Original material fine grinding device for lithium ion battery production

A technology for lithium ion batteries and raw materials, which is applied in the field of fine grinding devices for raw materials used in the production of lithium ion batteries, can solve the problems of adding water and mixing, inconvenient grinding boxes, and particles that do not conform to production, and achieves the effect of ensuring fineness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

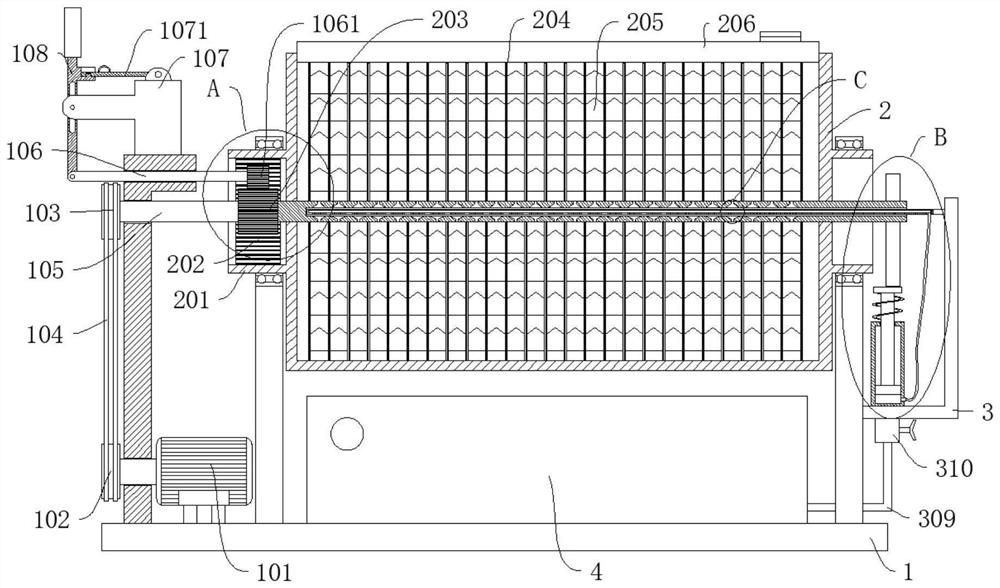

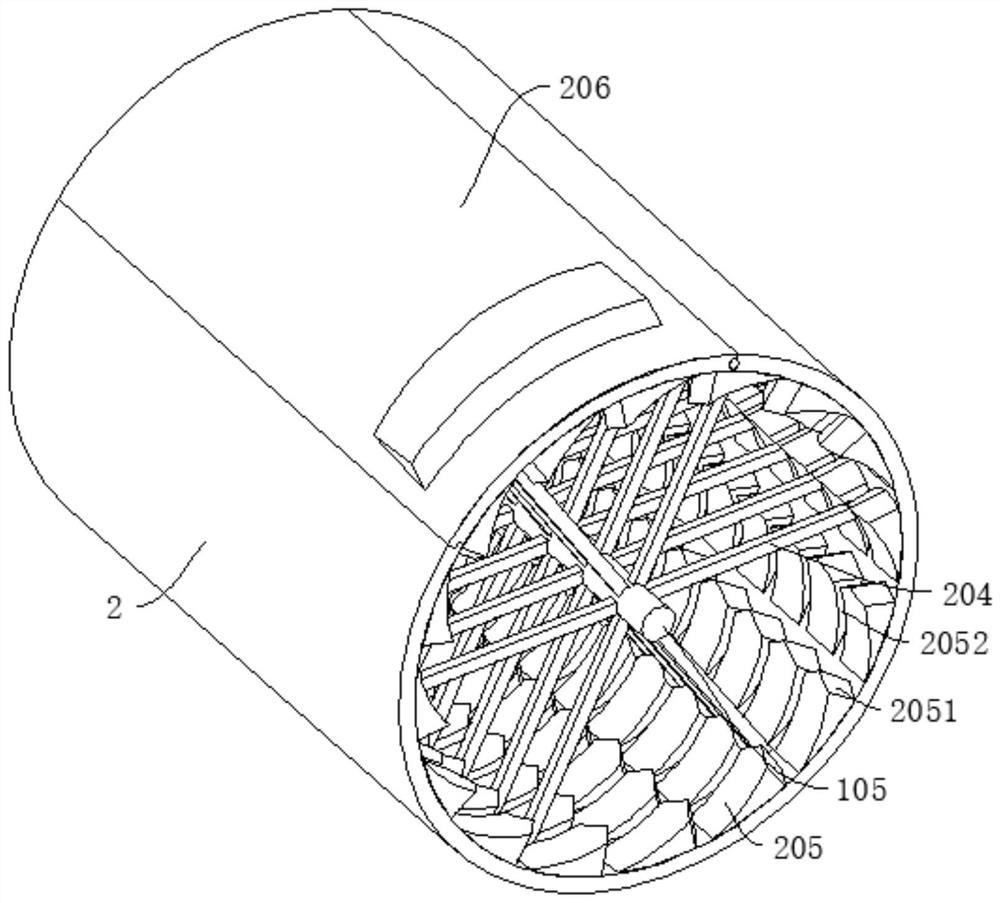

[0030] refer to Figure 1-7 , a raw material fine grinding device for lithium-ion battery production, including a base 1, a grinding box 2, the grinding box 2 is rotatably connected to the base 1, a door 206 is connected to the top of the grinding box 2, and a rotating shaft 105 is used. It is connected to the base 1 in rotation, and the extension end passes through the grinding box 2; wherein, both ends of the grinding box 2 are fixedly connected with an overhanging cover 201, the inner wall of the overhanging cover 201 is provided with gear teeth 202, and the rotating shaft 105 is fixedly connected with the first A gear 203, a sliding shaft 106 is slidably connected to the base 1, and a second gear 1061 is rotatably connected to the sliding shaft 106. When the second gear 1061 moves into the overhanging cover 201, the second gear 1061 is connected with the gear teeth 202 and the gear teeth 202 respectively. The first gear 203 is meshed; the rotating shaft 105 is fixedly conn...

Embodiment 2

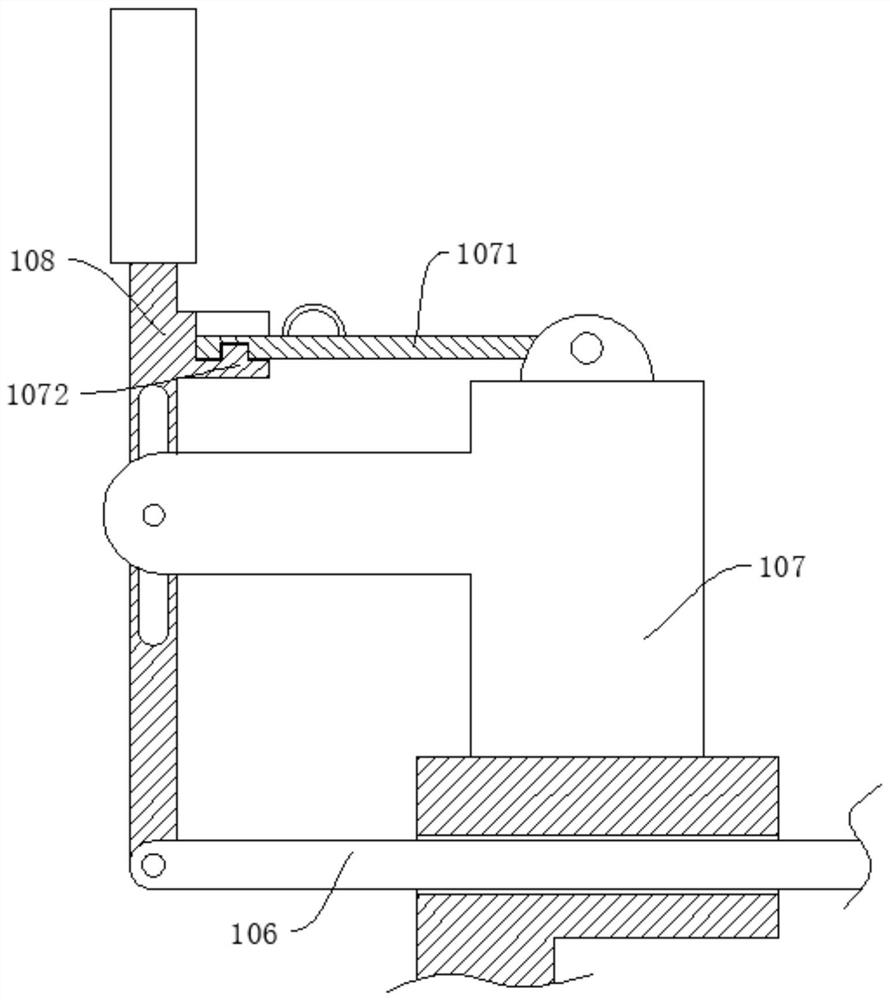

[0032] refer to image 3 , is basically the same as Embodiment 1, furthermore, the top wall of the base 1 is fixedly connected with a support 107, the side wall of the support 107 is rotatably connected with a rotating rod 108, and the top of the support 107 is rotatably connected with a clamping rod 1071, and the rotating rod 108 The bottom is rotatably connected with the sliding shaft 106 , and the end of the locking rod 1071 away from the support 107 can be fixed with the rotating rod 108 .

[0033] A convex plate 1072 is fixedly connected to the rotating rod 108, and a convex block is provided on the convex plate 1072, and a draw-in slot matching the convex block is provided at the bottom of the clamping rod 1071. By pulling the rotating rod 108, the rotating rod 108 is placed on the support 107. Rotate, its lower end drives the slide shaft 106 to move towards the grinding box 2, and then drives the second gear 1061 to be located between the first gear 203 and the gear tee...

Embodiment 3

[0035] refer to Figure 1-7 , a raw material fine grinding device for lithium-ion battery production, including a base 1, a grinding box 2, the grinding box 2 is rotatably connected to the base 1, a door 206 is connected to the top of the grinding box 2, and a rotating shaft 105 is used. It is connected to the base 1 in rotation, and the extension end passes through the grinding box 2; wherein, both ends of the grinding box 2 are fixedly connected with an overhanging cover 201, the inner wall of the overhanging cover 201 is provided with gear teeth 202, and the rotating shaft 105 is fixedly connected with the first A gear 203, a sliding shaft 106 is slidably connected to the base 1, and a second gear 1061 is rotatably connected to the sliding shaft 106. When the second gear 1061 moves into the overhanging cover 201, the second gear 1061 is connected with the gear teeth 202 and the gear teeth 202 respectively. The first gear 203 is meshed; the rotating shaft 105 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com