Shaping method of sealing gasket between windows and covering cap of cone-cylinder-shaped thermal shield

A molding method and technology of heat shield, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as cracks, low reliability of sealing, loss of elasticity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

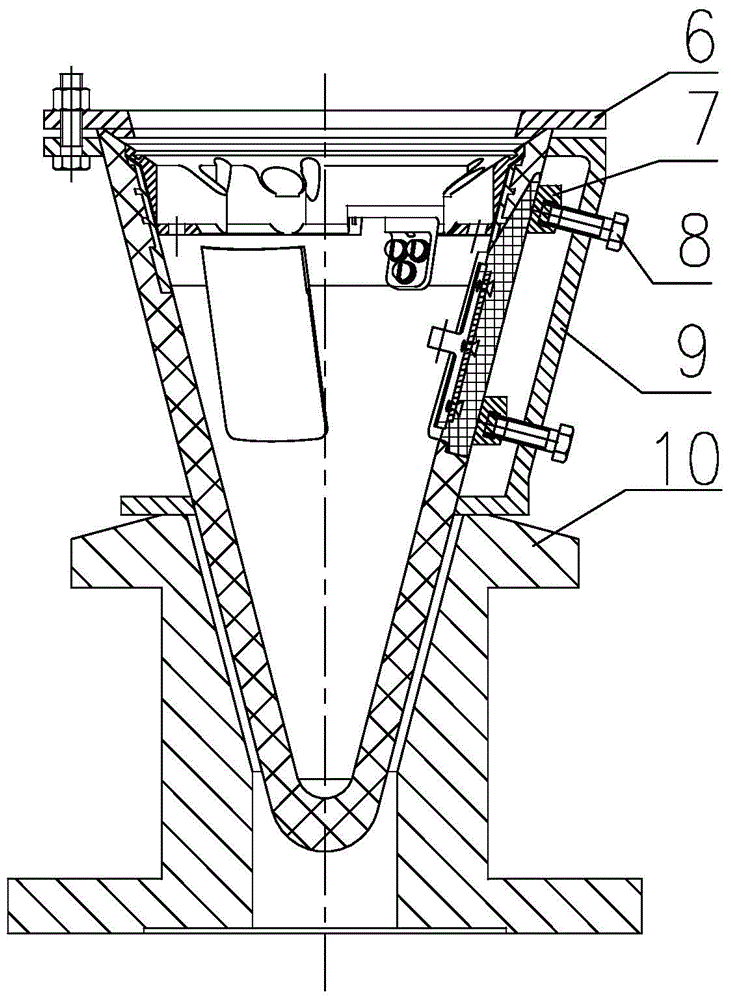

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

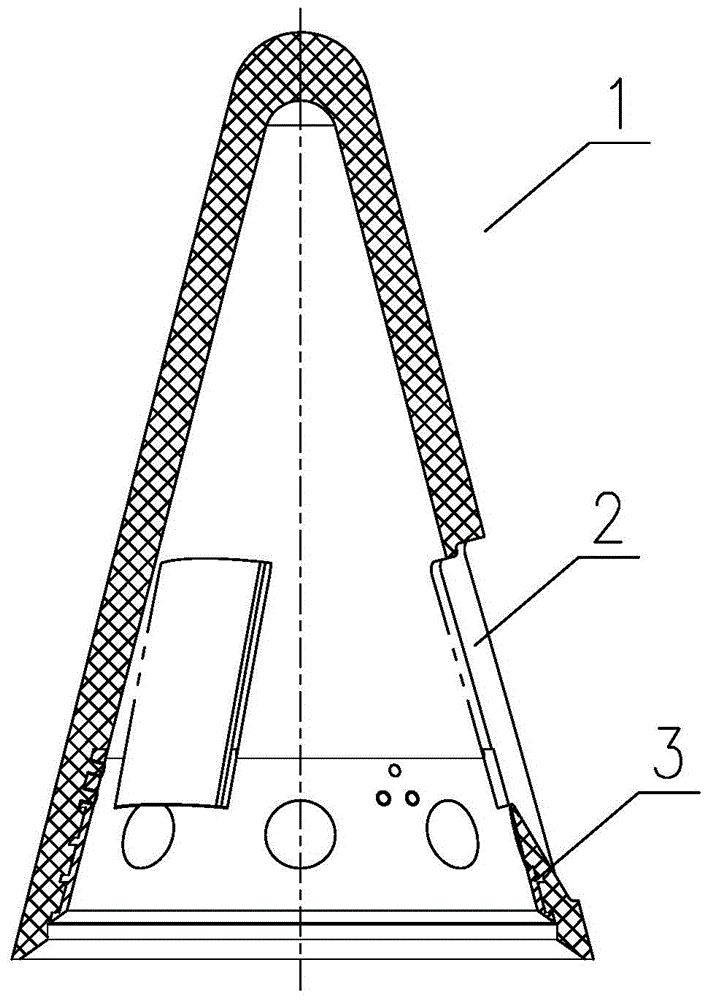

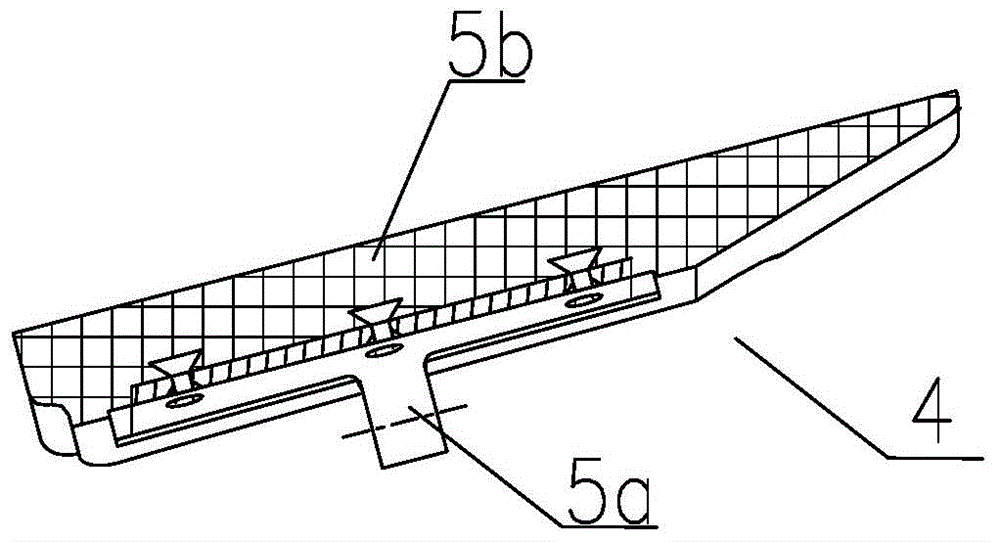

[0030] like figure 1 As shown, for a missile throwing system, the heat shield has a wall thickness of 20mm, a taper of 14.5°, a large end opening diameter of Φ302mm, and a height of about 470mm. The forming method steps of the gasket are as follows:

[0031] Step 1): The heat shield 1 is integrally molded by the glass fiber reinforced plastic body and the metal insert connecting ring 3, specifically: the heat shield 1 is formed by a four-column-guided high-precision mold at one time to ensure that the metal insert connecting ring at the large end of the heat shield 1 The relative position and coaxiality between 3 and the cover body, while ensuring the net size of the inner and outer cones of the heat shield 1, creates necessary conditions for the subsequent alignment and processing of the window 2. The heat shield 1 is made of high silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com