Purification separation system for hydrogasification synthesis gas and process of purification separation system

A technology for purifying separation and synthesis gas, applied in the field of coal gasification, can solve the problems of large sewage discharge, long process and high energy consumption, and achieve the effects of reducing waste water discharge, reducing investment, and rationally grading utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

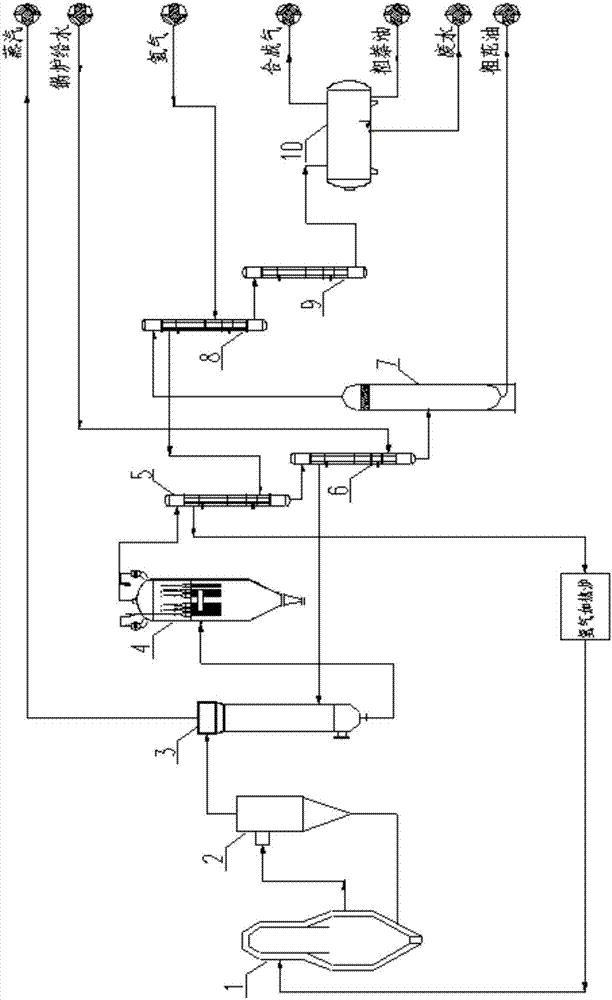

[0027] See attached picture.

[0028] A purification and separation system for hydrogenation gasification synthesis gas, which mainly includes a synthesis gas system, a hydrogen system and a boiler water system. The synthesis gas system includes a gasifier 1, and the gas outlet of the gasifier 1 is connected by a pipeline To the cyclone separator 2, the gas outlet after the separation of the cyclone separator 2 is connected to the synthesis gas waste pot 3 through a pipeline, and then passes through the synthesis gas filter 4, and the synthesis gas filter 4 is purified and then transported to the second First-level hydrogen heater 5 and boiler feed water preheater 6, and then through the first-level separation tank 7, the synthesis gas after passing through the first-level separation tank 7 enters the second-level through the first-level hydrogen heater 8 and circulating water cooler 8 Separation tank 10;

[0029] Described hydrogen system comprises the hydrogen pipeline that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com