Industrial stirring machine

A mixer and industrial technology, applied in mixer accessories, mixers with rotary mixing devices, mixers, etc., can solve the problems of short development time, easy material blockage, poor manufacturing level, etc., and achieve high mixing efficiency and uniform mixing. , The effect of not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

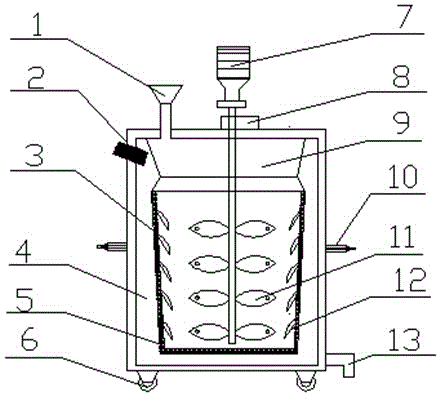

[0012] Such as figure 1 Shown, a kind of industrial mixer comprises a mixer body and a stirring mechanism arranged on the mixer body, a feed port 1, and a discharge port 13, and the stirring mechanism is composed of a stirring motor 7 arranged on the upper end of the mixer body and It consists of a plurality of stirring impellers 11 arranged on both sides of the stirring shaft of the stirring motor 7 . The stirring impellers 11 are provided with discharge holes, and the stirring motor 7 is connected to the speed reducer 8 .

[0013] As a preferred solution of the present invention, an observation window 2 is provided at the upper end of the mixer body shell of the present invention, so that the stirring progress can be observed at any time, and it is convenient to control the stirring force.

[0014] As a preferred solution of the present invention, air hammers 10 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com