Bending radius-adjustable corrugated steel web mould pressing die

A technology of corrugated steel web and bending radius, which is applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low production efficiency of corrugated steel web, poor precision of finished products, adjustment of molding dies, etc., and achieve scale Production, reduce equipment cost, improve the effect of manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

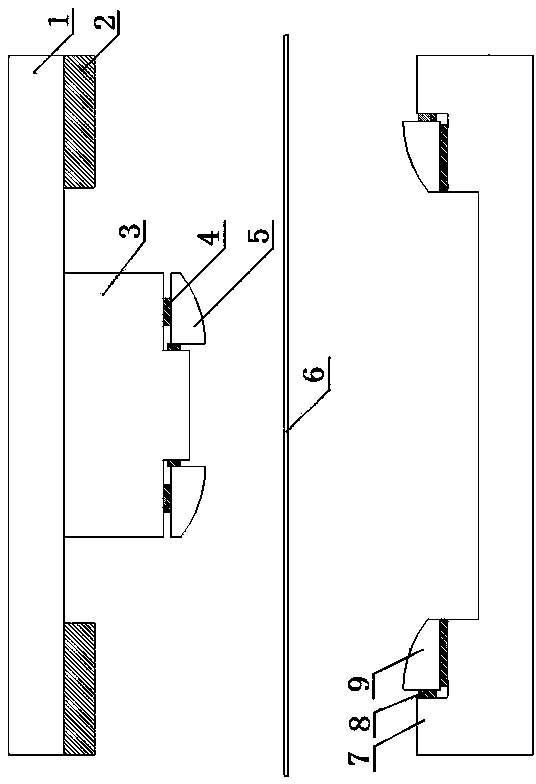

[0022] Below in conjunction with accompanying drawing, the present invention is further described:

[0023] A corrugated steel web molding die with adjustable bending radius, comprising a punching head 3 connected with a top seat 1, and a base 7 arranged under the top seat 1 corresponding to the top seat 1 and the punching head, the said The top seat 1 on both sides of the punching machine head 3 is fixed with a top seat pressing plate 2 by bolts; the tail of the punching machine head is welded and fixed with the top seat 1, and the head is connected with an upper stamping die 5; the base 7 is provided with a lower stamping die 9;

[0024] The head of the described punching head 3 is T-shaped, the T-shaped flange and the rib are provided with punching head fixing bolt holes, and the upper punching die 5 and the punching head 3 are located at the punching head 3 through bolts. The inner punching head fixing bolt holes are fixedly connected together;

[0025] The base 7 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com