Unsymmetrical-cross section special-shaped line production machining technique for bicycle transmissions

A processing technology and transmission technology, applied in the direction of wire drawing die, etc., to achieve high precision, good dimensional stability, and good surface lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A process for producing and processing a cross-section asymmetric profiled wire for a bicycle transmission, comprising the following steps:

[0021] (1) Material selection: The material of the model SCM415 produced abroad is selected as the base material.

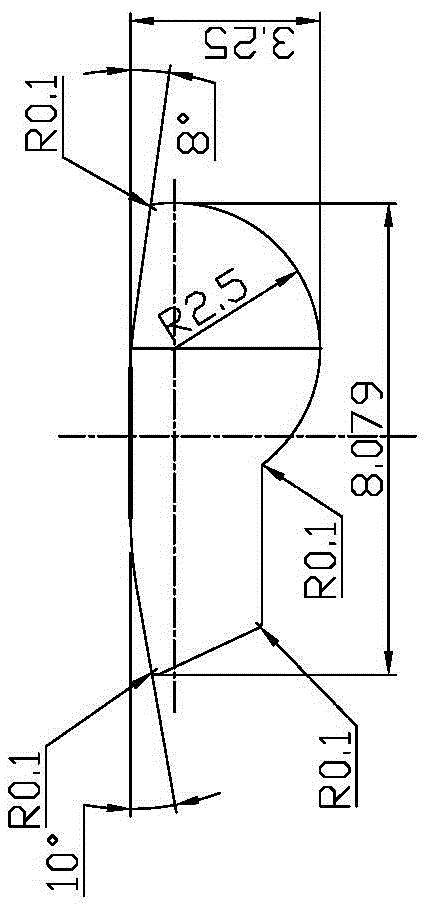

[0022] (2) Molding: Using the technology of roller drawing + die drawing, first use the roller drawing technology to produce semi-finished products, and then use the die drawing technology to determine the final finished product. The roller drawing speed is controlled at 0.8m / s, and the die drawing speed is controlled at 2.0 m / s, and the working taper of the drawing die used for die drawing is 8°, the length of the sizing belt is 3mm, and the rounded corner of the die is 0.1mm.

Embodiment 2

[0024] A process for producing and processing a cross-section asymmetric profiled wire for a bicycle transmission, comprising the following steps:

[0025] (1) Material selection: The material of the model SCM415 produced abroad is selected as the base material.

[0026] (2) Molding: Using the technology of roller drawing + die drawing, first use the roller drawing technology to produce semi-finished products, and then use the die drawing technology to determine the final finished product. The roller drawing speed is controlled at 1.0m / s, and the die drawing speed is controlled at 2.4 m / s, and the working taper of the drawing die used for die drawing is 8°, the length of the sizing belt is 3mm, and the rounded corner of the die is 0.1mm.

Embodiment 3

[0028] A process for producing and processing a cross-section asymmetric profiled wire for a bicycle transmission, comprising the following steps:

[0029] (1) Material selection: The material of the model SCM415 produced abroad is selected as the base material.

[0030] (2) Forming: Using the technology of roller drawing + die drawing, first use the roller drawing technology to produce semi-finished products, and then use the die drawing technology to determine the final finished product. The roller drawing speed is controlled at 1.2m / s, and the die drawing speed is controlled at 1.8 m / s, and the working taper of the drawing die used for die drawing is 8°, the length of the sizing belt is 3mm, and the rounded corner of the die is 0.1mm.

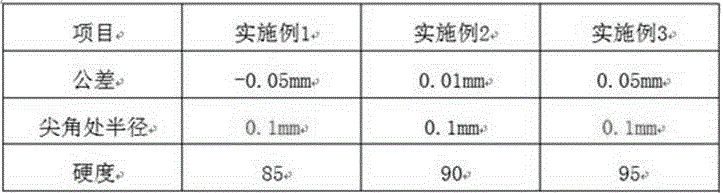

[0031] The products obtained after the above-mentioned various embodiments are processed for tolerance, sharp corner radius and hardness inspection. The inspection methods for tolerance, sharp corner radius and hardness are existing mature t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com