Fabric profiling mold

A technology for profiling molds and fabrics, which is applied to non-woven fabrics, textiles and papermaking, layered products, etc., can solve the problems of low profiling accuracy, low reusability, and unfavorable work efficiency of prefabricated bodies, and achieves high efficiency. The effect of profiling, convenient and fast processing, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

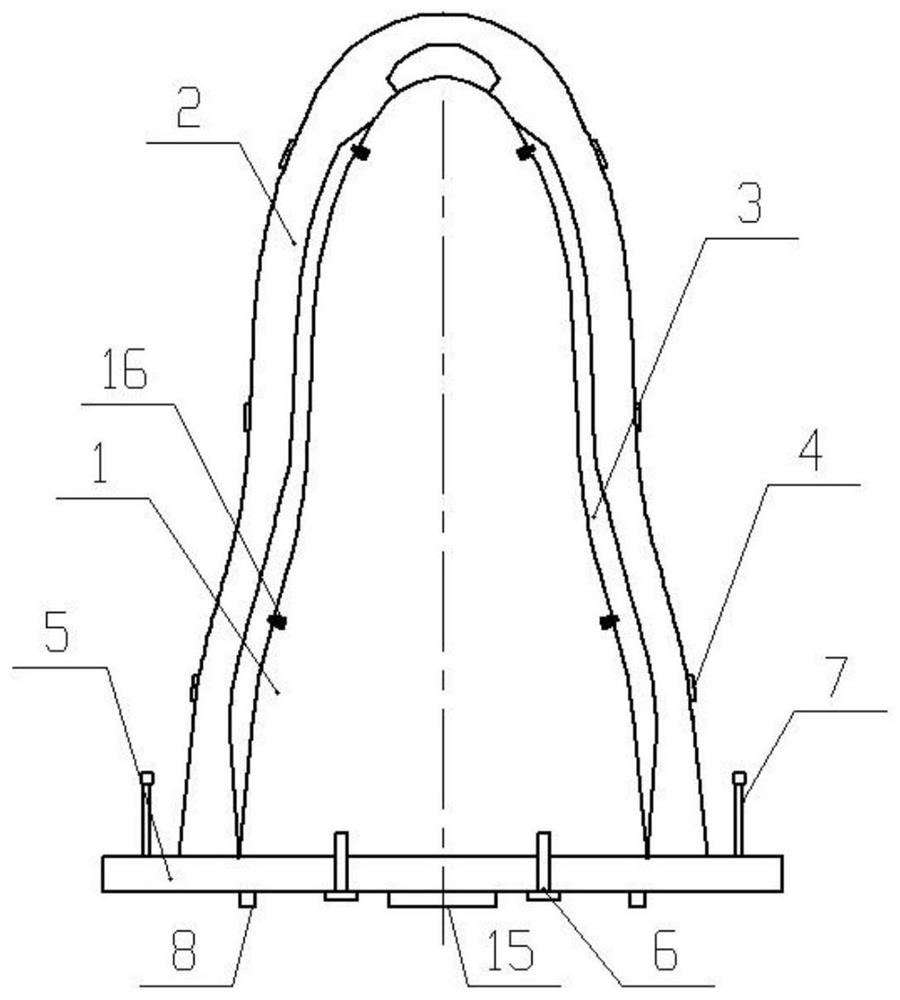

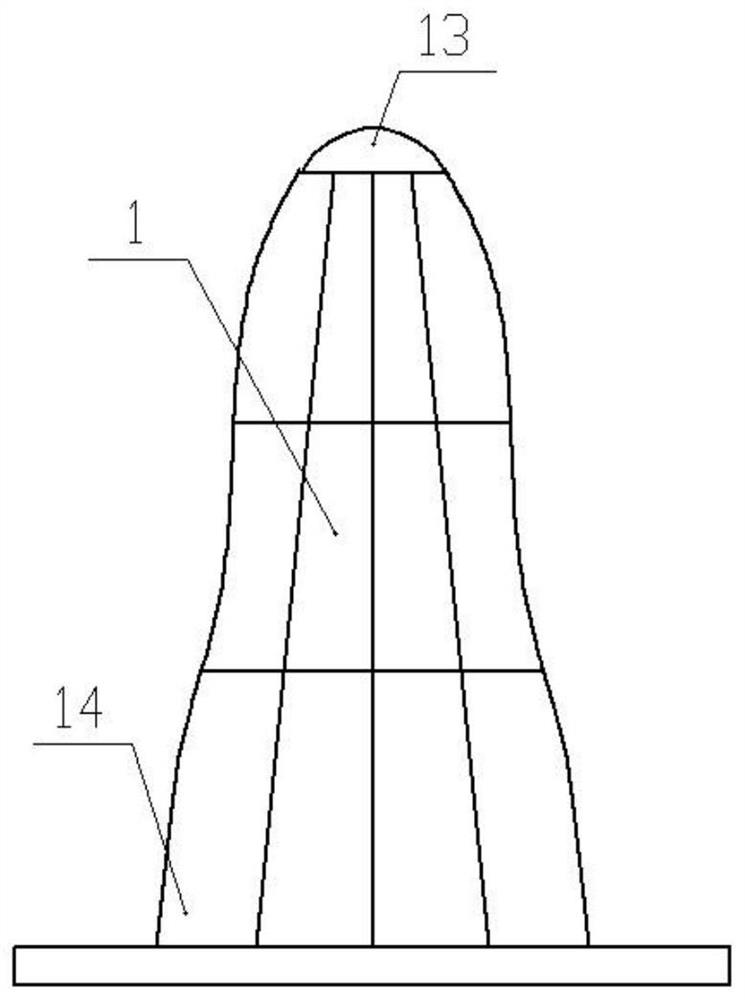

[0033] A fabric profiling mold, comprising an inner rigid mandrel 1, an outer flexible cushion 2, a middle variable rigid cushion 3, a stable chassis 5,

[0034] The bottom of described inner layer rigid mandrel 1 is fixedly connected with stable chassis 5, and described middle layer becomes rigid pad 3 is arranged between inner rigid mandrel 1 and outer flexible pad 2. After the mold is formed, its shape is exactly the same as that of the prefabricated body, and the error is not more than 1mm.

[0035] Further, the shape of the mold includes but not limited to a regular body of revolution, a body of revolution with variable cross-section, and a solid body with variable cross-section.

[0036] Further, the material of inner layer rigid mandrel 1 is selected to have certain rigidity, not easily deformed, the material that is easy to machine, including but not limited to iron, aluminum, copper. Its shape is contracted according to the shape of the prefabricated body, and the su...

Embodiment 2

[0052] Such as Figure 5 As shown, a profiling mold for acupuncture preforms includes 1-inner rigid mandrel, 2-outer flexible cushion, 3-middle variable rigid cushion, 5-stable chassis, 7-position calibration device, When the inner rigid mandrel 1 is formed by splicing multiple pieces, the inner rigid mandrel 1 includes a central axis mounting hole, a mold positioning hole 10, and an electrical component mounting hole. Through the central axis mounting hole, it is ensured that the mold can be fixed on the On the central axis; the positioning pin and the mold positioning hole 10 are used to ensure the accurate position of the mold; the installation holes of electrical components are convenient for the control components to be embedded in the fabric. The material of the outer flexible cushion layer 2 is organic material, spliced in pieces, and the single cushion layer is integrally formed.

[0053] Among them, the middle variable rigid cushion layer 3 and the outer flexible c...

Embodiment 3

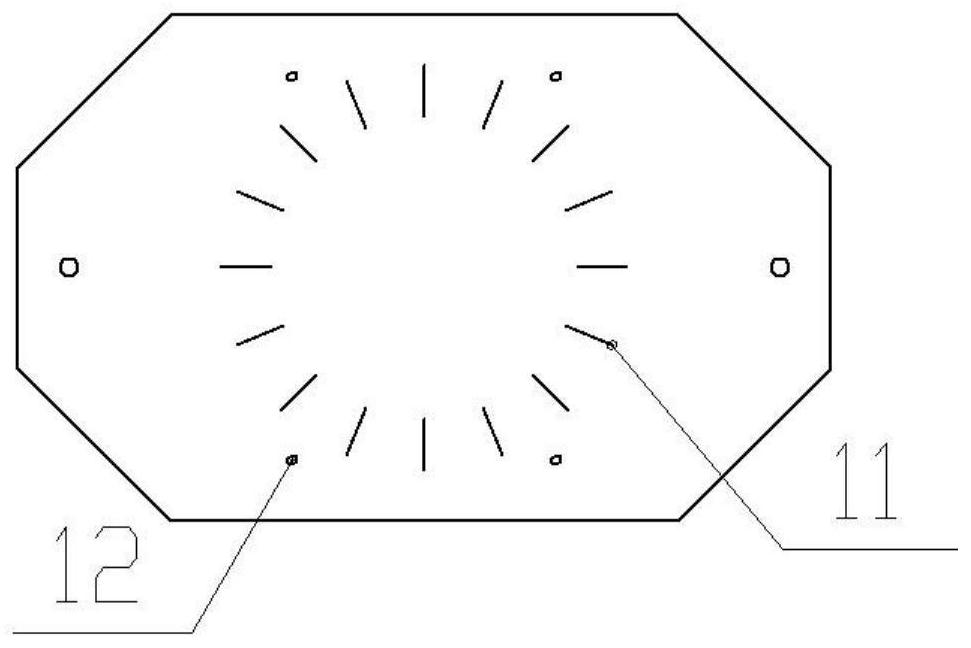

[0057] Such as Figure 6-8 As shown, this embodiment is a kind of three kinds of middle layer variable rigid cushion of acupuncture preform profiling mold, including 1-triangular variable rigid cushion, 2-square variable rigid cushion, 3-honeycomb variable rigid cushion layer.

[0058] Among them, three different rigid materials are filled in the triangular variable-rigidity cushion, and each filling unit is connected by side wall hook and loop to ensure the connection rigidity and can be disassembled at any time. The side wall of the filling unit is made of soft materials, such as EVA, etc. Made of high-quality materials, the shape of the cushion has good plasticity.

[0059] Among them, three different rigid materials are filled in the square variable-rigidity cushion respectively, and pins are used to connect each filling unit to ensure the connection rigidity and can be disassembled at any time. The side walls of the filling unit are made of hard materials, such as plexig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com