Construction method of lunar base outer shell layer

A construction method and a technology for a shell layer, applied in manufacturing tools, ceramic molding machines, additive processing, etc., can solve the problems of consumption, high cost, a lot of manpower and machinery, and achieve the effect of avoiding economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A method for building the outer shell of a lunar base, using the following measures:

[0028] 1) Relevant preparations:

[0029] a. According to the amount of powder used in the outer shell of the lunar base, collect enough lunar soil and prepare for screening;

[0030] b. Using methods such as solar power or nuclear power to provide sufficient energy for construction operations;

[0031] c. Preparation of related equipment and facilities such as laser printers and lunar vehicles for powder transportation;

[0032] d. The hardening treatment of the lunar surface around the lunar base.

[0033] 2) Use 3D modeling software to design a 3D solid model diagram of the outer shell of the lunar base;

[0034] 3) Use layered slicing software to slice the three-dimensional model of the outer shell of the lunar base along a specific direction in real time;

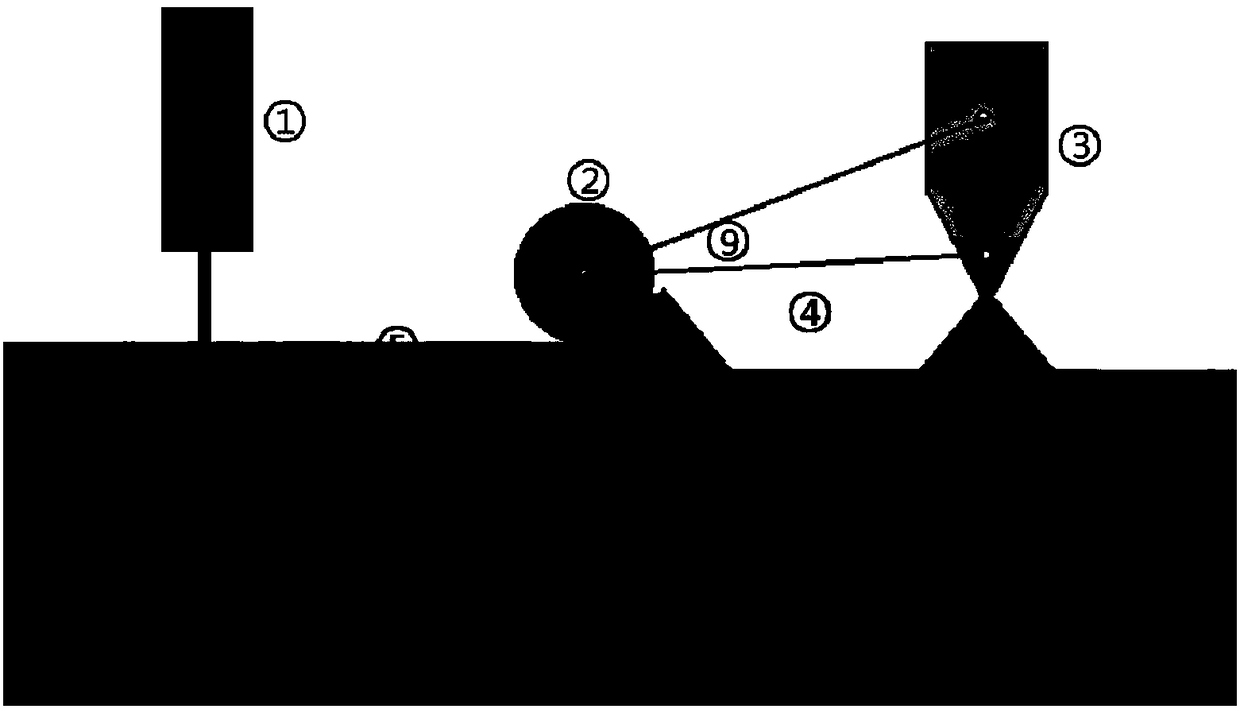

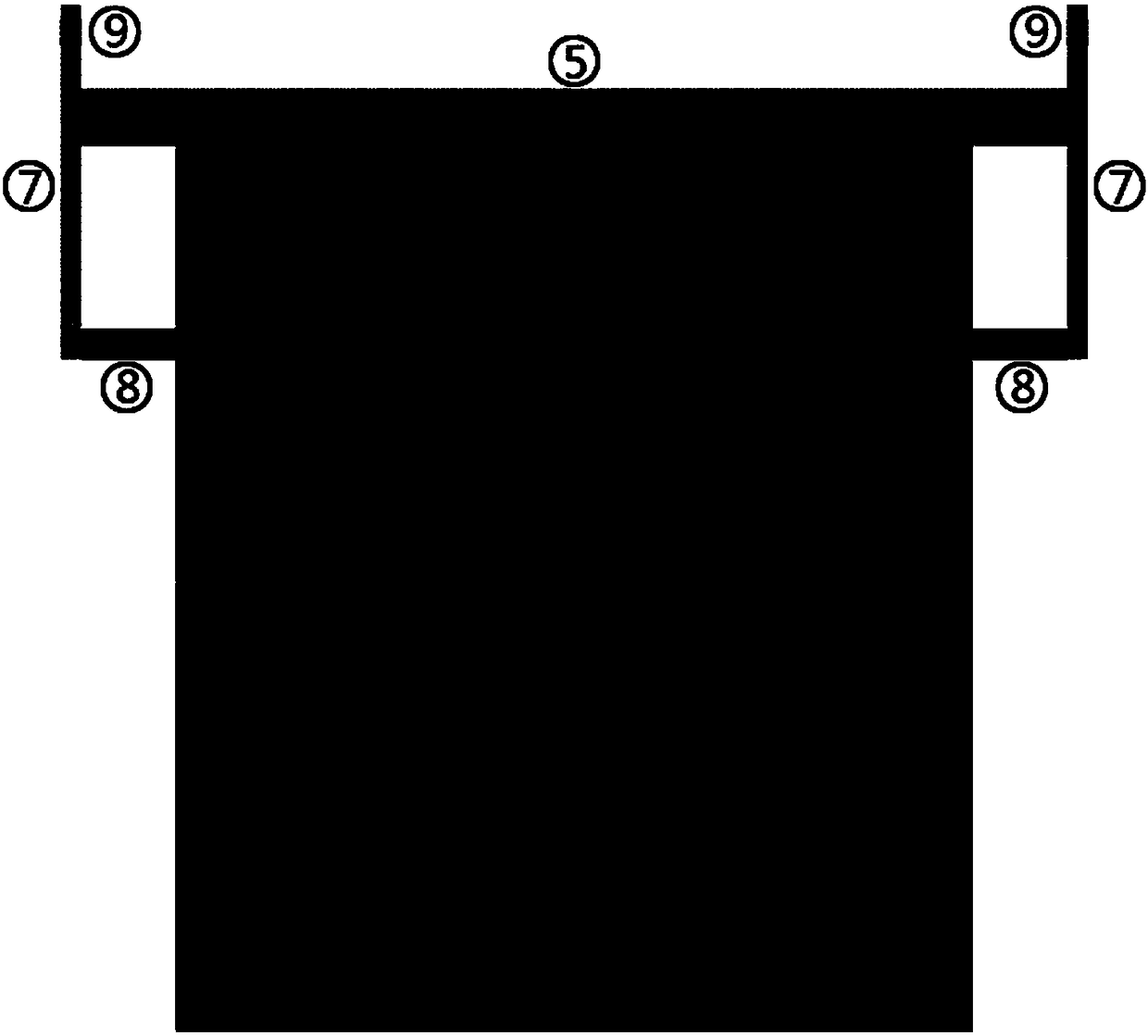

[0035] 4) The powder delivery cylinder 3 unloads the powder at intervals, and the pressing roller 2 immediately flattens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com