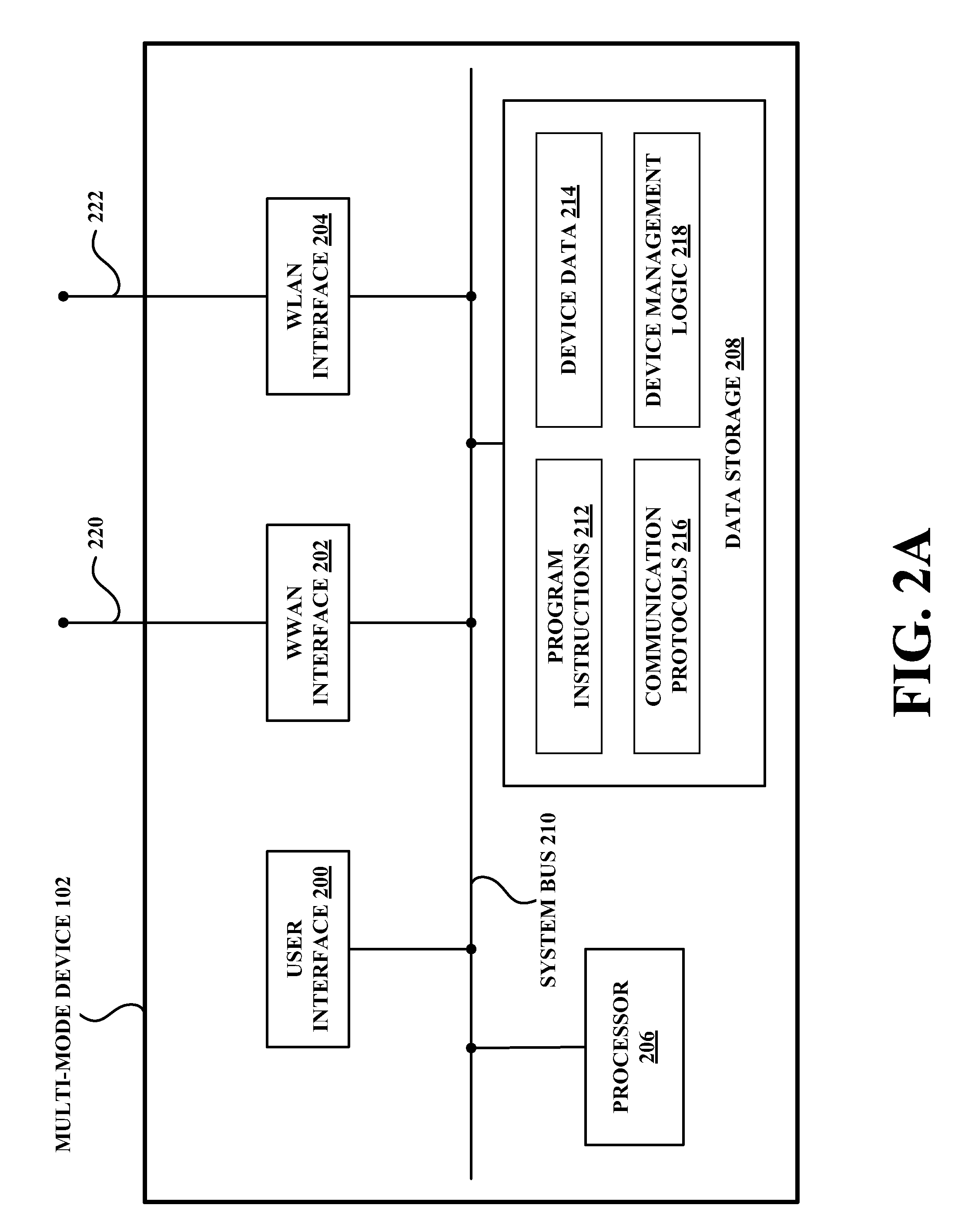

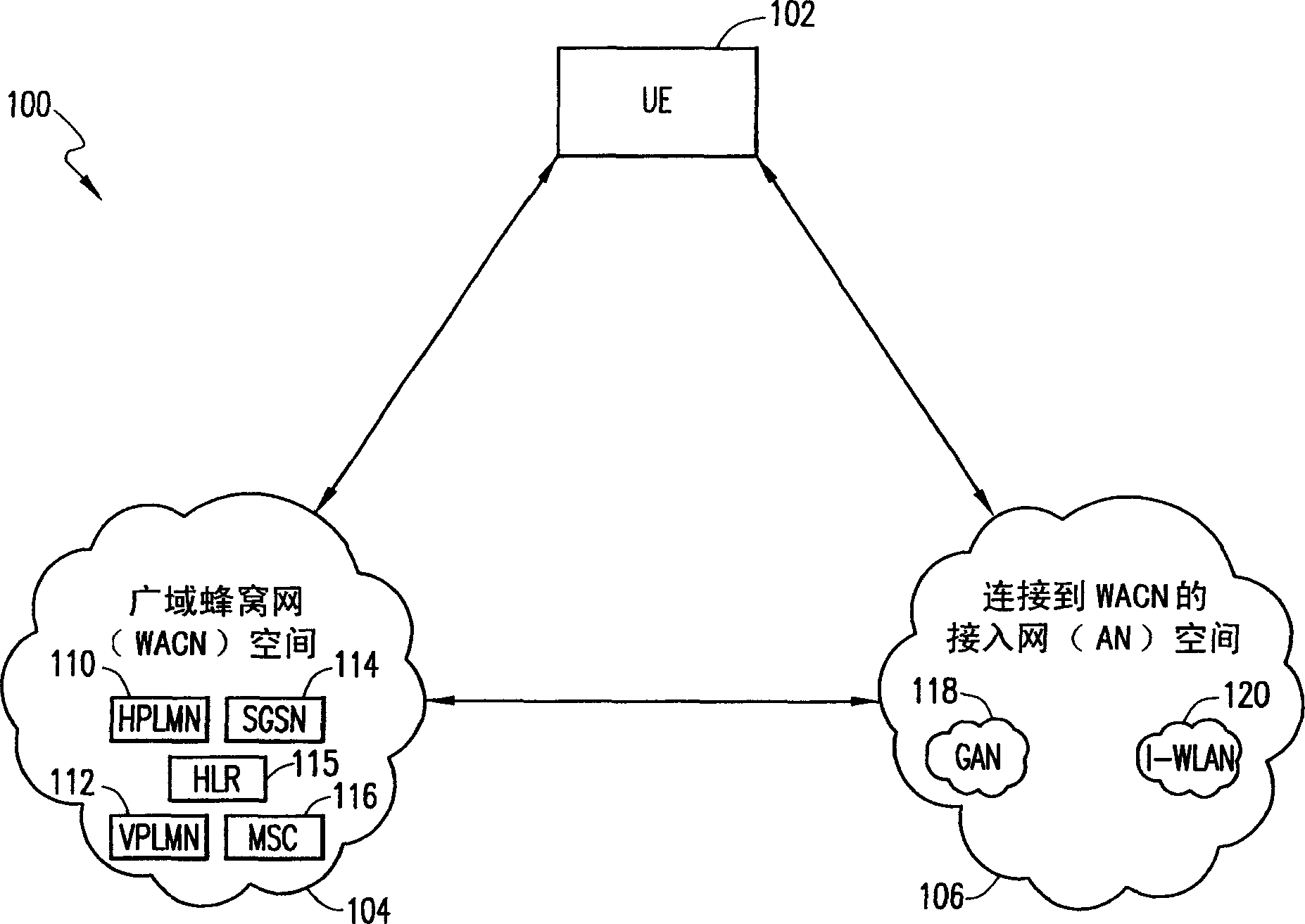

Selective scanning for WLAN coverage by a multi-mode device

ActiveUS8185092B1Resonant long antennasUnauthorised/fraudulent call preventionTelecommunicationsAir interface

Methods and systems are provided for selective scanning for WLAN coverage by a multi-mode device. In at least one embodiment, the multi-mode device determines whether it is both charging and authenticated via a wireless network that operates according to a first protocol, and if it is both, responsively storing reference data—in a profile corresponding with that wireless network—that reflects a current environment of a second wireless network that operates according to a second air-interface protocol that is different from the first. At a later point in time, the multi-mode device detects that a current environment of the second wireless network sufficiently matches the stored reference data, and responsively scanning for coverage according to the first air-interface protocol.

Owner:SPRINT SPECTRUM LLC

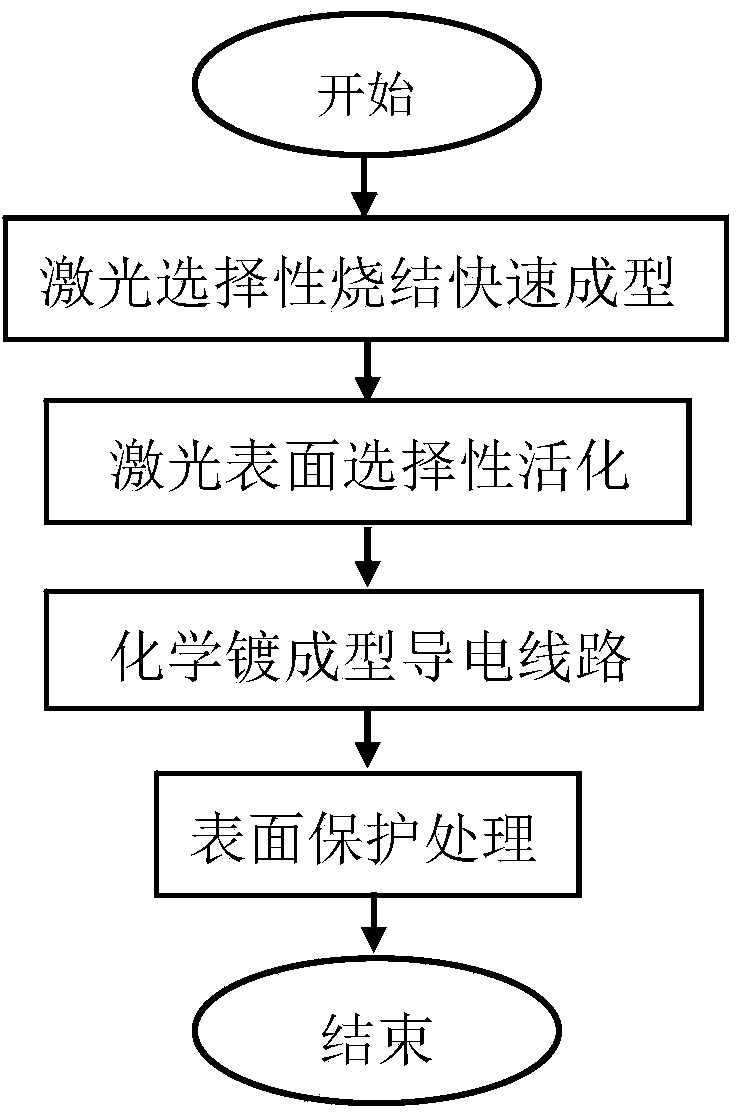

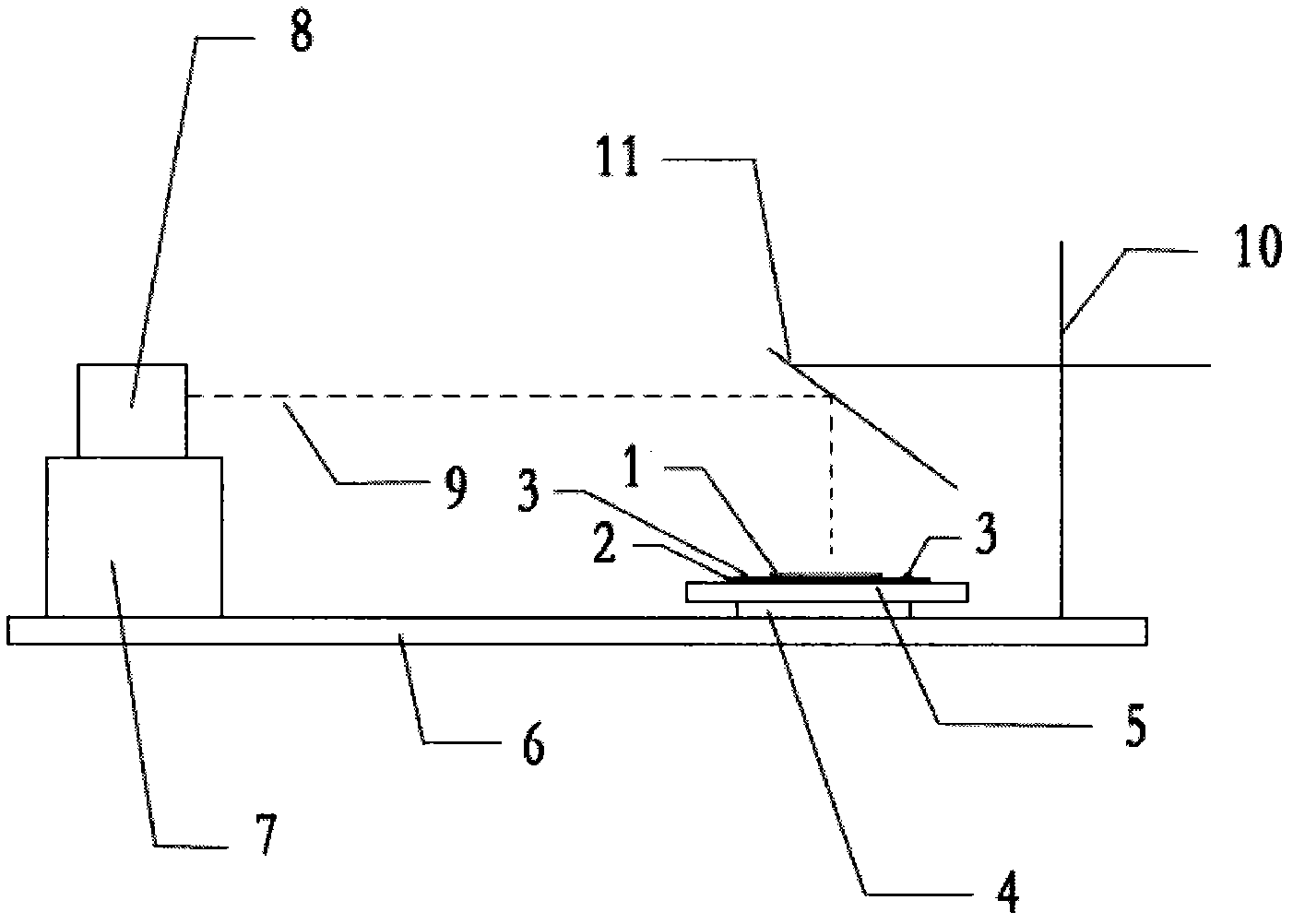

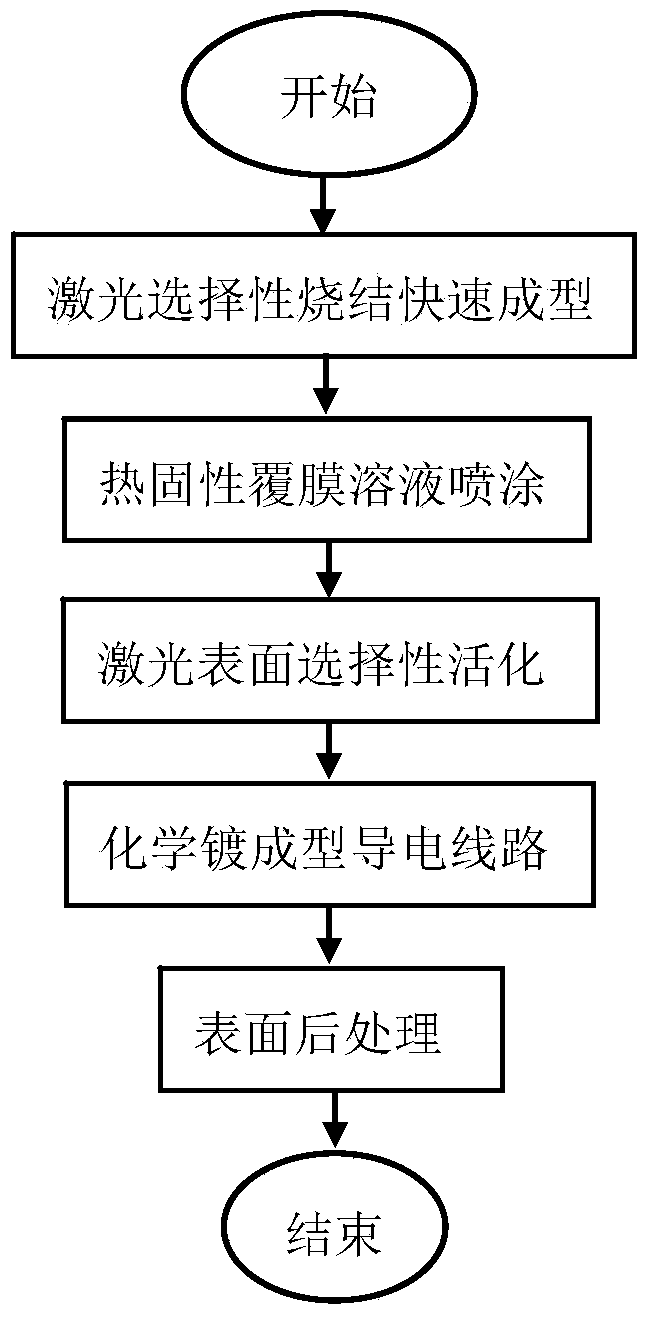

Three-dimensional circuit manufacturing method and modified laser sintering powder materials

ActiveCN104244588AFast preparationRapid Surface MetallizationConductive pattern formationSelective laser sinteringChemical plating

The invention discloses a three-dimensional circuit manufacturing method. The method comprises the steps that a prototype model is generated through a selective laser sintering method, wherein modified laser sintering powder materials comprising components suitable for laser surface activation are used as the raw materials for the prototype model; preset selective scanning is carried out on the surface of the prototype model through laser, so that a surface activation area is formed; a conductive circuit is formed in the surface activation area through chemical plating. The invention further discloses the modified laser sintering powder materials used for the three-dimensional circuit manufacturing method. According to the three-dimensional circuit manufacturing method and the modified laser sintering powder materials, the limitation brought by traditional SLS processing materials on the application is overcome, meanwhile, a matrix with the complex surface is formed, and the requirements for rapid manufacturing and forming of the conductive circuit and laser activation are effectively met.

Owner:SHENZHEN SUNSHINE LASER & ELECTRONICS TECH CO LTD

System and method for accelerating network selection by a wireless user equipment device

InactiveCN1901751AAssess restrictionRadio/inductive link selection arrangementsFull bandUser equipment

A system and method for accelerating network selection by a wireless user equipment (UE) device (102) without having to perform a full band scan (FBS). In one exemplary embodiment, the wireless UE device (102) is operable to determine its location using a satellite-based positioning system such as GPS. Based on determining (1004) that the wireless UE device is in a particular area defined by a set of corners, a subset of appropriate frequency data is determined for selective scanning (1006) by the wireless UE device (102). Using the subset of appropriate frequency data, a selective scanning (1006) is performed for locating a network by the wireless UE device (102).

Owner:RES IN MOTION LTD

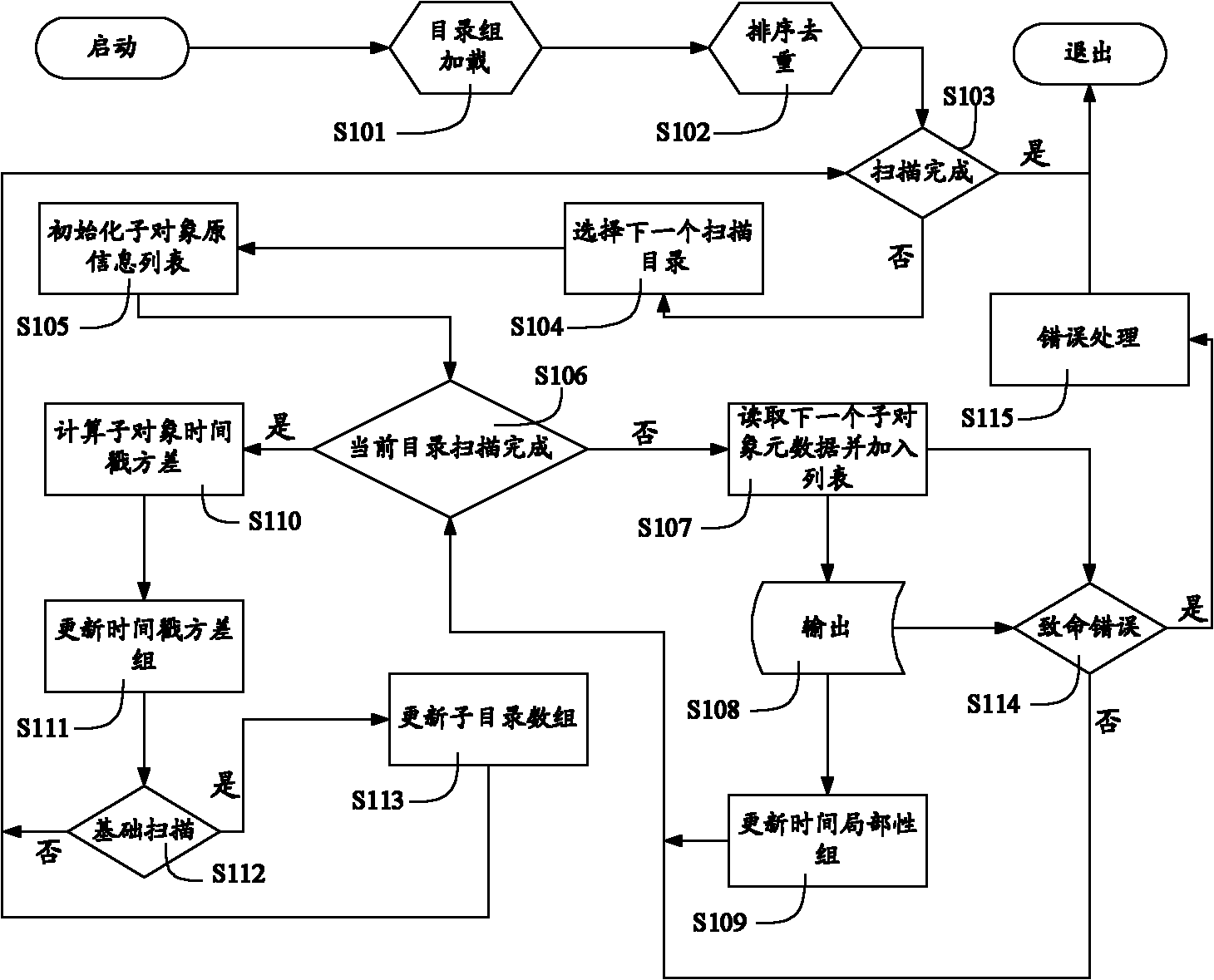

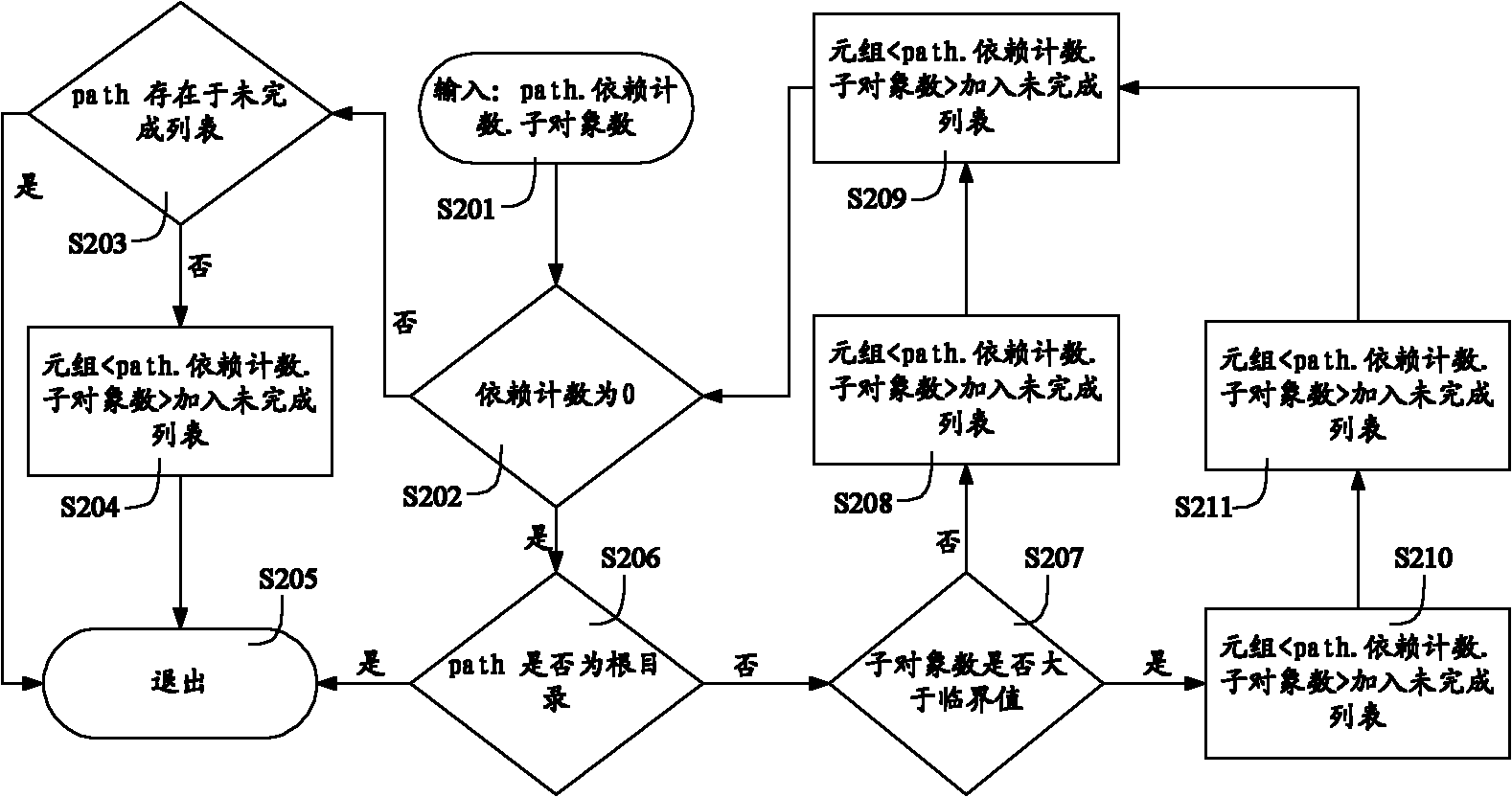

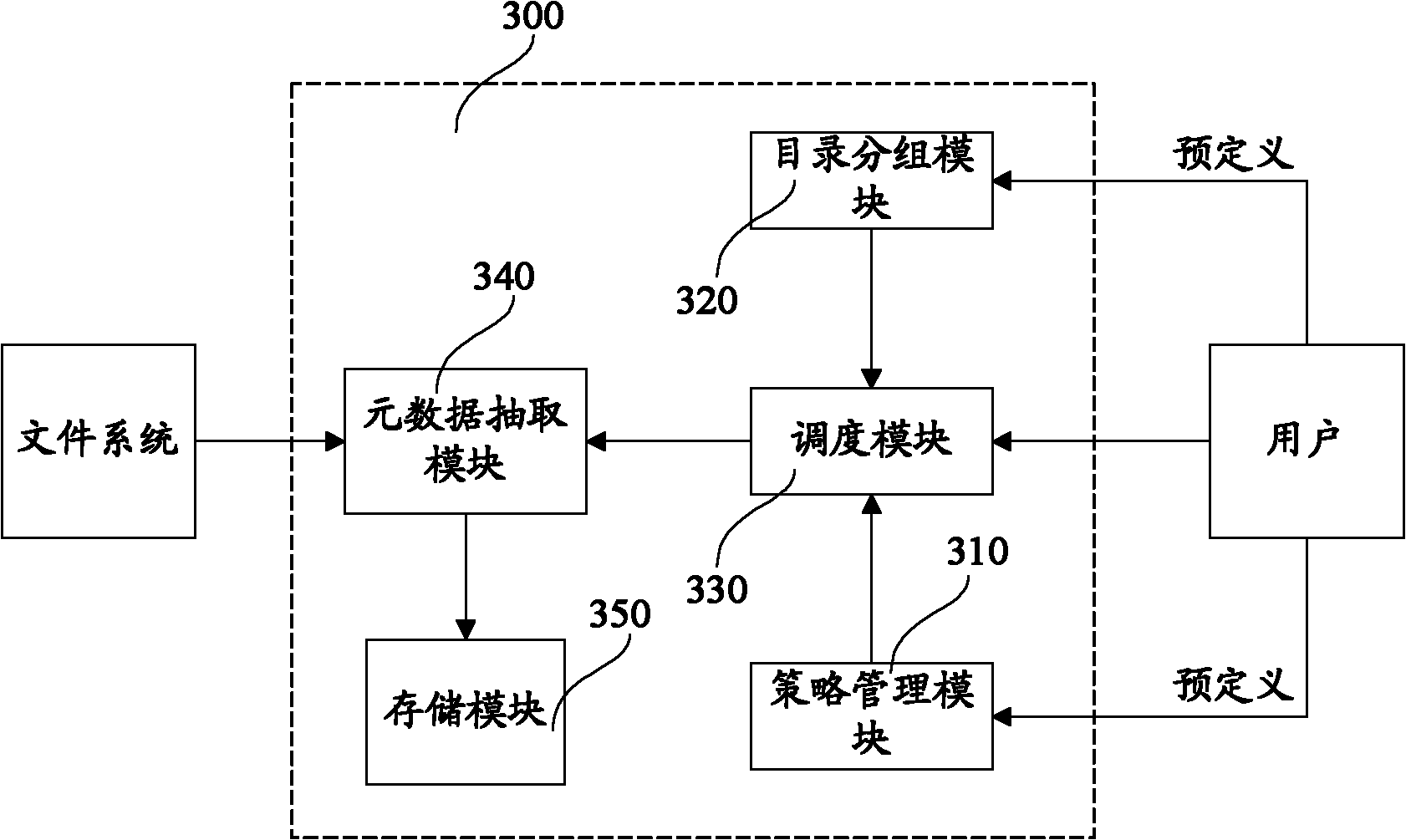

Method and device for extracting metadata of file system based on selective scanning

ActiveCN102110156AImprove extraction efficiencyReduce the number of directoriesSpecial data processing applicationsArray data structureFile system

The invention provides a method and device for extracting metadata of a file system based on selective scanning. The method comprises the following steps: A, defining a directory grouping mode; B, loading a directory group according to a scanning strategy; C, sorting and scanning directories; D, judging whether the scanning is completed, if not, selecting the directory to be scanned and initializing a subobject metadata list of the directories; E, judging whether the scanning is completed, if the scanning is not completed, reading the next subobject metadata and adding the metadata into the subobject metadata list, and updating a temporal locality directory group; F, if the scanning is completed, updating a time stamp variance directory group; and G, judging whether the current scanning is basic scanning, if the current scanning is the basic scanning, updating a subdirectory array of the current directory and executing the step D, and directly executing the step D if the current scanning is not the basic scanning. By applying the metadata extraction method in the embodiment of the invention, the extraction efficiency is greatly improved; besides, the method and device provided by the invention are simple in design and are easy to realize.

Owner:TSINGHUA UNIV

Apparatus and method for device selective scans in data streaming test environment for a processing unit having multiple cores

In a multi processor environment wherein the processors are capable of implementing a streaming data mode of operation, a technique is provided that reduces the number of bits shifted through the scan chain necessary to select a processor for operating in the streaming data mode. All test control device associated with the processor have an instruction entered therein. After execution of the instruction, all of the processors are entered in a bypass mode of operation. Then, a logic “0” in the bypass register will cause the associated target processor to enter the streaming data mode, while a logic “1” in the bypass register will cause the processor to enter the bypass mode. To select a new target processor, logic “1”s in the bypass register will reset the test control unit and thereafter the entry of a logic “1” will cause the non-target processors to enter the bypass mode, while a logic “0” in a bypass register will select the new target processor (i.e., for operating in the streaming data mode).

Owner:TEXAS INSTR INC

Method and apparatus for selective scan chain diagnostics

InactiveUS20060048028A1Shorten the timeReduce probabilityElectronic circuit testingShift registerElectronic chip

A method, apparatus and program product for testing at least one scan chain in an electronic chip in which the scan chain is formed by shift register latches arranged in the chain having a scan path with input pins and output pins. A flush test is executed for the scan chain under test and the flush test diagnostics for the flush test are recorded. A scan test is then executed for the scan chain under test and further test diagnostics are recorded in the event either or both the flush test or the scan test fails. The recorded flush test diagnostics and further test diagnostics are then analyzed to identify a call to one or more probable failed or failing shift register latches in the tested scan chain. The further scan chain diagnostics may include Disturb, Deterministic, ABIST, LBIST and Look-Ahead diagnostics. The tests may also be conducted for different voltage levels to determine the sensitivity of the scan chain being tested to differing voltage levels.

Owner:GOOGLE LLC

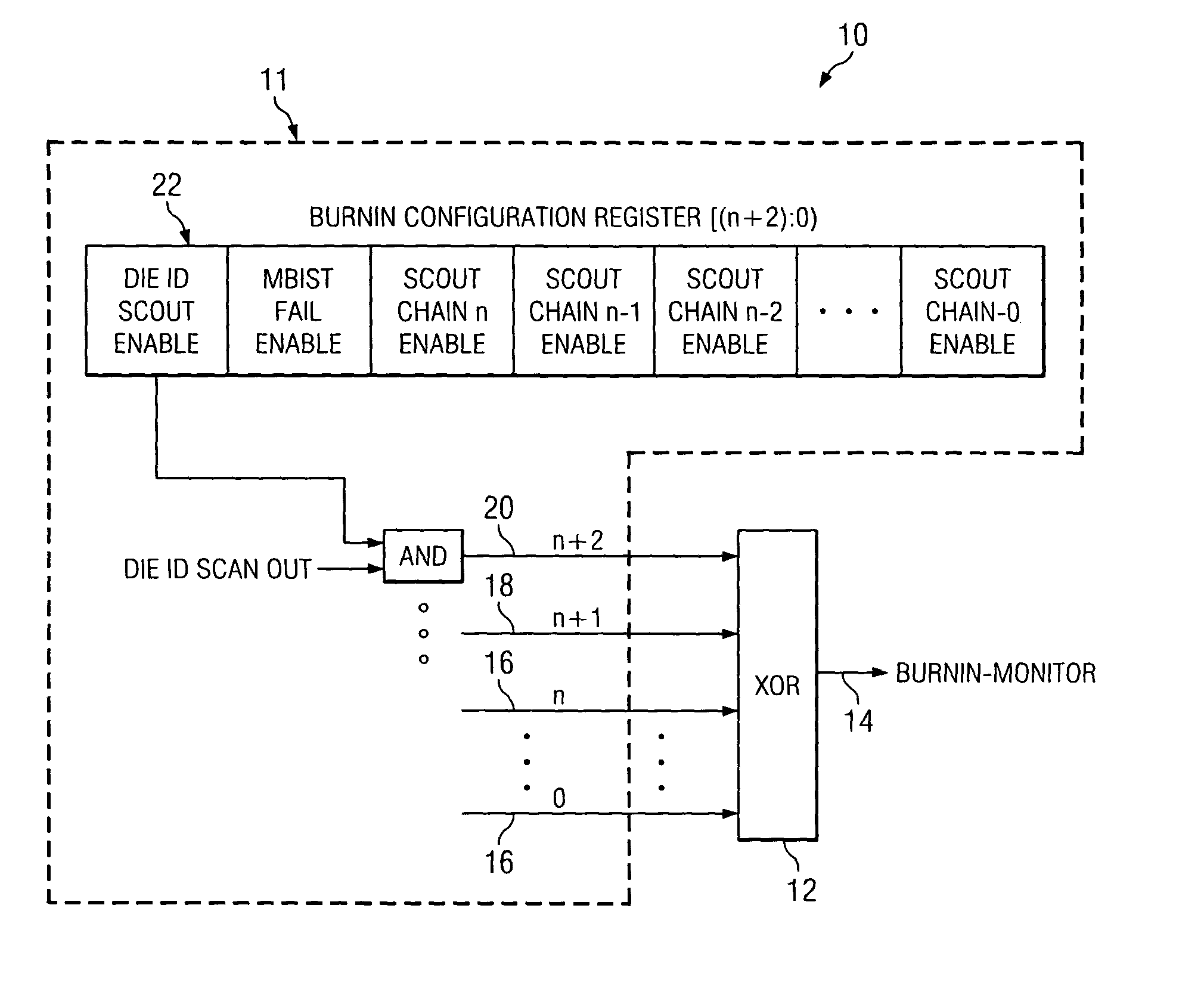

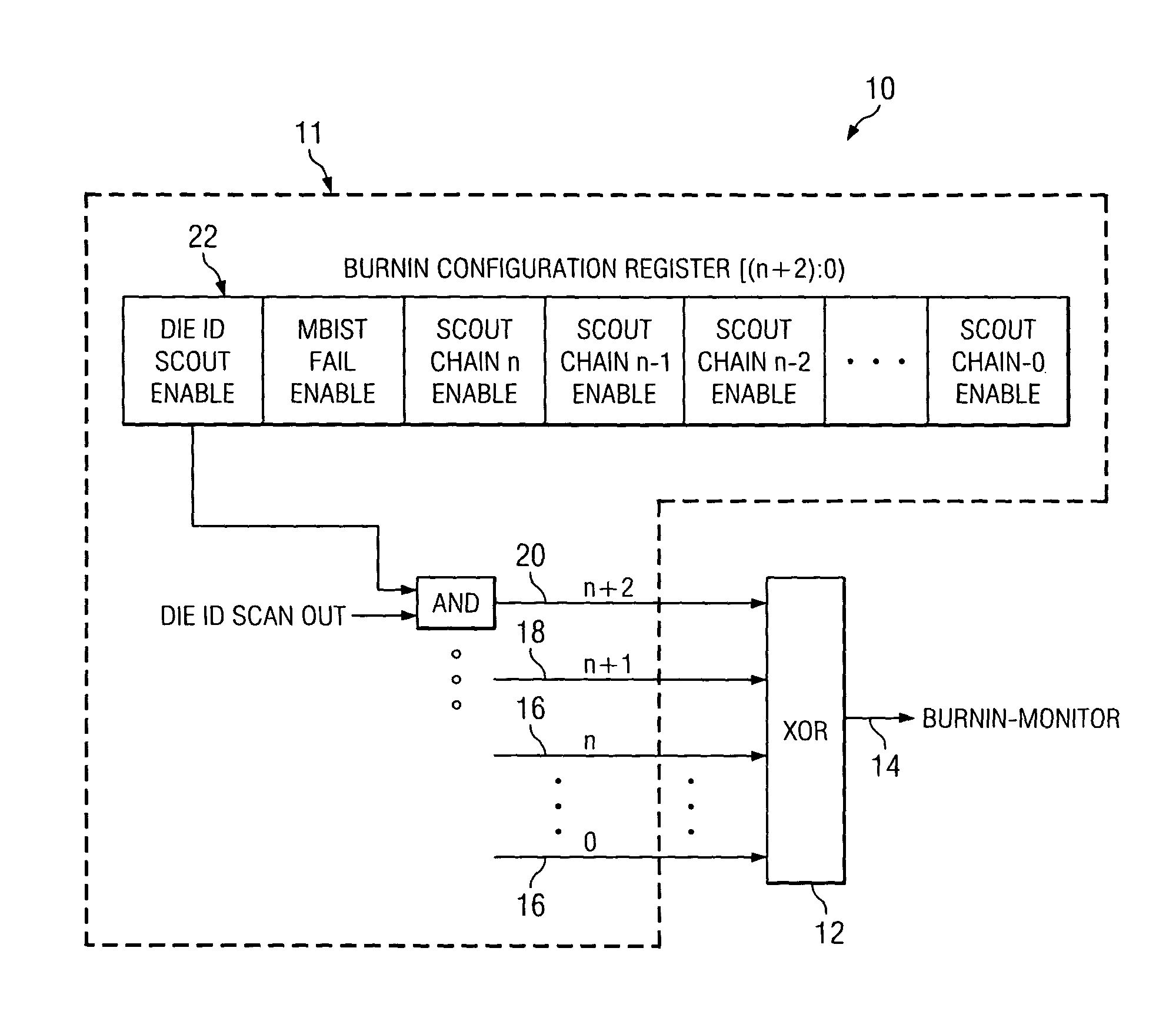

Mechanism to enhance observability of integrated circuit failures during burn-in tests

ActiveUS20050066243A1Expand the scope ofIncreased diagnostibilityDigital circuit testingStatic storageEngineeringAutomatic test pattern generation

A system and method enhance observability of IC failures during burn-in tests. Scan automatic test pattern generation and memory built-in self-test patterns are monitored during the burn-in tests to provide a mechanism for observing selective scan chain outputs and memory BIST status outputs.

Owner:TEXAS INSTR INC

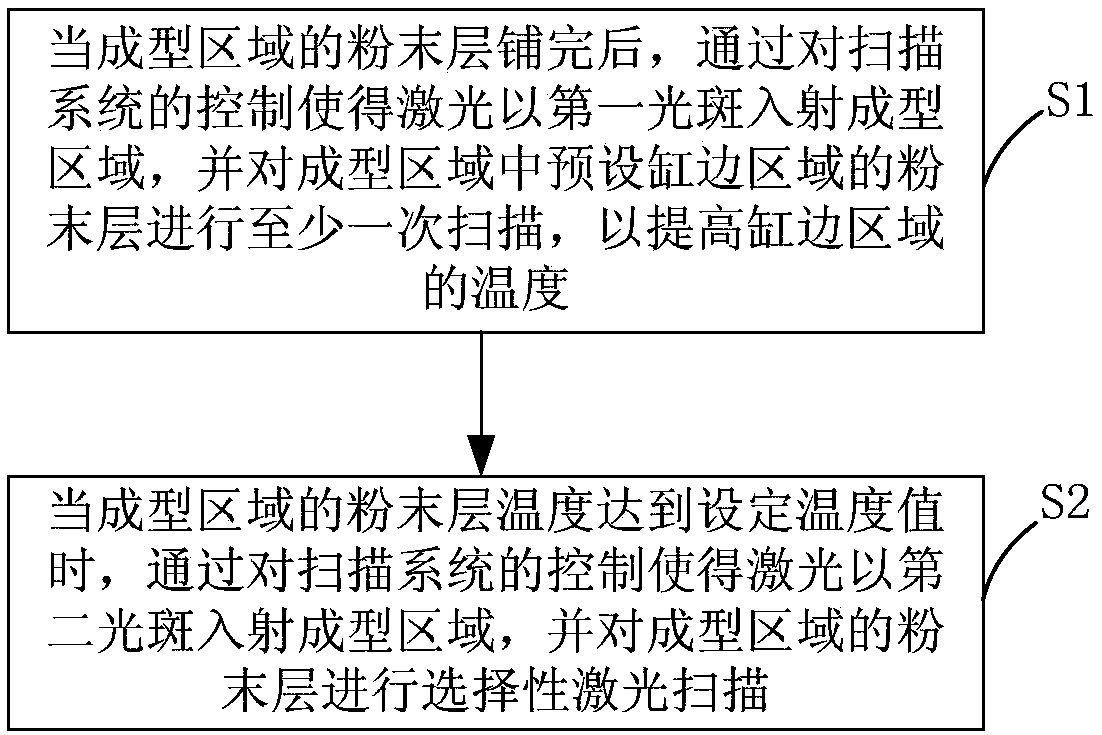

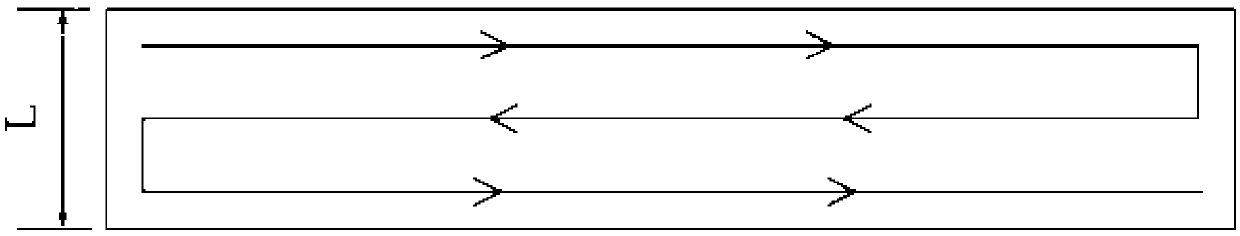

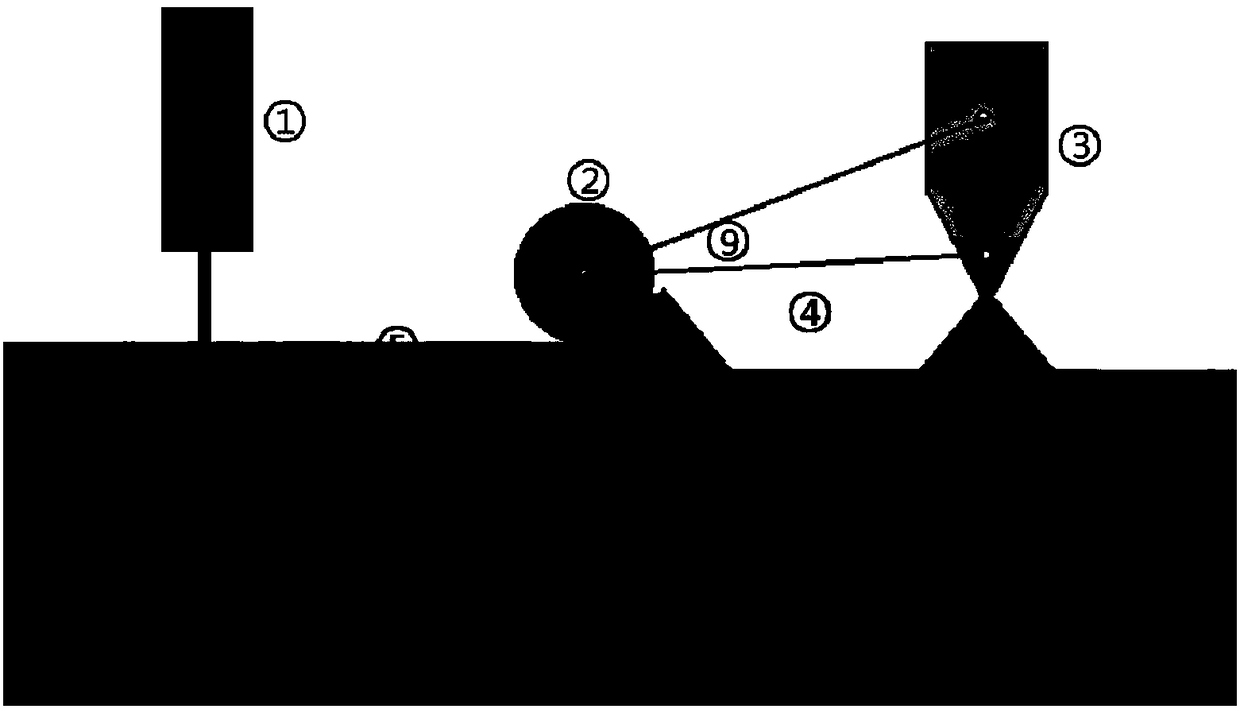

Three-dimensional object manufacturing device and method thereof as well as computer storage medium

ActiveCN109571942AIncrease temperatureIncrease the areaAdditive manufacturing apparatus3D object support structuresControl systemEngineering

The invention relates to a three-dimensional object manufacturing device and a method thereof as well as a computer storage medium. The device comprises a powder spreading device, an energy source, ascanning system, a heating system and a control system; the powder spreading device is used for spreading powder material on a bottom plate or a selectively-cured layer to form a powder layer; the energy source is used for generating lasers; the heating system is used for preheating the powder layer in a forming area; the control system is used for controlling the scanning system to enlarge lightspots of the lasers before the powder layer in the formed area is subjected to selective scanning and sintering, at least one-time scanning is carried out on the powder layer of a preset cylinder edgearea in the forming area through the lasers with the enlarged light spots under the control of the scanning system, so that the temperature of the cylinder edge area is improved. According to the three-dimensional object manufacturing device and the method thereof as well as the computer storage medium, the temperature of the edge area of a cylinder body is increased, then the area of the formingarea is effectively enlarged, so that the powder utilization rate is improved, and the structure is simple.

Owner:HUNAN FARSOON HIGH TECH CO LTD

Construction method of lunar base outer shell layer

InactiveCN108437153AAvoid high economic costsAvoid time costAdditive manufacturing apparatusCeramic shaping apparatusSelective laser sinteringLunar soil

The invention discloses a construction method of a lunar base outer shell layer. The method comprises the following steps of designing and slicing a three-dimensional model diagram of the lunar base outer shell layer; spreading powder along the outer side of a lunar base inner shell layer by a powder sending cylinder and a pressing roller; selectively scanning a powder spreading layer by a laser so as to form a sintered layer; lifting the laser, the pressing roller, the powder sending cylinder and an auxiliary device at the same time by the thickness of one layer by utilizing a mechanical armevery time after one layer is sintered, then sending powder, spreading powder, slicing and scanning with a laser beam so as to form a new sintered layer again, and combining with the previous sinteredlayer; and repeating the process, and overlaying layer by layer until the whole lunar base outer shell layer is constructed. According to the construction method, lunar soil is used for directly printing the lunar base outer shell layer by utilizing a selective laser sintering process, so that the transportation cost of construction materials transported from the earth to the moon is reduced, a constructed lunar base has good compactibility and is easy to repair after being damaged, and the mode that a plurality of laser printers are operated at the same time can be adopted, so that the construction time is shortened.

Owner:NANJING UNIV OF SCI & TECH

Method for preparing primary circuit by jet-printing metal conductive printing ink by virtue of laser or microwave processing

InactiveCN102398438AHigh purityImprove conductivityPrinting after-treatmentContinuous scanningMicrowave

The invention belongs to an ink jet printing (jet printing for short) circuit technology, relating to a primary circuit or microwave processing primary circuit prepared by jet-printing metal conductive printing ink by utilizing a laser sintering method, and aiming at degrading organic components in the printing ink and improving conductive properties of the obtained jet printing circuit. In the method for preparing the primary circuit by printing the metal conductive printing ink by virtue of laser or microwave processing, laser continuous scanning, exposing and sintering, selective scanning, exposing and sintering, overall exposing and sintering or selective exposing and sintering are carried out on the primary circuit prepared by jet-printing the metal conductive printing ink, or the primary circuit prepared by jet-printing the metal conductive printing ink is sintered by virtue of microwave processing, so as to improve electric conductivity of the jet-printed circuit; the jet-printed primary circuit is processed by utilizing the laser with high speed, high efficiency and positioning accuracy, thus being applicable to extensive printing boards or films; and requirements on material and shape (hard board or film) of the printing board or film are not strict, and thus the method is applicable to automation.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Three-dimensional circuit manufacturing method and thermosetting spraying solution

ActiveCN104244587AFast preparationRapid Surface MetallizationConductive pattern formationCoatingsSelective laser sinteringChemical plating

The invention discloses a three-dimensional circuit manufacturing method. The method comprises the steps that a prototype model is generated through a selective laser sintering method; spraying treatment and curing are carried out on the surface of the prototype model through a thermosetting spraying solution containing a soluble metal complex, and a coating film with the surface capable of being activated by laser is formed; the laser is used for carrying out preset selective scanning on the coating film to form a surface activation area; a conductive circuit is formed on the surface activation area through chemical plating. On the basis that the prototype model is obtained through the selective laser sintering method, the surface of the prototype model is coated with the coating film through the thermosetting solution, the limitation brought by traditional SLS processing materials on the application is overcome, a matrix with the complex surface is formed with no appearance limitation, and the requirements for rapid manufacturing and forming of the conductive circuit and laser activation are effectively met.

Owner:SHENZHEN SUNSHINE LASER & ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com