Moldable two-way stretch polypropylene film as well as preparation method and application thereof

A technology of polypropylene film and biaxial stretching, applied in chemical instruments and methods, lamination, lamination auxiliary operations, etc., can solve the problems of high melting point softening temperature, low preheating temperature of molding surface, and limitation of molding processing speed, etc. Achieve the effect of increasing preheating and stretching temperature, ensuring thermoplasticity and fluidity, and improving thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

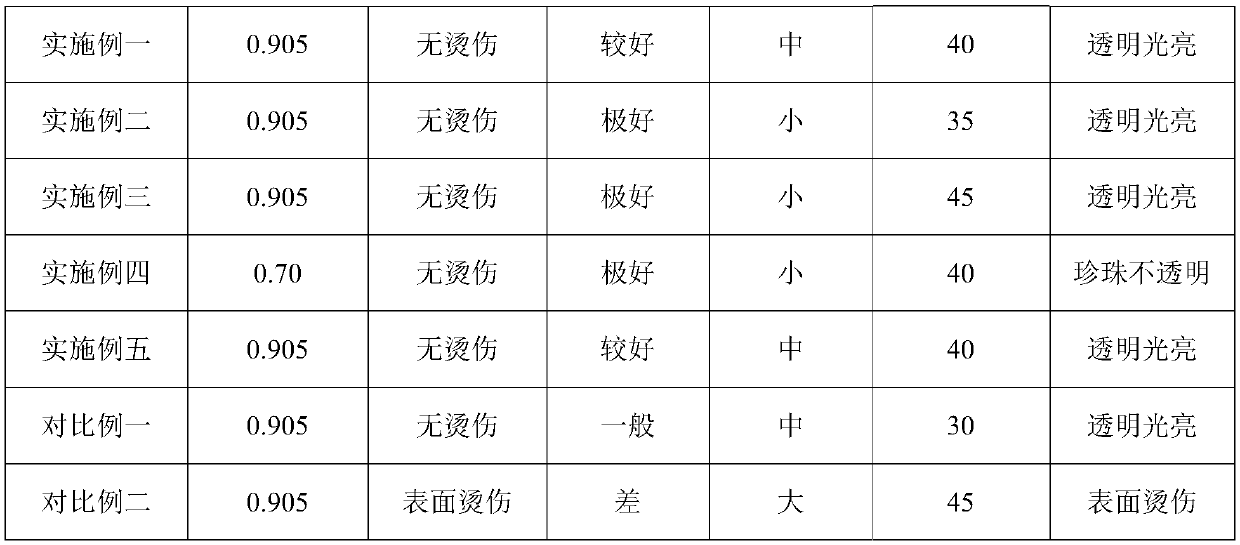

Examples

Embodiment 1

[0026] Embodiment one: the preparation of moldable biaxially oriented polypropylene film of the present invention

[0027] 1. Prepare the first moldable layer resin

[0028] An ethylene-propylene binary copolymer with a melting point of 140° C. and a melt index of 7.5 g / 10 min was used as the first moldable layer resin.

[0029] 2. Prepare the second moldable layer resin

[0030] An ethylene-propylene-butene terpolymer with a melting point of 130° C. and a melt index of 5 g / 10 min was used as the second moldable layer resin.

[0031] 3. Prepare the core polypropylene resin

[0032] A polypropylene resin with an isotacticity of 95% and a melt index of 2.8 g / 10 min was used as the core layer polypropylene resin.

[0033] 4. Prepare the surface polypropylene resin

[0034] Take polypropylene resin with isotacticity of 95% and melt index of 2.8g / 10min, and AB6018CPP anti-blocking masterbatch (purchased from Suzhou Constamp Engineering Plastics Co., Ltd., with a silicon dioxide...

Embodiment 2

[0040] Embodiment two: the preparation of moldable biaxially oriented polypropylene film of the present invention

[0041] 1. Prepare the first moldable layer resin

[0042] An ethylene-propylene binary copolymer with a melting point of 140° C. and a melt index of 5.5 g / 10 min was used as the first moldable layer resin.

[0043] 2. Prepare the second moldable layer resin

[0044] An ethylene-propylene-butene terpolymer with a melting point of 135° C. and a melt index of 5 g / 10 min was used as the second moldable layer resin.

[0045] 3. Prepare the core polypropylene resin

[0046] Take a polypropylene resin with an isotacticity of 96% and a melt index of 3.0g / 10min, and a polypropylene resin with an isotacticity of 50% and a melt index of 50g / 10min, and mix them uniformly in a weight ratio of 90:10, A core layer polypropylene resin was obtained.

[0047] 4. Prepare the surface polypropylene resin

[0048] Respectively take polypropylene resin with isotacticity of 96%, me...

Embodiment 3

[0054] Embodiment three: the preparation of moldable biaxially oriented polypropylene film of the present invention

[0055] 1. Prepare the first moldable layer resin

[0056] An ethylene-propylene binary copolymer with a melting point of 140° C. and a melt index of 7.5 g / 10 min was used as the first moldable layer resin.

[0057] 2. Prepare the second moldable layer resin

[0058] An ethylene-propylene-butene terpolymer with a melting point of 137° C. and a melt index of 7.5 g / 10 min was used as the second moldable layer resin.

[0059] 3. Prepare the core polypropylene resin

[0060] Take a polypropylene resin with an isotacticity of 96% and a melt index of 3.0g / 10min, and a polypropylene resin with an isotacticity of 50% and a melt index of 25g / 10min, and mix them uniformly in a weight ratio of 97:3. A core layer polypropylene resin was obtained.

[0061] 4. Prepare the surface polypropylene resin

[0062] Get respectively the polypropylene resin that isotacticity is 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com