Method for preparing aluminum oxide ceramic sphere without fingernail line defect

A nail grain defect and alumina technology, which is applied in the field of alumina ceramic ball preparation, can solve the problems that nail grain defects cannot be improved, cannot meet the production requirements of large-sized alumina ceramic balls, and are difficult to completely eliminate, so as to meet the requirements of improving product performance , meet the molding requirements, reduce shrinkage and loss on fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

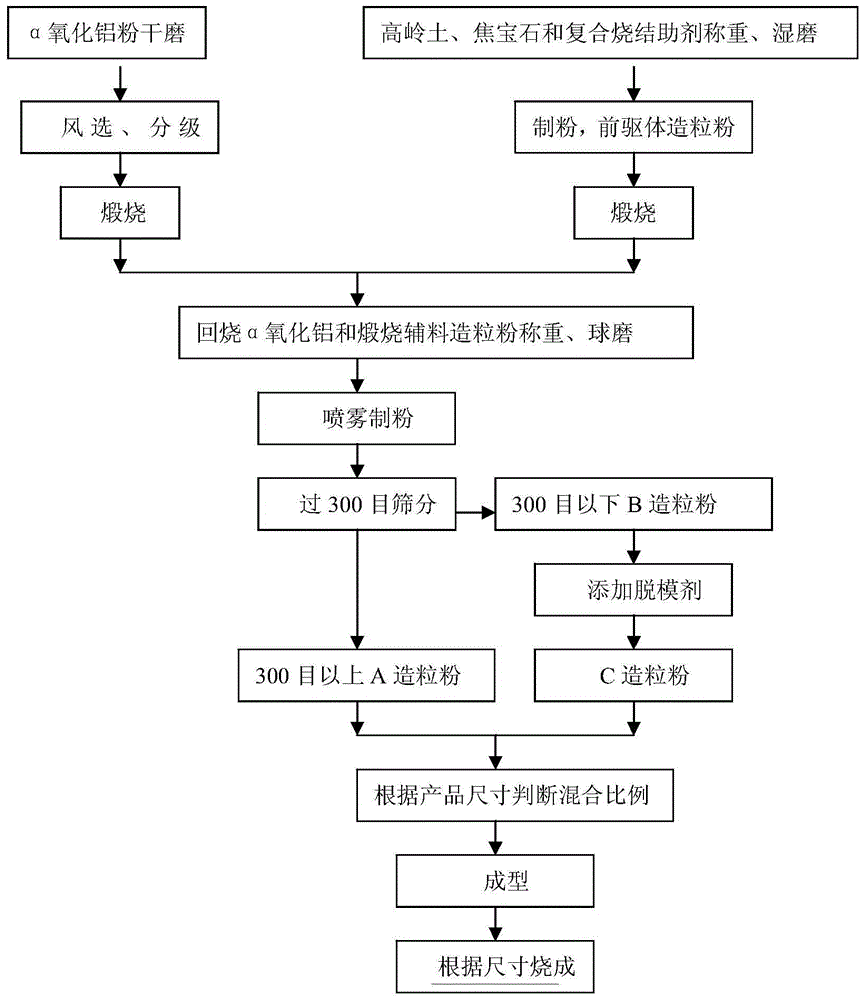

Method used

Image

Examples

Embodiment 1

[0043] (1) Raw materials and parts by weight

[0044] Main ingredients: 90 parts of α-alumina powder, 5 parts of kaolin, 3 parts of burnt gemstone;

[0045] Composite sintering aid: 0.5 part of heavy calcium, 0.5 part of talc, 1 part of dolomite;

[0046] (2) Put the α-alumina powder into the cylinder with a length of 7.48m and a cylinder diameter of 1.5m. The alumina ball is used as the grinding medium, and the material: ball = 1:2.8 in a continuous ball mill. After dry grinding for 5 hours, air selection is used Classify by machine, select α-alumina powder with a particle size of D90=3-6 microns, heat it up to 1350°C at a constant speed of 35°C in a tunnel kiln for calcination, and keep it for 1h;

[0047] (3) Weigh kaolin, coke gemstones and composite sintering aids according to the formula weight, respectively put them into a ball mill with external dimensions of 3000*4500mm and a speed of 13r / min for wet ball milling for 15h, slurry fineness D90=15μm, pass 180 Mesh siev...

Embodiment 2

[0054] (1) Raw materials and parts by weight

[0055] Main ingredients: 90 parts of α-alumina powder, 5 parts of kaolin, 3 parts of burnt gemstone;

[0056] Composite sintering aid: 0.5 part of heavy calcium, 0.5 part of talc, 1 part of dolomite;

[0057] (2) Put the α-alumina powder into the cylinder with a length of 7.48m and a diameter of 1.5m. The alumina ball is used as the grinding medium. After 8 hours of dry grinding in a continuous ball mill with ball = 1:2.8, air selection is used Classify by machine, select α-alumina powder with a particle size of D90=3-6 microns, heat it up to 1340°C at a constant speed of 35°C in a tunnel kiln for calcination, and keep it for 2 hours;

[0058] (3) Weigh kaolin, coke gemstones and composite sintering aids according to the formula weight, respectively put them into a ball mill with external dimensions of 3000*4500mm and a speed of 13r / min for wet ball milling for 18h, slurry fineness D90=10μm, pass 180 Mesh sieve, put it into the ...

Embodiment 3

[0065] (1) Raw materials and parts by weight

[0066] Main ingredients: 90 parts of α-alumina powder, 5 parts of kaolin, 3 parts of burnt gemstone;

[0067] Composite sintering aid: 1 part of heavy calcium, 0.5 part of talc, 0.5 part of dolomite;

[0068] (2) Put the α-alumina powder into a cylinder with a length of 7.48m and a diameter of 1.5m. Alumina balls are used as the grinding medium. After dry grinding for 7 hours in a continuous ball mill with balls = 1:2.8, air selection is used Classify by machine, select α-alumina powder with a particle size of D90=3-6 microns, heat it up to 1325°C at a constant speed of 35°C in a tunnel kiln for calcination, and keep it for 3 hours;

[0069] (3) Weigh kaolin, coke gemstones and composite sintering aids according to the formula weight, respectively put them into a ball mill with external dimensions of 3000*4500mm and a speed of 13r / min for wet ball milling for 17h, slurry fineness D90=11μm, pass 180 Mesh sieve, put it into the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com