Tea leaf forming machine

A molding machine and tea technology, which is applied in tea processing before extraction, etc., can solve the problems of not being able to adapt to high-grade tea molding production, unable to form batch production, and large influence of human operation, so as to achieve good compression molding effect and reduce the overall volume of the equipment , using flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

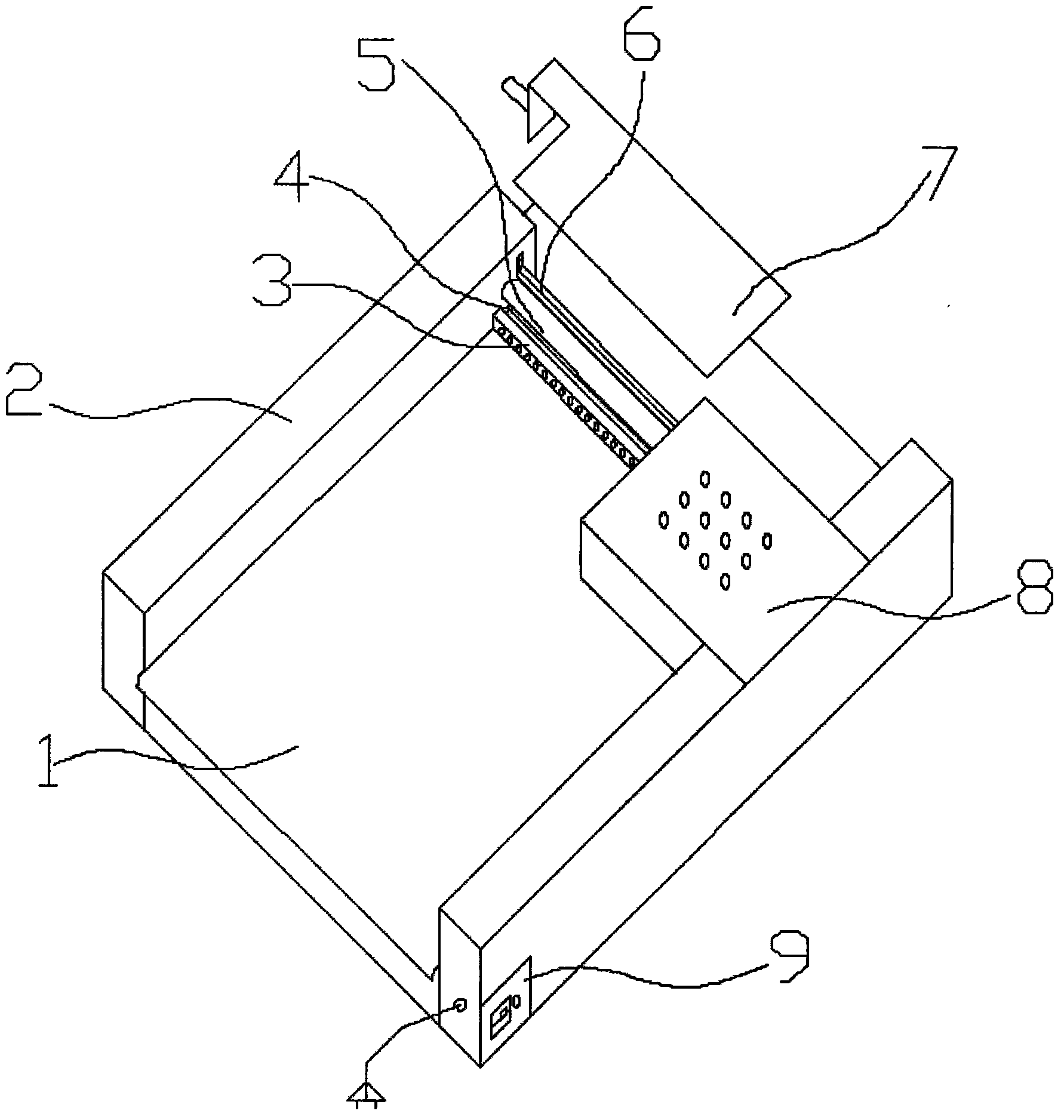

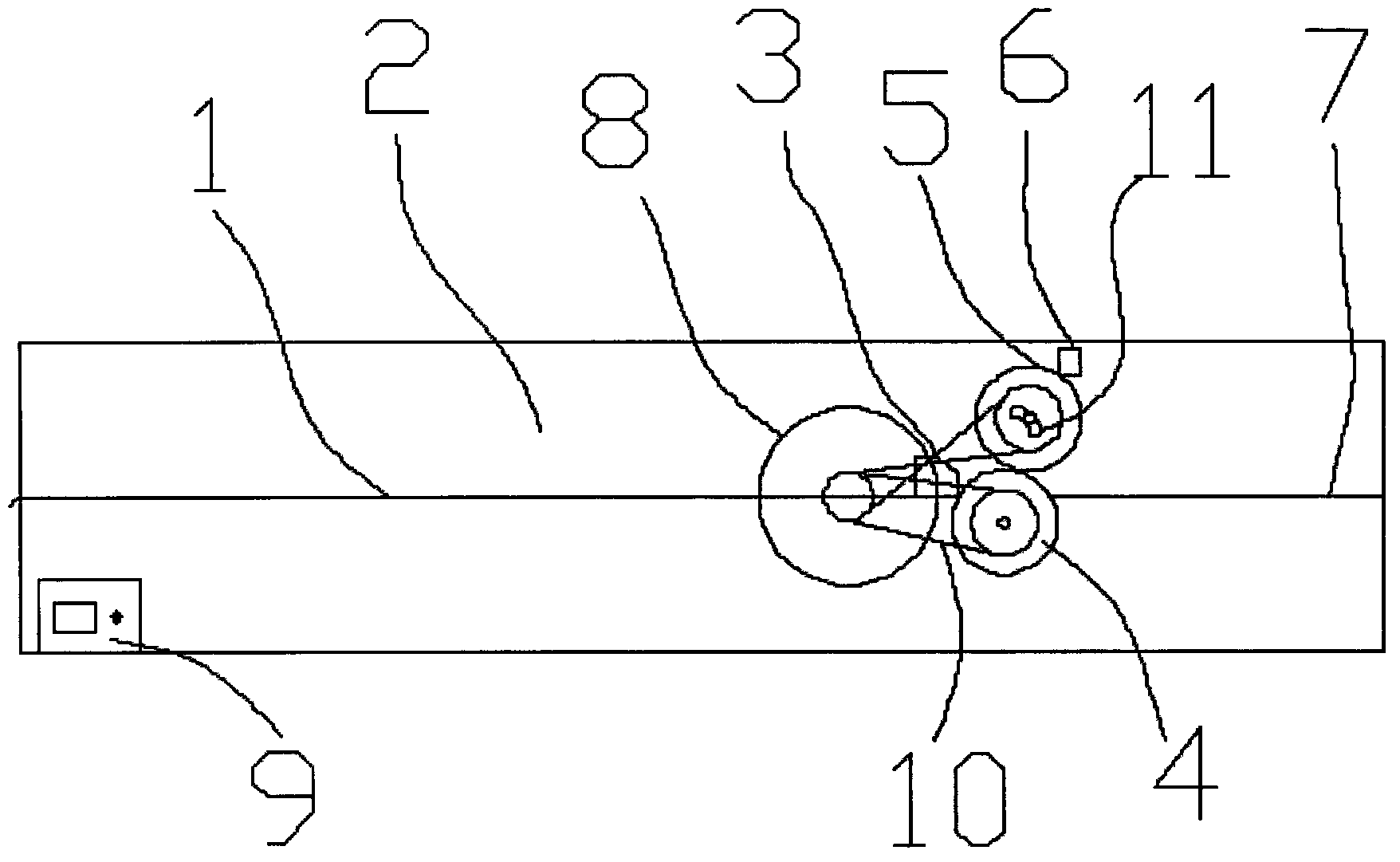

[0017] The present invention will be further explained below in conjunction with the drawings.

[0018] As attached figure 1 , Attached figure 2 As shown, a new type of tea forming machine, the longitudinal sides of the feeding platform 1 are racks 2, the upper surface of the feeding platform 1 is located in the horizontal center position of the rack 2, and the feeding platform 1 has an opening horizontally with the width of the lower opening The diameter of the pressing roller 4 is the same, and the opening length is the same as the length of the lower pressing roller 4; the two ends of the lower pressing roller 4 are connected to the fixed bearings on the frame 2, the lower pressing roller 4 is connected with the driving device 8 through the transmission mechanism 10; the upper pressing roller 5 is two The end is equipped with bearings, which are installed on the pressure adjusting mechanism 11, and the pressure adjusting mechanism 11 is installed on the frame 2 on both sides;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com