A plate type multi-stage flash desulfurization wastewater treatment and recovery device and its method

A technology of desulfurization waste water and recovery device, applied in water/sewage multi-stage treatment, water/sewage treatment, heating water/sewage treatment, etc., can solve problems such as evaporator corrosion and scaling, improve heat transfer coefficient and prolong time , to avoid the effect of corrosion and scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

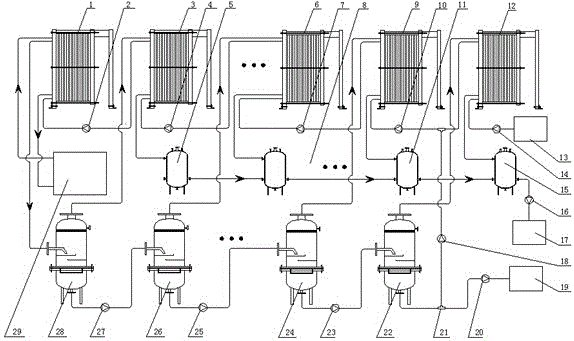

[0026] Such as figure 1 , 2 , 3, 4, and 5, the plate-type multi-stage flash desulfurization wastewater treatment device includes a first-stage plate heat exchanger 1, a first-stage booster pump 2, a second-stage plate heat exchanger 3, and a second-stage booster pump Pump 4, first stage fresh water tank 5, n-1th stage plate heat exchanger 6, n-1st stage booster pump 7, second stage fresh water tank 8, nth stage plate heat exchanger 9, nth stage Booster pump 10, n-1st stage fresh water tank 11, plate condenser 12, desulfurization wastewater pretreatment pool 13, booster pump 14, nth stage fresh water tank 15, fresh water pump 16, fresh water pool 17, circulating water pump 18, Concentrate treatment tank 19, nth stage delivery pump 20, three-way valve 21, nth stage flash tank 22, n-1st stage delivery pump 23, n-1st stage flash tank 24, second stage delivery pump 25. The second-stage flash tank 26, the first-stage delivery pump 27, the first-stage flash tank 28, and the boiler ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com