Vertical-parting core shooting machine

A vertical parting and core-shooting machine technology, applied in the field of foundry machinery, can solve the problems of high price, complicated operation, and various specifications and models, and achieve the effect of high production efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

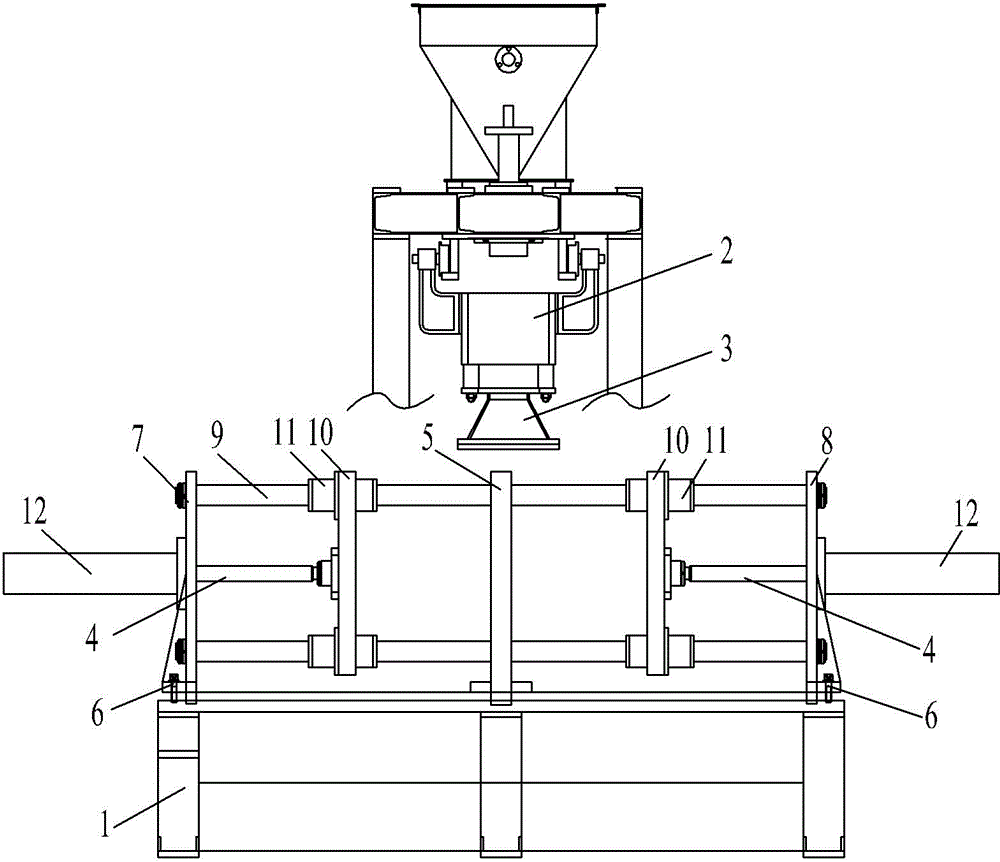

[0007] Such as figure 1 As shown, the present invention includes a base 1, the base 1 is provided with a sand-shooting cylinder 2, the sand-shooting cylinder 2 is equipped with a shooting head 3, the center of the end face of the base 1 is fixed with a fixed template 5, and the left and right ends of the base 1 correspond to each other through bolts 6. The left side plate 7 and the right side plate 8 are fixed, the upper and lower ends of the left side plate 7 and the right side plate 8 are connected with the fixed template 5 through the guide post 9, and the movable template 10 matched with the fixed template 5 passes through the guide post 9 The upper sliding sleeve 11 is fixed and placed between the left side plate 7, the right side plate 8 and the fixed template 5, the mold clamping cylinder 12 is installed on the outside of the left side plate 7, the right side plate 8 and the ejector pin of the mold clamping cylinder 12 4 passes through the left side plate 7, the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com