Drying gas temperature and flow self-regulating control device and method in coke drying system

A technology of drying system and control device, which is applied in drying gas arrangement, drying, dryer and other directions, can solve the problems of inability to realize the economical and rational utilization of waste gas heat, waste of waste gas heat of hot blast stove, unable to meet stable operation, etc. Achieve significant economic and energy-saving benefits, improve the level of automation control, and eliminate potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

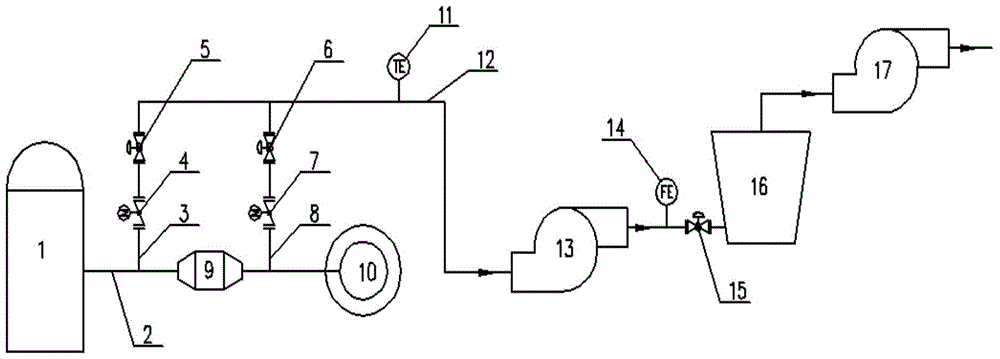

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

[0021] like figure 1 As shown, it is a structural schematic diagram of an embodiment of the drying gas temperature and flow self-regulating control device of the coke drying system. The drying gas temperature and flow self-regulating control device of the coke drying system of this embodiment includes a hot blast stove 1, a heat exchanger 9, a hot blast stove chimney 10, an induced draft fan 13, a coke groove 16 and an axial flow fan 17; the hot blast stove The waste flue gas in 1 is transported to the heat exchanger 9 through the waste flue gas pipeline 2 of the hot blast stove, and the high-temperature waste gas branch pipe 3 and the low-temperature waste gas branch p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com