Mold for manufacturing glass container

A technology of glass containers and moulds, which is applied in glass blowing, manufacturing tools, and glass molding, etc. It can solve the problems affecting the molding of the bottle neck, not seen, troubles, etc., and achieve the effect of avoiding cooling speed and meeting the molding requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

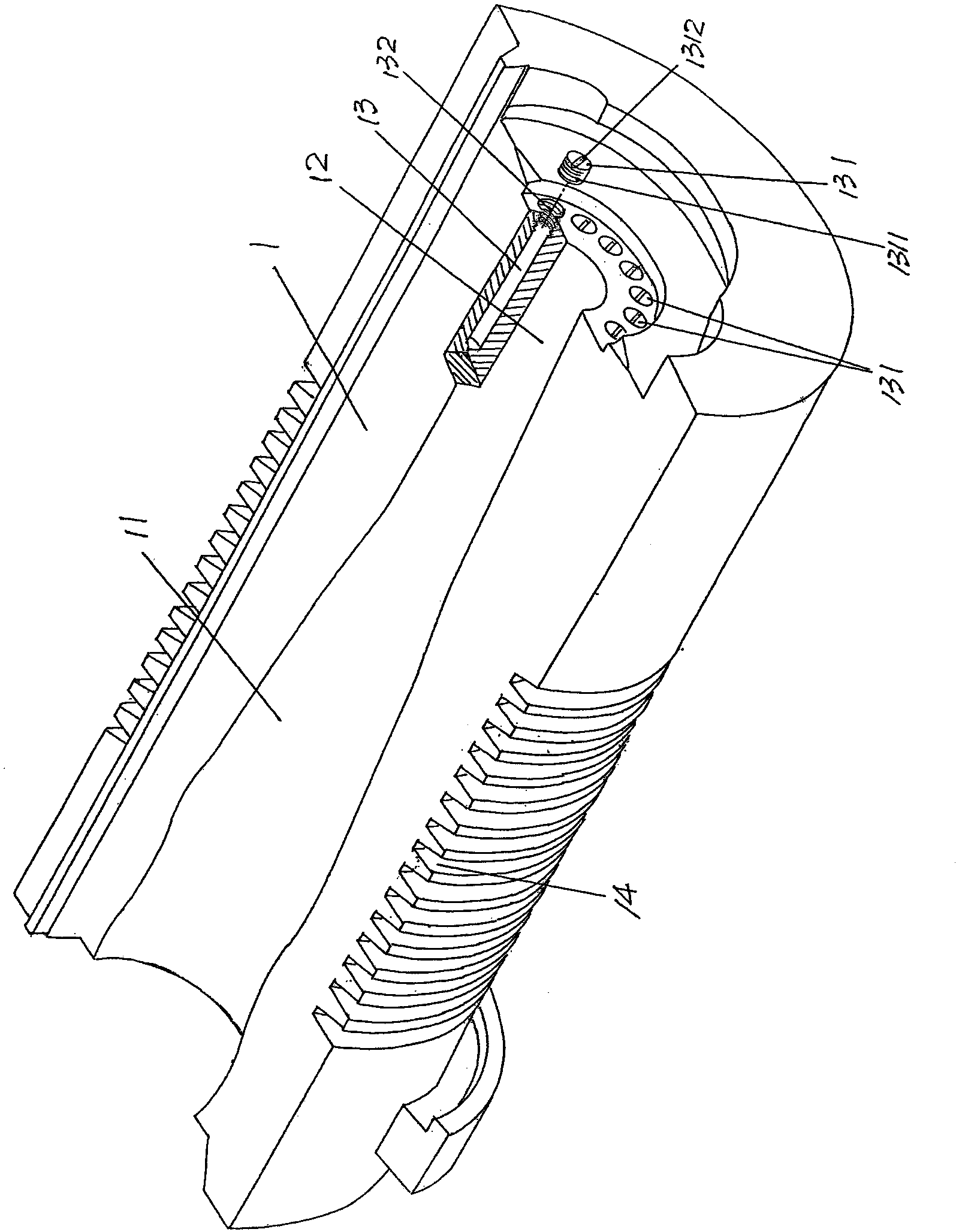

[0022] See figure 1 , because according to the known common sense, the initial model half-mould 1 appears in the form of matching pairs when in use, that is, in a manner of face-to-face cooperation with each other, and because the shape and structure of a pair of preliminary model half-moulds 1 are the same, so in figure 1 Although only an initial mold half-mould 1 is shown in , it will not confuse the public's understanding. The blank mold half 1 has a glass container blank forming cavity 11 and a glass container blank mouth forming cavity 12 formed by narrowing one end (the right end of the illustrated state) of the glass container blank forming cavity 11 .

[0023] As the technical points of the technical solution provided by the present invention: on the aforementioned blank mold half-mould 1 and around the position of the wall of the glass container blank mouth forming cavity 12, a group of glass container blank mouth molding cavities are provided in a spaced state 12 pa...

Embodiment 2

[0029] Only change the distance between the heat preservation hole 13 and the cavity wall of the glass container prototype mouth forming cavity 12 to 5mm, change the diameter of the heat preservation hole 13 to 3mm, and change the distance between adjacent heat preservation holes 13 to 5㎜. A group of heat dissipation grooves 14 are formed on the outer wall of the initial mold half 1 in a longitudinal state, and the width of the heat dissipation grooves 14 expands outward from the bottom of the groove to form a V shape. All the other are the same as the description to embodiment 1.

Embodiment 3

[0031] Only change the distance between the heat preservation hole 13 and the cavity wall of the glass container prototype mouth forming cavity 12 to 7mm, change the diameter of the heat preservation hole 3 to 4mm, and change the distance between adjacent heat preservation holes 3 to 4mm, all the other are the same as the description of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com