A kind of expansion equipment for downhole branch system

A branch system and equipment technology, applied in wellbore/well components, earthwork drilling and production, etc., can solve the problems of lack of mechanical integrity, hydraulic integrity and re-entry ability, and achieve convenient downhole, small size, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

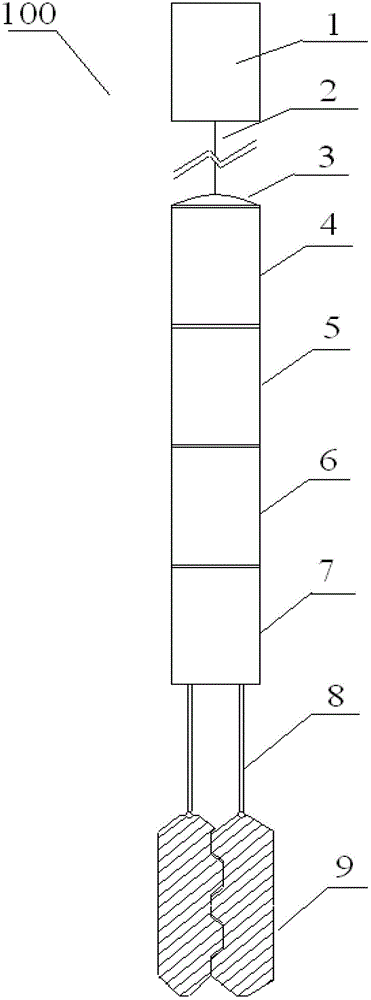

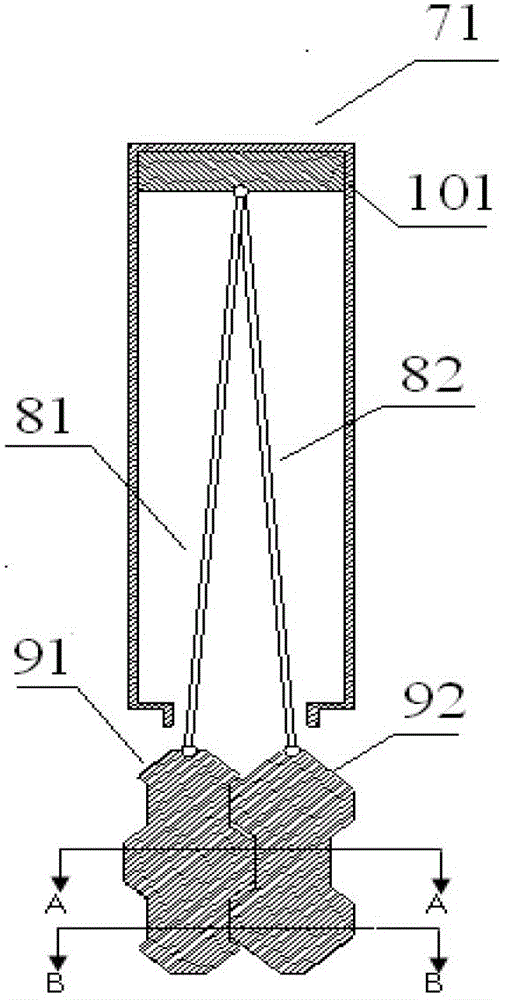

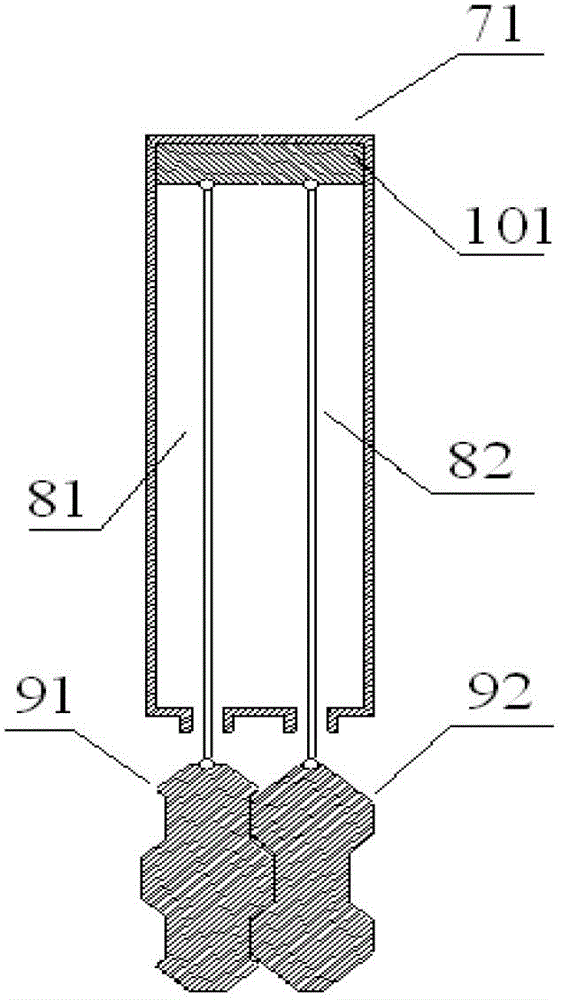

[0032] figure 1 An overall schematic diagram of the expansion device 100 of the downhole lateral system according to the present invention is shown. As shown in the figure, the downhole branch system expansion device according to the present invention includes an uphole power and control unit 1 , an operating unit, a piston assembly and an expansion assembly 9 in order from top to bottom. Wherein, the working unit includes a power supply control module 4 , a hydraulic pump 5 and a positioning and grasping joint 6 from top to bottom. In the illustrated embodiment, the power supply control module 4 is connected with the uphole power and control unit 1 through the cable 2 and the cable joint 3 . The piston assembly includes a piston cylinder 7 and a piston rod 8 . These are well known to those skilled in the art, so detailed descriptions are omitted here.

[0033] It should be noted that, in the description of the present invention, both "upper" and "lower" refer to figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com