High laminating degree PU leather, and preparation method thereof

A fit and leather technology, applied in the field of artificial leather, can solve the problems of weakening the high-end feeling of car interiors, delamination, and affecting user experience, etc., and achieve the effect of tight and reliable process, fine steps, and uniform and continuous fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

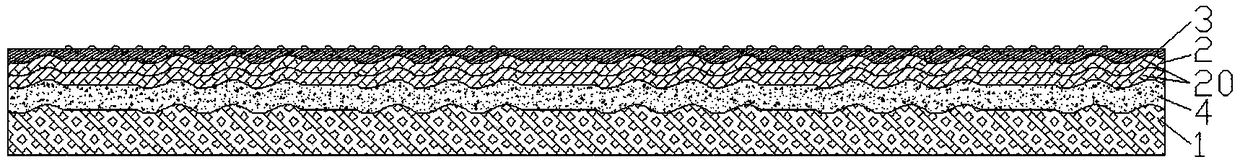

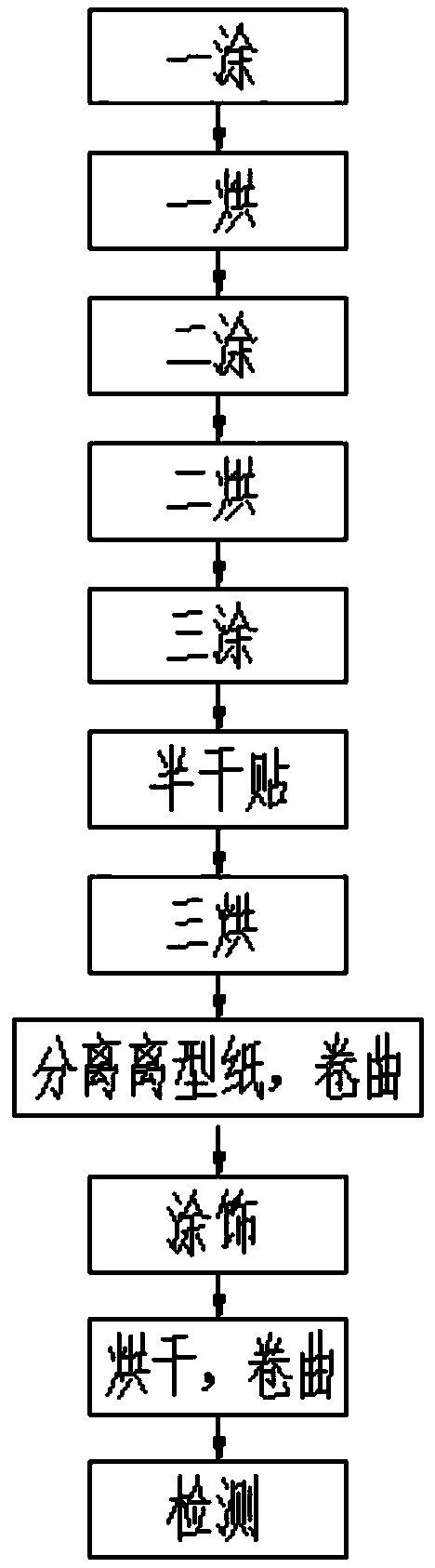

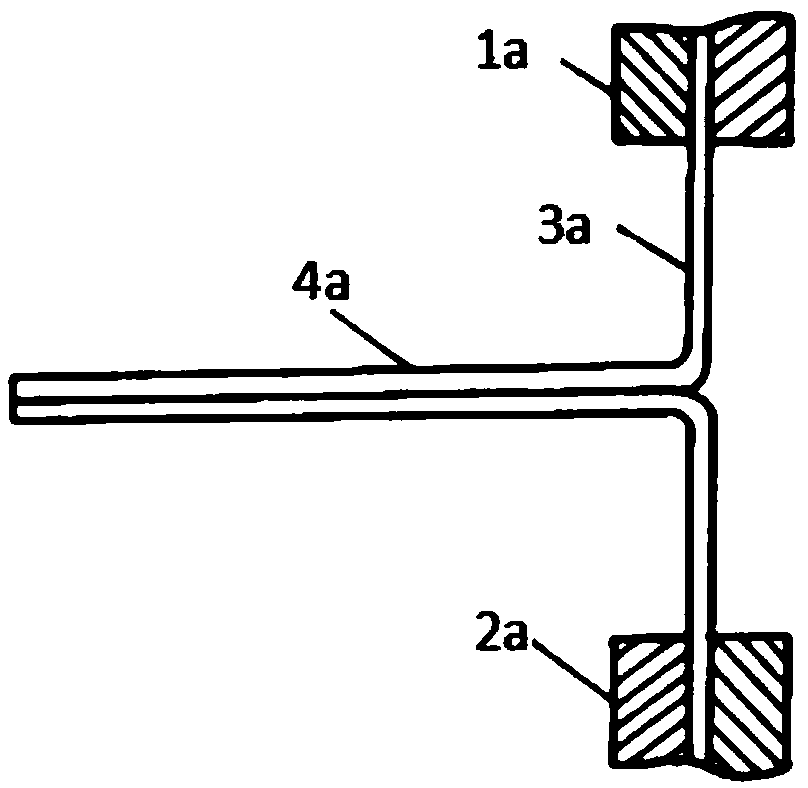

[0032] Such as Figure 1~2 , a kind of high fit PU leather, comprising a base cloth layer 1, a PU layer 2, a finishing layer 3 in sequence, an adhesive layer 4 is arranged between the base cloth layer 1 and the PU layer 2, and the adhesive layer The raw material of 4 is a solvent-free PU adhesive, the finish layer 3 is a water-based finish layer, and the PU layer 2 includes two PU monolayers 20; the thickness of the PU layer 2 is 0.1-0.15mm, and the adhesive The thickness of the mixture layer 4 is 0.25-0.35mm, and the material of the base cloth layer 1 is a special base cloth for automobile door panel leather.

[0033] The PU layer 2, the finishing layer 3, and the adhesive layer 4 contain the components shown in Table 1 in parts by weight in Examples 1-5. The components in parts by weight of the following layers only represent the proportions in parts by weight relative to the layer, and the basis of parts by weight between the layers is irrelevant.

[0034] The component (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com