Waste heat recovery system of setting machine

A technology of waste heat recovery system and setting machine, which is applied in the direction of machine operation, mechanical equipment, heat exchange equipment, etc. It can solve the problems that the heat energy recovery device cannot operate normally for a long time, cannot recycle and supplement the heat energy of exhaust gas, and the working environment is harsh. , to achieve the effect of improving heat utilization efficiency, reducing emissions, and simple ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

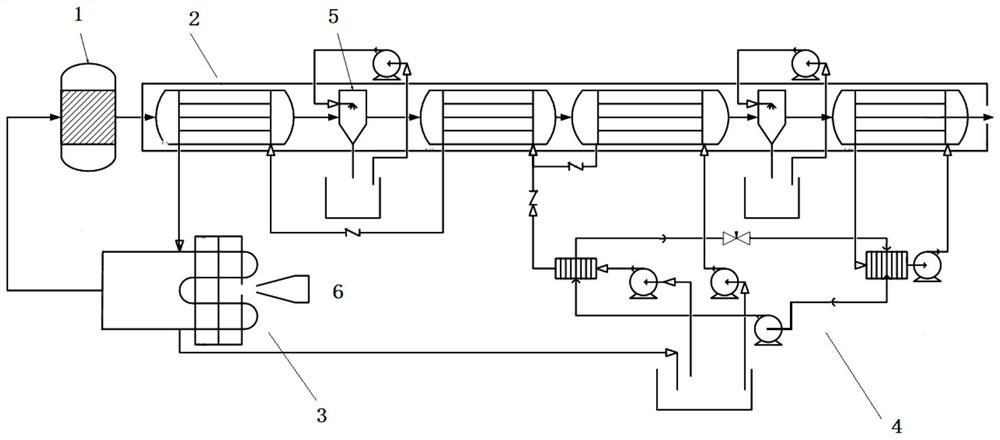

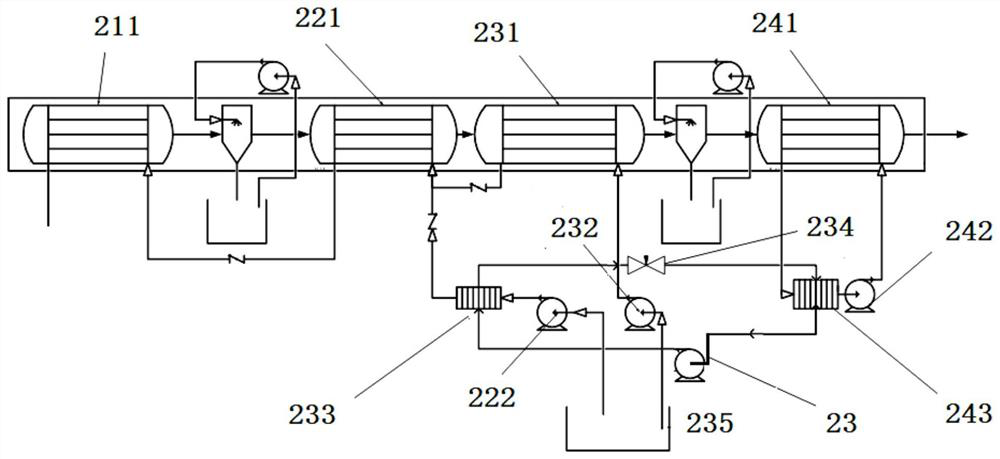

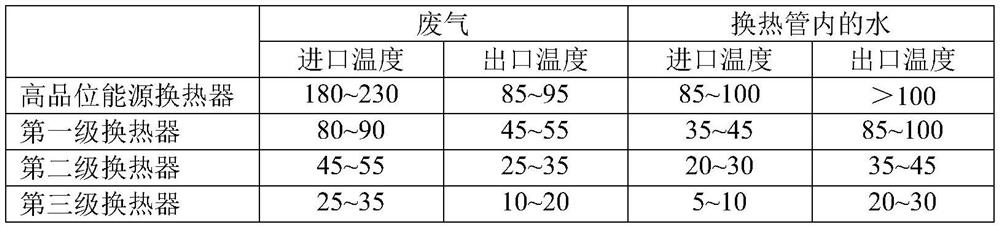

[0015] In order to make the purpose, technical solution and advantages of the application clearer, the embodiments of the application will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other. This application is not only applicable to waste heat recovery of setting machines in the textile printing and dyeing industry, but also can be used in equipment similar to setting machines in the pharmaceutical and chemical industries, and can perform waste heat recovery and waste gas treatment. The heat exchange medium in the heat exchange tube of this application may not undergo phase change during the waste heat recovery process. For example, heat transfer oil may be preferred so that the heat exchange medium can obtain a higher temperature after waste heat recovery; it may also be a mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com