Uniformly-heated raw material mixing device for chemical industry

A technology for uniform heating and mixing equipment, which is applied to mixers with rotating stirring devices, mixers, shaking/oscillating/vibrating mixers, etc. It can solve problems such as uneven mixing of raw materials, simple structure, and impact on product quality. Avoid stirring dead ends, improve the effect, and fully mix the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

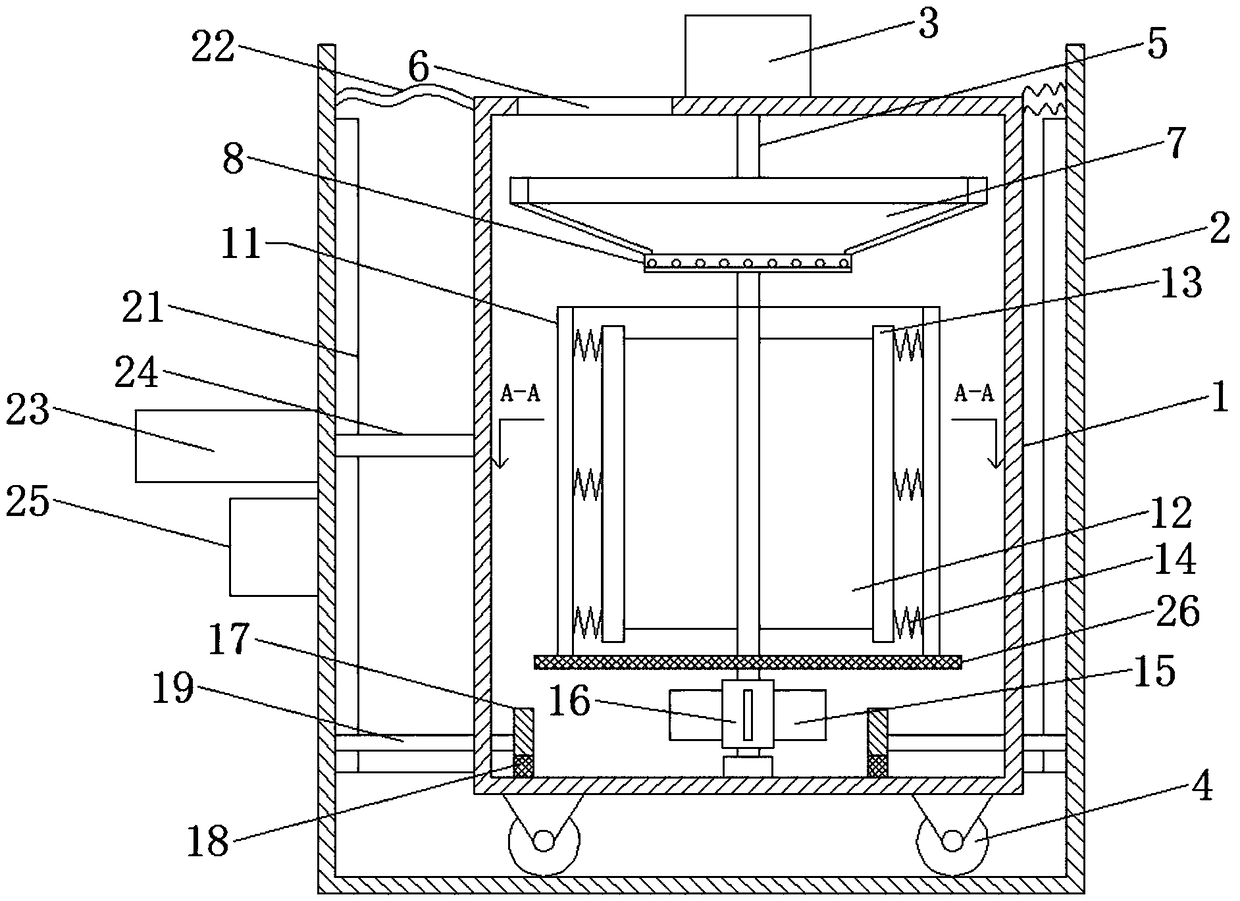

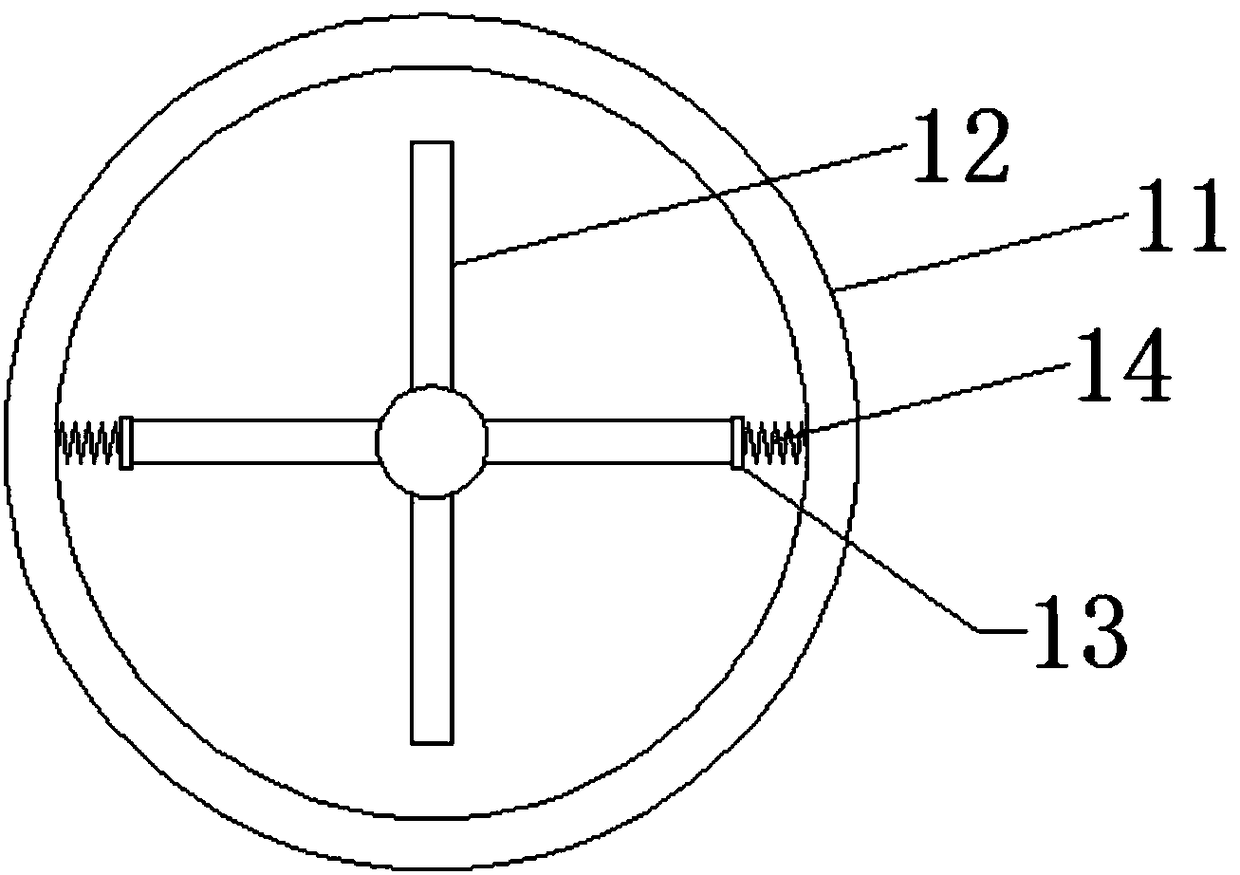

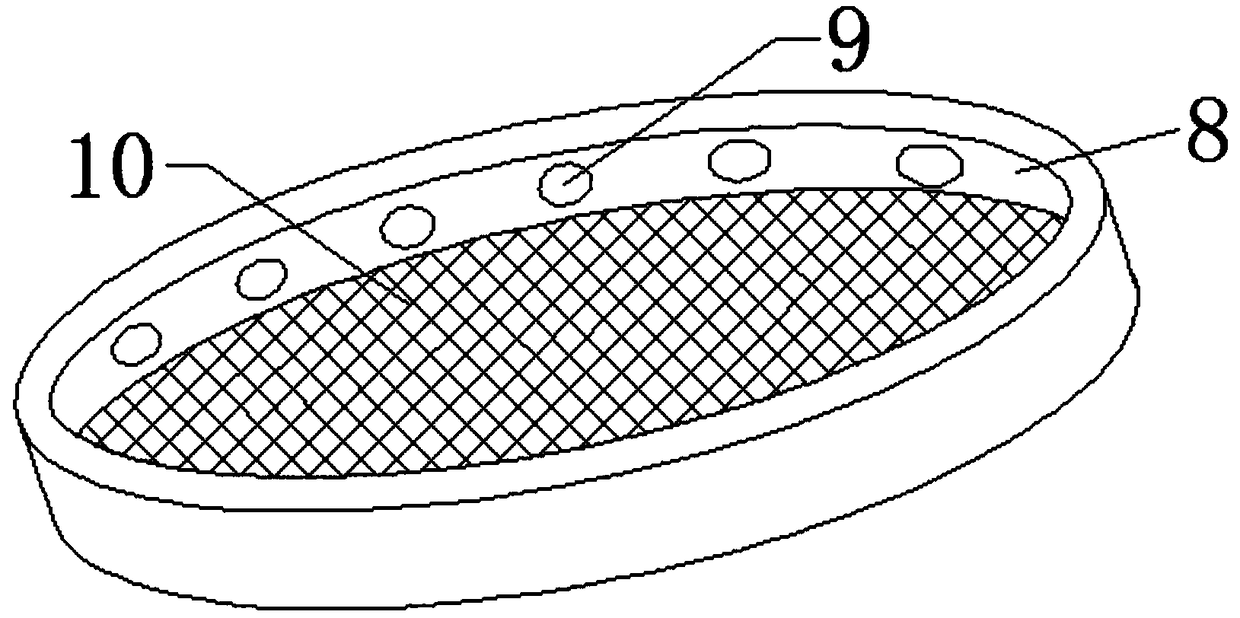

[0017] Please refer to the figure. In the embodiment of the present invention, a uniformly heated raw material mixing equipment for chemical industry includes a cylinder body 1, a housing 2, a motor 3 and a feed port 6; the cylinder body 1 is located in the housing 2, and the housing 2 The upper end of the cylinder 1 is set as an opening, and a plurality of moving wheels 4 are fixedly installed at the bottom of the cylinder 1. The moving wheels 4 are located in the cylinder 1, so that the cylinder 1 can move horizontally in the housing 2; the cylinder 1 and A heating cavity is set between the shell 2 and a heating layer 21 is installed on the inner wall of the shell 2. The main heating element of the heating layer 21 is an electric heating wire, which heats the air in the heating cavity and transfers heat to the inside through the cylinder 1 ,Provide suitable heat for the cylinder 1; A sealing cover 22 is arranged between the top of the cylinder 1 and the shell 2. The material o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com