Underground fluid laminated sampling device and method based on U-shaped pipe technology

A technology for underground fluids and sampling devices, which is applied in earth-moving drilling, wellbore/well components, etc., can solve the problems of inability to adapt to field sites, large disturbance of formation fluids, and inability to carry out continuous sampling, and achieves novel and good design. The effect of improving competitiveness and system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

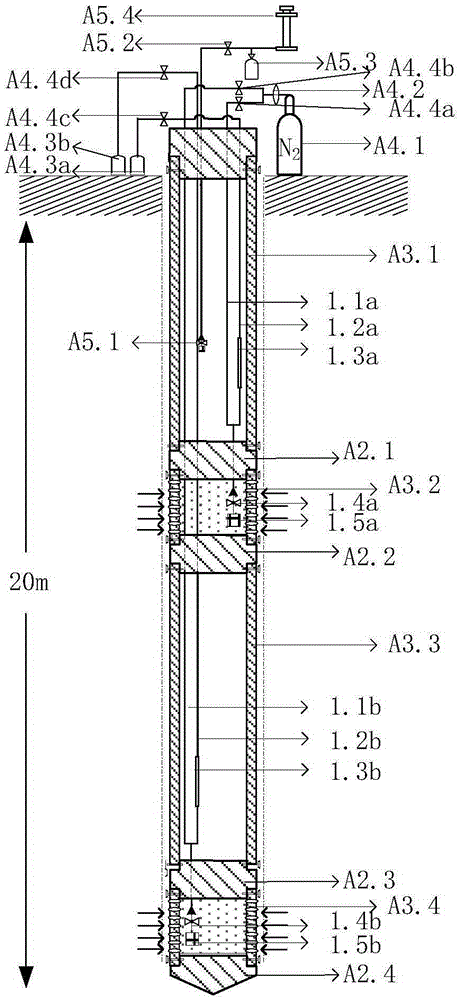

Embodiment 1

[0066] Example 1: U-shaped tube subsurface fluid layered sampling device suitable for shallow 20m level, including

[0067] Subsurface fluid intake subsystem, including:

[0068] 1.1a—the first drive tube 1.1b—the second drive tube; (catheter with an outer diameter of 8mm, PU-08);

[0069] 1.2a—the first sample tube; 1.2b—the second sample tube; (catheter with an outer diameter of 8mm, PU-08);

[0070] 1.3a—the first storage container; 1.3b—the second storage container; (depending on the single sampling capacity, such as volume 200ml);

[0071] 1.4a—the first liquid phase one-way valve; 1.4b—the second liquid phase one-way valve; (connected to the first shallow drive pipe, the circulation medium is underground fluid, only conduction from bottom to top, and always closed from top to bottom );

[0072] 1.5a—the first filter element; 1.5b—the second filter element; (the filtered particle size level is 35 microns, which is equivalent to a filter screen of 500 mesh, according ...

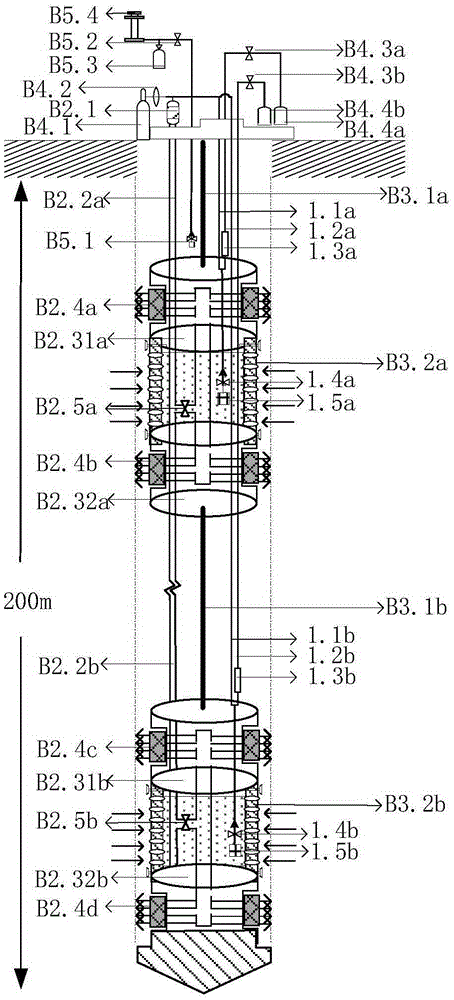

Embodiment 2

[0094] Example 2: U-shaped tube underground fluid stratified sampling device suitable for 200m level in middle strata,

[0095] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0096] Subsurface fluid intake subsystem, including:

[0097] 1.1a—the first drive tube; 1.1b—the second drive tube; (1 / 8 stainless steel tube, Swagelok);

[0098] 1.2a—the first sample tube; 1.2b—the second sample tube; (1 / 8 stainless steel tube, Swagelok);

[0099] 1.3a—the first storage container; 1.3b—the second storage container; (depending on the single sampling capacity, such as volume 500ml);

[0100] 1.4a—the first liquid phase one-way valve; 1.4b—the second liquid phase one-way valve; (connected to the first drive pipe, the circulation medium is underground fluid, only conduction from bottom to top, and always closed from top to bottom);

[0101] 1.5a—the first filter element; 1.5b—the second filter element; (the particle size level o...

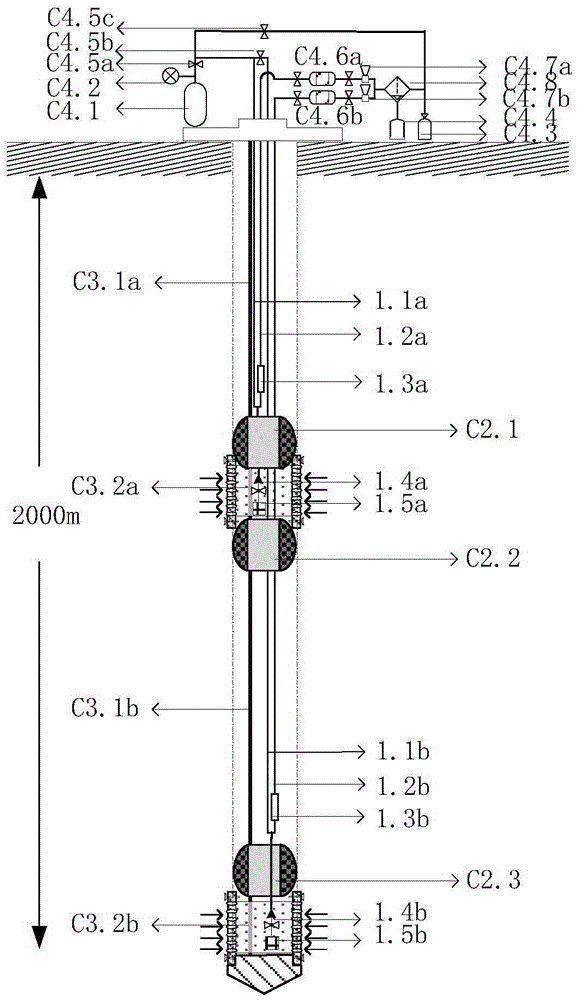

Embodiment 3

[0128] Example 3: U-shaped tube underground fluid layered sampling device suitable for 2000m deep strata, such as image 3 shown.

[0129] Subsurface fluid intake subsystem, including:

[0130] 1.1a—the first drive tube; 1.1b—the second drive tube; (1 / 8 stainless steel tube, Swagelok);

[0131] 1.2a—the first sample tube; 1.2b—the second sample tube; (1 / 8 stainless steel tube, Swagelok);

[0132] 1.3a—the first storage container; 1.3b—the second storage container; (depending on the single sampling capacity, such as volume 500ml);

[0133] 1.4a—the first liquid phase one-way valve; 1.4b—the second liquid phase one-way valve; (connected to the first drive pipe, the circulation medium is underground fluid, only conduction from bottom to top, and always closed from top to bottom);

[0134]1.5a—the first filter element; 1.5b—the second filter element; (the particle size level of the filter depends on the particle size distribution of the soil on site d 10 choose).

[0135] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com