Self-adjusting fabric and preparation method thereof

A self-adjusting and fabric technology, applied in the direction of fabrics, multi-strand fabrics, embossed fabrics, etc., can solve the problems of easy wear and failure of functional yarns, limited improvement of textile functions, and short service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

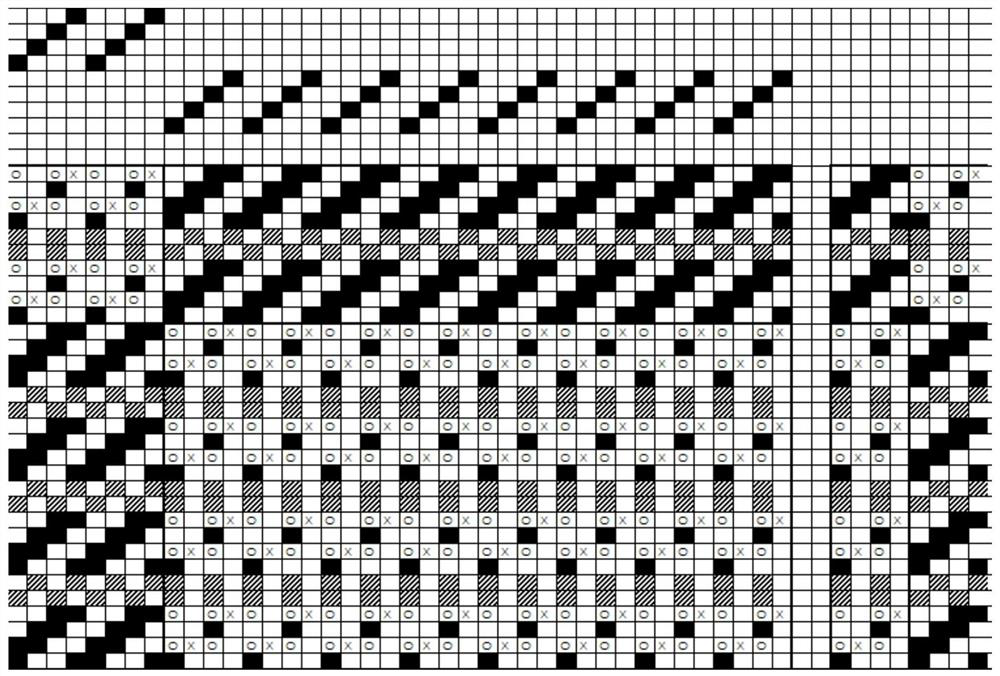

[0038] see Figure 1 to Figure 7 As shown, the invention provides a kind of preparation method of self-adjusting fabric, comprises the steps:

[0039] S1, determining the organizational structure of the first structural area, the second structural area, the third structural area and the fourth structural area, and determining the ratio of the latitudinal width of the first structural area to the second structural area;

[0040] S2, selecting the warp yarn, weft yarn and breakpoint pad weft yarn of predetermined raw materials;

[0041] S3, weaving after threading and reeding according to the drawing on the machine;

[0042] Wherein, in the first structure area and the fourth structure area, the breakpoint pad weft yarn does not participate in interweaving, but is only placed between two layers of weave in the double-layer weave structure;

[0043] In the second structure area and the third structure area, the weft yarn of the break point pad participates in interweaving;

[...

Embodiment 1

[0055] A preparation method of self-adjusting functional wall covering fabric:

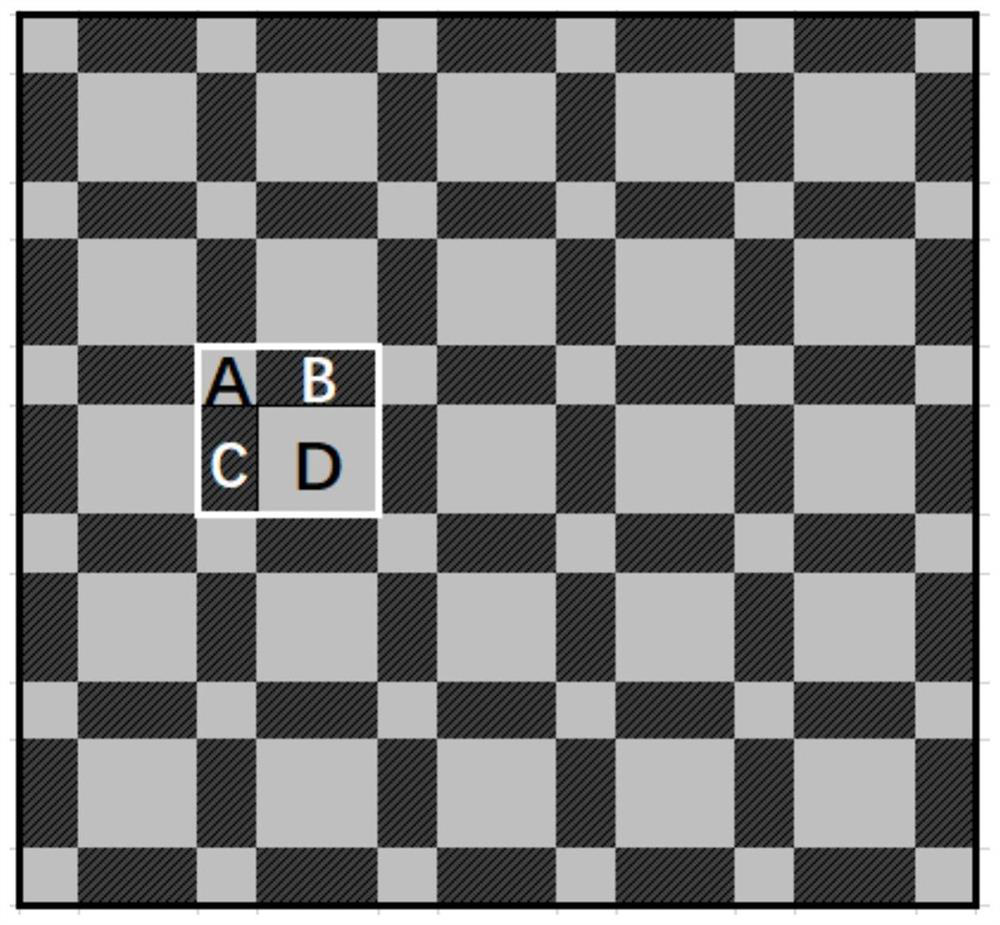

[0056] S1, determine that the inner and outer weaves of the first structure area A and the fourth structure area D adopt plain weave to form a double-layer structure; the second structure area B and the third structure area C both use two upper and two lower twill weaves to form a single-layer structure ; Determine the ratio of the latitudinal width of the first structure area to the second structure area as W A :W B =1:4;

[0057]S2, determine the material (as shown in table 1) of the warp yarn, weft yarn and breakpoint pad weft yarn of the first structure area A, the second structure area B, the third structure area C, the fourth structure area D; according to table 1, The breakpoint weft yarn is composed of kapok roving, water-soluble vinylon filament 1 wrapped continuously outside the kapok roving, and polyester filament 2 intermittently wrapped outside the kapok roving;

[0058] S3, accord...

Embodiment 2

[0083] Preparation of a self-adjusting woven thermal fabric:

[0084] The difference from Embodiment 1 lies in the difference in fabric material, structural design and weaving process parameters, as shown in Table 4, and other steps are basically the same, and will not be repeated here.

[0085] Table 4 Organization structure design and weaving process parameter setting of embodiment two

[0086]

[0087]

[0088] In the fabric, similar to Example 1, its A and D structural regions form a fluffy and raised double-layer structure, and the surface layer structure is PI, which provides good heat insulation, moisture-proof, and antibacterial properties; the inner layer structure is cotton , providing good wearing comfort. After untwisting the breakpoint pad weft yarn, the PI spun yarn is distributed between the double-layer fabrics in the form of loose fibers. The bulkiness of the loose fibers and the heat insulation performance of PI endow the fabric with better heat insulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com