High-efficiency material distribution powder selector

A powder concentrator and high-efficiency technology, which is used in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problem that the external feed distribution materials cannot be spread evenly, and increase the resistance consumption of the gas outlet pipeline. , uneven distribution of materials into the grading area, etc., to improve the sorting quality and sorting efficiency, eliminate ineffective movement, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

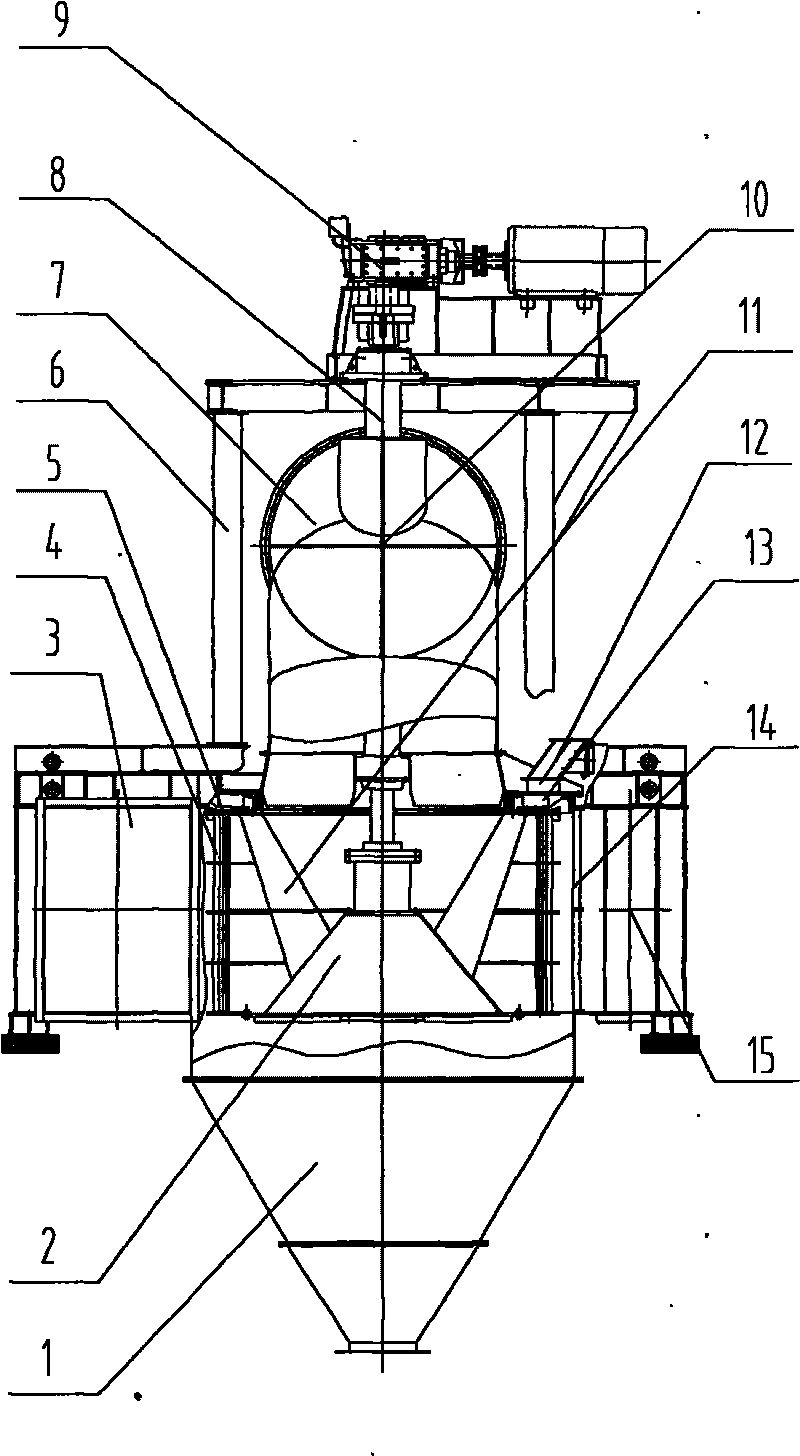

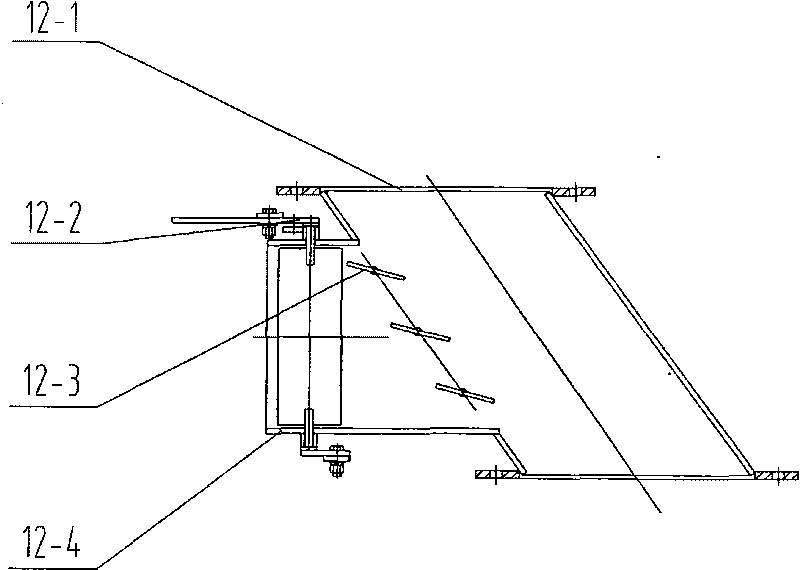

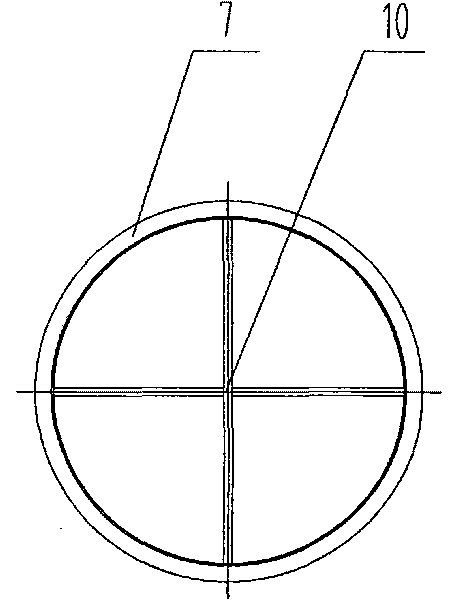

[0029] This specific embodiment includes a cone bucket 1, a cage rotor 2, a primary air inlet 3, a powder selection housing 4, a slope-shaped spreading plate 5, an involute-shaped slope-type spreading plate 5-1, and a baffle plate 5- 2. Rib plate connection device 5-3, bracket 6, air outlet pipe 7, main shaft 8, driving device 9, secondary vortex breaker 10, vortex breaker blade 11, window feed device 12, feed pipe 12 -1. Air inlet regulating valve 12-2, adjustable louver 12-3, square pipe 12-4, equalizing plate 13, air guiding blade 14, secondary air inlet 15.

[0030] The cage rotor 2 is fixed on the main shaft 8 and driven to rotate by the driving device 9; the slope-shaped spreading disc 5 is installed on the upper part of the cage rotor 2 and below the window-type feeding device 12; the cage rotor 2, the main shaft 8, and the slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com