Double-shaft adjustable stirrer

A technology of agitators and agitating components, which is applied in the directions of agitator accessories, mixers with rotary stirring devices, chemical instruments and methods, etc., can solve problems such as the influence of product quality stability, data deviation, uneven material stirring, etc., to reduce the Manpower expenditure, reduce the damage of the mixer, reduce the effect of mixing dead angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

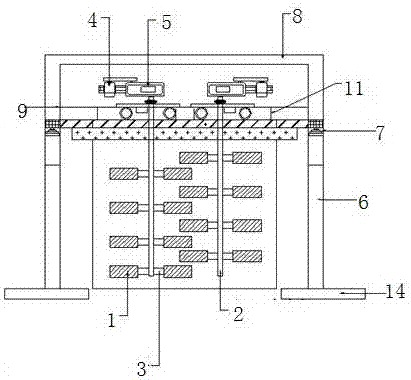

[0017] Embodiment 1: see Figure 1-Figure 2 , a double-shaft adjustable stirrer, the double-shaft adjustable stirrer includes a stirring tank body, a stirring assembly, a support assembly and a power assembly, the stirring assembly is located in the stirring tank; the power assembly is located on the support assembly and It is connected with the stirring assembly through the stirring transmission shaft, and the stirring assembly includes the stirring blade 1, the transmission shaft 2 and the blade connecting rod 3. The stirring blade 1 is connected with the transmission shaft through the blade connecting rod, and the angle between the blade and the blade connecting rod can be adjusted. Adjustment, the angle range of the stirring blade and the blade connecting rod is 20°-70°. When stirring solid objects, use an included angle of 30° to increase the transverse cutting force. When stirring liquid objects, use an included angle of 60° to increase the liquid The flow speed can quic...

Embodiment 2

[0018] Example 2: see Figure 1-Figure 2 , as an improvement of the present invention, the support assembly includes a support frame 6, a hydraulic rod 7 and a gantry bridge 8; the support frame 6 is fixed on the support frame foundation 14; one end of the hydraulic rod is fixed on the support frame, The other end is connected with the gantry bridge. The hydraulic rod controls the rise and fall of the gantry bridge, so that the whole mixer can move up and down freely during work. The supporting frame stands on the supporting foundation, which can effectively reduce the resonance phenomenon generated by the agitator in the working process, and protect the mechanical structure of the entire agitator.

Embodiment 3

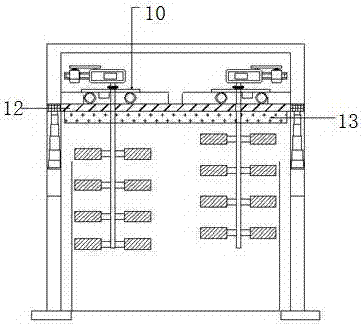

[0019] Embodiment 3: see Figure 1-Figure 2 , as an improvement of the present invention, the power assembly includes a motor 4, a reduction box 5, a limit track 9, a track flat car 10, a limiter 11 and a power support bridge 12; the motor is connected with the reduction box and placed together on the track flat car One end of the gearbox is connected to the motor and the other end is connected to the transmission shaft; the track flatbed is erected on the restricted track; both ends of the restricted track are provided with stoppers; the restricted track is laid on the power support bridge; the two ends of the power support bridge are fixed on the gantry bridge . Through the reciprocating motion of the rail flatbed, the stirring blades of the agitator can fully act on the entire tank, so that the raw materials can be stirred faster and more fully. Adding a limiter on the track used by the flatbed truck can effectively prevent the flatbed truck from overrunning during operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com