Full automatic chocolate button forming machine

A bean forming machine and chocolate technology, applied in the field of automatic chocolate bean forming machines, can solve the problems of low production efficiency, bad taste, complicated equipment, etc., achieve low labor intensity, improve the scope of application of equipment, production efficiency, and hygiene. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

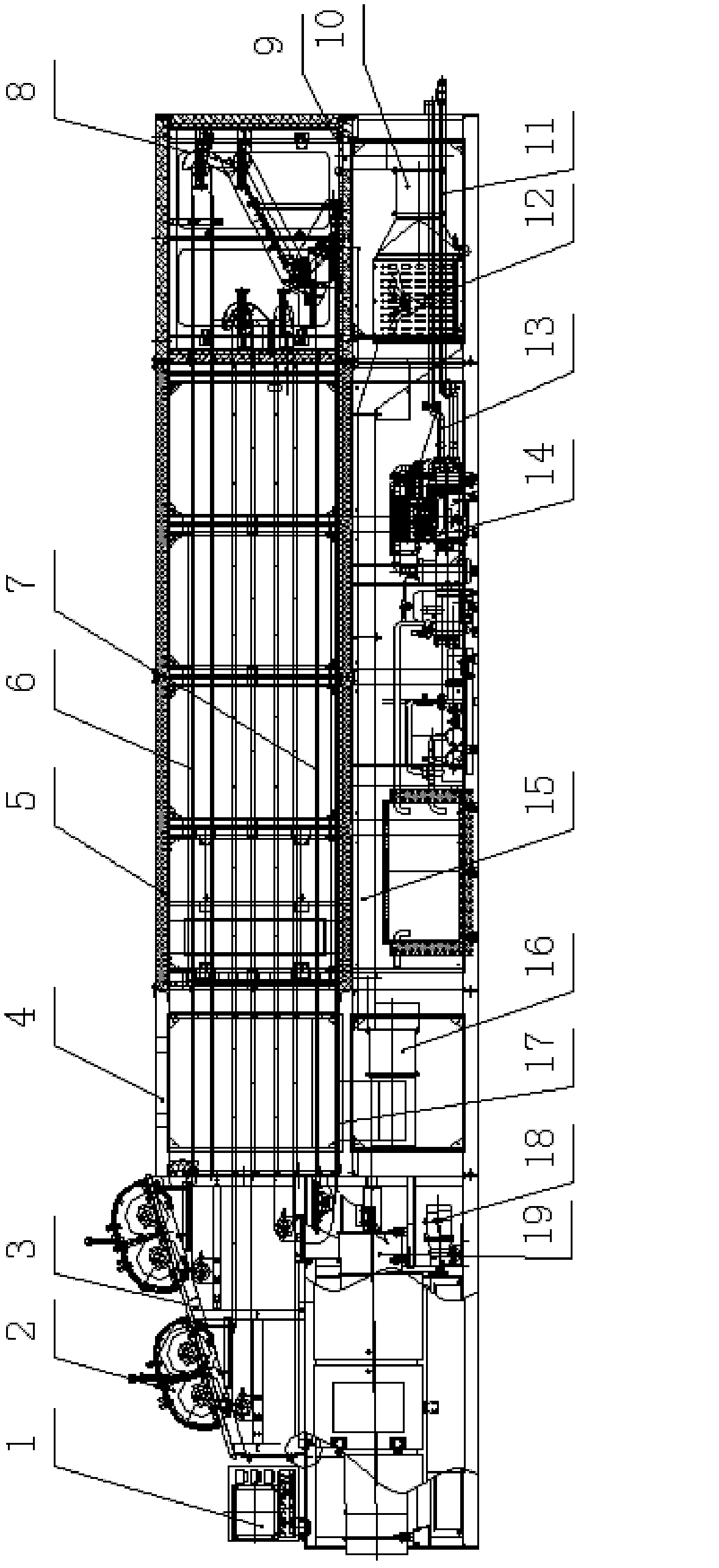

[0019] A chocolate bean forming machine is composed of a feeding system, a cooling conveying system, a cooling and granulating system, a rotary screen system and a cooling system.

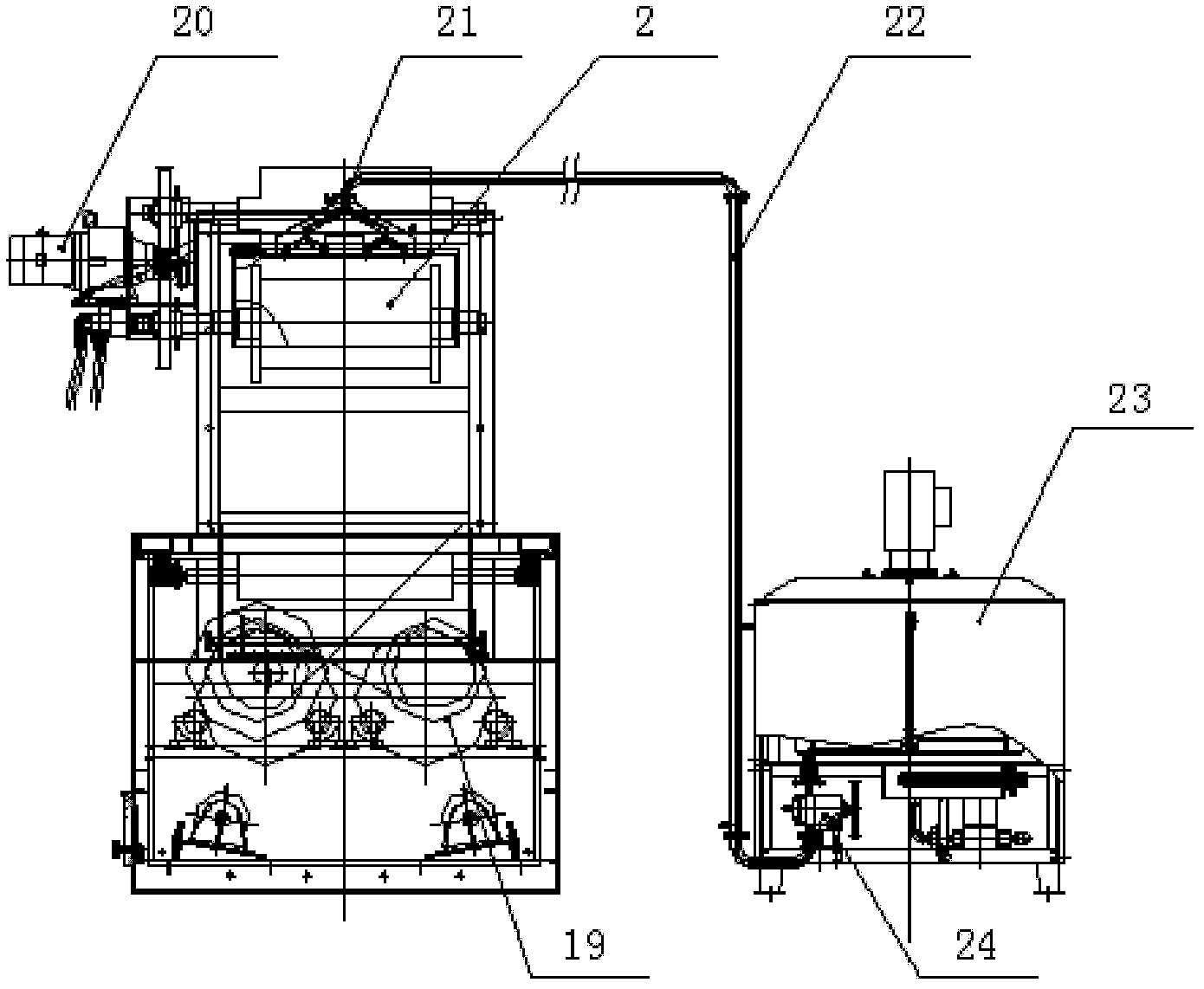

[0020] Among them, the feeding system is composed of a stirring tank 23, a rotor pump 24 and a pouring head 21. A rotor pump is installed at the bottom of the stirring tank. The rotor pump is connected to the pouring head through a pipeline 22. A stirring shaft and a stirring shaft are installed on the upper end of the stirring tank. The motor and the outer wall of the stirring tank are provided with a thermal insulation cover.

[0021] The cooling conveying system consists of a conveying chamber 4 and a conveying belt installed inside the conveying chamber. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com