Antistatic color master batch and preparation method thereof

A color masterbatch and antistatic technology, which is applied in the field of antistatic color masterbatch and its preparation, can solve the problems of sticking dust, poor antistatic performance, and affecting the use of products, so as to achieve easy mixing, improve performance, and prevent static electricity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

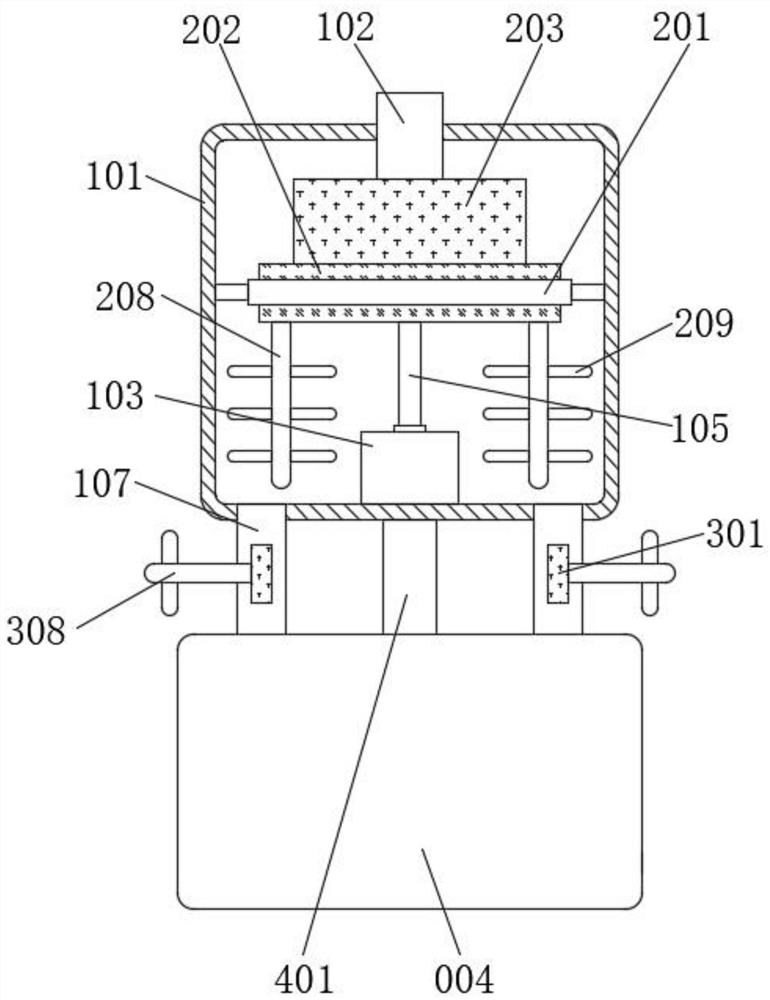

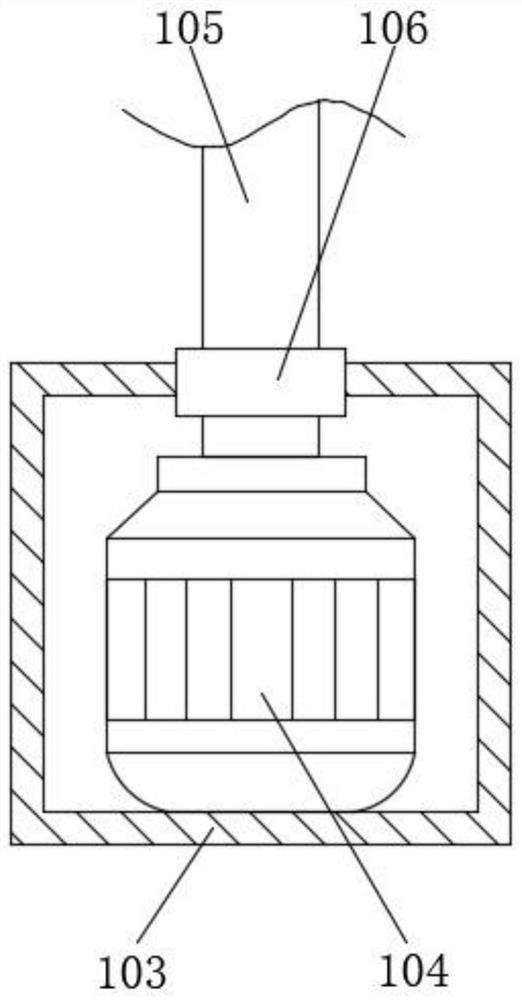

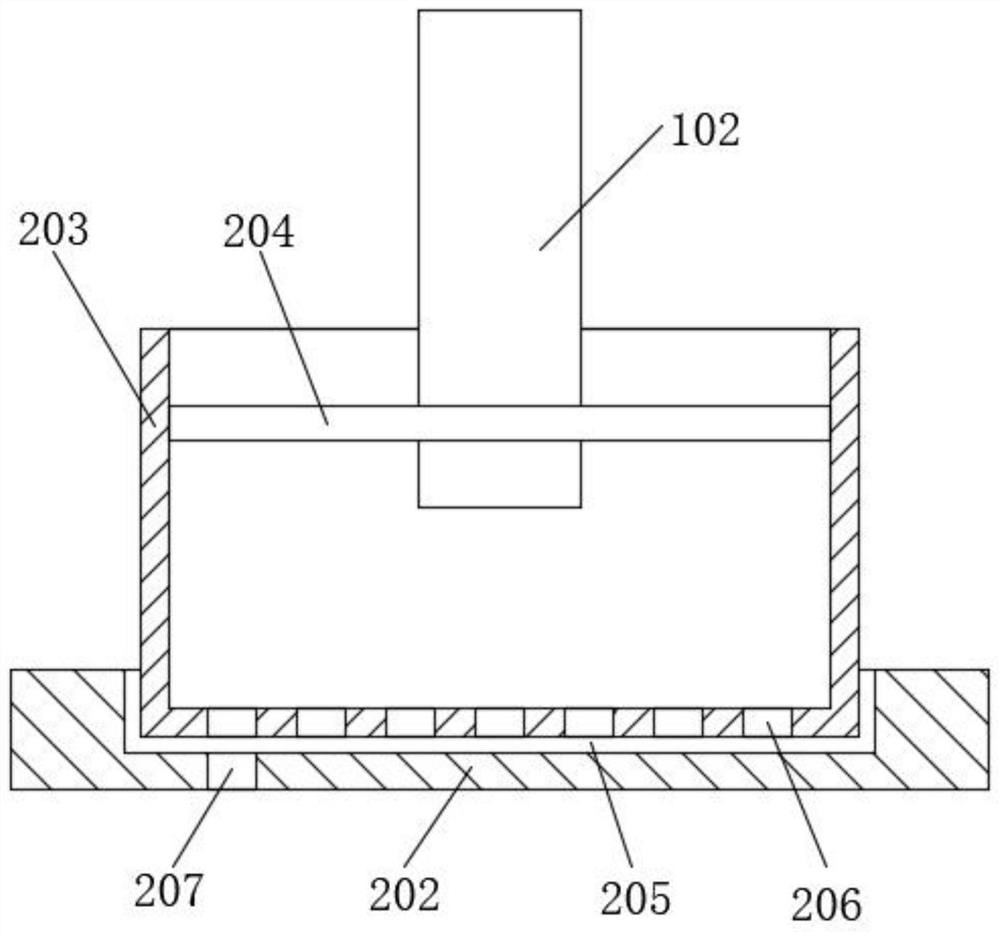

Image

Examples

Embodiment 1

[0044] An antistatic masterbatch, composed of the following components by weight: 50-85 parts of carrier resin, 20-30 parts of pigment, 5-10 parts of dispersant, 10-15 parts of antistatic agent, 3-30 parts of heat stabilizer 5 parts, 3-5 parts of plasticizer, carrier resin is polystyrene, pigment is organic pigment, dispersant is polyethylene wax, thermal stabilizer is zinc stearate, antistatic agent is polyethylene oxide, One of polyether ester amide and polyether ester imide, the plasticizer is dioctyl phthalate, the addition of antistatic agent can greatly improve the antistatic ability of color masterbatch, and then effectively prevent the product from Static electricity is generated on the surface, which significantly improves the performance of masterbatches. Compared with inorganic pigments, organic pigments have the advantages of complete color spectrum, bright colors, high tinting strength, and strong chemical resistance and stability. However, organic pigments have po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com