an isostatic press

A technology of isostatic presses and racks, applied in mechanical equipment, fluid pressure actuation devices, fluid pressure actuation system components, etc., can solve the problem of easily damaged components such as hydraulic valves, damage to pressurized cylinders, and safety accidents and other problems, to achieve the effect of reducing processing difficulty, reliable sealing, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

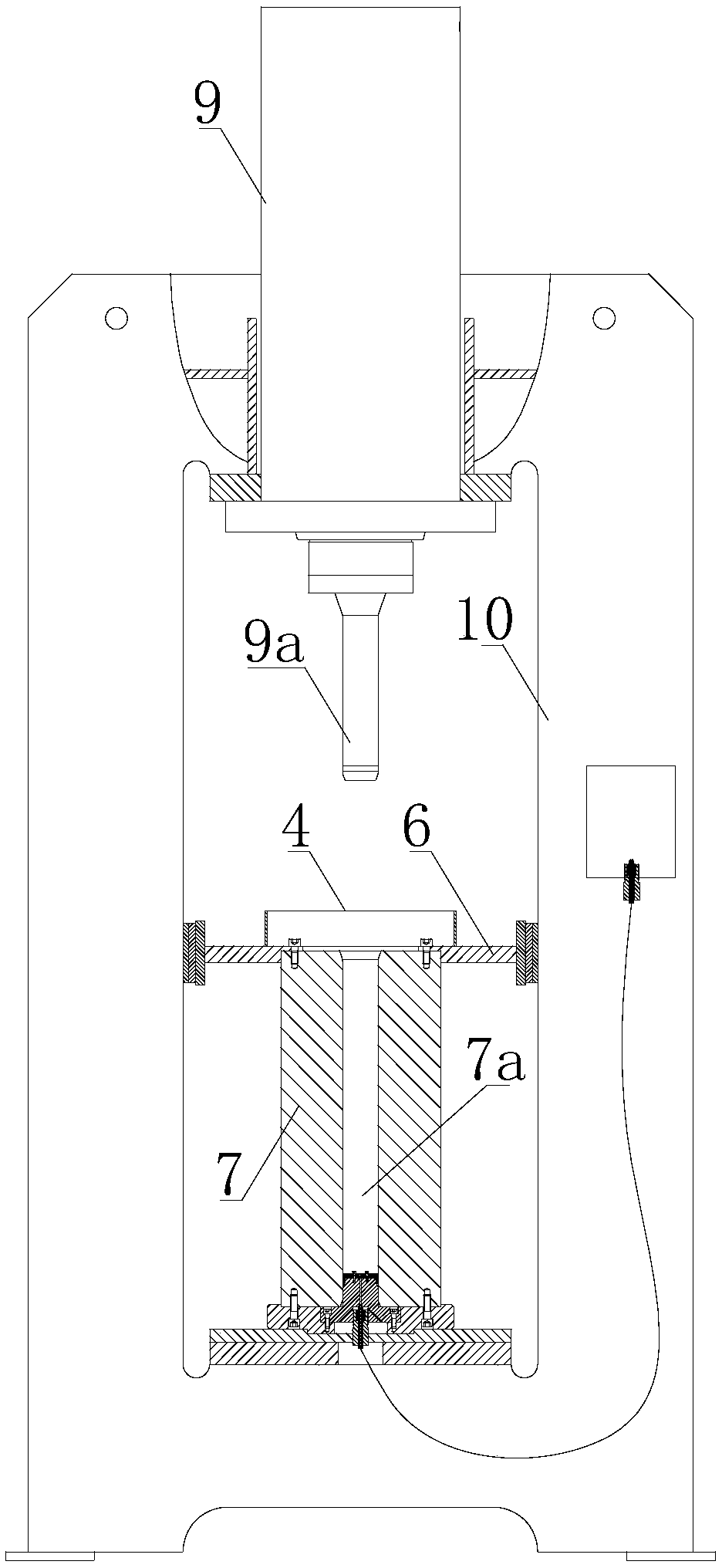

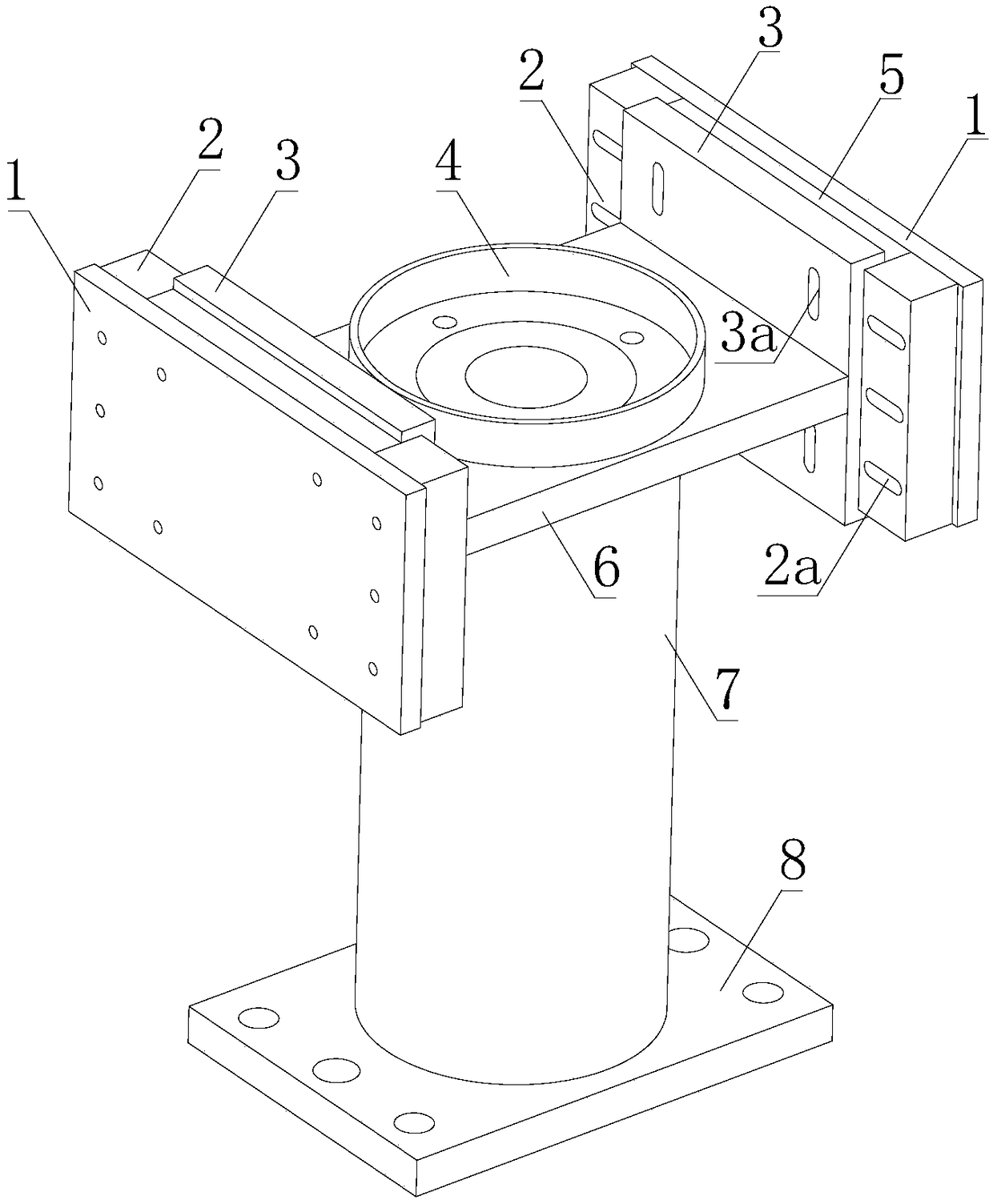

[0034] like Figure 1-9 As shown, a kind of isostatic press of the present embodiment comprises a frame 10, a booster cylinder 9 fixedly arranged at the top of the frame 10, a working cylinder fixedly arranged at the bottom of the frame 10, and a working cylinder fixedly arranged at the top of the frame 10. The pressure head 9a on the piston rod of the booster cylinder 9; the working cylinder is provided with a working chamber 7a; it also includes a positioning device and a hydraulic control system for controlling the action of the booster cylinder 9;

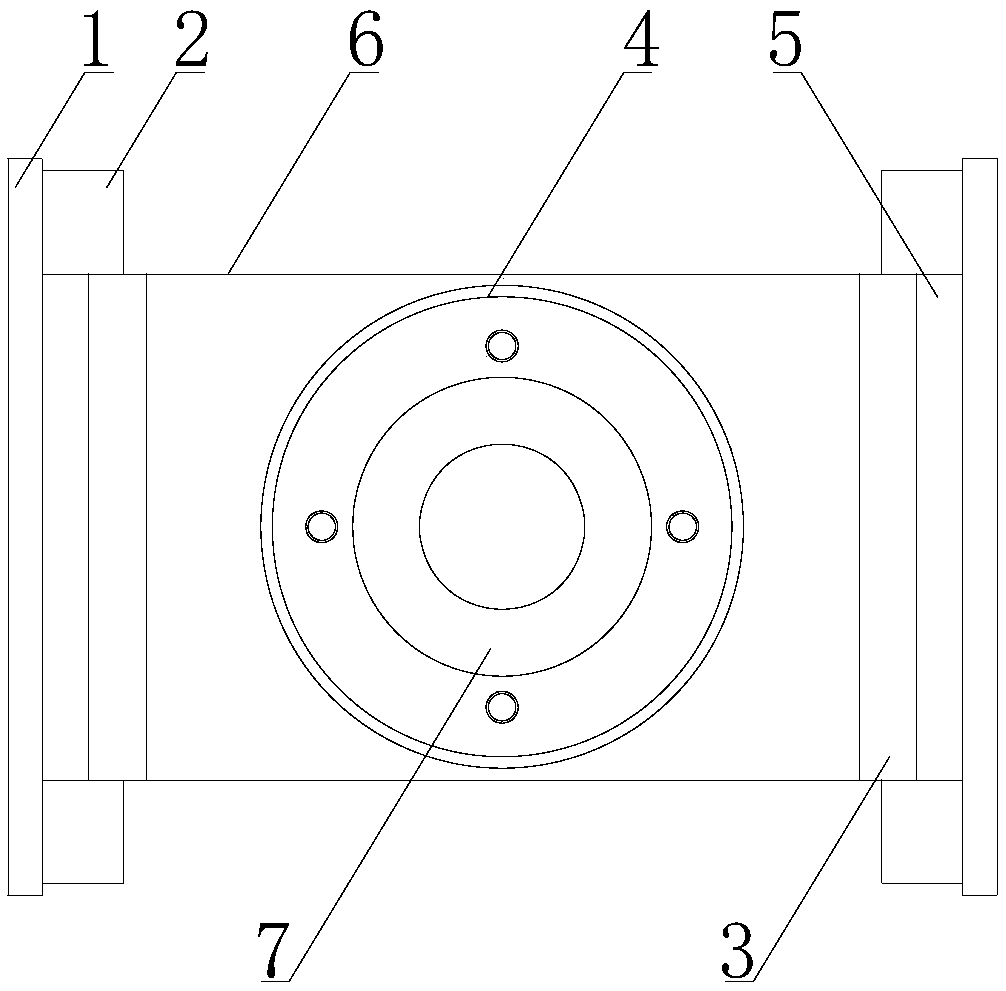

[0035] The positioning device includes an adjustment assembly and a working cylinder positioning plate 6; the bottom end surface of the working cylinder positioning plate 6 is provided with a positioning stop for positioning the working cylinder; the working cylinder positioning plate 6 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com