Technology for recycling potassium and sodium salts from lithium-precipitated liquid of lepidolite by means of ethanol

A technology of lepidolite and precipitation of lithium, applied in the field of potassium and sodium salt recovery, can solve the problems of high energy consumption, lithium loss, unsatisfactory sodium ion removal effect, etc., and achieve the effects of easy industrialization and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

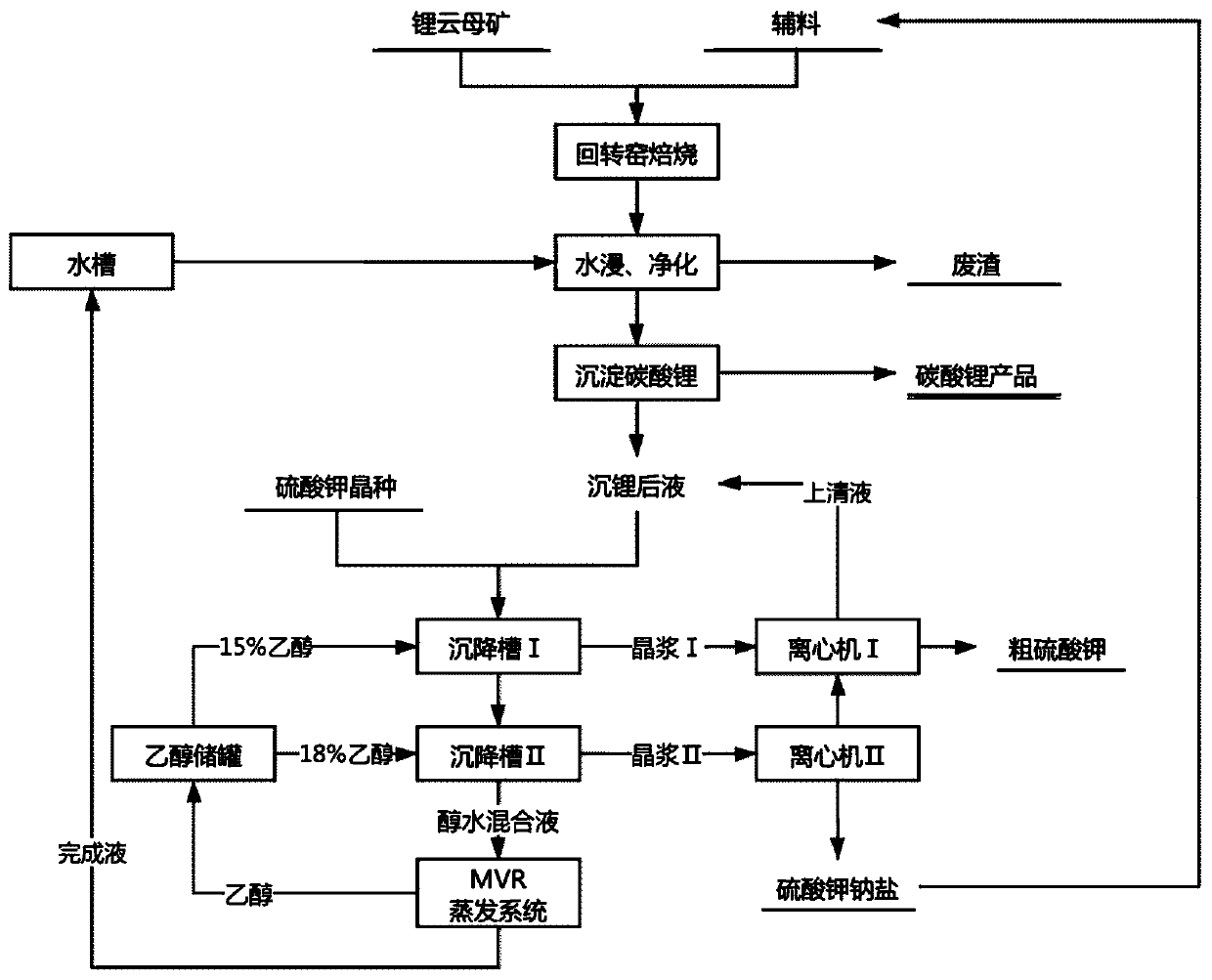

Method used

Image

Examples

Embodiment 1

[0024] Proceed as follows:

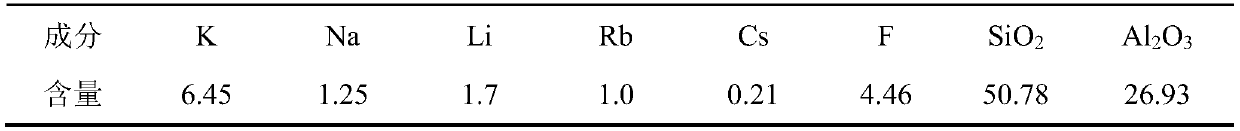

[0025] After roasting, water immersion, purification, and precipitation of lithium carbonate, the lepidolite ore contains 80.7g / L of sodium, 28.9g / L of potassium, and 3.6g / L of lithium;

[0026] Take 10L of the above-mentioned lithium-precipitated liquid and import it into the settling tank, pump 1.5L of ethanol from the ethanol storage tank, mix evenly, cool naturally to 18°C, add 10g of finely ground potassium sulfate crystals, let stand for 30min, and filter to obtain crystal slurry I ;Pump 1.8L of ethanol into the above-mentioned filtrate, stir and mix quickly, let stand for 30min, and filter to obtain crystal slurry II and alcohol-water mixture;

[0027] Crystal slurry I and crystal slurry II are pumped into a centrifuge for separation, the centrifuge rotates at 1000r / min, and after centrifugation for 20 minutes, the crude potassium sulfate and potassium sulfate sodium salt are discharged from the solid phase outlet, and the supernatant is mer...

Embodiment 2

[0031] Proceed as follows:

[0032] After roasting, water immersion, purification, and precipitation of lithium carbonate, the lepidolite ore contains 78.6g / L sodium, 27.9g / L potassium, and 3.4g / L lithium;

[0033] Take 10L of the above lithium-precipitated liquid and introduce it into the settling tank, pump 1.5L of ethanol from the ethanol storage tank, mix well, cool naturally to 18°C, add 8g of finely ground potassium sulfate crystals, let it stand for 30min, and filter to obtain crystal slurry I ;Pump 2.0L of ethanol into the above filtrate, stir and mix quickly, let stand for 30min, filter to obtain crystal slurry II and alcohol-water mixture;

[0034] Crystal slurry I and crystal slurry II are pumped into a centrifuge for separation, and the centrifuge rotates at 1000r / min. After centrifugation for 25 minutes, the crude potassium sulfate and potassium sulfate sodium salt are discharged from the solid phase outlet, and the supernatant is merged into the lithium sink solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com