Magnetically driven deviation self-adjustment belt type conveyer

A belt conveyor, magnetic drive technology, applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of low conveyor belt conveyor efficiency, cost increase, low conveyor belt speed, etc., to prevent coal sprinkling and conveyor belt tearing , The effect of reducing thickness cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

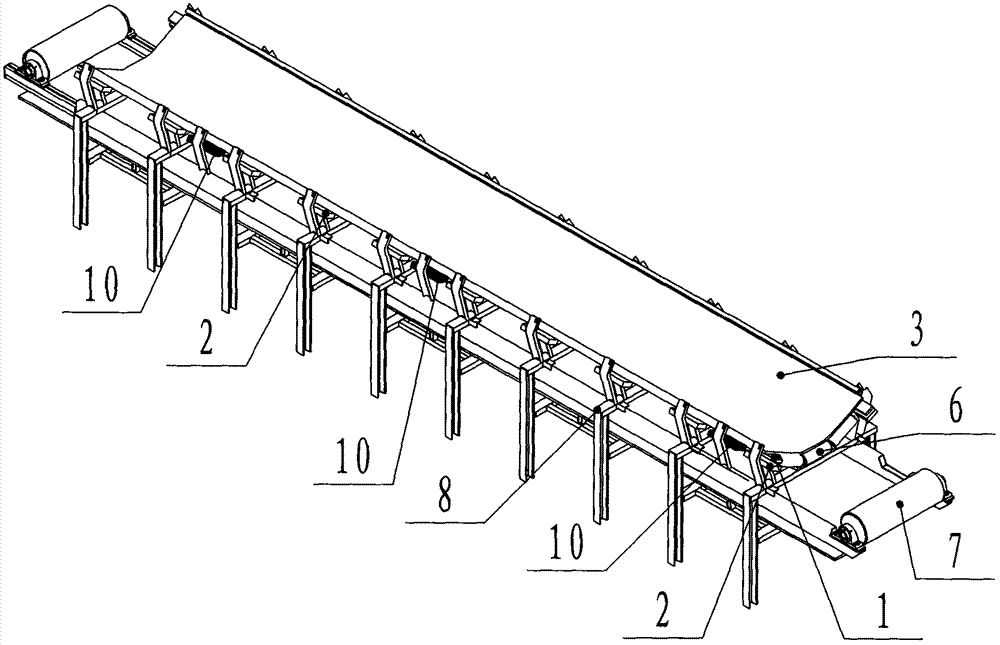

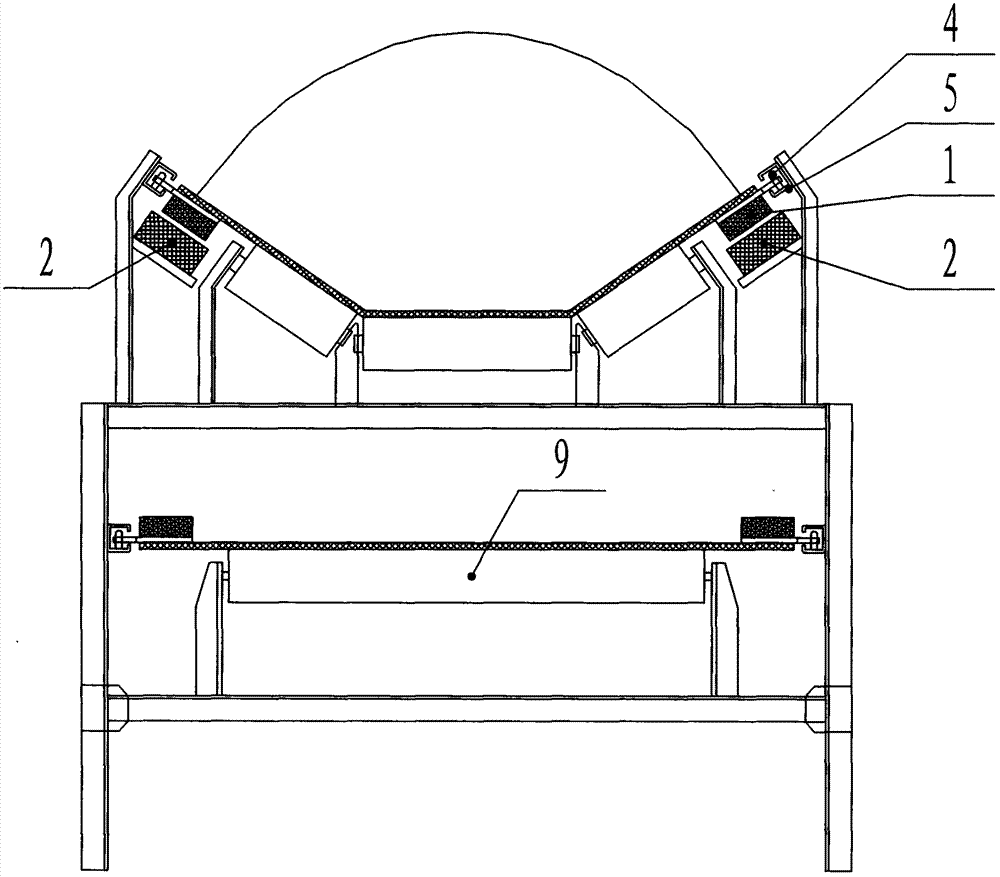

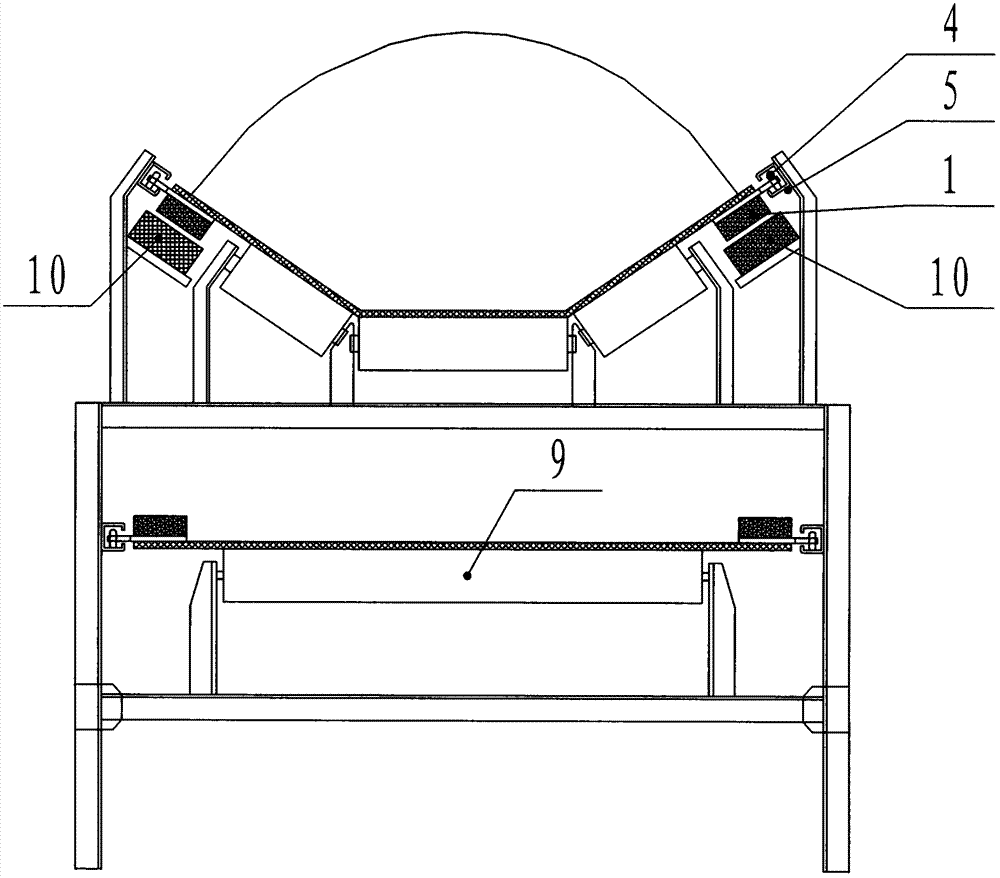

[0016] See attached figure 1 and attached figure 2 , a magnetically driven self-adjusting belt conveyor, including a permanent magnet array 1 (linear motor rotor), a linear motor stator 2, a conveyor belt 3, a guide roller 4, a guide groove 5, a load bearing roller assembly 6, and a reversing roller 7. Frame 8, return roller 9 and deflection adjustment magnet 10; the permanent magnet array 1 and the guide roller 4 are fixed on both edges of the surface of the conveyor belt 3 and arranged along the conveying direction of the conveyor belt 3; the straight line The motor stator 2 is installed on the frame 8 and arranged along the conveying direction of the conveyor belt 3; the guide groove 5 is installed on the frame 8, and the guide roller 4 moves in the guide groove 5 to support the conveyor belt 3 both sides; The carrying idler roller assembly 6 is installed on the top of the frame 8, and has the same structure as the common belt conveyor; the reversing roller 7 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com