A kind of oil-based drilling fluid regeneration treatment method

A technology of oil-based drilling fluid and treatment method, which is applied in the field of oil-based drilling fluid regeneration treatment, can solve the problems of affecting the performance of the configured drilling fluid, reducing thermal efficiency, and high solid content of recovered oil, and achieves complete and efficient reduction and recycling. Economic benefits, the effect of solving environmental risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

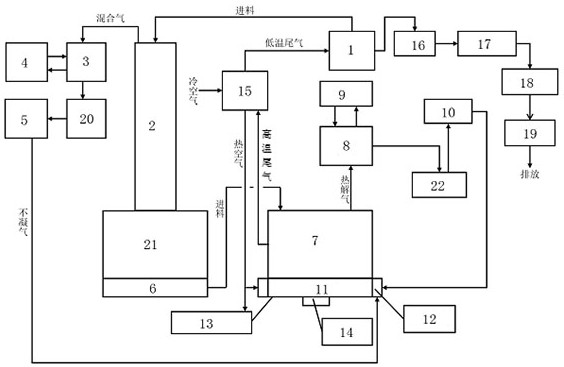

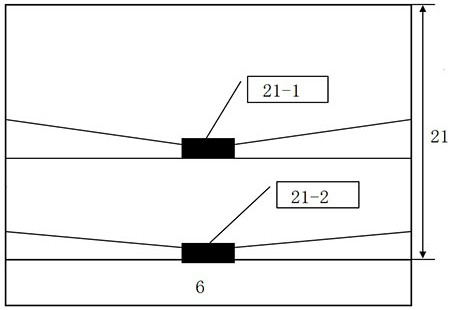

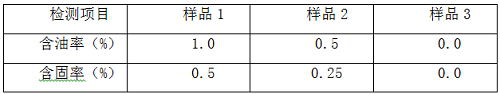

[0044] Take the oil-based drilling fluid from a mud station in Nanhai, CNOOC, with a density of 1.25g / cm³, preheat the oil-based drilling fluid to any temperature of 75℃-90℃ through the drilling fluid preheating tank 1, and transport it to the vacuum low temperature high efficiency membrane type In the evaporator 2, the pressure value of the vacuum low-temperature high-efficiency film evaporator 2 is set to be ≤-0.095MPa, and the set temperature range is 100-300°C. The evaporated gas phase is condensed and collected to obtain the liquid phase, and the liquid phase enters the first A collection tank 20 is recovered, and the oil-solid mixture enters the mixed collection tank 21 .

[0045] The oil and solid mixture are transported to the circulating pyrolysis desorption device 7 through the plunger pump 6, and pyrolyzed at a temperature of 350°C-500°C. The temperature of the circulating liquid in the condensing device is set to 35°C, and the gas phase is collected by the condensin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com