A kind of adjustment and control method of wet dct clutch oil filling process

A technology for regulating control and clutches, which is applied to clutches, fluid-driven clutches, and non-mechanical-driven clutches. It can solve the problems of large differences in delayed response time of solenoid valves, frustrating starting, and poor clutch pressure follow-up control, etc., to achieve optimal pressure. Controlling the Effects of Poor Consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

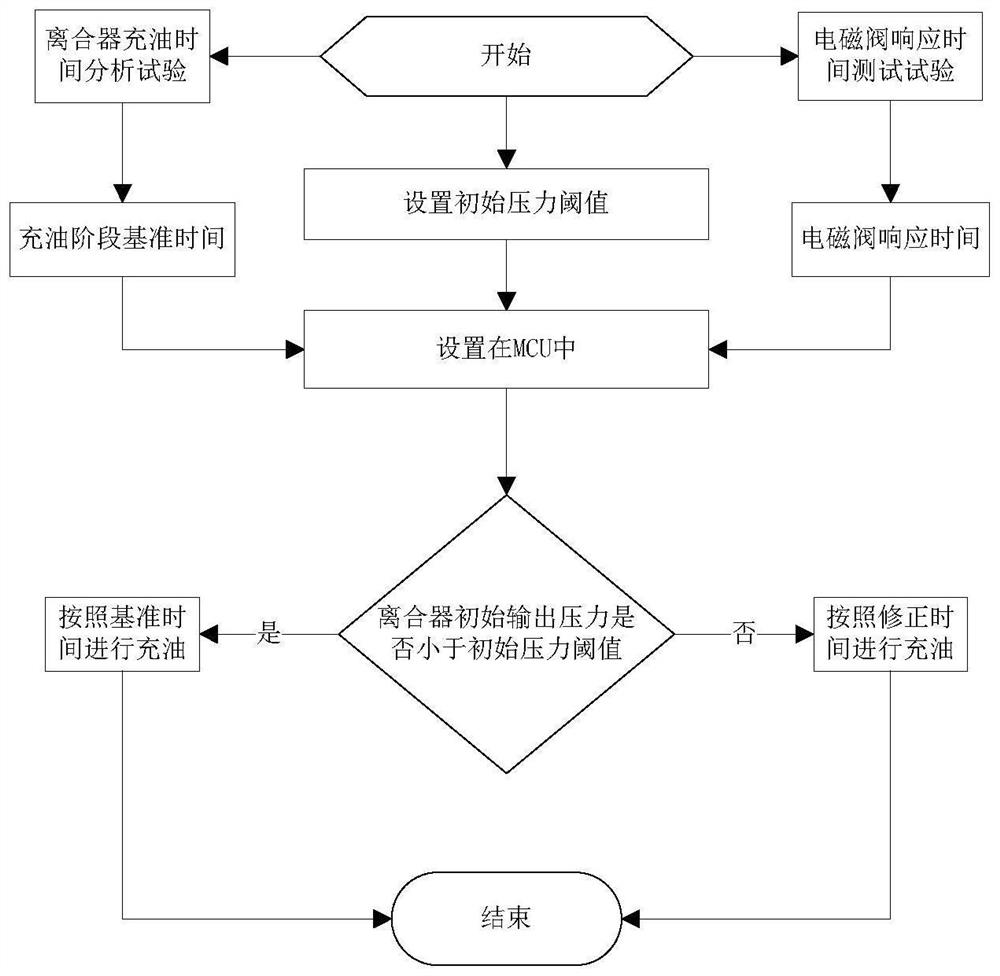

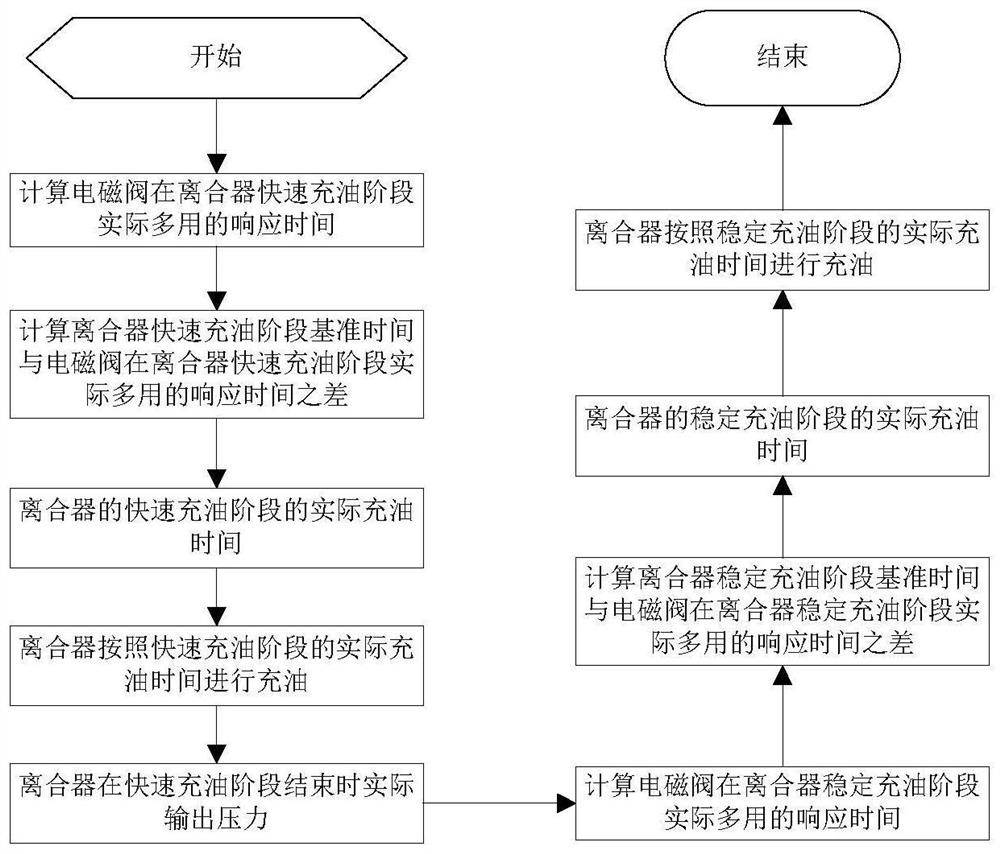

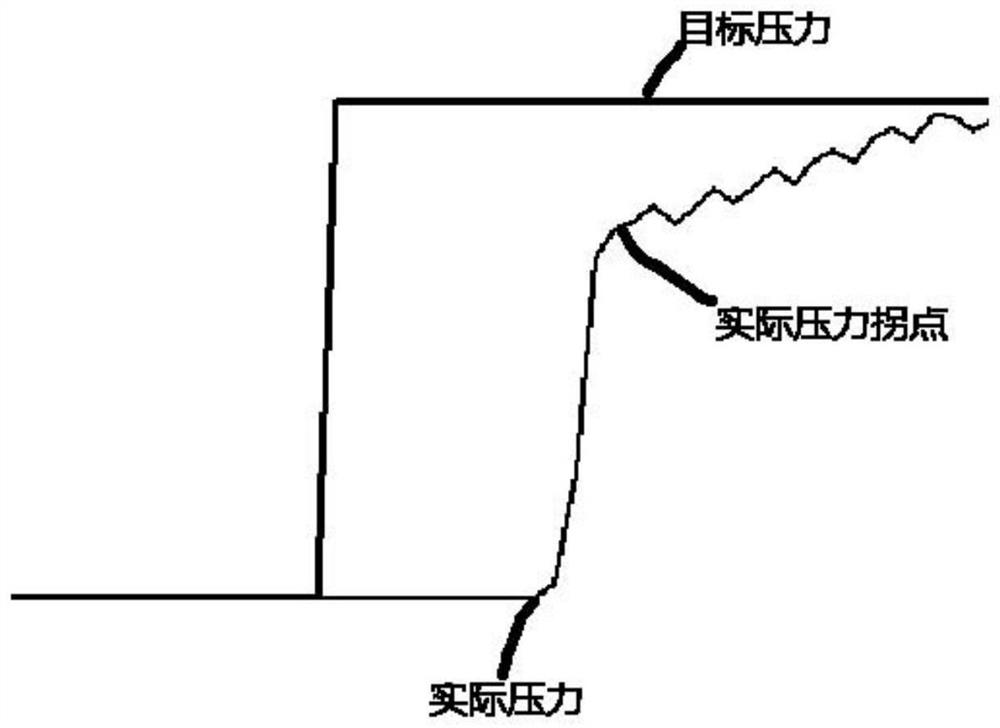

[0048] like Figure 1 to Figure 3 As shown, a method for adjusting and controlling the oil filling process of a wet DCT clutch includes the following steps:

[0049] 1) The clutch oil filling process is divided into a rapid oil filling stage and a stable oil filling stage;

[0050] 2) Through the clutch oil filling time analysis test, the reference time of the clutch rapid oil filling stage and the reference time of the clutch stable oil filling stage are obtained, and stored in the TCU;

[0051] 3) The corresponding relationship curve between the clutch output pressure and the real-time delay response time of the solenoid valve is obtained through the solenoid valve delay response time test, and stored in the TCU;

[0052] 4) Obtain the reference delay response time of the solenoid valve under different DCT oil temperatures through the solenoid valve delay response time test and store it in the TCU;

[0053] 5) Set the initial pressure threshold;

[0054] 6) Set the refere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com