A kind of temporary plugging material and preparation method thereof

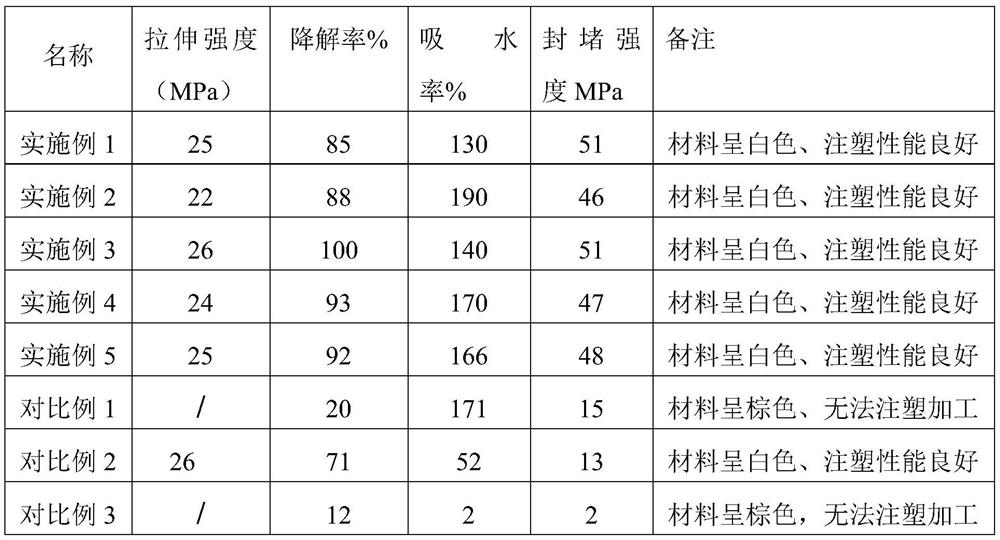

A material, polyethylene glycol technology, applied in the field of plugging materials, can solve the problems of easy stickiness and poor low temperature degradation performance, and achieve the effect of improving environmental protection performance, excellent thermal processing performance, and high plugging strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of temporary plugging material, its preparation method comprises the following steps:

[0042] (1) Put 10mol oxalic acid, 10.1mol polyethylene glycol (number average molecular weight 2000), 20.2g antimony trioxide, and 101g boric acid into a glass kettle with stirring, and react under nitrogen protection and normal pressure stirring at 100°C 1h, then raise the temperature to 180°C, maintain an absolute pressure of 200Pa, and stir in vacuum for 4h to obtain polyester polyol material;

[0043] (2) Put 11mol of hexamethylene-1,6-diisocyanate into a glass kettle with stirring, start stirring, heat up to 60°C, add 10mol of polydiethylene glycol adipate diol (number average molecular weight 1000 ), keep an absolute pressure of 10Kpa, and react with vacuum stirring for 1h to obtain a low-temperature temporary blocking prepolymer material;

[0044] (3) Inject the polyester polyol material in step (1) and the low-temperature temporary plugging prepolymer material in step...

Embodiment 2

[0046] A kind of temporary plugging material, its preparation method comprises the following steps:

[0047] (1) Put 5 mol oxalic acid, 5.25 mol polyethylene glycol (number-average molecular weight 4000), 210 g antimony trioxide, and 101 g boric acid into a glass kettle with stirring, and react under nitrogen protection at 100 °C and stirring at normal pressure for 1 h , and then heated up to 150°C, maintained an absolute pressure of 50Pa, and stirred and reacted in vacuum for 2 hours to obtain a polyester polyol material;

[0048] (2) Put 13 mol of toluene diisocyanate into a stirred glass kettle, start the stirring, raise the temperature to 60°C, add 10 mol of poly(diethylene glycol adipate) diol (number average molecular weight 1000), keep the absolute pressure at 10Kpa, vacuum Stirring and reacting for 1 hour to obtain a low-temperature temporary plugging prepolymer material;

[0049] (3) Inject the polyester polyol material in step (1) and the low-temperature temporary p...

Embodiment 3

[0051] A kind of temporary plugging material, its preparation method comprises the following steps:

[0052] (1) Put 4mol oxalic acid, 4.06mol polyethylene glycol (number-average molecular weight 6000), 50g antimony trioxide, 50g stannous chloride, and 243.6g boric acid into a glass kettle with stirring, and nitrogen at 140°C Protect, stir and react at normal pressure for 1 hour, then raise the temperature to 170°C, maintain an absolute pressure of 110Pa, and stir and react in vacuum for 3 hours to obtain polyester polyol materials;

[0053] (2) 3.6 mol of diphenylmethylene diisocyanate is put into a stirred glass kettle, the stirring is started, the temperature is raised to 65°C, and 3 mol of polydiethylene adipate diol (number average molecular weight 3000) is added, Maintain an absolute pressure of 10Kpa, stir and react in vacuum for 1 hour, and obtain a low-temperature temporary plugging prepolymer material;

[0054] (3) Inject the polyester polyol material in step (1) an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com