Smoke exhaust heat utilization device of directly-fired triple effect machine

A heat and direct combustion technology, which is applied in the direction of machines using waste heat, machine operation mode, climate change adaptation, etc., can solve the problems of increasing flue gas exhaust heat loss and smoke exhaust loss, so as to reduce fuel consumption and operation cost, reduce exhaust loss, and improve the effect of refrigeration COP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

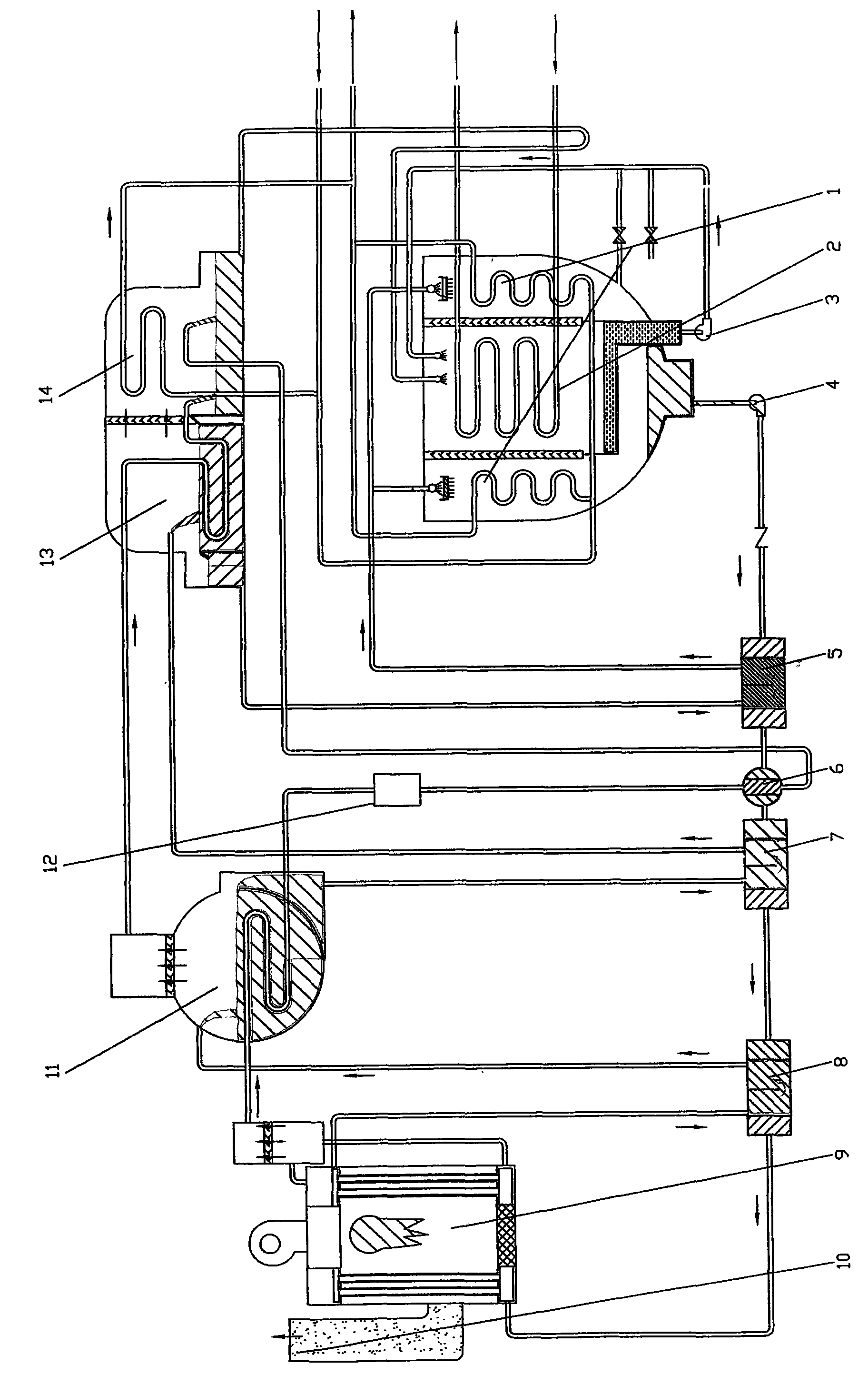

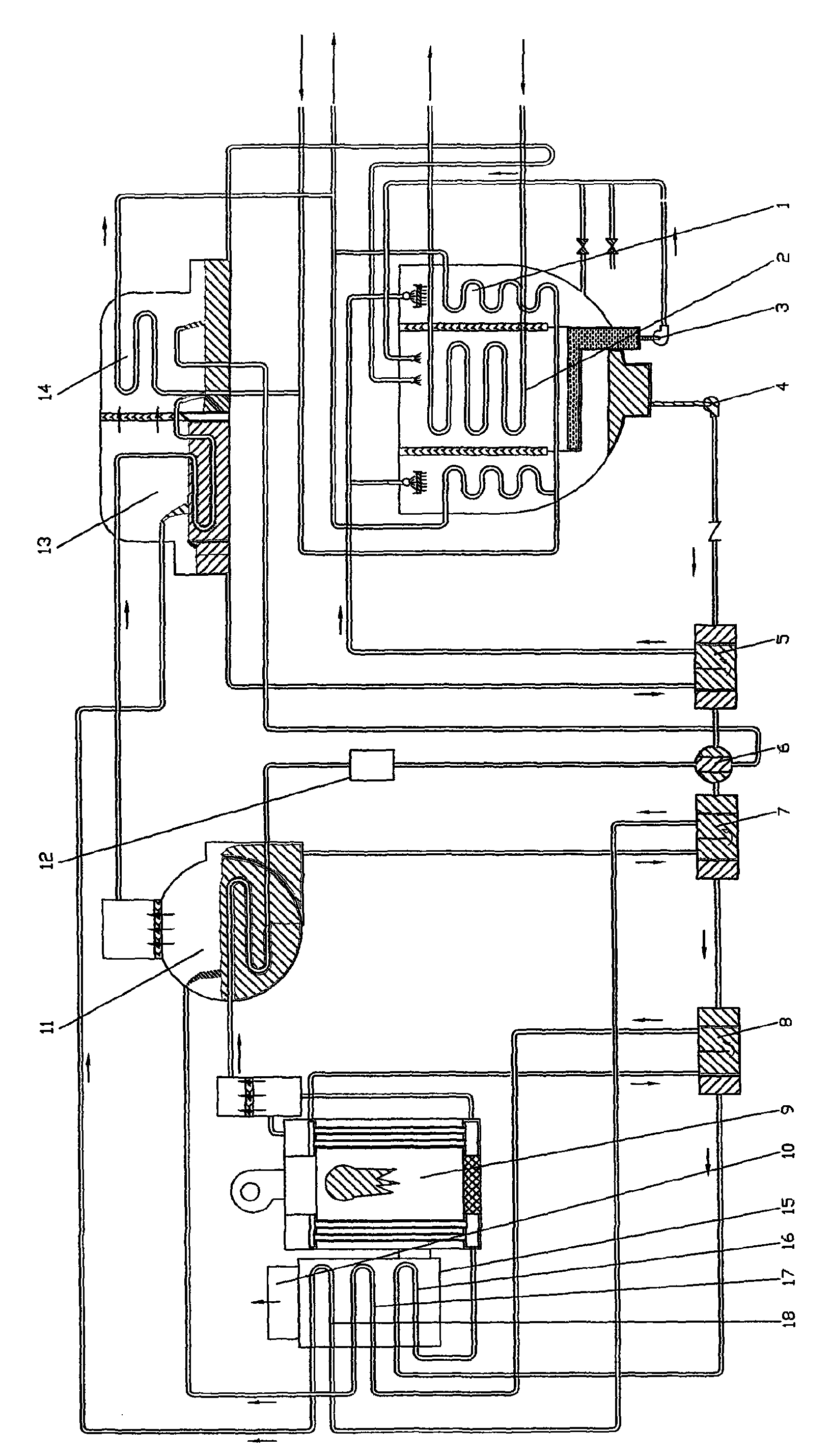

[0010] Such as figure 2 The solution flow shown in the figure is a direct-fired three-effect machine with a positive series flow, consisting of a direct-fired high-pressure generator 9, a medium-pressure generator 11, a low-pressure generator 13, an evaporator 2, an absorber 1, and a high-temperature solution heat exchanger 8 , medium temperature solution heat exchanger 7, low temperature solution heat exchanger 5 and connecting pipelines, pumps and valves. A smoke heat utilization device 15 is added in the flue gas outlet pipe 10 of the direct-fired high-pressure generator 9. The shell side of the smoke heat utilization device 15 is provided with high-temperature flue gas heat exchange tube bundles 16, medium-temperature flue gas Gas heat exchange tube bundle 17, low temperature flue gas heat exchange tube bundle 18. The tube side of the high-temperature flue gas heat exchange tube bundle 16 is arranged in series on the solution pipeline that exits the high-temperature solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com