Novel small concrete mixer

A concrete mixer, a small technology, is used in cement mixing devices, clay preparation devices, liquid batching supply devices, etc., and can solve the problems of inconvenient movement, poor spraying effect, and unstable cylinder fixing, and achieves convenient movement and lightening. The labor intensity of transporting materials and the effect of ensuring the quality of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

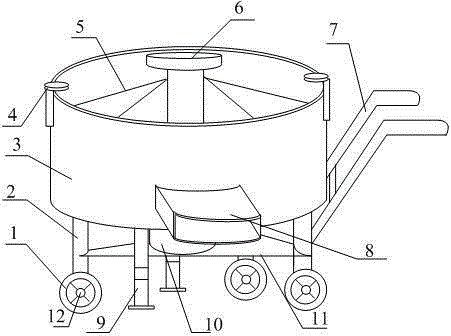

[0022] as attached figure 1 , with figure 2 And attached image 3 shown

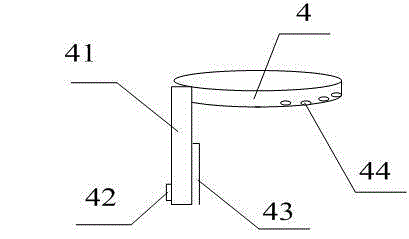

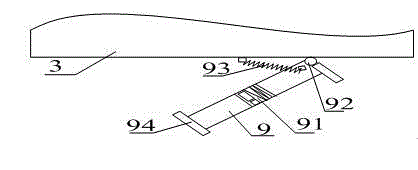

[0023] The invention provides a new type of small concrete mixer, which includes a moving wheel 1, a bracket 2, a cylinder body 3, a nozzle 4, a stirring rod 5, a rotating shaft 6, a push handle 7, a discharge port 8, a balance leg 9, a motor 10, and a motor base 11 and wheel shaft 12, the moving wheel 1 is fixed on the lower part of the bracket 2 through the wheel shaft 12; the cylinder body 3 is arranged on the top of the bracket 2; the nozzle 4 is fixed on the left and right sides of the cylinder body 3 through the claws Side edge; the stirring rod 5 is fixed on the rotating shaft 6; the push handle 7 is welded on the right side of the support 2; the discharge port 8 is arranged on the front side of the cylinder body 3; the balance leg 9 is connected to the lower part of the cylinder body 3 through the folding shaft 92; the motor 10 is arranged at the lower part of the cylinder body 3; the motor b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com