Construction method for vertical-type hoisting deep-shaft tunnel ballast-soil

A muck and shaft technology, which is applied in the construction field of vertical lifting of muck in deep shaft tunnels, can solve the problems of inability to realize continuous muck removal, low construction efficiency, and large occupied space, and achieve reliable construction equipment and construction methods, The effect of reducing construction costs and transporting a large amount of muck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

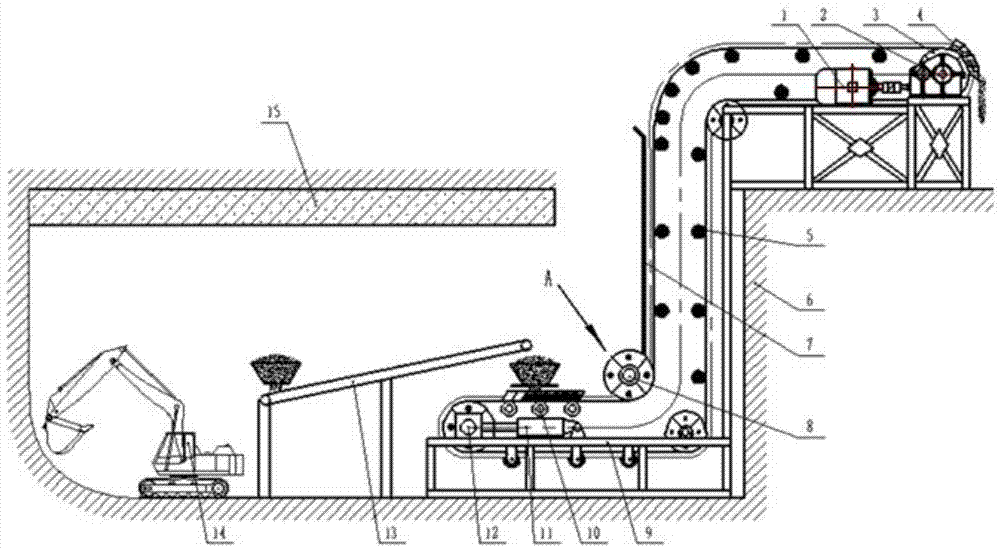

[0023] Attached below Figure 1-3 The technical solution of the present invention is further explained, and the parts not described are subject to the technical solution, and will not be described in detail.

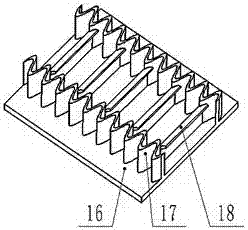

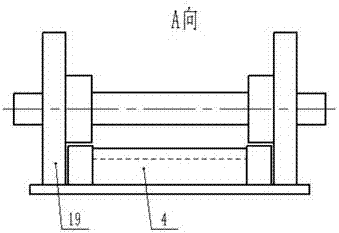

[0024] The structure and construction principle of the corrugated belt conveyor: the mechanical structure of the corrugated belt conveyor can be divided into a horizontal head, a vertical fuselage and a horizontal tail, which correspond to muck unloading, muck vertical lifting and muck loading respectively. . The horizontal machine head mainly includes a motor 1, a reducer 2 and a driving drum 3. The motor 1 drives the driving drum 3 to rotate through the reducer 2, and the friction between the driving drum 3 and the conveyor belt 4 is used to drive the conveyor belt 4 to move smoothly. The hour hand turns. The vertical fuselage is the key part to realize the lifting of the muck, and the anti-spreading device 7 installed at this position can avoid the falling of the mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com