Method for preparing primary circuit by jet-printing metal conductive printing ink by virtue of laser or microwave processing

A primary circuit, metal conductive technology, applied in the post-processing, printing and other directions of printing, can solve problems such as difficult application, difficult operation, high price, etc., to achieve a wide range of substrates or films, improve conductivity, and increase the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

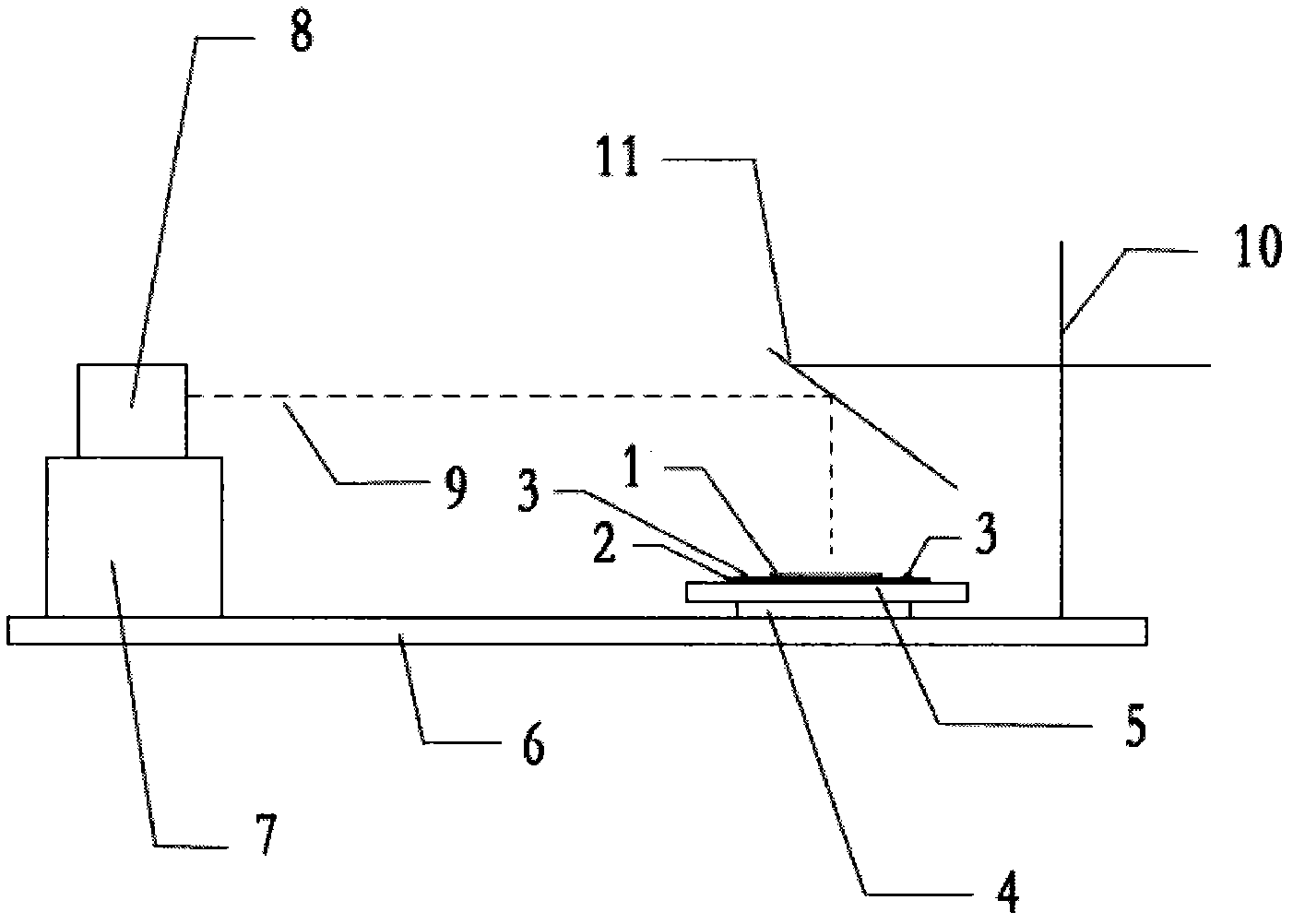

[0057] See figure 2 The shown device for continuous scanning exposure sintering primary circuit: a base 7 is installed on one side of an optical table 6, and a laser 8 is installed on the base 7; The stage of the X-direction electric translation stage 4 and the Y-direction electric translation stage 5, on which the substrate / film 2 carrying the primary circuit 1 is placed, and the substrate / film 2 carrying the primary circuit 1 can be Fixed on the object stage capable of electric translation in the X direction and the Y direction through the fixing buckle 3; a support frame 10 is installed on the optical table 6 on the side of the object stage; a mirror 11 is installed on the support frame 10, And the reflector 11 is located above the stage, and can make the laser beam 9 emitted by the laser head 8 be perpendicular to the stage after being reflected by the reflector. The method of using the device for continuous scanning exposure sintering primary circuit is as follows:

[...

Embodiment 2

[0062] 1) According to the preset circuit pattern by the inkjet printer, the metallic silver conductive ink (NanoMas Technologies, Inc., NMTI NanoGold Inks (NTG05)) with a mass fraction of 20% and a particle size of 20nm was electrostatically printed on the On the polycarbonate film, the primary circuit with a film thickness of 0.4 μm formed by the above-mentioned conductive ink is obtained on the polycarbonate film, and the PET polyester film carrying the primary circuit is fixed on the stage;

[0063] 2) Position the laser head at the starting point of the primary circuit in step 1), use a computer program to control the laser beam (wavelength: 432nm; power: 1w) emitted by the laser head, follow step 1) when the inkjet printer is printing the circuit pattern The running track moves, and the moving speed of the laser beam emitted by the laser head is 30cm / s; the laser beam emitted by the laser head only selects the primary circuit on the polycarbonate film on the stage 1) Sca...

Embodiment 3

[0067]1) According to the preset circuit pattern by the inkjet printer, the metal copper conductive ink (NovaCentrix. On the imide plate, obtain a primary circuit with a film thickness of 40 μm formed by the above-mentioned conductive ink on the polyimide plate, and fix the polyimide plate with the primary circuit on the stage;

[0068] 2) Position the laser head at the starting point of the primary circuit in step 1, use a computer program to control the laser beam (wavelength: 1064nm; power: 1.5w) emitted by the laser head, and the moving speed of the laser beam emitted by the laser head is 50cm / s, the spot where the laser beam emitted by the laser head falls on the primary circuit is obtained by vertically and directly irradiating the primary circuit with the laser beam emitted by the laser head;

[0069] Use the laser beam emitted by the laser head to continuously scan the polyimide plate on the stage 1) carrying the primary circuit, control the laser beam emitted by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com