A kind of self-adjusting moisture content fruit and vegetable fresh-keeping packaging bag and its manufacturing method

A fruit and vegetable preservation and packaging bag technology, applied in packaging, food packaging, biological packaging and other directions, can solve problems such as condensation, aggravate fruit and vegetable rot and rot, and achieve the effect of overcoming serious condensation and improving moisture permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

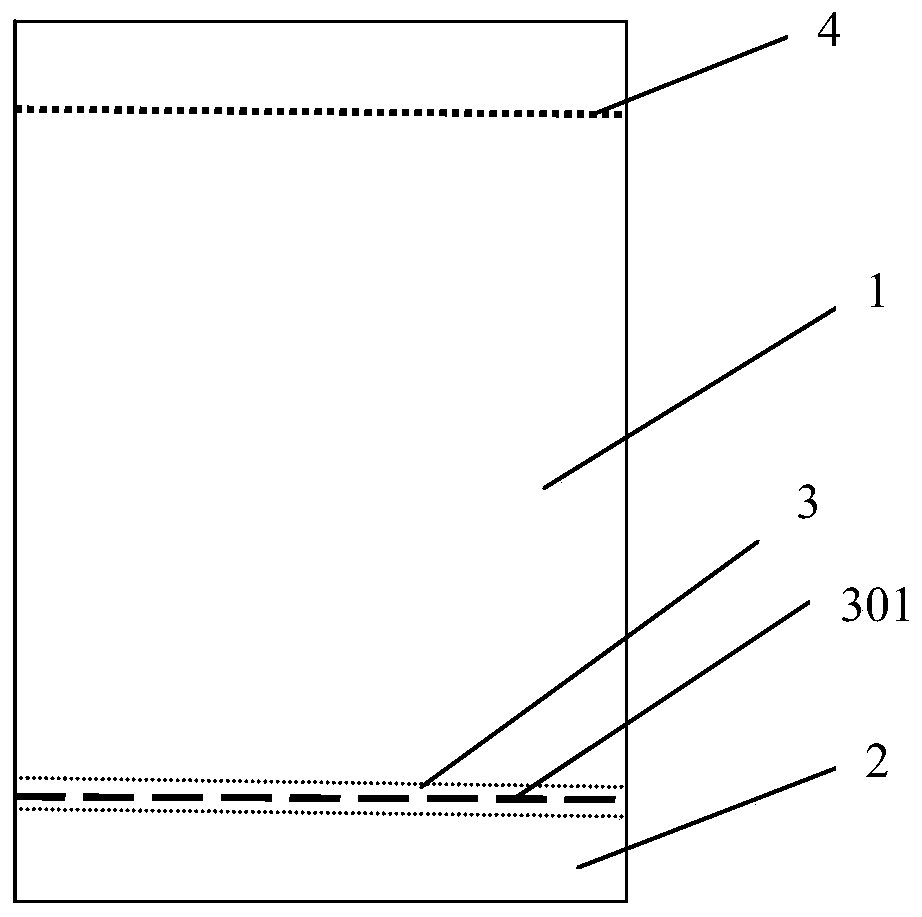

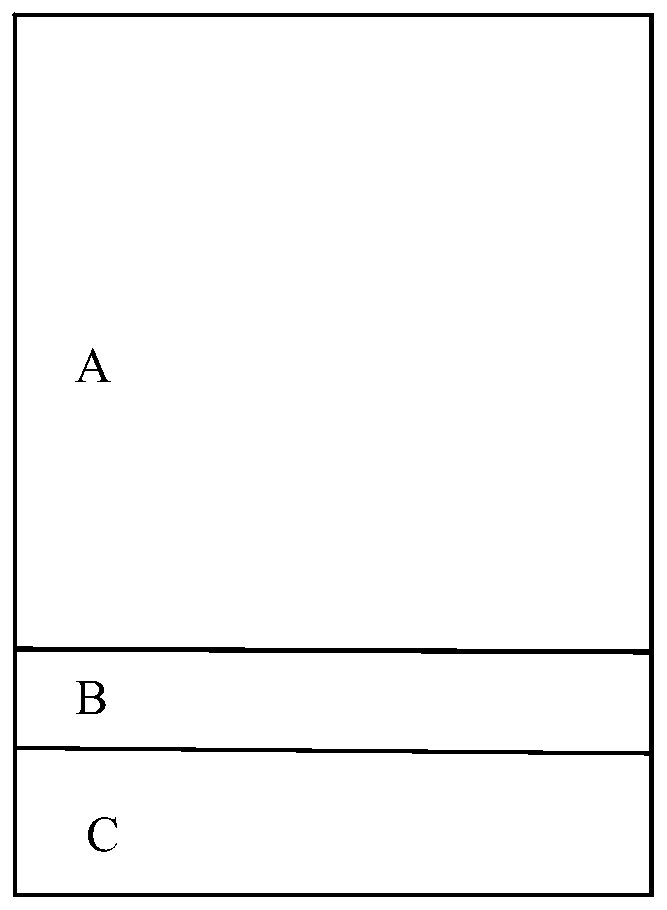

[0057] Select PE anti-fog film a, anti-fog agent b and anti-fog agent c, wherein the film material a is an acrylamide modified PE anti-fog film, and the anti-fog agent b is hexapolyglyceryl stearate and nano-SiO 2 and nano Al 2 o 3 The compound, the anti-fogging agent c is triglyceride trioleate and nano-SiO 2 and nano Al 2 o 3 The compound, θa, θb, θc are 50°, 45°, 40° in turn; as figure 2 As shown, the membrane material a is divided into three adjacent strip areas A, B, and C. Apply and cure anti-fogging agent b and anti-fogging agent c on strips B and C adjacent to area A of the film material a respectively, and control the widths of the two strips of B and C to 0.2cm and 1cm respectively , the reverse side of area C is polished; then the heating copper strip of the ordinary hot-press sealing machine is grooved, the width of the groove is 0.5cm and the cover is sealed with an insulating strip, and the distance between adjacent grooves is 0.3cm, so as to be converted i...

Embodiment 2

[0065] Select PE anti-fog film a, anti-fog agent b and anti-fog agent c, wherein film material a is AFPEGE10 anti-fog masterbatch added to LDPE for mixing, and anti-fog agent b is triglycerol monostearate and nano-SiO 2 and nano Al 2 o 3 The anti-fogging agent c is ten polyglycerol monolaurate, six polyglycerol monooleate and nano-SiO 2 and nano Al 2 o 3 The composites, θa, θb, θc are 40°, 25°, 15° in turn; the membrane material a is divided into three adjacent strip regions A, B, and C. Anti-fogging agent b and anti-fogging agent c are coated and cured on the adjacent strips B and C of the film respectively, and the widths of the two strips of B and C are controlled to be 0.4cm and 5cm respectively, and the opposite side of C Grinding treatment; then groove the heating copper bar of the ordinary heat-pressing sealing machine, the width of the groove is 0.5cm and it is sealed with an insulating strip, and the distance between adjacent grooves is 0.3cm, thereby refitting in...

Embodiment 3

[0072] Select PE anti-fogging film a, anti-fogging agent b and anti-fogging agent c, wherein the film material a is a mixed film of modified PE and anti-fogging masterbatch, and the anti-fogging agent b is alkylamine ethylene oxide and nano SiO 2 and nano Al 2 o 3 The compound, anti-fogging agent c is fatty alkanolamide and nano-SiO 2 and nano Al 2 o 3The composites, θa, θb, θc are 45°, 36°, 30° in turn; the membrane material a is divided into three adjacent strip regions A, B, and C. The antifogging agent b and antifogging agent c are coated and cured on the adjacent strips B and C of the film respectively, and the widths of the two strips of B and C are controlled to be 0.3cm and 3cm respectively, and the reverse side of the C zone is polished treatment; then slot the heating copper bar of the ordinary heat-pressing sealing machine, the slot width is 0.5cm and seal the cover with heat-insulating strips, and the distance between adjacent slots is 0.3cm, thereby refitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com