Semi-automatic rice steamer loading device of solid brewing grain tank

A semi-automatic technology for brewing grains, which is applied in the fields of liquor distillation and retorts, mechanical equipment or devices, and retort loading devices for wine grains. It can solve the problems of high requirements for retorts, difficulty in realization, and high viscosity and humidity of wine grains, so as to ensure quality and output. The effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

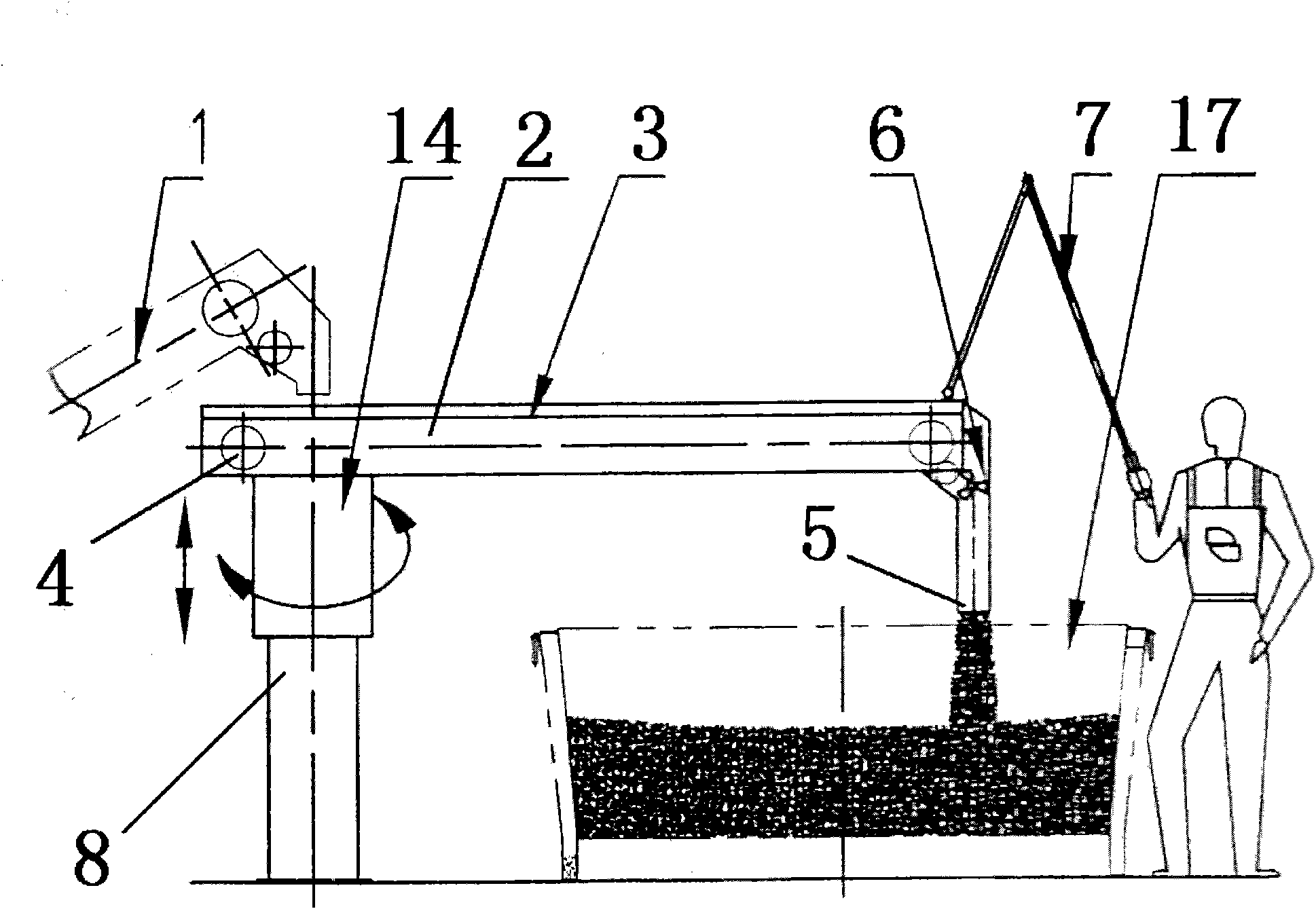

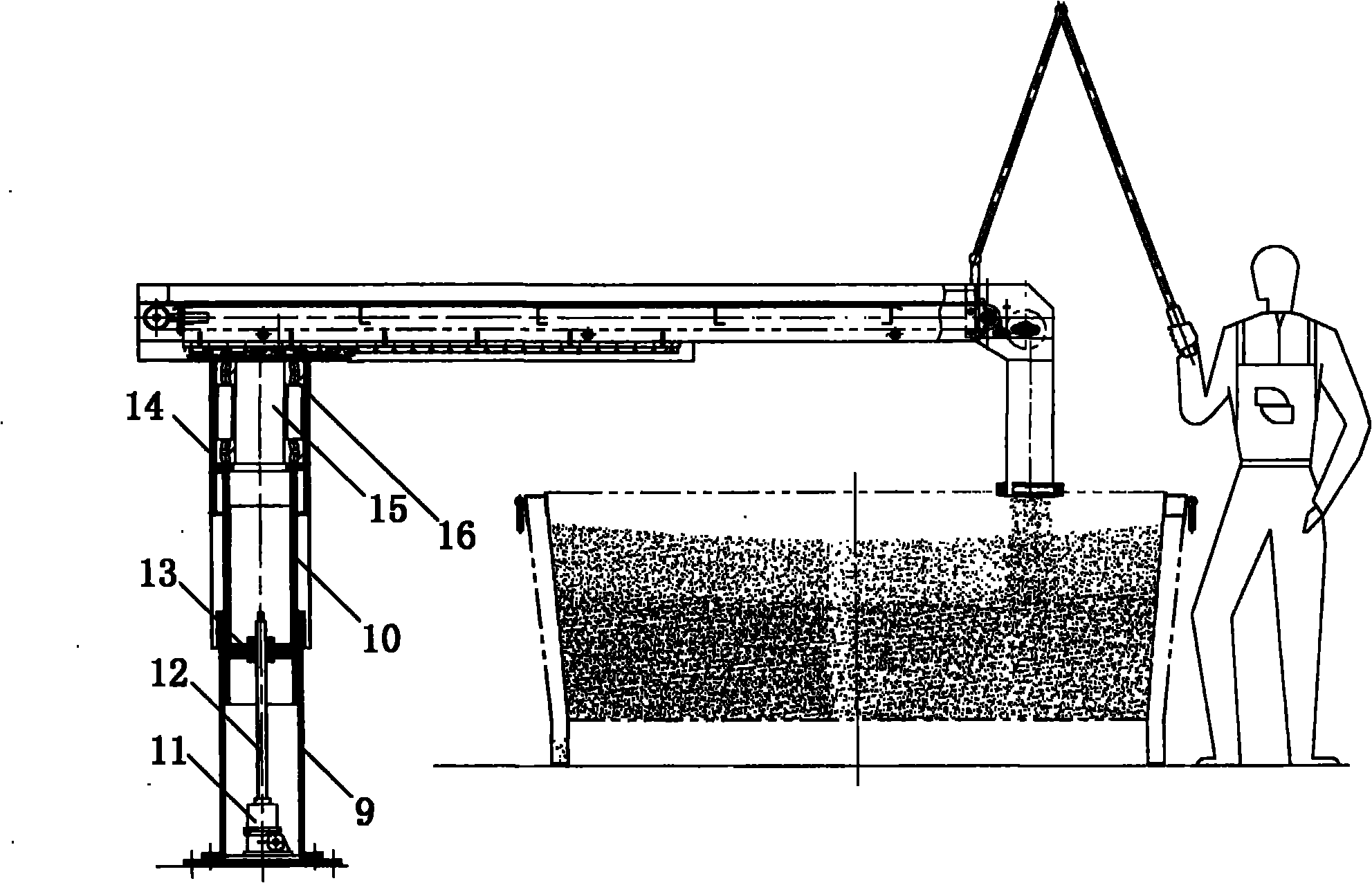

[0013] Once the device is assembled, it is ready to use.

[0014] When in use, the feeding device 1 continuously transports the fermented fermented grains to the top of the conveying channel 2, and drops the material onto the conveying belt 3 in the conveying channel 2, and the conveying belt 3 moves forward continuously under the drive of the conveying wheel 4 , and drop the fermented grains from the feeding port 5.

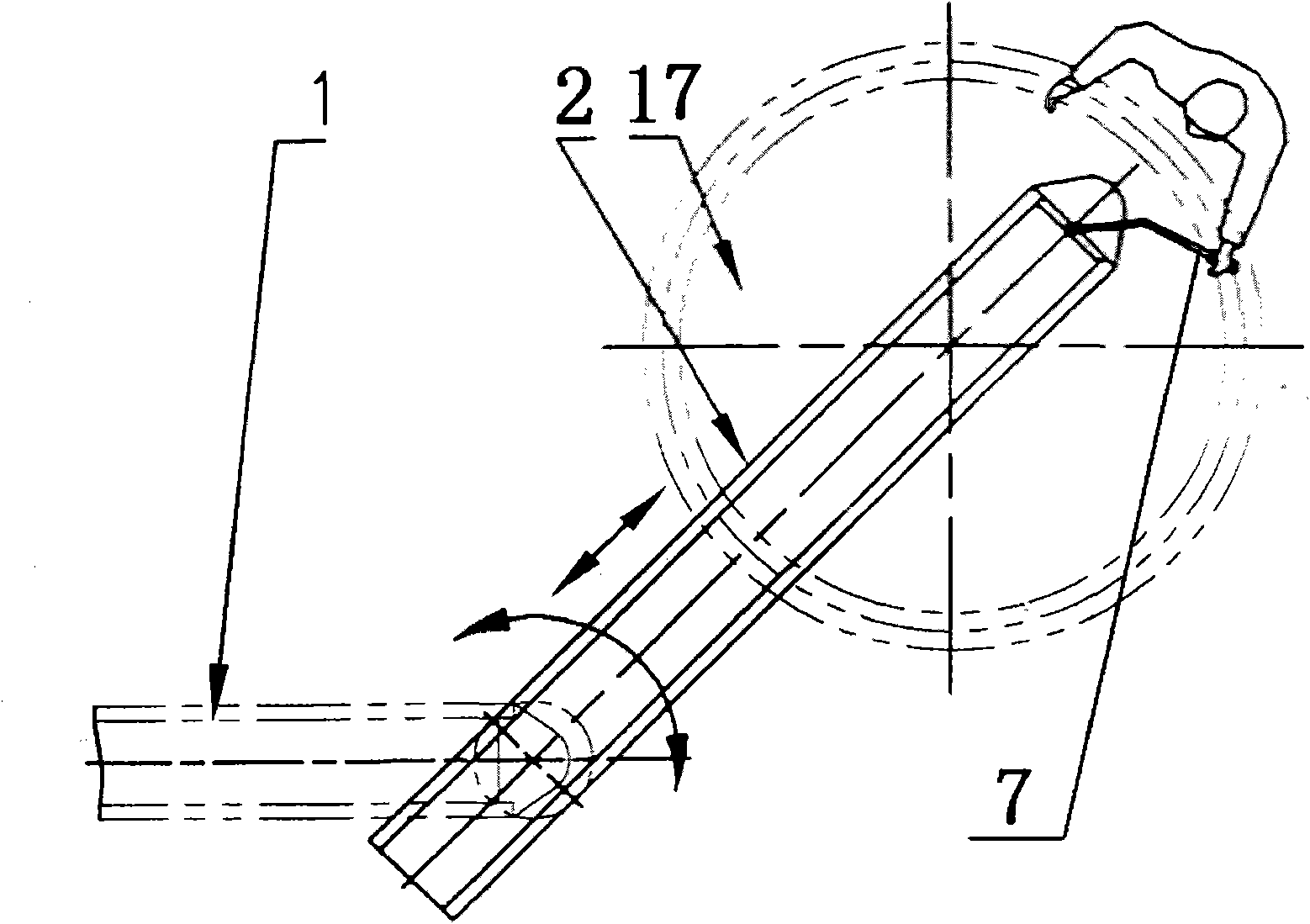

[0015] In addition to the way of conveying wheel 4 and conveyor belt 3, the material conveying method can also adopt chain plate, screw and vibrating conveying methods.

[0016] And before the fermented grains arrive at the feed opening 5, the broken-up wheels 6 will be passed through, and the blades of the broken-up wheels 6 will keep rotating to break up the fermented grains to keep looseness and uniformity.

[0017] While continuously blanking, the worker is operating the handle 7, and exerts force on the conveying path 2 through the handle 7, so that the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com