Method and device for reducing methanol content in formaldehyde process by silver method

A technology for methanol content and formaldehyde, which is applied in the field of reducing methanol content, can solve the problems of unfavorable heat recovery efficiency, no obvious reduction in raw material methanol consumption, no obvious reduction in raw material methanol consumption, and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

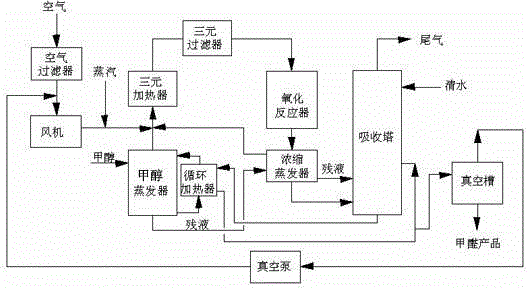

[0017] Example 1: The present invention is applied to a silver method formaldehyde production process using a composite evaporator. The methanol evaporator is a composite evaporator.

[0018] See attached for details figure 1 , The specific process flow is: air passes through an air filter and is pressurized by a fan into the composite evaporator. The composite evaporator uses the absorption tower and one tower to circulate the formaldehyde liquid as the heat source. In the composite evaporator, the mixed liquid of methanol and water and air Contact, the gas evaporates under normal pressure and 60-70℃ to form a ternary mixed gas of water vapor, methanol vapor, and air. After adding water vapor, it is heated by a ternary heater, and the temperature is increased to 110-120℃. The ternary filter enters the oxidation reactor. Under the action of silver catalyst at 600-650℃, methanol undergoes oxidative dehydrogenation reaction to generate formaldehyde. The reacted gas passes through t...

Embodiment 2

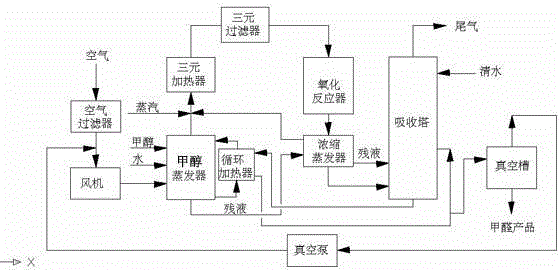

[0020] Embodiment 2: The present invention is applied to a silver-method formaldehyde production process using a common evaporator, and the methanol evaporator is a single methanol evaporator.

[0021] See attached for details figure 2 , The main process is the same as in Example 1, the difference is: the methanol evaporator is a single methanol evaporator, the evaporation temperature of the methanol evaporator is 70-80℃, the evaporation temperature is higher than that of the compound evaporator, and the bottom residue of the methanol evaporator The weight percentage is: water 70-80%, methanol 20-30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com