Extruding type raw material mixing and stirring equipment for processing of new materials

A mixing and extruding technology, used in mixers, shaking/oscillating/vibrating mixers, dissolving, etc., can solve the problems affecting the product characteristics of new materials, simple stirring structure, and new material stirring, so as to avoid the inconvenience of stirring. Thorough, well-mixed, improved mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

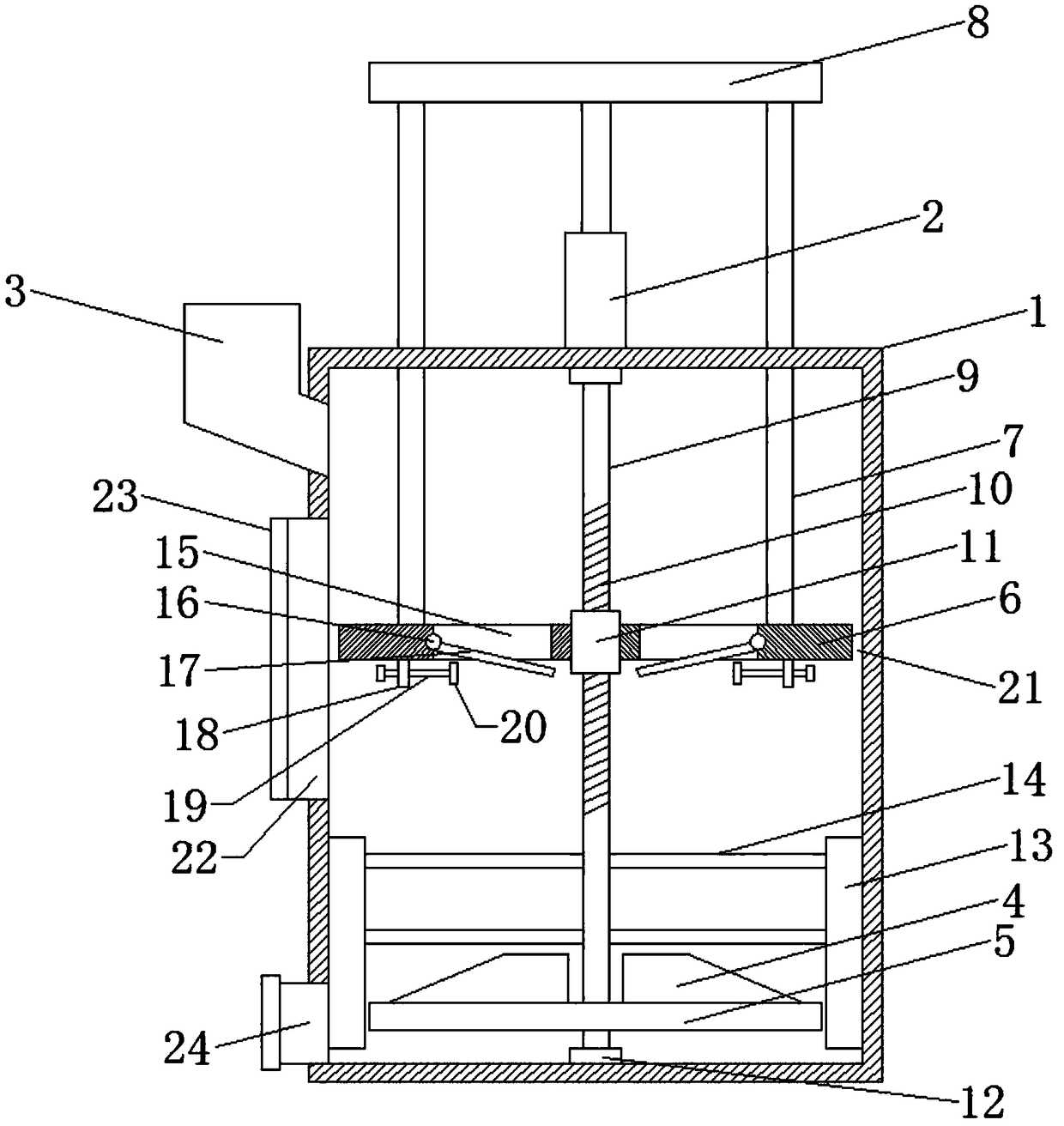

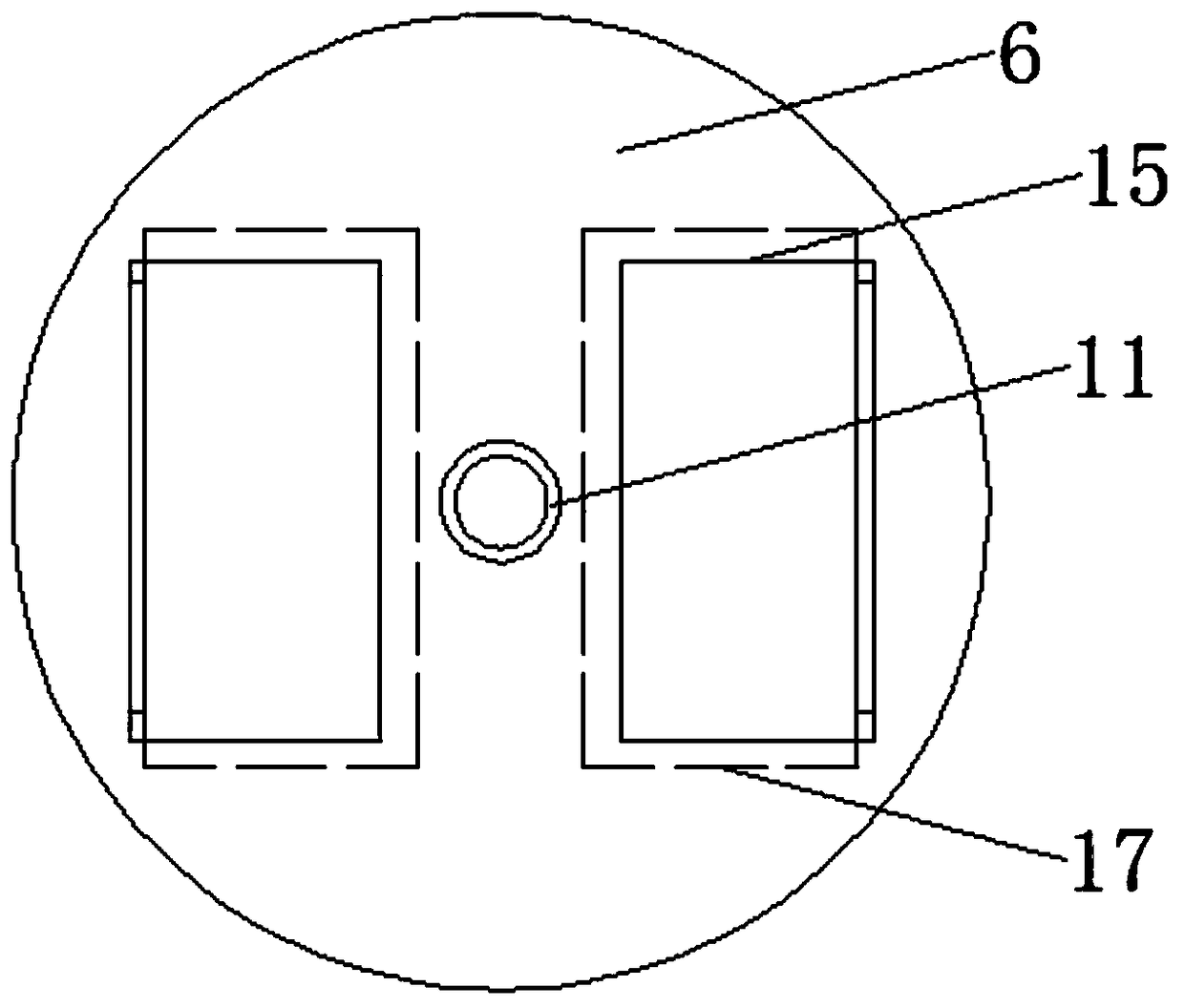

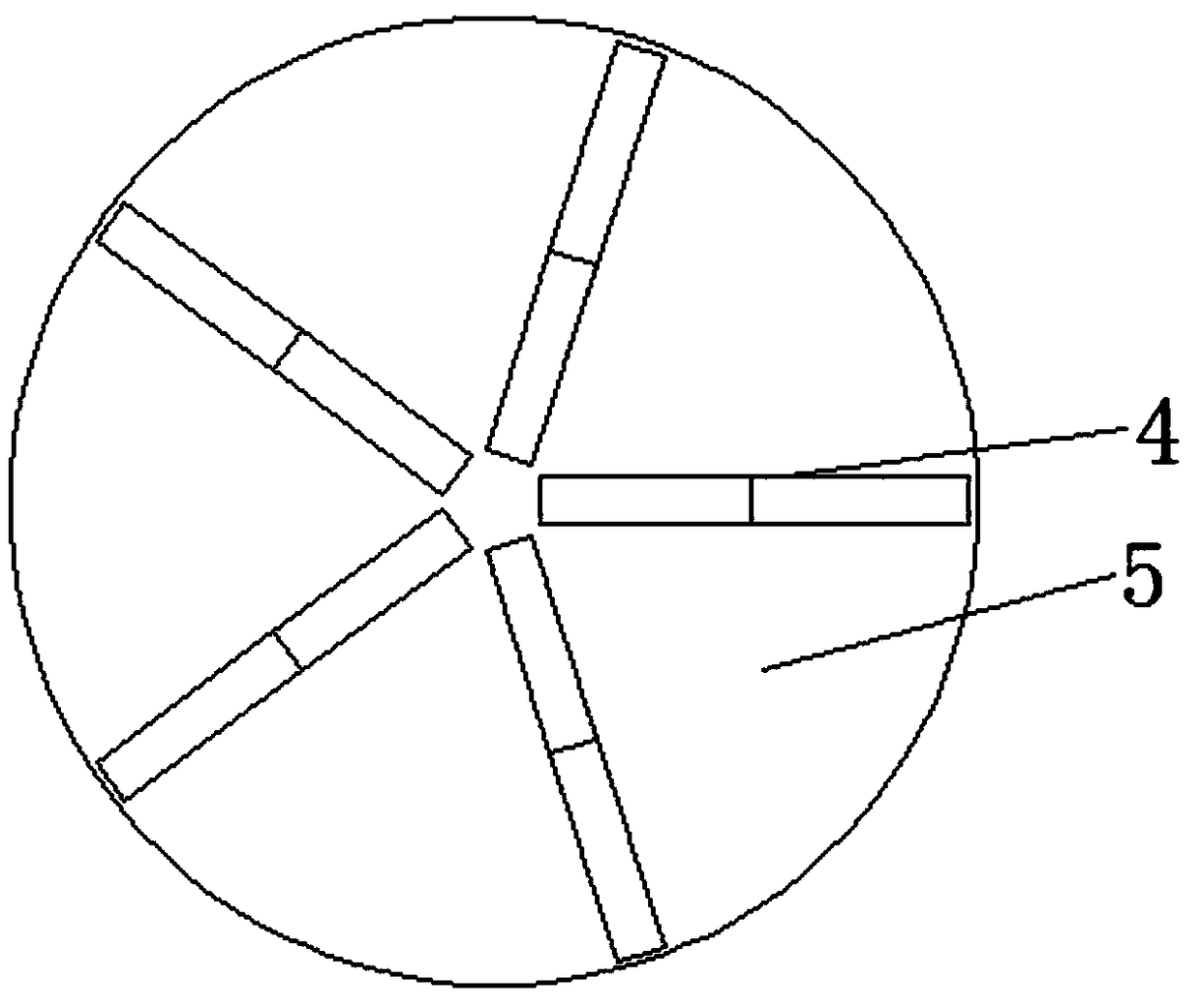

[0018] Please refer to the figure, in the embodiment of the present invention, an extruded raw material mixing and stirring equipment for new material processing includes a cylinder body 1, a hydraulic telescopic cylinder 2, a feeding hopper 3, a stirring blade 4 and a stirring disc 5; The feed hopper 3 is communicated with the side wall of the cylinder 1, and the bottom of the cylinder 1 is communicated with a discharge pipe 24. The hydraulic telescopic cylinder 2 is vertically and fixedly installed on the top of the cylinder 1. The central shaft is provided with a vertical transmission rod 9, the upper end and the lower end of the transmission rod 9 are rotatably connected to the cylinder body 1 through a fixed bearing 12, and the lower end of the transmission rod 9 is coaxially fixed to the stirring disc 5, and the stirring circle A plurality of vertical stirring blades 4 are fixed on the upper surface of the disc 5 to stir the raw material liquid above the stirring disc 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com