Halogen-free flame-retardant high-liquidity PC/ABS material used for shells of TV sets and preparation method of PC/ABS material

A TV shell and ABS material technology, applied in the field of thermoplastic polymer materials, can solve the problems of not being able to meet environmental protection requirements, fluidity needs to be further improved, and achieve the effect of large cost advantage, good fluidity, and guaranteed impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

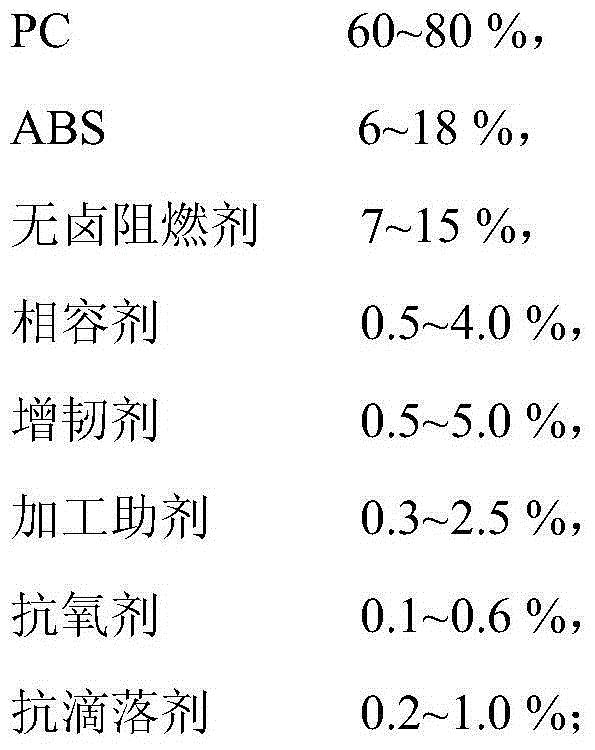

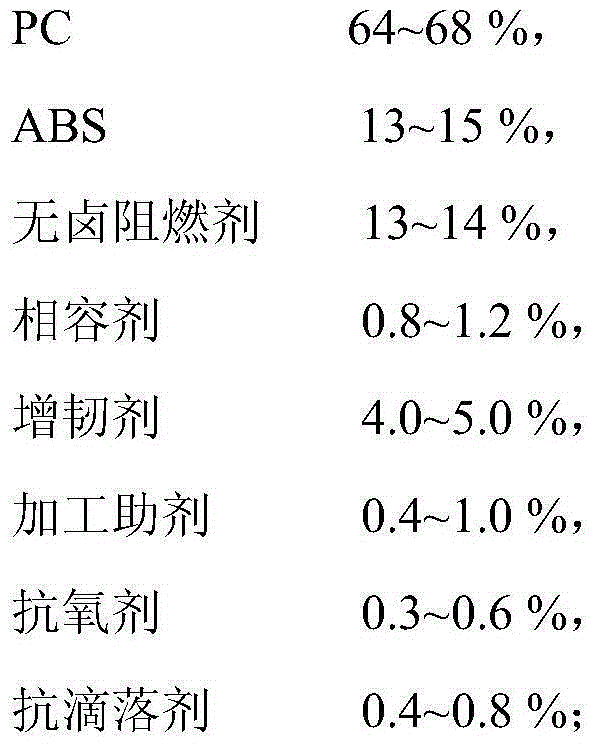

Method used

Image

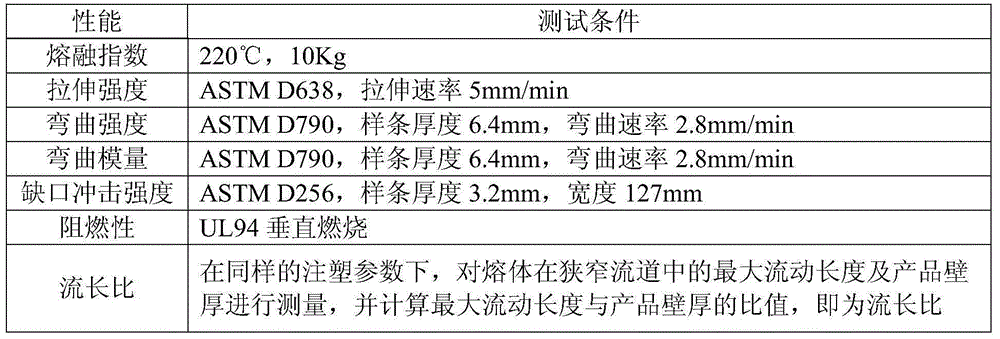

Examples

Embodiment 1

[0025] The weight percent of the halogen-free flame-retardant high-flow PC / ABS material used for the TV casing of embodiment 1 consists of: PC: 65.4%, ABS: 13%, bisphenol A-bis(diphenyl phosphate): 14%, Maleic anhydride grafted ABS with a graft rate of 1%: 1%, butadiene copolymer: 5%, stearic acid amide: 0.6%, tetrakis[β-(3,5-di-tert-butyl-4 -Hydroxyphenyl)propionic acid]pentaerythritol ester and tris(2,4-di-tert-butylphenyl phosphite) in a weight ratio of 1:2: 0.4%, polytetrafluoroethylene Acrylate-modified polytetrafluoroethylene anti-dripping agent with a content of 50% by weight and whose surface is graft-modified with styrene-acrylonitrile copolymer: 0.6%, and its preparation method includes the following steps:

[0026] 1) Dry PC and ABS in a blast dryer at 120°C for 3.5 hours respectively, and set aside;

[0027] 2) Prepare various raw materials according to the weight percentage composition;

[0028] 3) PC, ABS, maleic anhydride grafted ABS, butadiene copolymer, stea...

Embodiment 2

[0030]The weight percent of the halogen-free flame-retardant high-flow PC / ABS material used for the TV casing of embodiment 2 consists of: PC: 65.5%, ABS: 14%, resorcinol bis(diphenyl phosphate): 13.5%, Methyl methacrylate-glycidyl methacrylate-ethyl acrylate terpolymer with a melt index of 8g / 10min: 1%, methyl methacrylate-butadiene-styrene copolymer 2%, ethylene- Butyl acrylate-maleic anhydride copolymer 2.5%, pentaerythritol stearate: 0.6%, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and triphosphite (2,4-di-tert-butylphenyl ester) compounded at a weight ratio of 1:2: 0.4%, acrylate-modified polystyrene-acrylonitrile copolymer graft-modified surface Tetrafluoroethylene anti-dripping agent: 0.5%, its preparation method comprises the following steps:

[0031] 1) Dry PC and ABS in a blast dryer at 110°C for 4 hours respectively, and set aside;

[0032] 2) Prepare various raw materials according to the weight percentage composition;

[00...

Embodiment 3

[0035] The percentage by weight of the halogen-free flame-retardant high-flow PC / ABS material used for the TV casing of Example 3 consists of: PC: 65.6%, ABS: 15%, organosilicon flame retardant: 13%, and grafting rate: 1.1% Acrylonitrile-styrene copolymer grafted glycidyl methacrylate: 1%, rubber content: 60% core-shell structure methyl methacrylate-butadiene-styrene copolymer: 4 %, N, N-ethylene bis stearic acid amide: 0.5%, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and phosphite tris(2,4 -di-tert-butylphenyl ester) compounded at a weight ratio of 1:2: 0.4%, acrylate-modified polytetrafluoroethylene graft-modified with styrene-acrylonitrile copolymer on the surface Anti-dripping agent: 0.5%, its preparation method comprises the following steps:

[0036] 1) Dry PC and ABS in a blast dryer at 125°C for 4 hours respectively, and set aside;

[0037] 2) Prepare various raw materials according to the weight percentage composition;

[0038] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com