Paint production mixing device provided with agitating tank

A technology of mixing device and mixing tank, which is applied in mixers, mixer accessories, dissolving, etc., can solve the problems that the mixing degree cannot reach a high standard and the quality of paint is affected, so as to improve the mixing effect, avoid mixing dead ends, and maintain the working environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

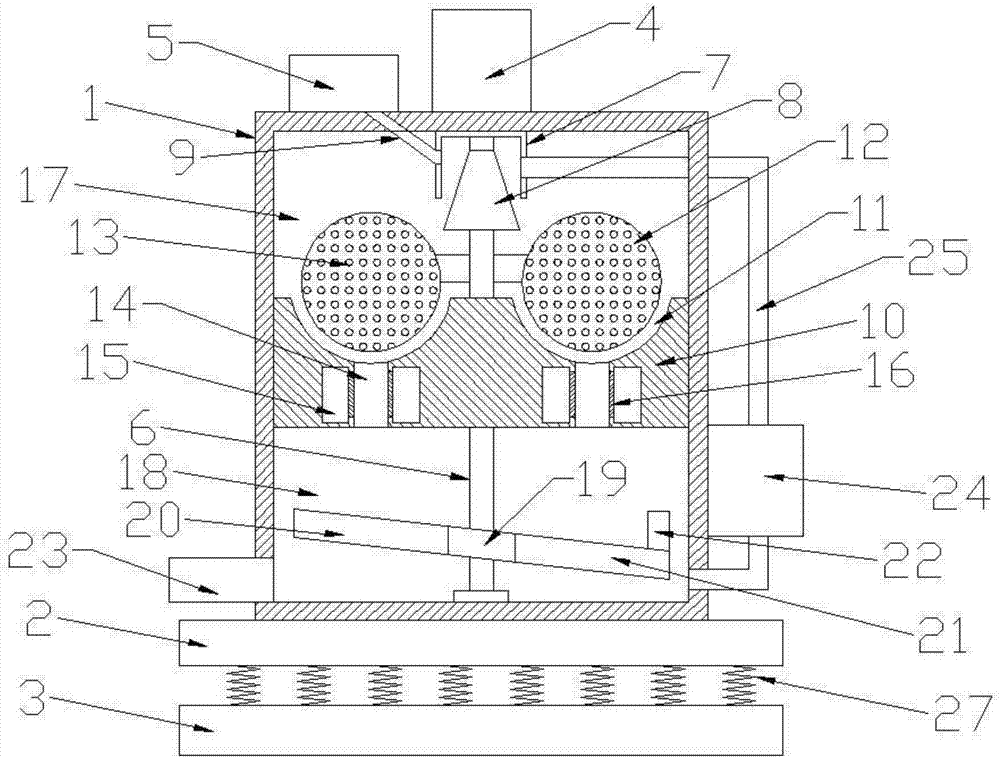

[0019] Please refer to the figure, in the embodiment of the present invention, a mixing device for paint production with a stirring tank includes a housing 1, a base 2, a fixed seat 3, a motor 4 and a feed box 5; the housing 1 is fixed on On the base 2, the fixed base 3 is located below the base 2, and several springs 27 are fixedly connected between the base 2 and the fixed base 3, the base 2 is supported by the springs 27, and the base 2 and the base are damped.

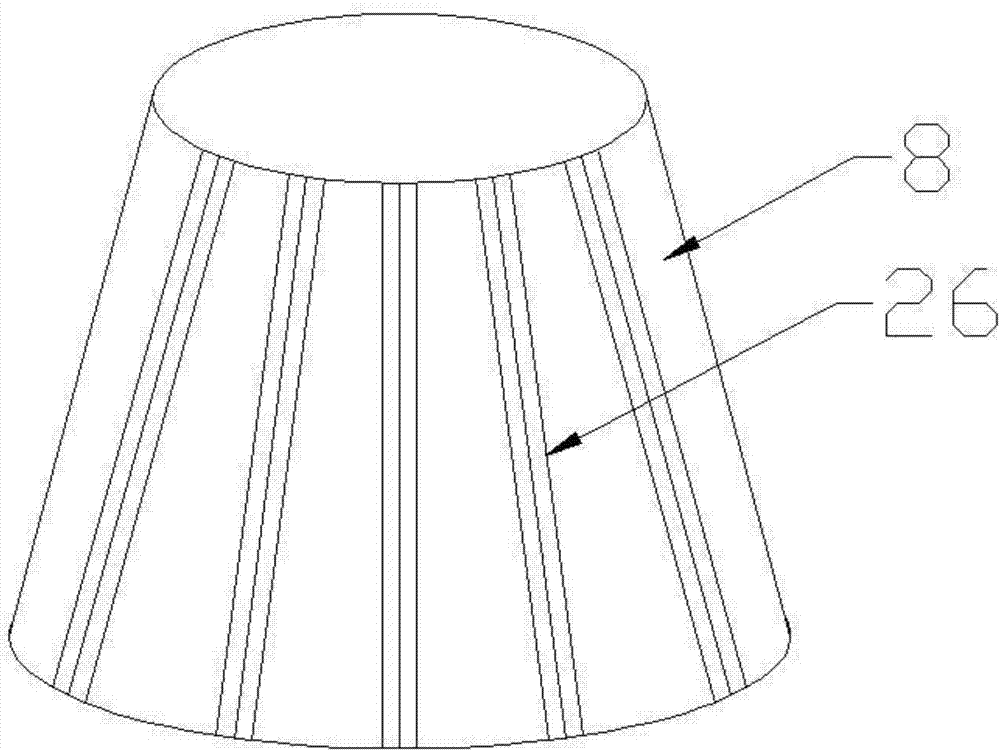

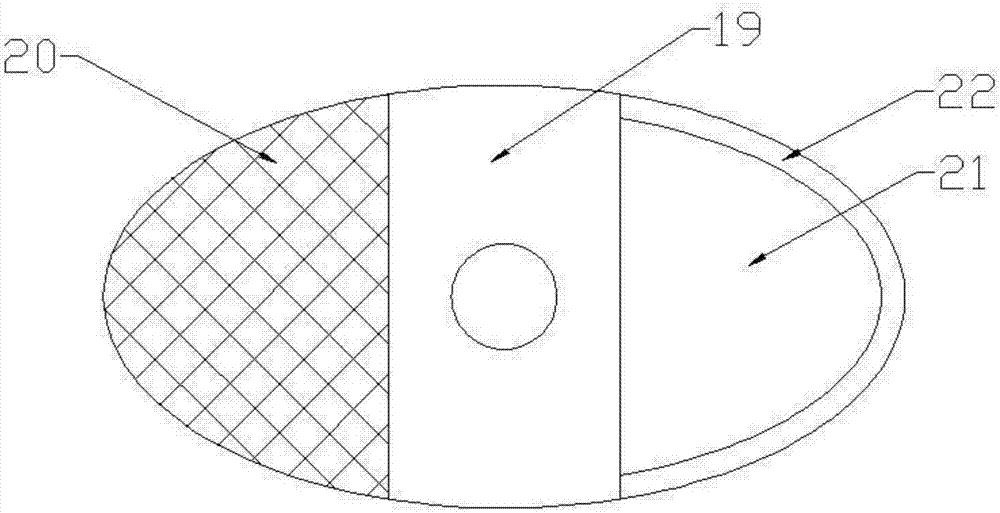

[0020] The housing 1 is fixed with a horizontal partition plate 10, which divides the housing 1 into the first stirring chamber 17 and the second stirring chamber 18 above it; the motor 4 is fixedly mounted on the housing 1, the output shaft of the motor 4 extends vertically downward into the housing 1, and the lower end of the output shaft of the motor 4 is fixedly connected with the transmission shaft 6 that passes through the partition plate 10 vertically, and the lower end of the transmission shaft 6 passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com