Vertical air extraction sintering machine and sintering process

A sintering machine and ventilation technology, applied in furnaces, charge control, lighting and heating equipment, etc., can solve the problems of large consumption of grate bars, short replacement period, waste of waste heat and energy resources, etc., to improve the preheating effect , reduce the resistance of the material layer and improve the combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

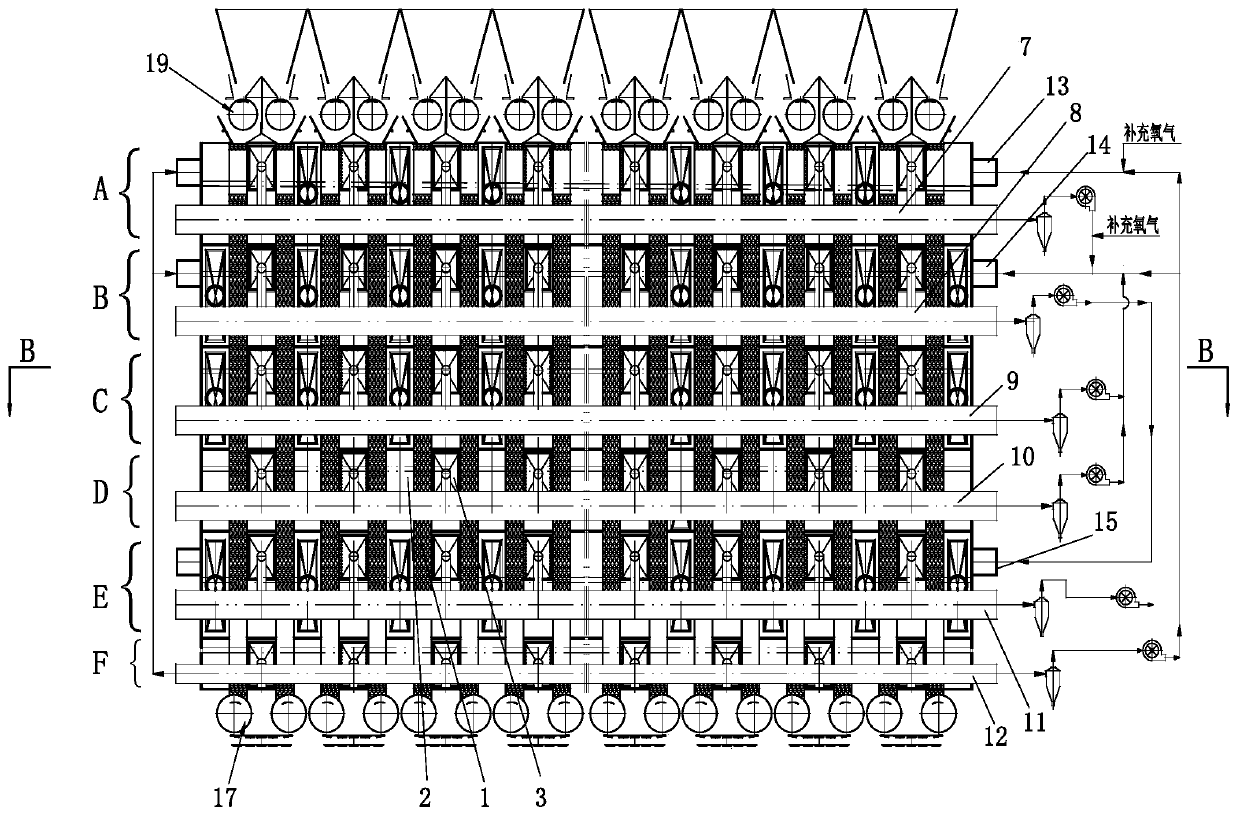

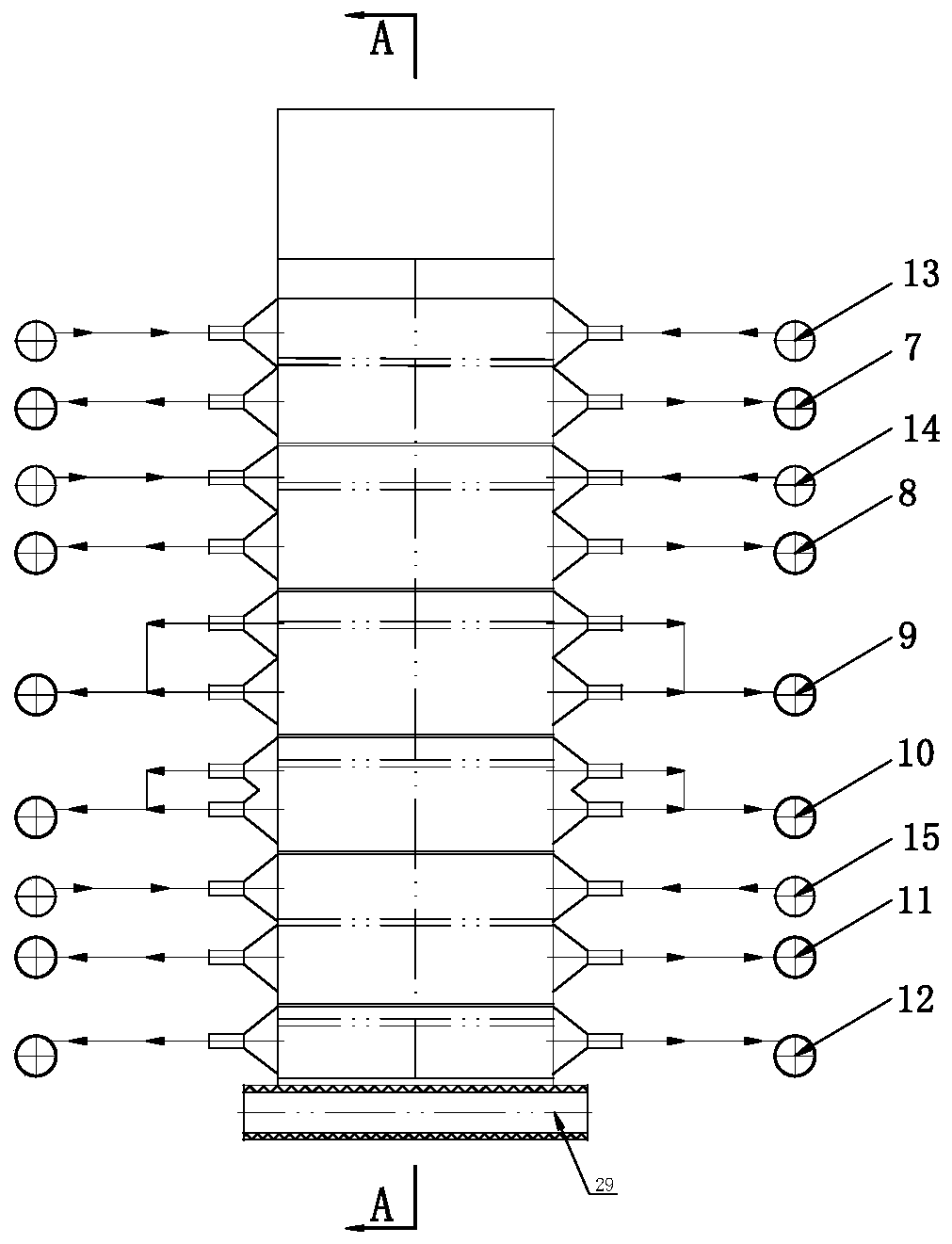

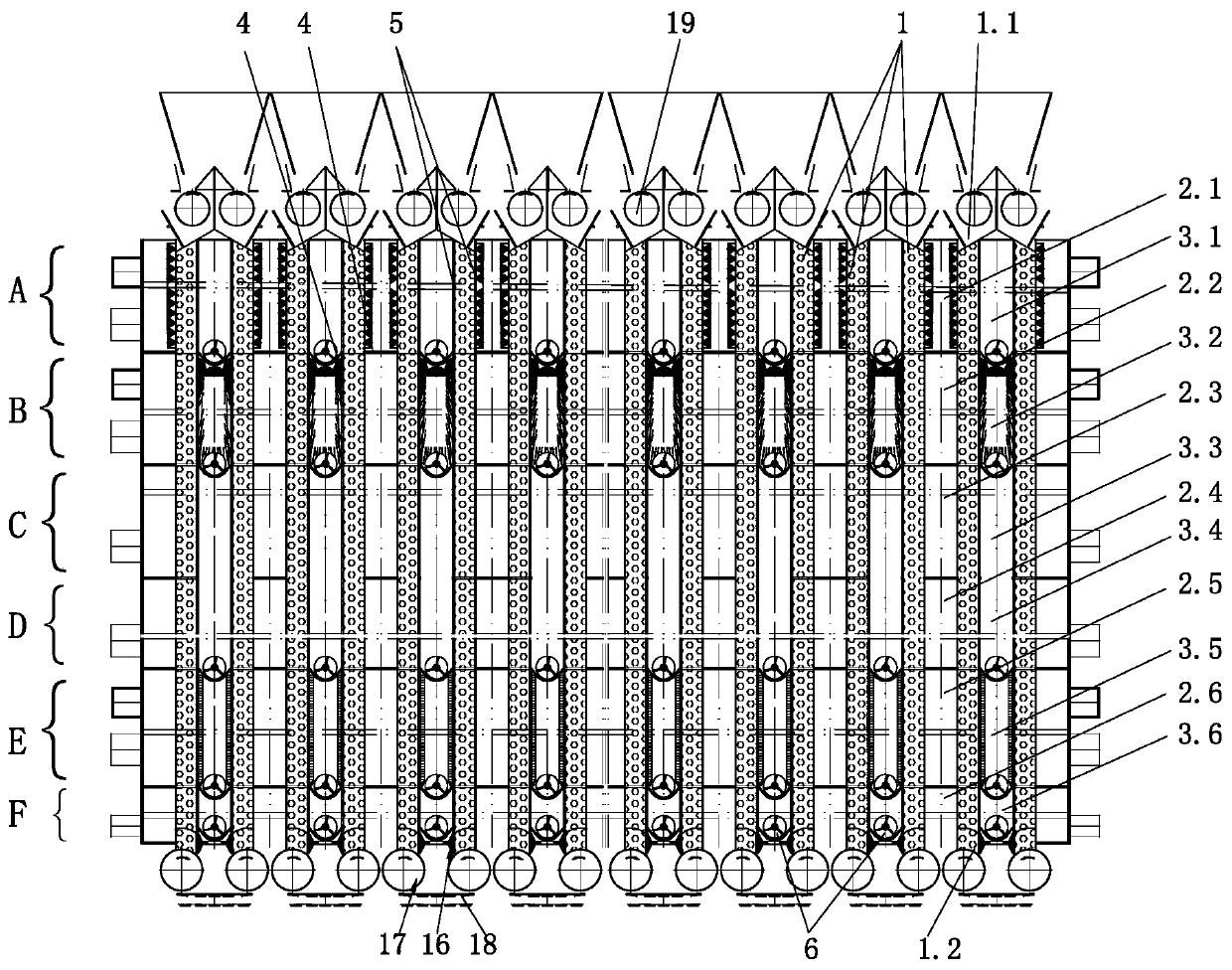

[0047] Below in conjunction with accompanying drawing, the present invention is further explained as sintering machine:

[0048] see figure 1 , figure 2 with image 3 , the vertical draft sintering machine of the present invention comprises at least two sintering chambers 1 arranged at vertical intervals (there are multiple sintering chambers in this embodiment), the sintering chamber 1 is a vertical cuboid shape, and its top is a feed end 1.1 , The bottom is the discharge end 1.2, the front and rear sides of the sintering chamber 1 are baffle plates, the left and right sides are grate bars 5, one side is connected to the air intake channel 2 through the grate bars 5, and the other side is connected to the air outlet through the grate bars 5 The flue 3 is shared between two adjacent sintering chambers 1, and the air inlet passage 2 and / or the gas outlet flue 3 are shared, for example: figure 2 It can be seen from the figure that a certain sintering chamber 1 shares the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com