Lubricating grease blending kettle

A technology of lubricating grease and blending, applied in the field of grease production equipment, can solve the problems of insufficient blending of lubricating grease, affecting the quality of grease production, etc., to prolong the cooling action time, improve the cooling effect, and increase the overall fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

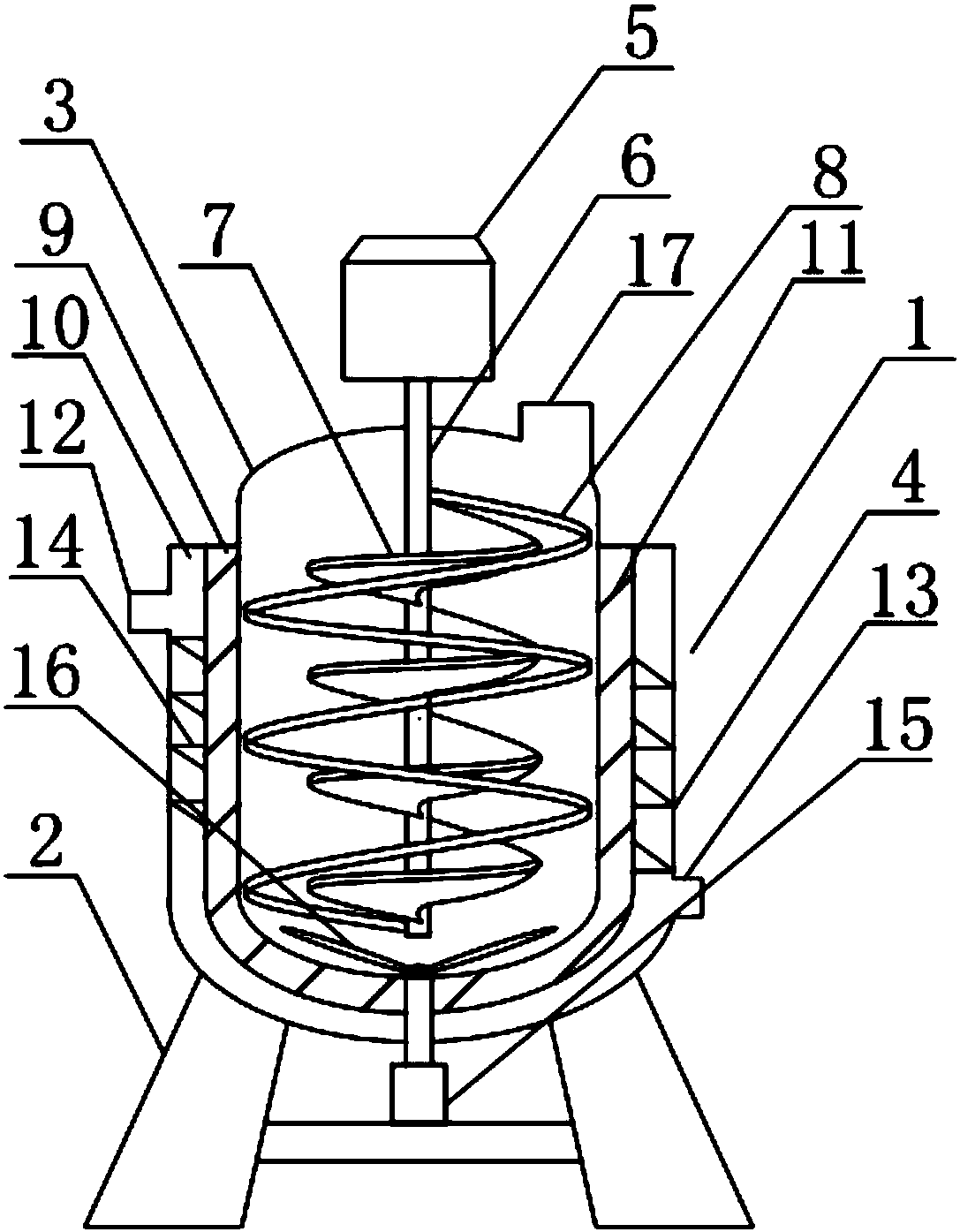

[0022] Such as figure 1 As shown, a grease blending kettle of the present invention includes a blending kettle body 1, and the blending kettle body 1 is installed on a support 2, and the blending kettle body 1 includes a kettle body 3 and is arranged on the kettle body 3 The outer jacket 4, the top of the kettle body 3 is provided with a stirring mechanism extending into the inside of the kettle body 3 and a stirring motor 5 for driving the stirring mechanism to rotate, and the stirring mechanism includes a stirring shaft 6 and a helical blade 7, so The top of the stirring shaft 6 is connected to the power output end of the stirring motor 5, the stirring shaft 6 is fixed with a helical blade 7, and the outside of the helical blade 7 is provided with a circle of spiral scraping strips 8, and the spiral scraping strip 8 is One end is fixed near the upper part of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com