N-stage stepped sealing and 360-degree flue gas recovery system for circular cooler trolley

A flue gas recycling, stepped technology, applied in the field of iron-making sintering ring cooler, to achieve the effect of improving the utilization rate of cold air, reducing the outflow resistance, and preventing the leakage of flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

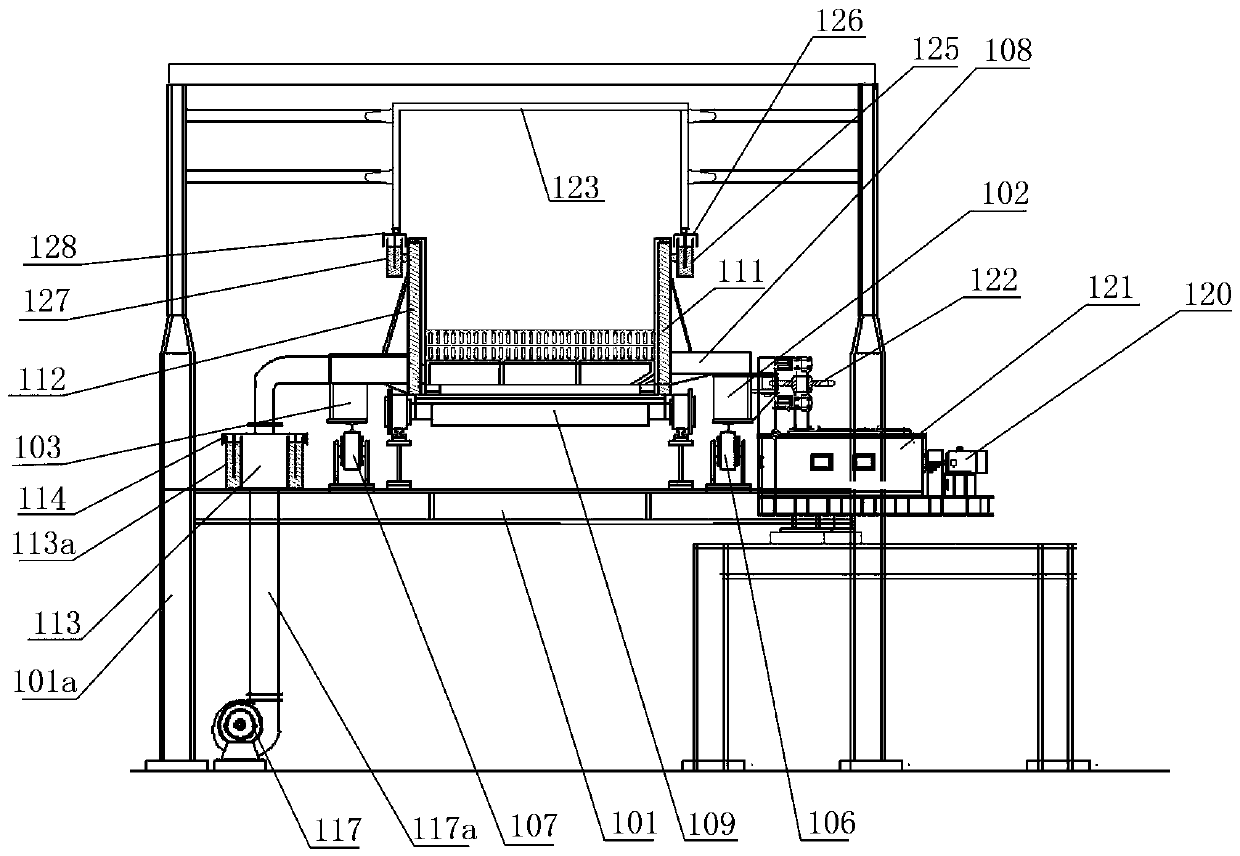

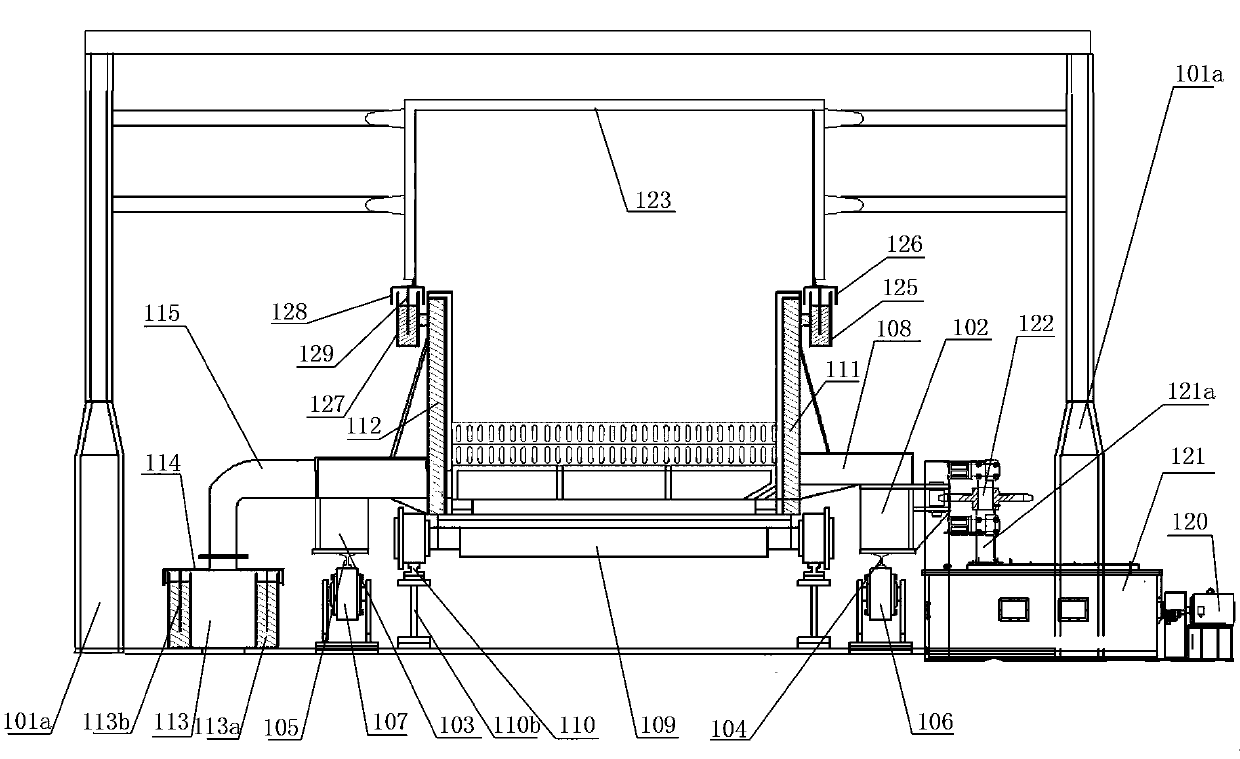

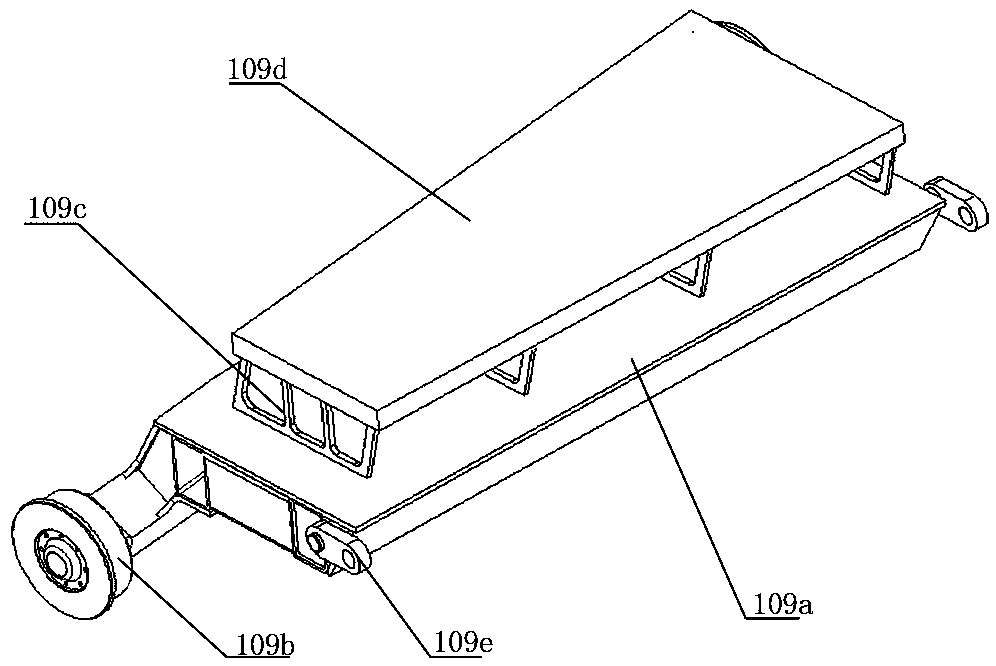

[0036] An independent air-supply annular cooler, including N-level stepped sealing of a trolley and a 360-degree flue gas recovery system. Among them, the rotating mechanism of the annular cooler has various modes, and this embodiment introduces the use of gear drive, specifically as figure 1 As shown, the bottom frame 101 is provided with an inner slewing frame 102 and an outer slewing frame 103, the bottom surface of the inner slewing frame 102 is located on the inner roller ring 106 (consisting of several inner rollers) through the inner guide rail 104, and the bottom surface of the outer slewing frame 103 The outer guide rail 105 is located on the outer idler ring 107 (composed of several outer idler rollers), and the inner idler ring 106 and the outer idler ring 107 are installed on the bottom frame 101 . The inner surface of the inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com